Buckle assembly

A buckle and component technology, applied to buckles, fasteners, clothing, etc., can solve problems such as buckle loosening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

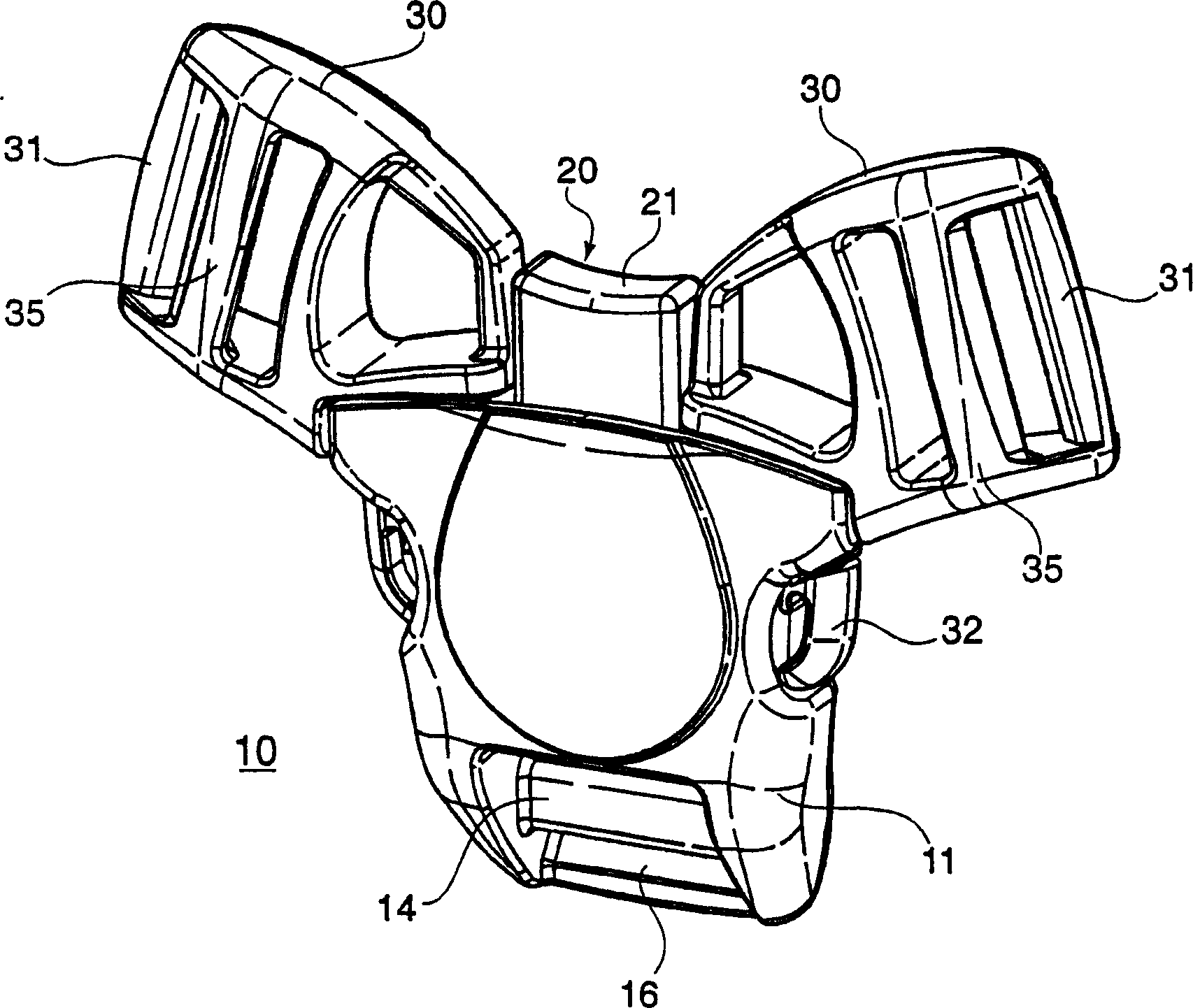

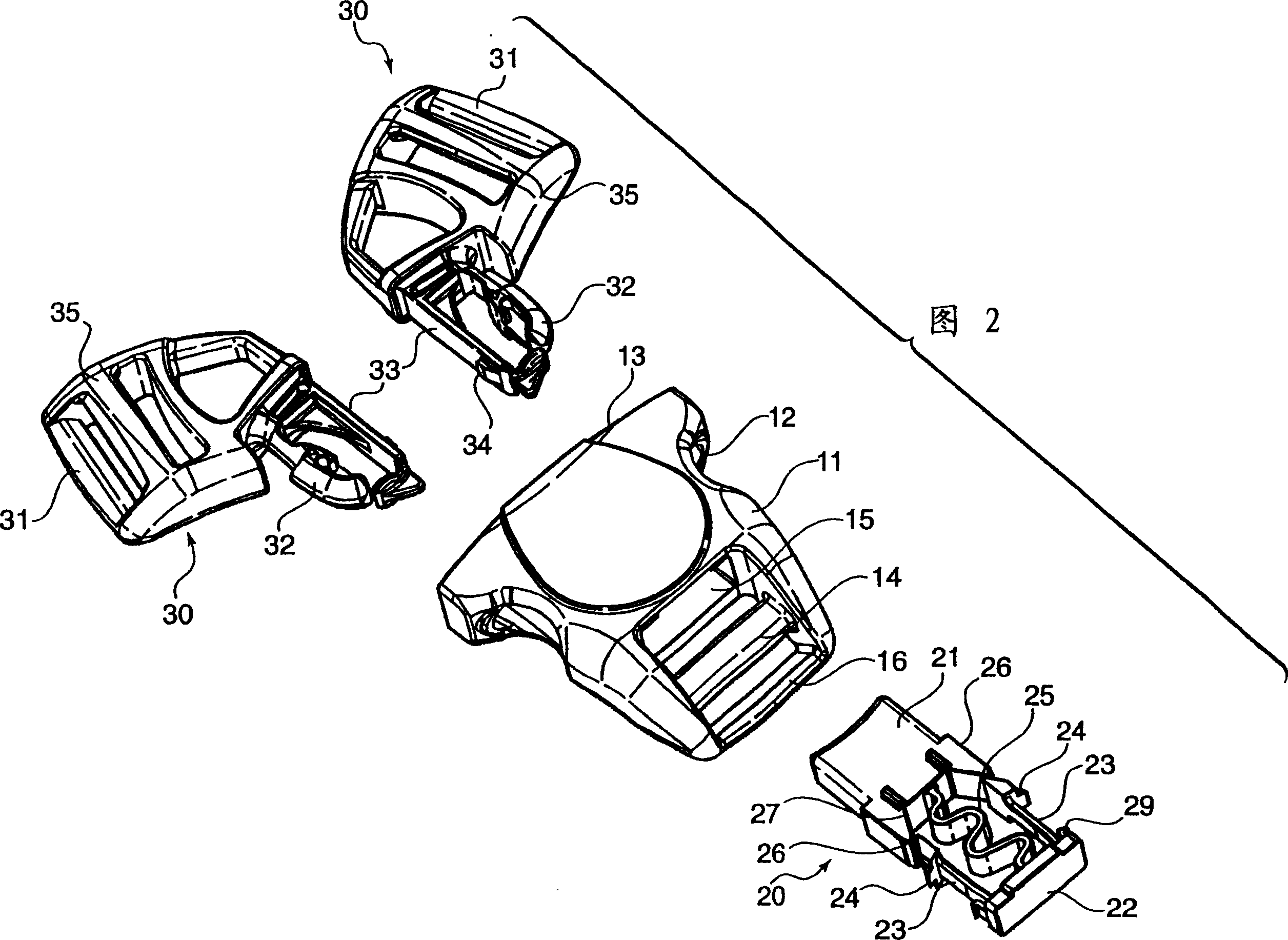

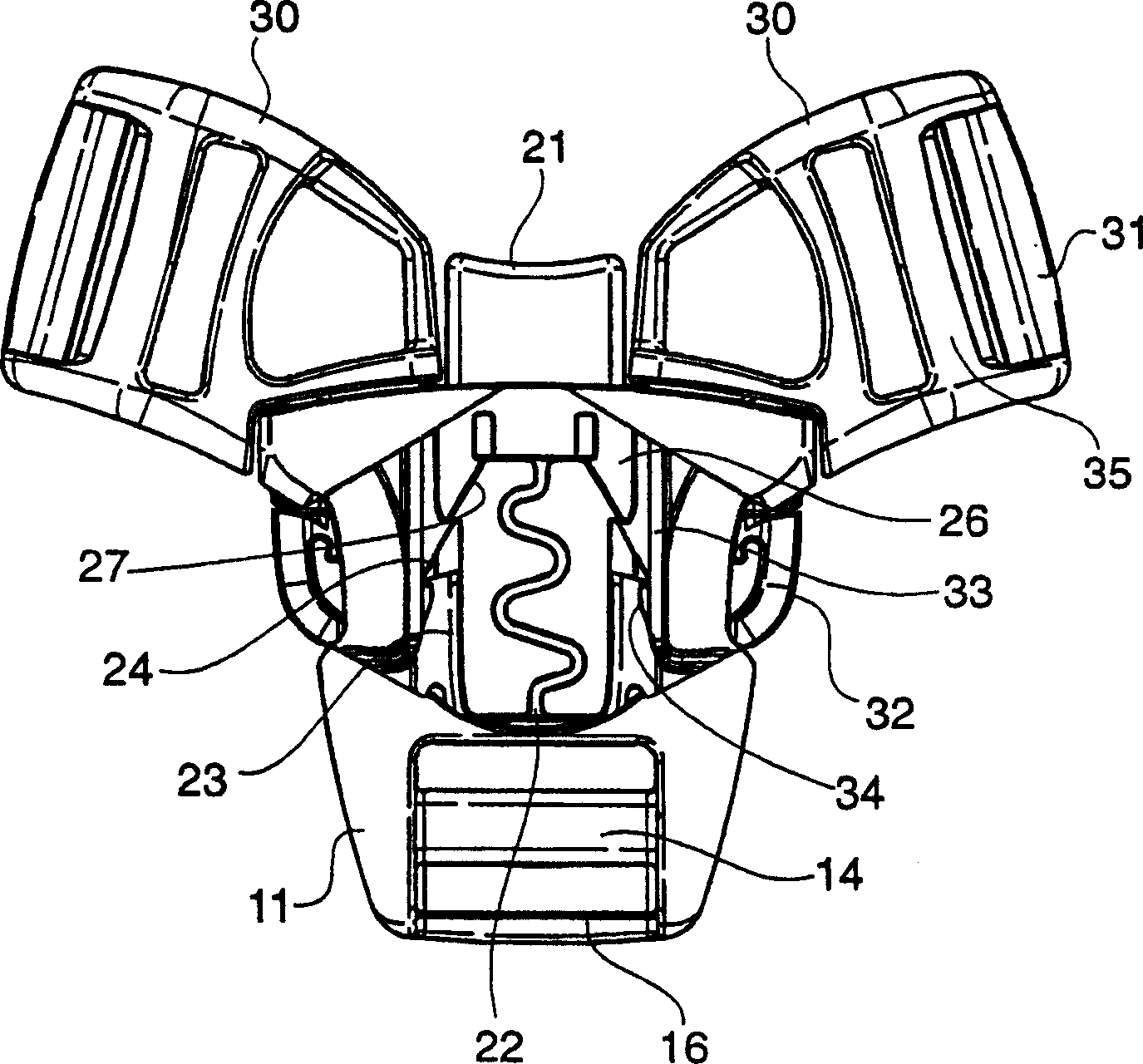

[0022] Referring to these drawings in detail, figure 1 A preferred embodiment buckle assembly 10 according to the present invention is shown in an assembled condition. The buckle assembly 10 includes a socket portion 11 and two insertion portions 30 inserted into the socket portion 11 . The insert portions 30 each have belt retaining bars 31, 35 to allow waist belts and / or shoulder belts to pass therethrough. The socket portion 11 has belt retaining bars 14, 16 to allow a crotch belt to pass therethrough. In this way, the buckle assembly 10 can be used in a 3- or 5-point hitch system to restrain infants and toddlers in various types of restraints such as high seats and strollers. in juvenile products. In a 3-point hitch system, only the waist or shoulder straps are attached to the insert portion 30 , whereas in a 5-point hitch system, both the waist and shoulder straps are attached to the insert portion 30 . Instead of having two separate straps for the waist and shoulder ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com