Light guide panel of edge-light type backlight system and edge-light type backlight system employing the same

A technology of edge lighting and backlight system, applied in the field of backlight system, can solve the problem of uneven brightness of FPD screen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will now be described more fully with reference to the accompanying drawings, in which preferred embodiments of the invention are shown.

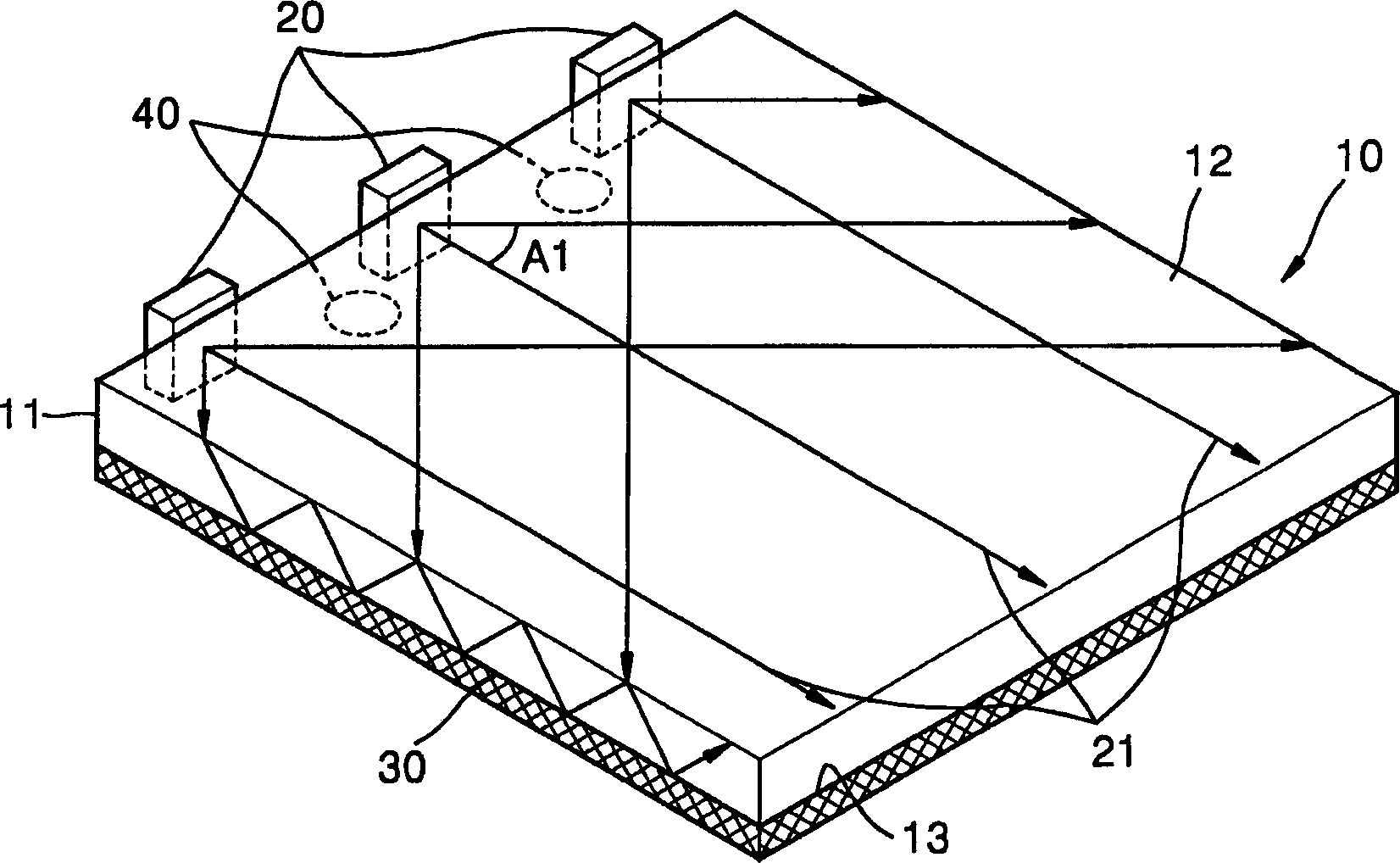

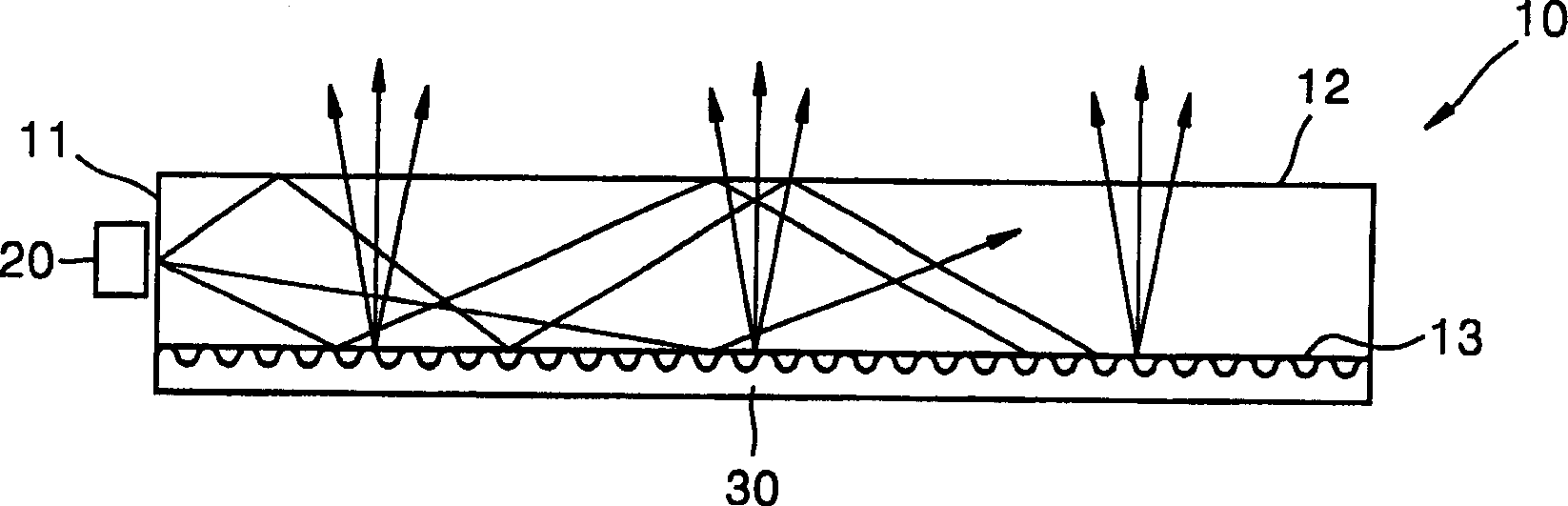

[0028] Figure 4 is a perspective view of an edge-lit backlight system according to a preferred embodiment of the present invention, Figure 5 yes Figure 4 An enlarged perspective view of the light incident portion 120 of the edge-lit backlight system is shown.

