Oil seal structure of downhole power tools

A power tool and oil sealing technology, applied in drilling equipment, drilling equipment and methods, earthwork drilling, etc., can solve problems such as damage to the sealing structure of the lubricating oil cavity, high solid content of drilling fluid, and high bottom hole temperature, etc. Achieve improved reliability and service life, continuous supply and sealing requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to make the objectives, technical solutions and advantages of the present invention clearer, the embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings.

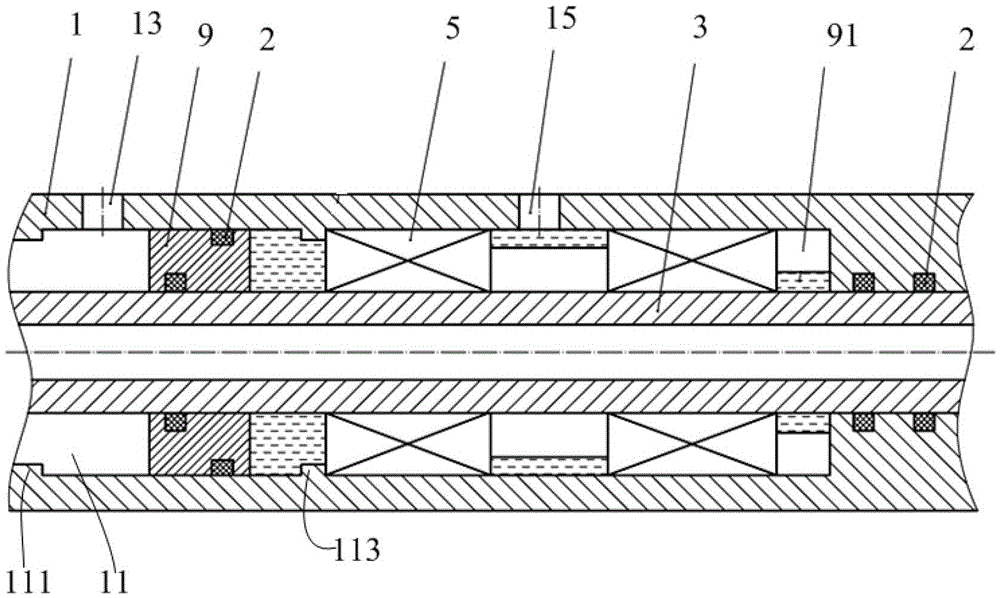

[0019] Please refer to figure 1 The present invention provides an oil sealing structure for a downhole power tool, which includes the downhole power tool and a sealing piston 9 installed in the downhole power tool.

[0020] The downhole power tool includes an oil cavity fixed shell 1, a main shaft 3 installed in the oil cavity fixed shell 1, and an oil cavity inner part 5 installed in the oil cavity fixed shell 1. Among them, the parts 5 in the oil chamber are installed on the main shaft 3, and the parts 5 in the oil chamber may be bearings, rotors, coils, disc springs and other parts suitable for an oil lubrication environment. The main shaft 3 is a hollow shaft.

[0021] A hollow oil cavity 11 is provided in the oil cavity fixed shell 1, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com