Burner apparatus

A combustion device and main combustion technology, applied in the direction of combustion chamber, combustion method, combustion type, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

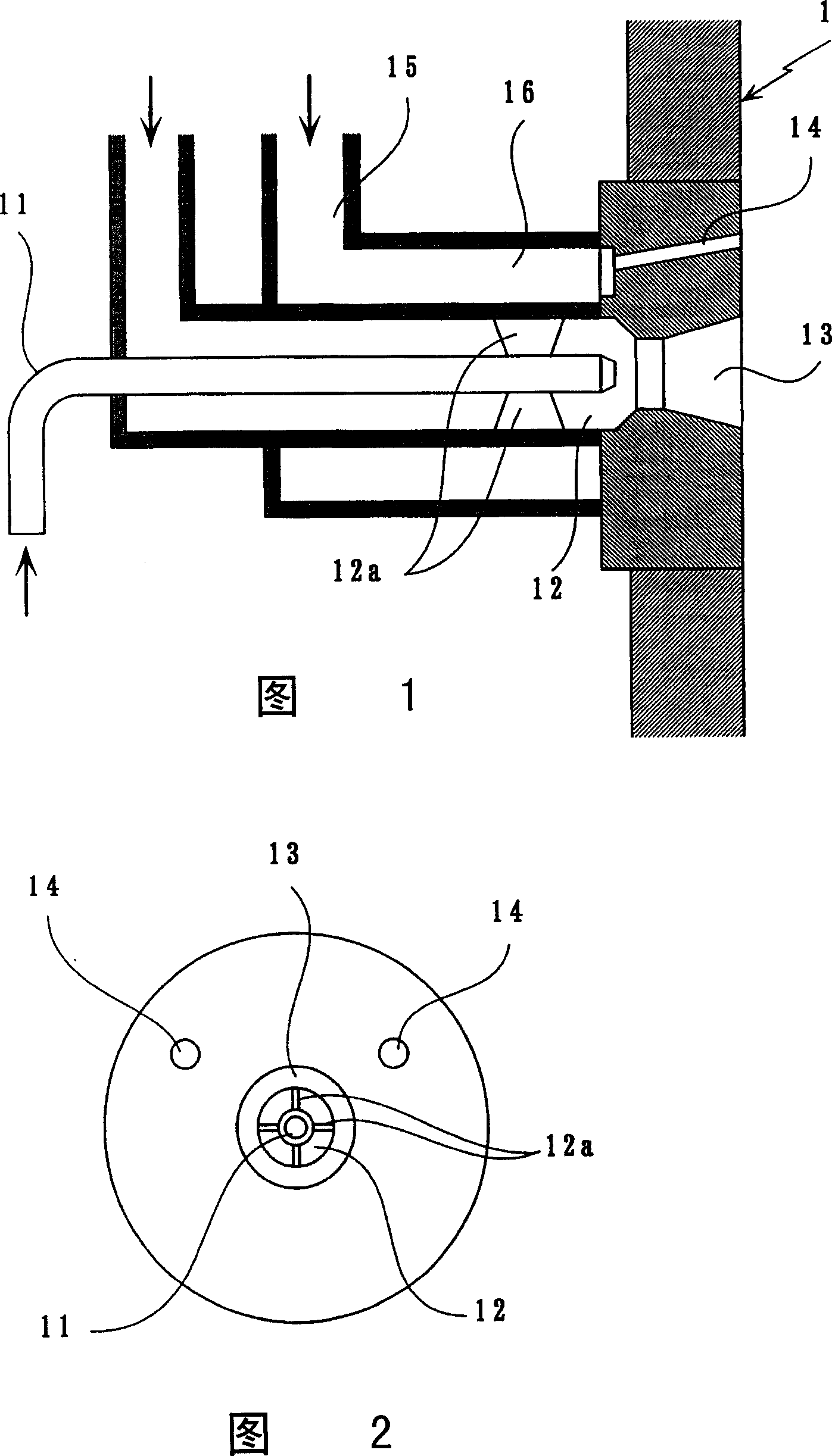

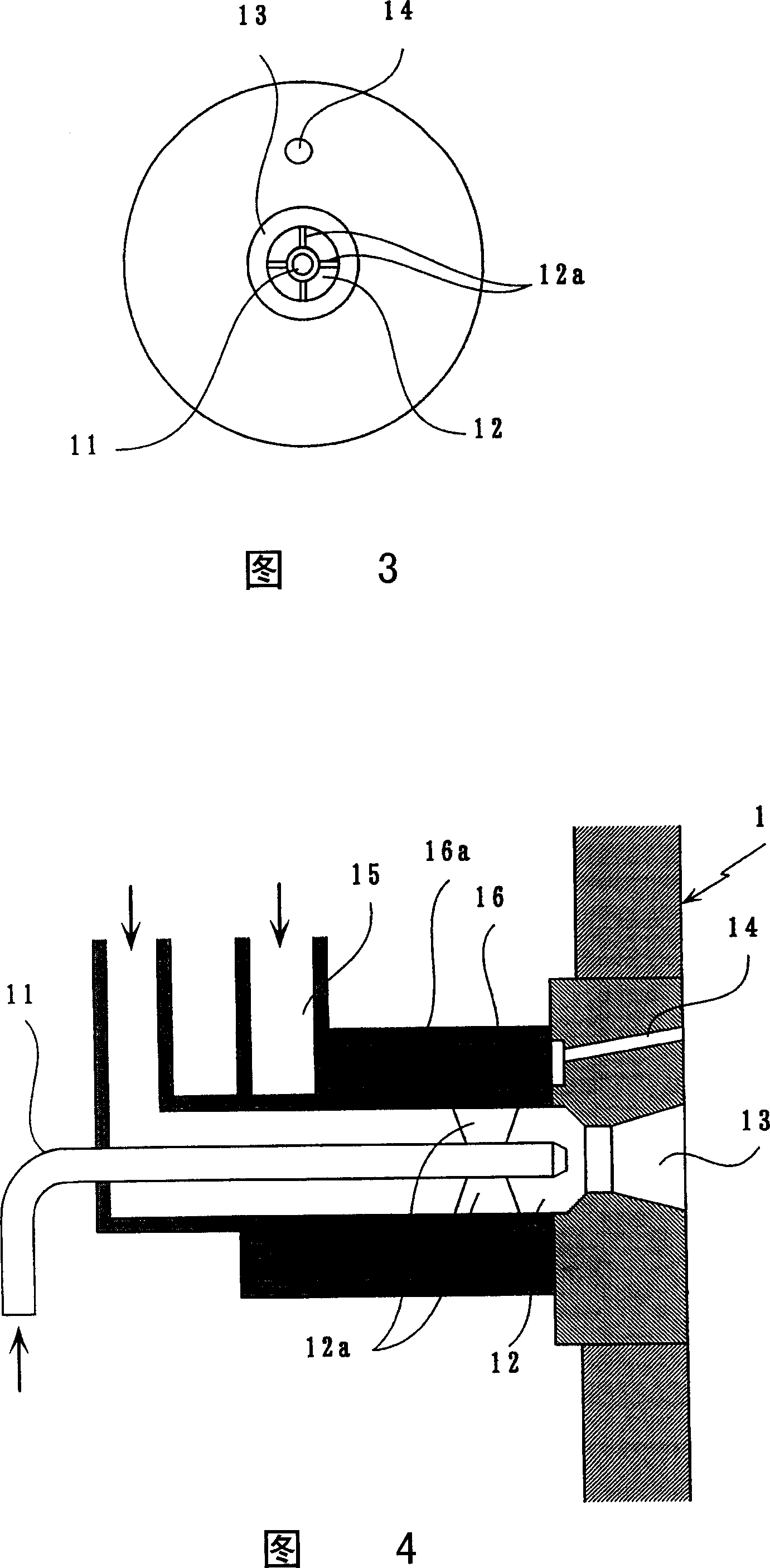

[0022] A combustion device according to embodiment 1, such as figure 1 As shown in and 2, fuel is supplied to the main combustion portion 13 via a fuel supply nozzle 11, and less than a theoretical amount of main air calculated based on the above-mentioned fuel is introduced into a main air supply nozzle 12, which Formed outside the fuel supply nozzle 11 . The swirl vanes 12a provided in the main air nozzles 12 are operable to swirlly supply the main air to the main combustion sections 13 so that the thus supplied fuel and the main air can be combusted in the main combustion sections 13. The main combustion flame is introduced into a furnace 1 .

[0023] When making less than a theoretical amount of main air and fuel burn in the main combustion section 13, the main combustion in the main combustion section 13 is incomplete, so that it is inhibited due to the temperature reduction of the main combustion flame entering the furnace 1. NOx production. By the way, the amount of ...