[0029] refer to Figure 4 and 5 , the light guide plate 100 is in the shape of a flat plate. Three light emitting diodes (LEDs) 110 are disposed along the effective edge surface 101 of the light guide plate 100 . The light path changing unit 130 is disposed under the light guide plate 100 .

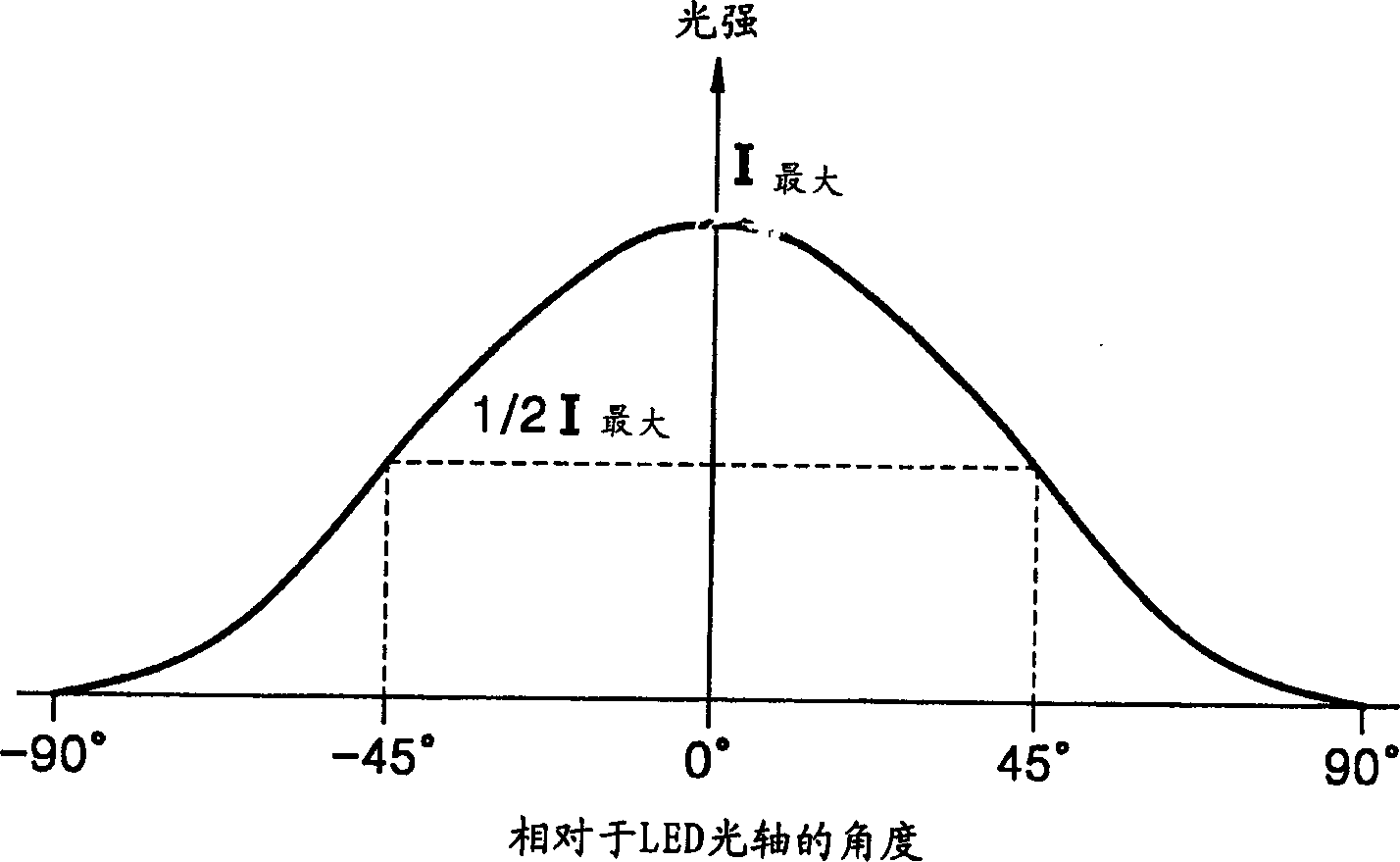

[0030] Each of the LEDs 110 serving as a point light source emits light within a range of ±90 degrees with respect to the optical axis 112 . Such as image 3 As shown, here, the angle at which the LED emits light at half its maximum value is about 45 degre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com