Fastening construction, in particular for a wing mirror of a motor vehicle

A technology for fastening structures and motor vehicles, which is applied in vehicle components, optical observation devices, transportation and packaging, etc., and can solve the problems affecting the degree of freedom in the design of the rearview mirror housing and the difficulty in controlling the fastening force of screw parts, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The above-mentioned drawings are merely schematic representations of preferred embodiments of the present invention. In the drawings, identical or corresponding parts are designated by the same reference numerals.

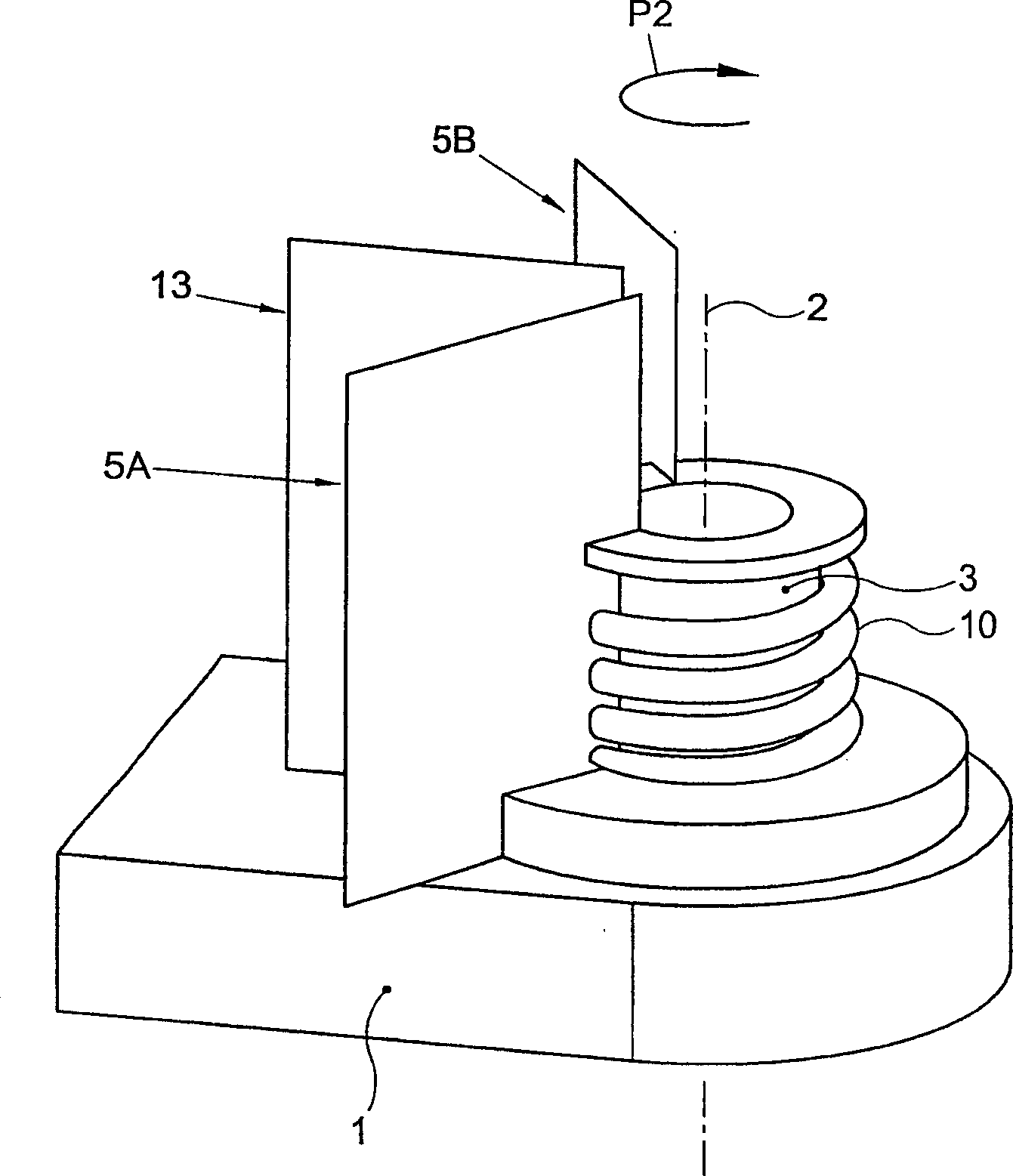

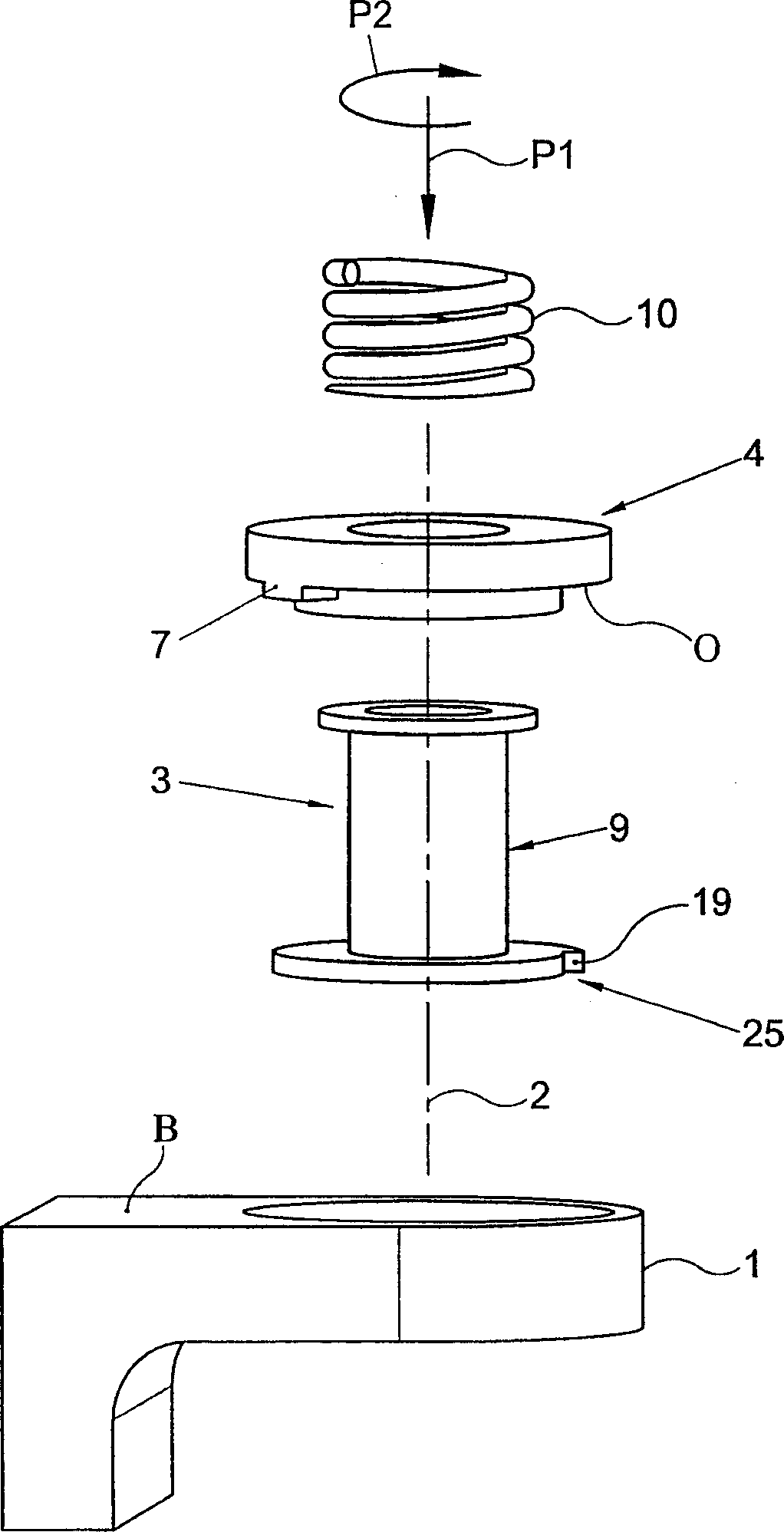

[0024] in the attached Figures 1 to 4 , a first embodiment of a fastening structure for a rear-view mirror unit (not shown) on a fender of a motor vehicle is shown. The fastening structure includes a base part 1 and a rotating part 3 . The base part 1 can be fixedly connected to the vehicle. The swivel part 3 is arranged to be connected to the base part 1 and in the connected state constitutes a central axis around which the housing of the mirror unit on the fender can be pivotally supported for pivotal movement.

