Backlight assembly

A technology for backlight assembly and light source, applied in optics, diffusing elements, nonlinear optics, etc., can solve the problems of increasing the volume of the backlight assembly 10 assembly difficulty, product competitiveness slippage, light source energy loss, etc., to simplify the assembly process. and cost, enhance competitiveness, and reduce the effect of product volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

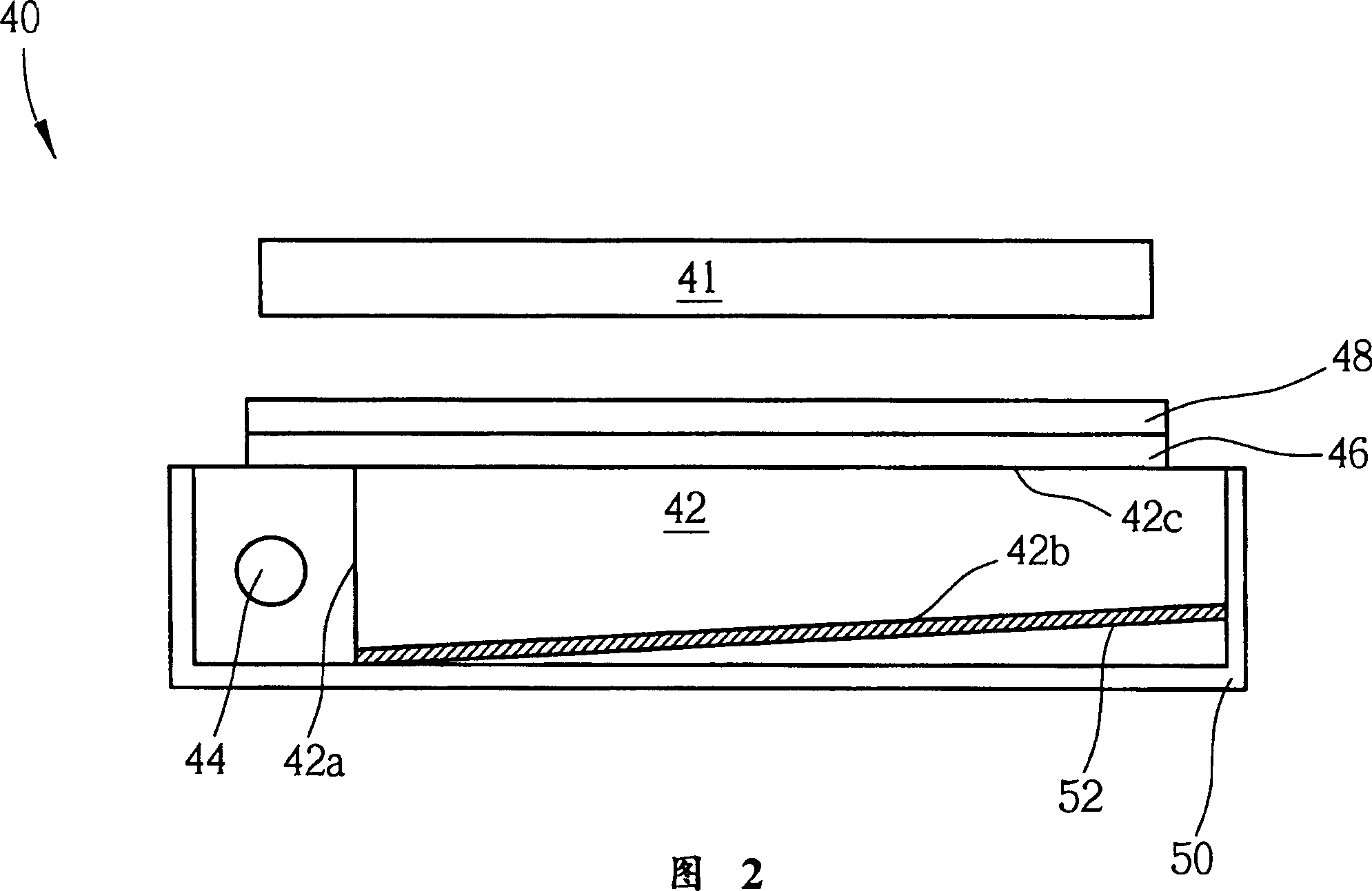

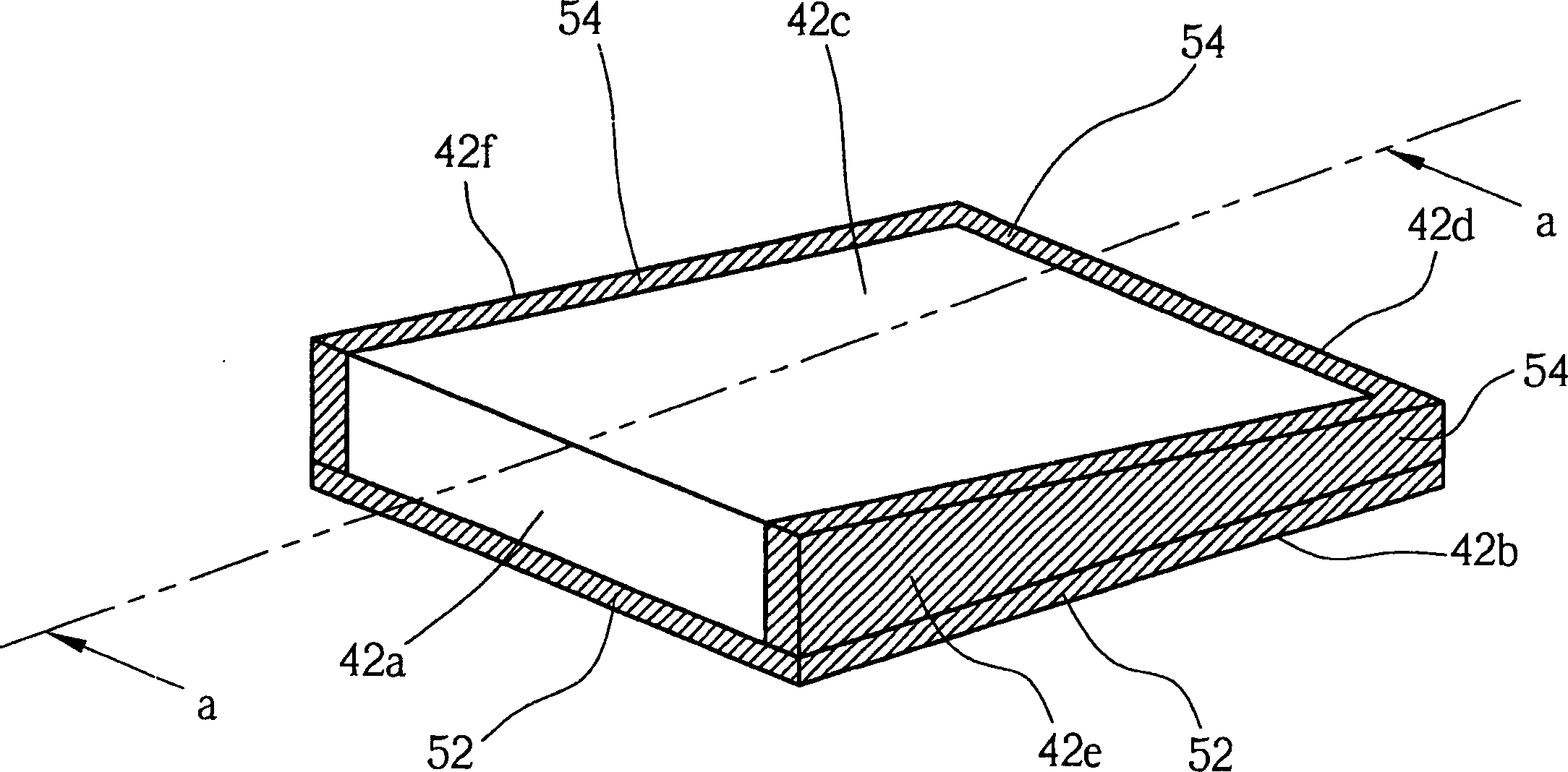

[0028] Referring to FIG. 2 , FIG. 2 is a schematic cross-sectional view of an edge light (edge light) backlight unit (BLU) 40 of the present invention. As shown in FIG. 2 , the backlight assembly 40 is disposed under a display panel (displaypanel) 41, and the backlight assembly 40 includes: a light guide plate (LGP) 42, a first side surface of the light guide plate 42 A light source generator (light source generator) 44 of 42a, a diffusing plate (diffusing plate) 46 located above the light guide plate 42, at least one prism (prism) 48 located on the surface of the diffusing plate 46, and a diffuser plate (prism) 48 located on the light guide plate 42 and covers the housing 50 around the light guide plate 42 and the light source generator 44 .

[0029] The light source generator 44 is generally a lamp tube used to provide a light source, and the light guide plate 42 includes a bottom surface (bottom surface) 42b coated on the light guide plate 42 for upward reflection (reflec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com