Low-loss high-selectivity and high-power multicavity filter

A high-selectivity, filter technology, applied in waveguide-type devices, electrical components, circuits, etc., can solve the problems of increased processing difficulty, complex processing technology, large insertion loss, etc., to reduce the debugging workload and improve the selection. The effect of performance, low loss selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in detail below with reference to the accompanying drawings and examples. However, the invention is not limited to the examples given.

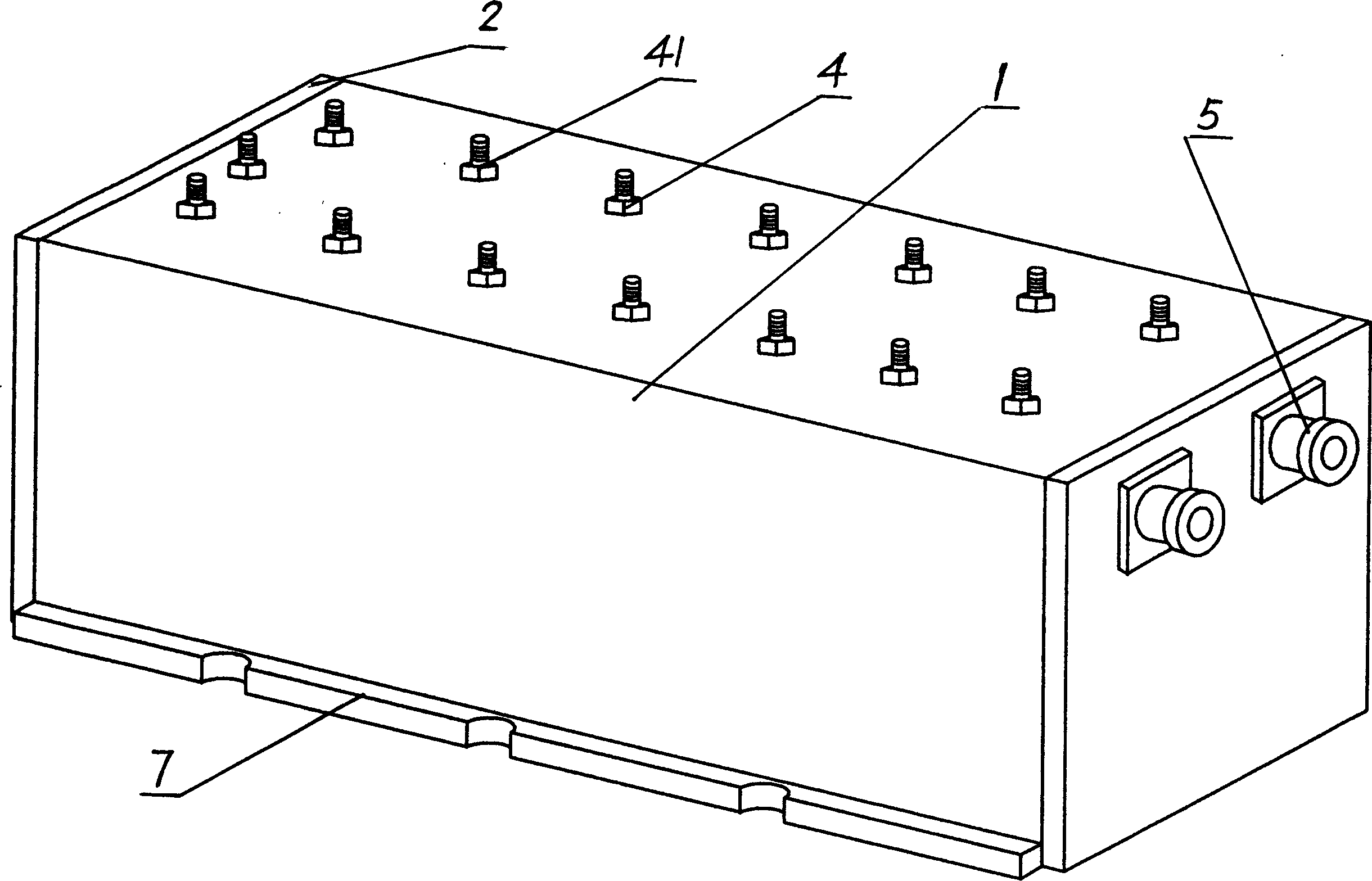

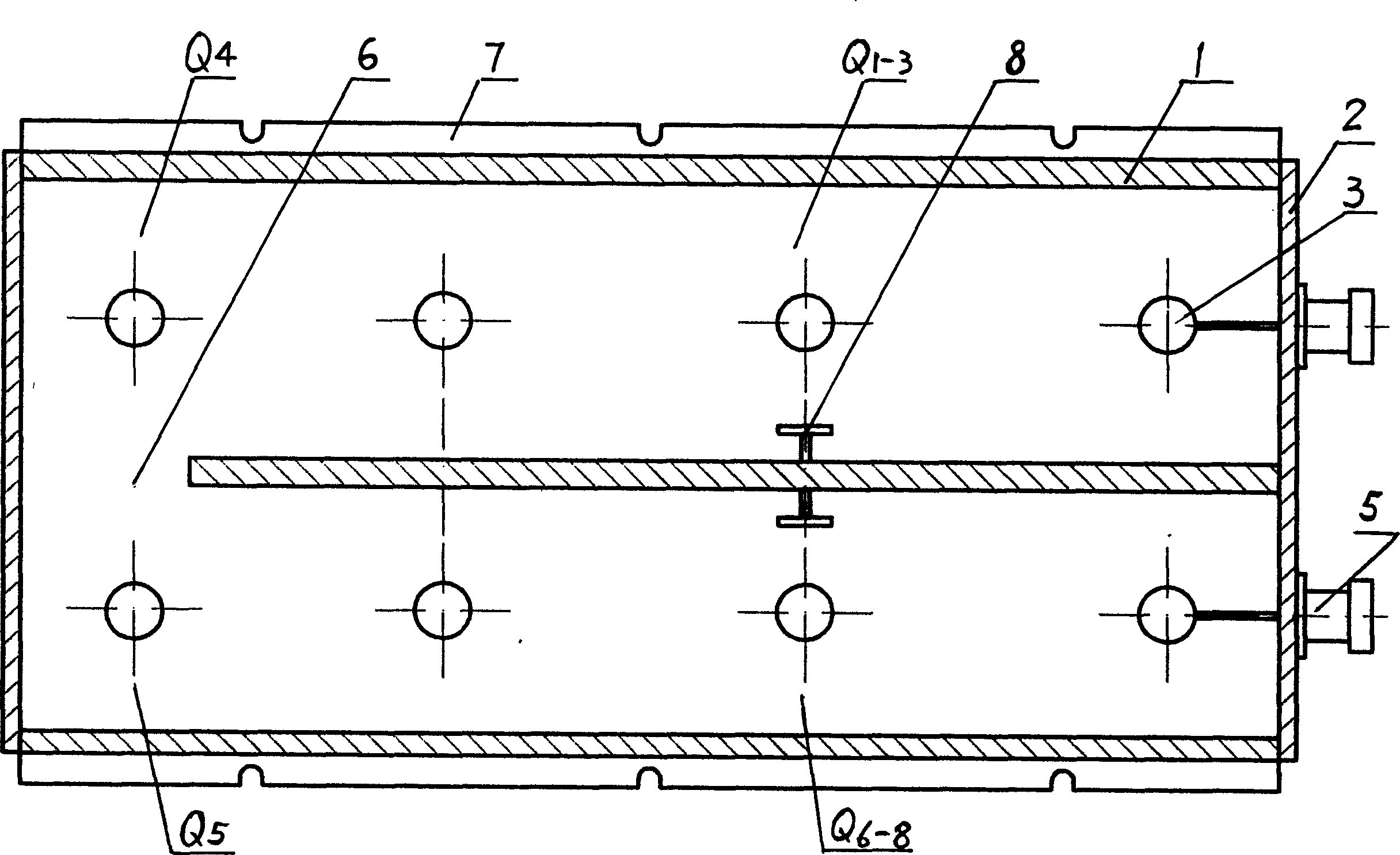

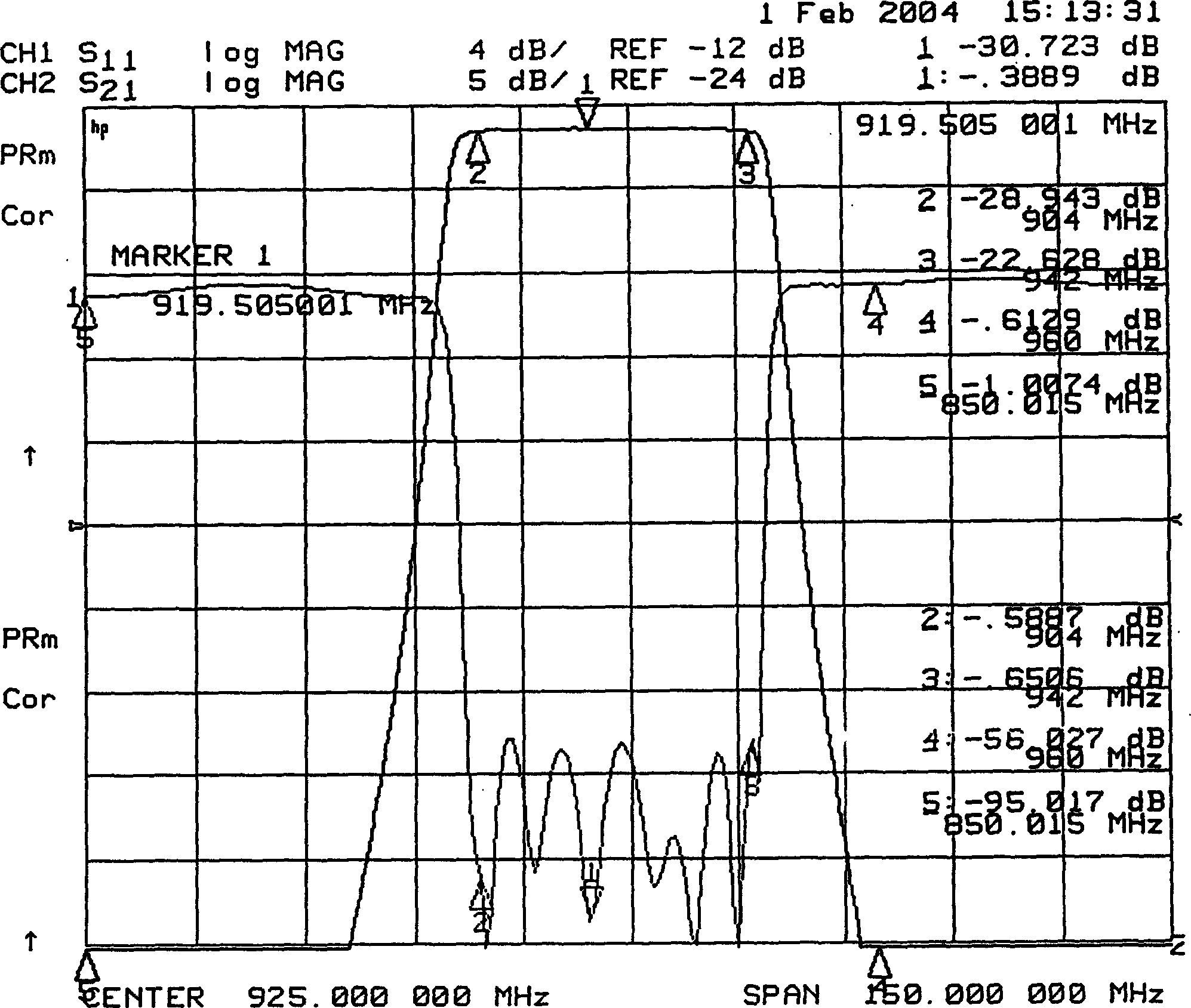

[0025] Such as figure 1 with figure 2 As shown, Example 1 is an eight-cavity filter, which has a resonant cavity main body 1, a cover plate 2, an inner conductor 3, a resonant frequency adjustment screw 4, and an input and output interface device 5. The main body 1 is flat Q1-8, and the resonant cavities on both sides Q1-3 and Q6-8 are comb-shaped symmetrical distributed coupling cavities, and the two resonant cavities Q4 and Q5 in the middle are coaxial resonant cavities with centralized coupling. Figure 6 shows the gaps of Q4 and Q5 cavity spacers, 41 7 is the adjustment screw for inter-cavity compensation, and 7 is the positioning edge for filter installation. In the embodiment shown in the figure, a further feature is that there is a cavity coupling device 8 located between the third and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com