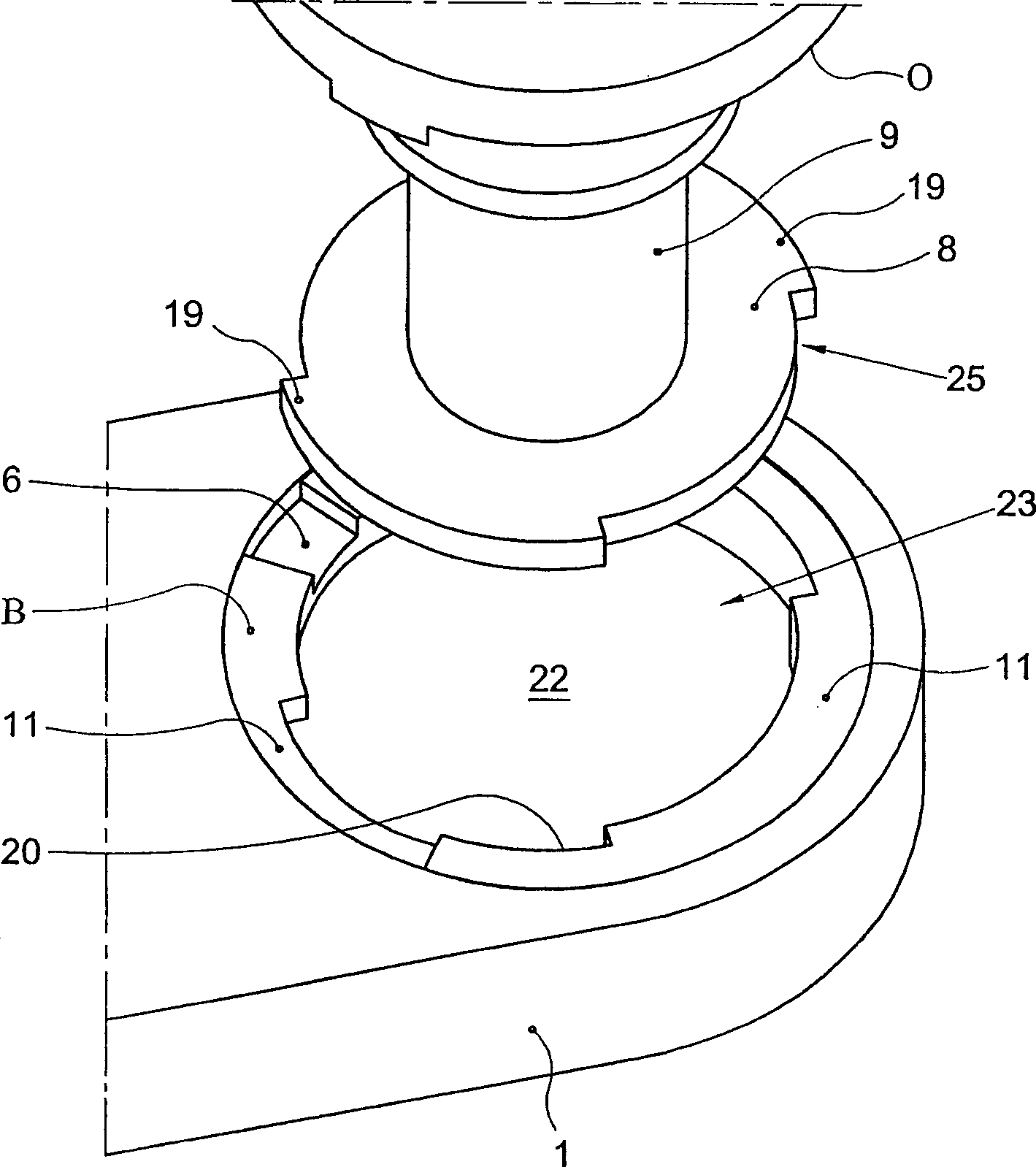

[0025] The rotating part 3 has a main shaft part 9 extending along the geometrical axis 2 . The rotating part 3 also has a bearing part 25 extending substantially radially with respect to the geometrical axis 2 . The support part 25 is desig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com