Back reflector and back projecting picture displaying appts. using same

A technology of rear projection and image display, applied in projection devices, projectors with built-in/external screens, mirrors, etc., can solve the problems of reduced light quantity, color shift or deterioration of brightness performance, etc., to improve the surface smoothness , the effect of suppressing color shift or brightness deterioration, and improving contrast performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

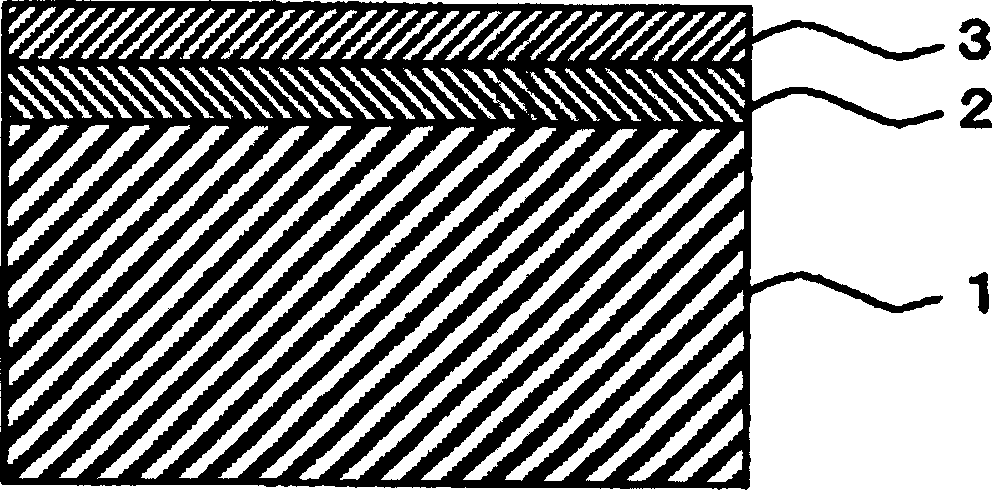

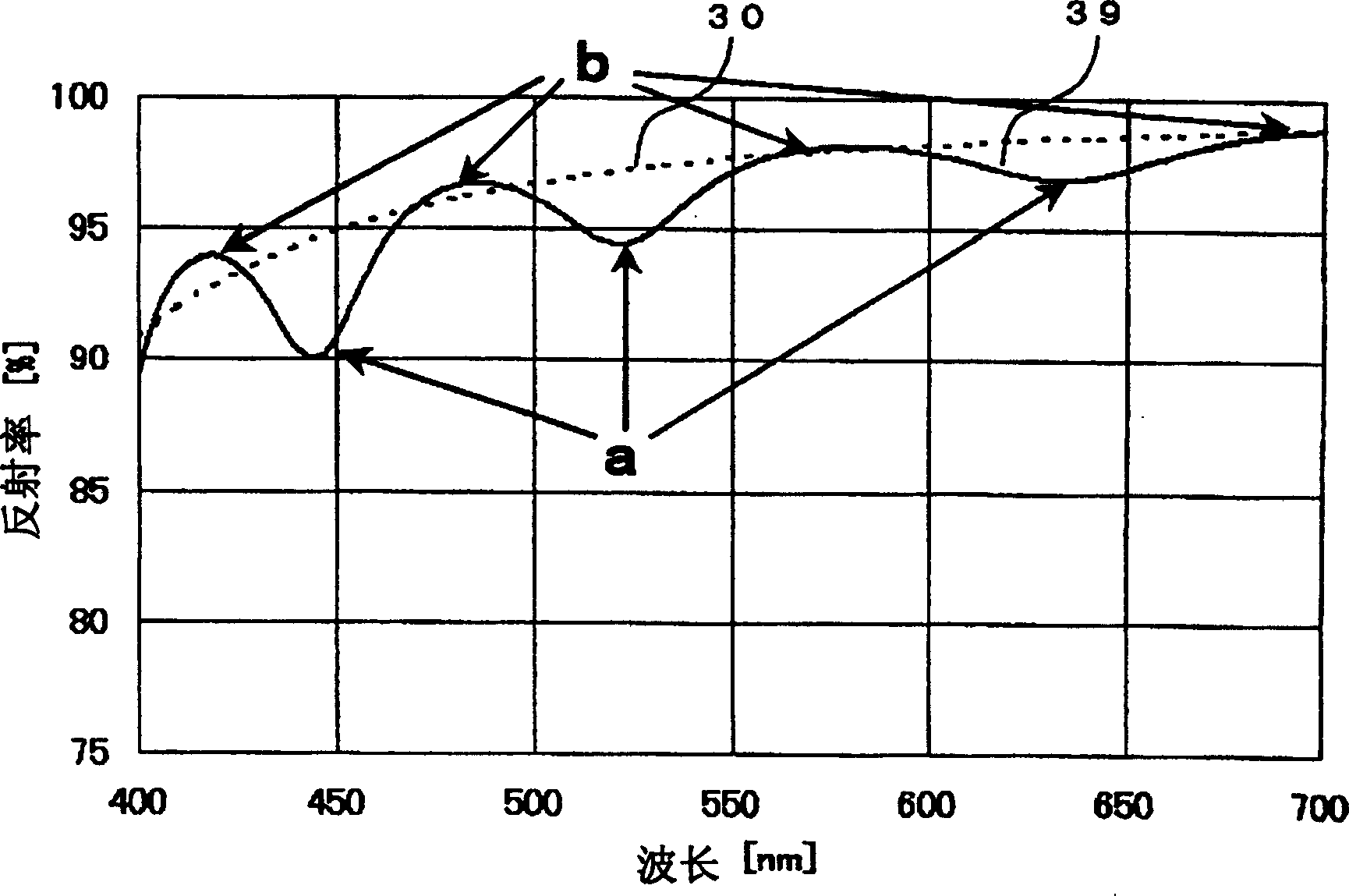

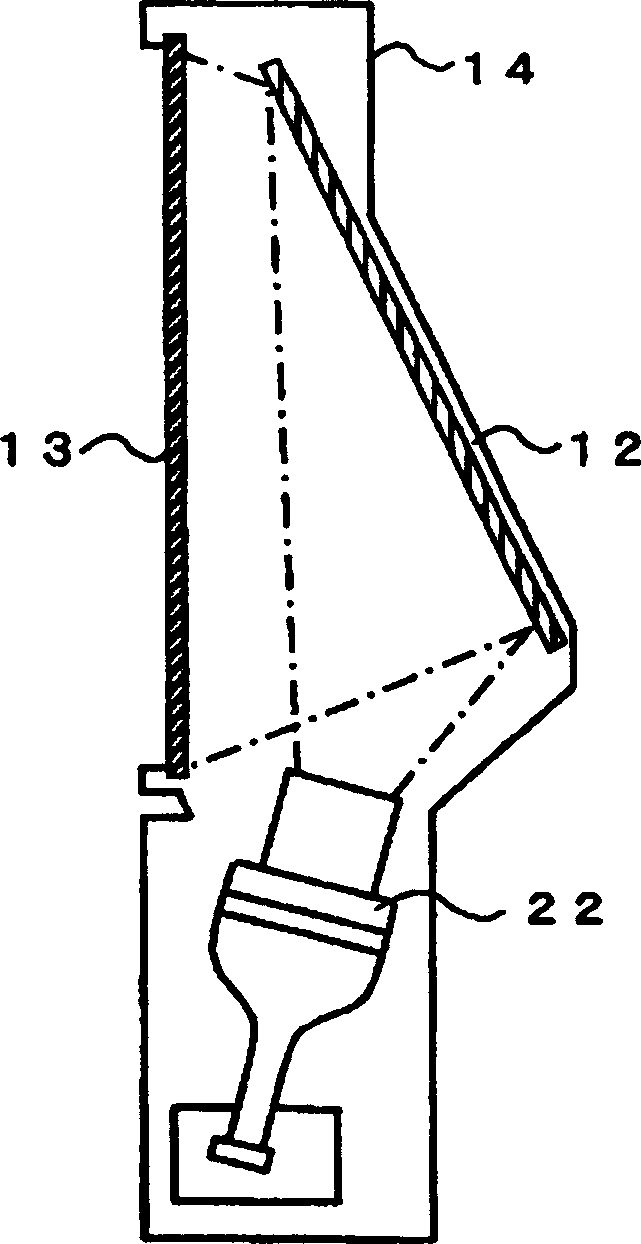

[0032] Next, embodiments of the present invention will be described with reference to the drawings. The present invention is characterized in that a single-layer overcoat layer of a colorless and transparent resin is formed as a protective film on a reflective film provided on a base material for a rear reflector used in a rear projection type image display device. In addition, the film thickness of the overcoat layer is set to a thin film below 1 μm to obtain substantially the same contrast performance and resolution performance as those of ordinary glass mirrors. In addition, it is characterized in that the film thickness of the above-mentioned overcoat layer is formed to such a thickness that the wavelength of the peak of the wave due to interference due to thinning is different from the projection image light projected from the projection device or the light source built in the projection device. The wavelengths of the green bright lines are approximately equal.

[0033] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com