Four-fingered welding glove

A glove and index finger technology, applied in the field of four-finger gloves, can solve the problems of reduced work efficiency, low usage rate of middle finger, ring finger, little finger, and small number of finger forming parts, so as to improve work efficiency, easy and meticulous operation, and reduce hand fatigue. The effect of fatigue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

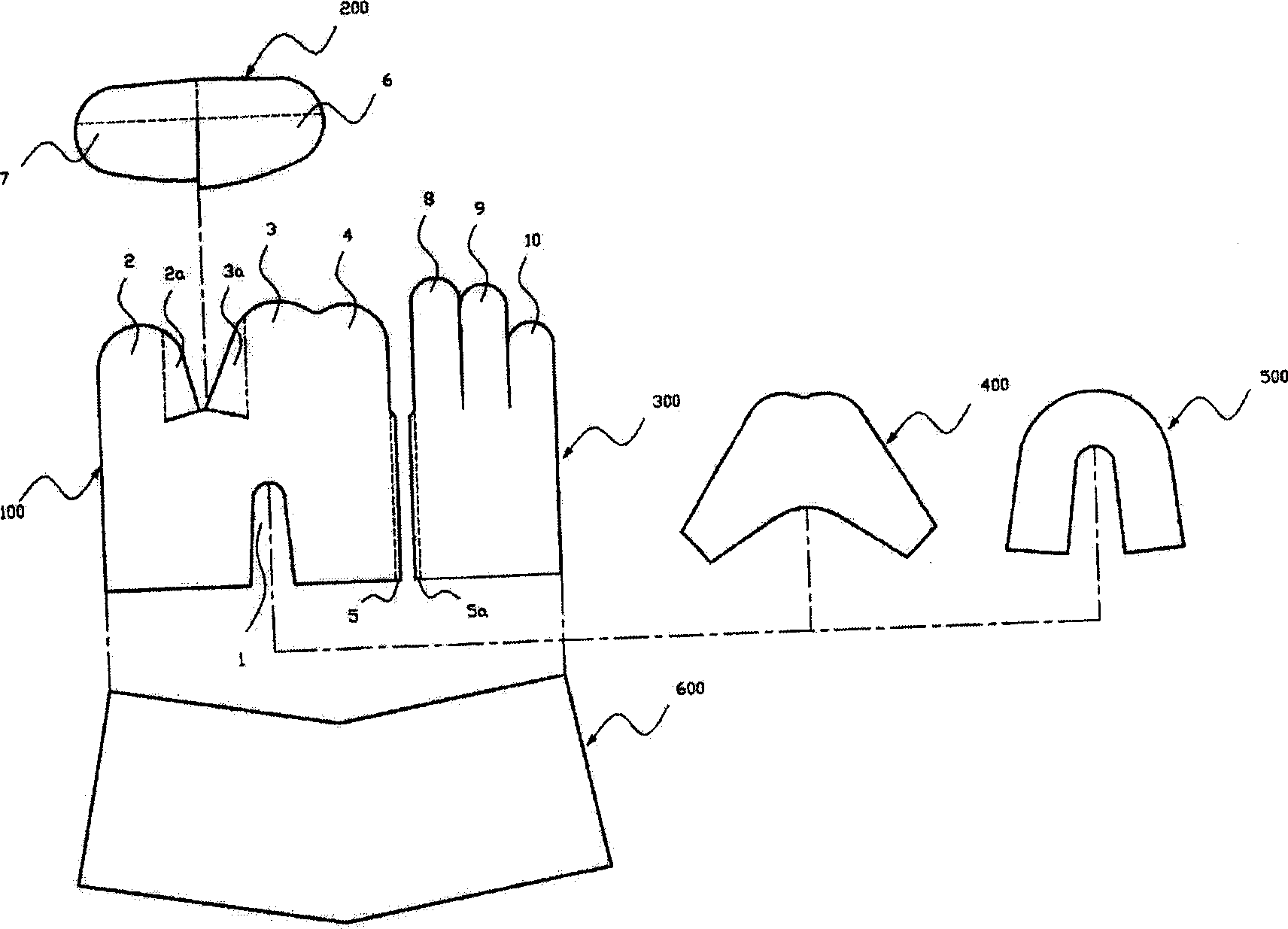

[0024] According to the preferred embodiment of the present invention, the four-fingered glove will be described in detail in accordance with the accompanying drawings.