Embodiment 2

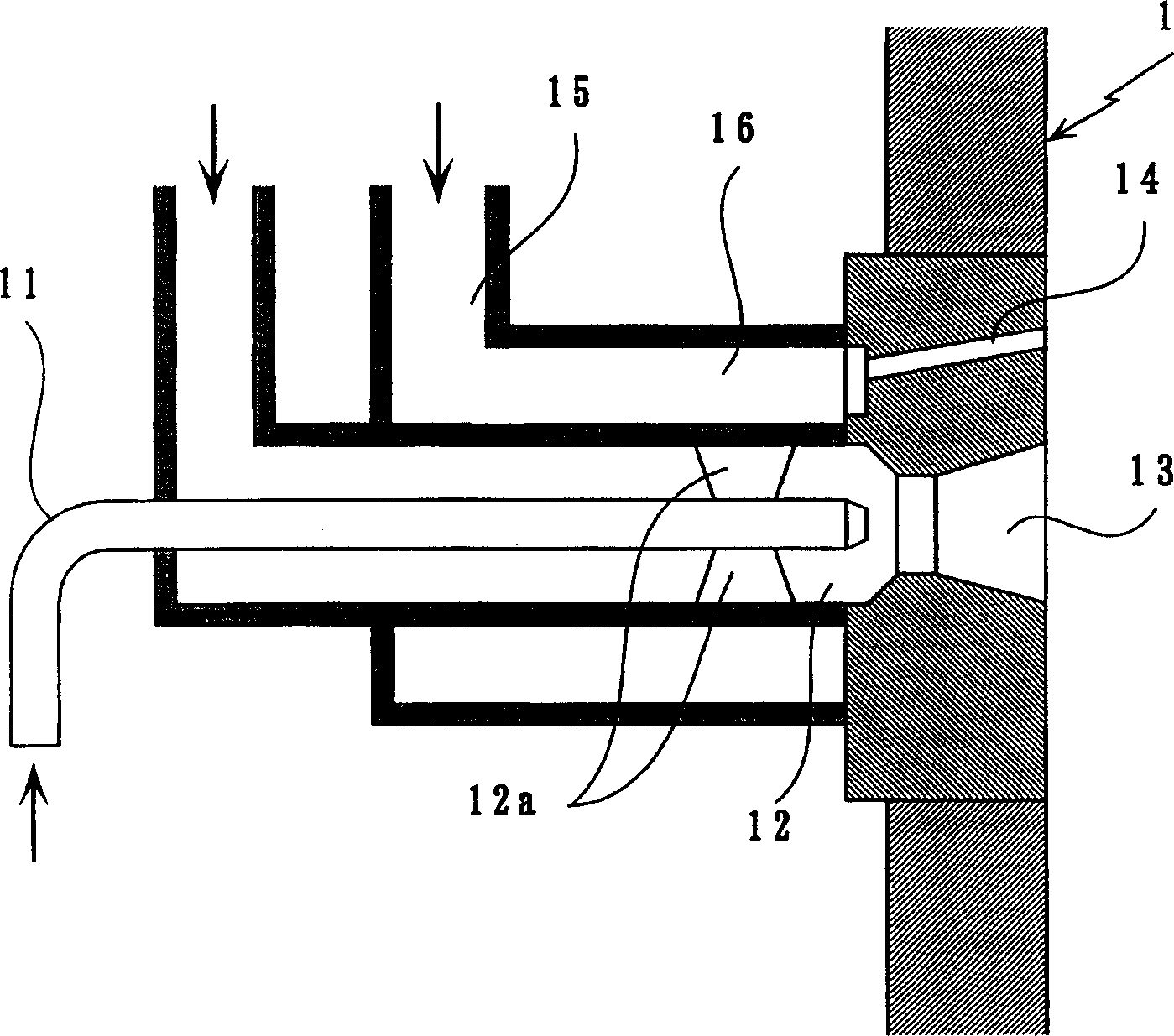

[0037] A combustion device of Embodiment 2 has the same feature as that of the foregoing Embodiment 1, that is, the fuel is supplied to the main combustion portion 13 via the fuel supply nozzle 11, and the main combustion unit will be less than the theoretical amount calculated from the above-mentioned fuel. The air is introduced into a main air supply nozzle 12 formed outside the fuel supply nozzle 11 . The swirl vanes 12a provided in the main air nozzles 12 are operable to swirlly supply the main air to the main combustion sections 13 so that the thus supplied fuel and the main air can be combusted in the main combustion sections 13. The main combustion flame is introduced into a furnace 1 .

[0038] On the other hand, two auxiliary air supply nozzles 14 for supplying auxiliary air are provided outside the periphery of the above-mentioned main combustion portion 13 within an angle range of 160° relative to the center of the main combustion portion 13 . In addition, two auxi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com