Seal ring sealing with pressure and releasing without pressure

A sealing ring and sealing groove technology, applied in the direction of engine sealing, engine components, mechanical equipment, etc., can solve problems such as non-compliance with irrigation requirements, leakage, and inability to meet sealing conditions, and achieve improved sensitivity and reliability. Reasonable, precise structure, simple and compact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with drawings and embodiments.

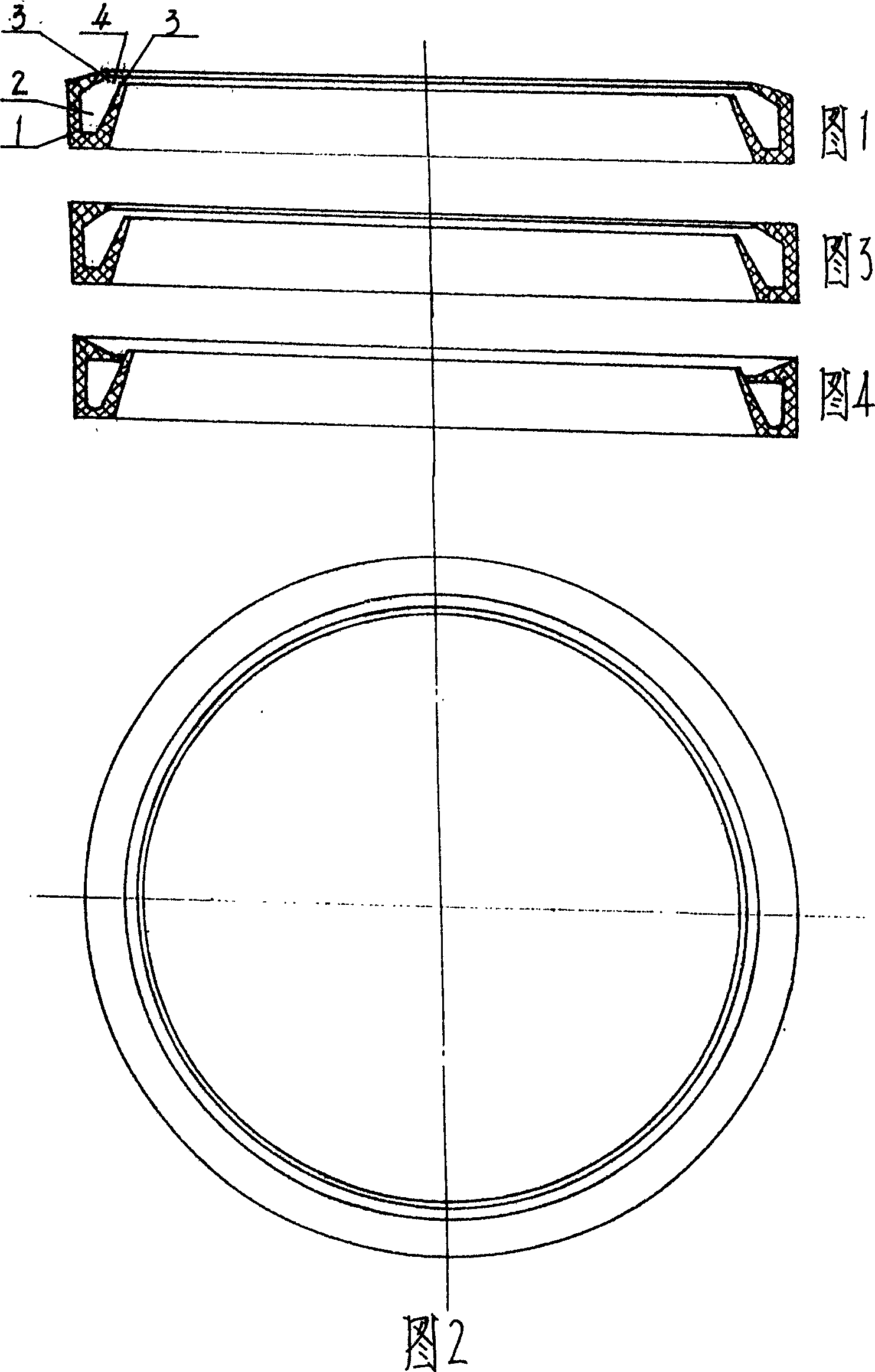

[0013] The meanings represented by the leading numbers in the attached drawings: 1 elastic ring body 2 semi-closed shell cavity 3 sealing tongue 4 annular opening

[0014] The first embodiment is a tongue sealing ring, which is used for quick joints of spherical pipes. Its specific size is φ144.5×15.8mm, and it weighs about 40g. The specific structure of the -1.5MPa sealing ring is shown in Figures 1 and 2.

[0015] The specific production of the sealing ring in this example is the same as that of the conventional sealing ring, except that the ring 1 used to maintain the shape and strength of the sealing ring during assembly maintains a matching gap of 0.25mm with the sealing groove of the joint, and the radial cross section of the ring section of the sealing ring is hollow. The cavity body has a wall thickness of 2.75mm. The cavity body is located at the inner end sec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com