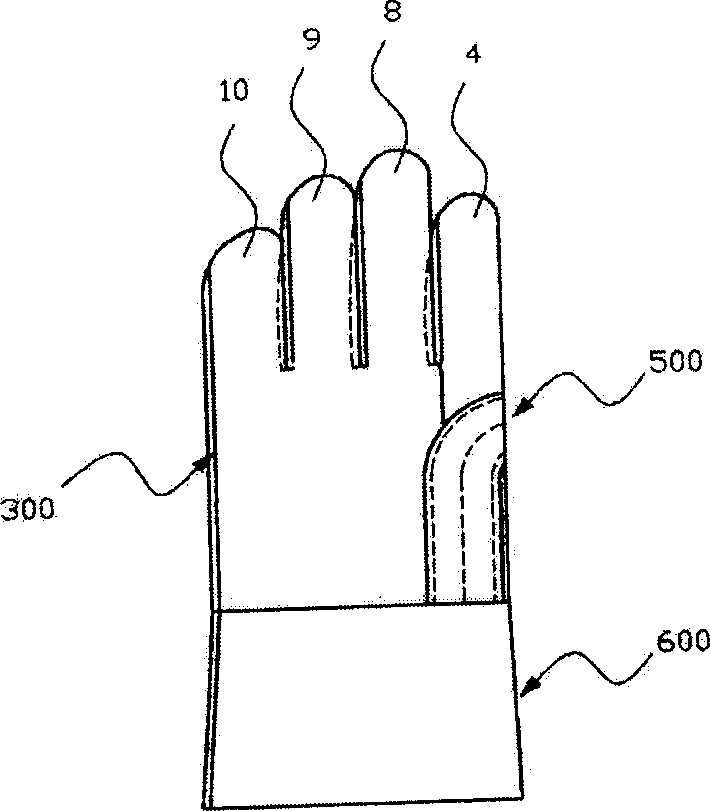

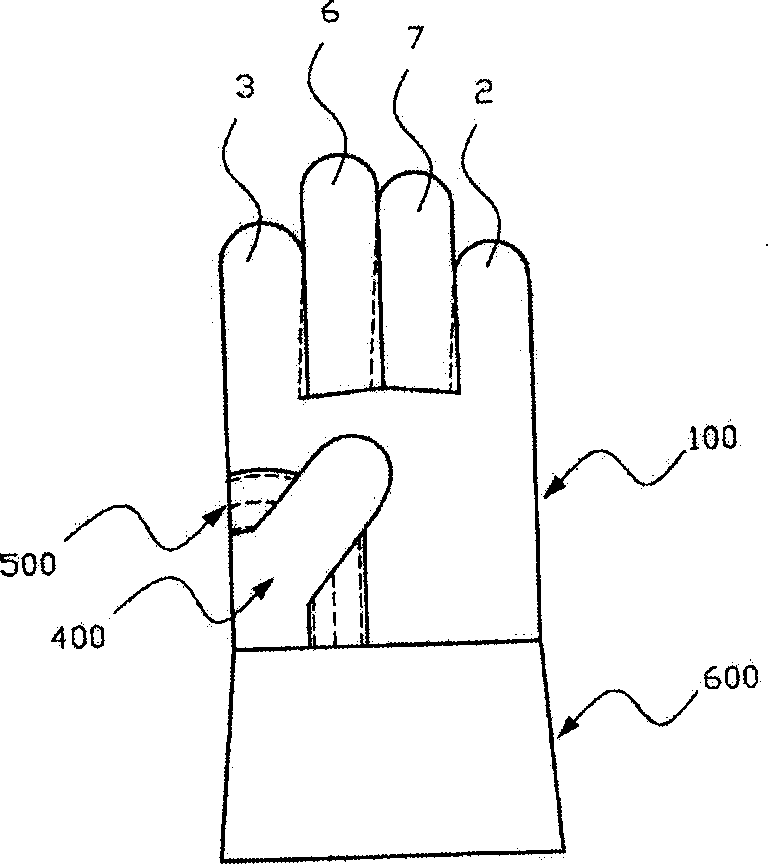

[0025] Figure 1a to Figure 1d Respectively represent the back view of the hand, the palm view, the cropped view, and the three-dimensional view of the existing glove. Figure 2a to Figure 2c Respectively represent the back view of the glove hand, the palm view, and the cutout view according to another embodiment of the existing glove. Figure 3a to Figure 3d Respectively, on the first embodiment of the present invention, the back view of the hand, the palm view, the cutout view, and the perspective view of the integrated four-finger glove. Figure 4a to Figure 4d On the first embodiment of the present invention, respectively represent the back view of the hand, the palm view, the cutout view, and the three-dimensional view of the four-fingered glove with the stitching point (A) on the back of the overall boa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com