Air blast hold down apparatus and sheet alignment apparatus provided therewith

A technology of pressing device and blowing equipment, which is applied in the directions of coiling strips, transportation and packaging, and object supply, and can solve problems such as high costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

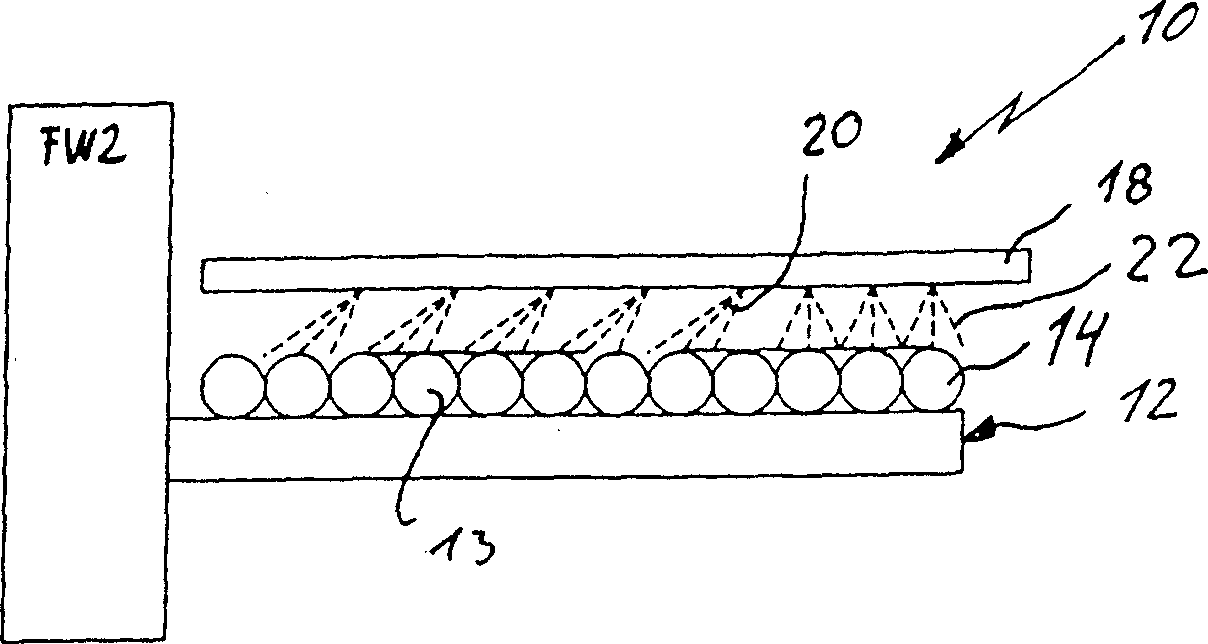

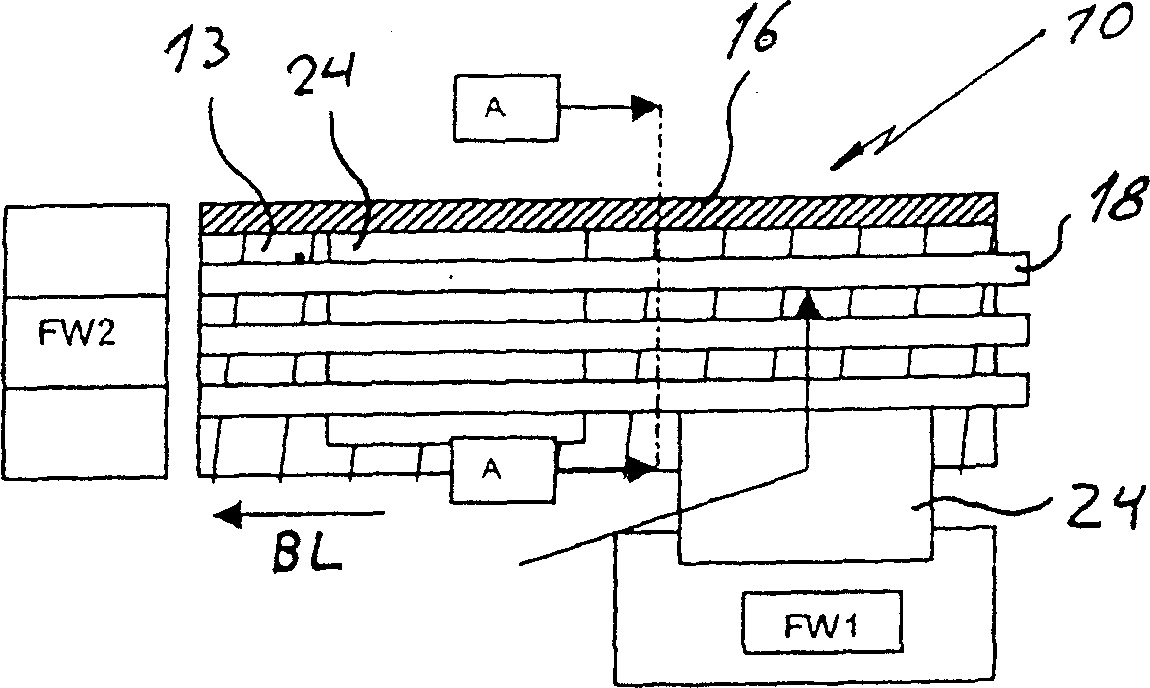

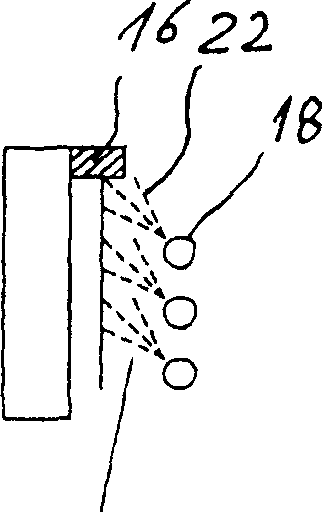

[0017] figure 1 The sheet (eg, paper aligning device) alignment device 10 shown in FIG. The sheet aligning apparatus 10 includes an angled-roller table 12 with a plurality of driven rollers 13 arranged sequentially in the longitudinal direction. An alignment rail (aligning rail) 16 is arranged on a longitudinal side of the roller table 12, which is located at figure 2 in the upper part. The rollers 13 extend in the transverse direction of the roller table table 12 . The axes of the rollers 13 are slightly inclined in the direction of the alignment rail 16 opposite to the sheet running direction BL. The first folding unit FW1 is located on one side of the roller table 12 opposite to the alignment rail 16, and is located at figure 2 One end of the case 12 on the right side of the inclined roller table. The second folding unit FW2 is located on one end side of the roll table 12 which is located downstream in the sheet running direction BL.

[0018] The sheet carrying surf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com