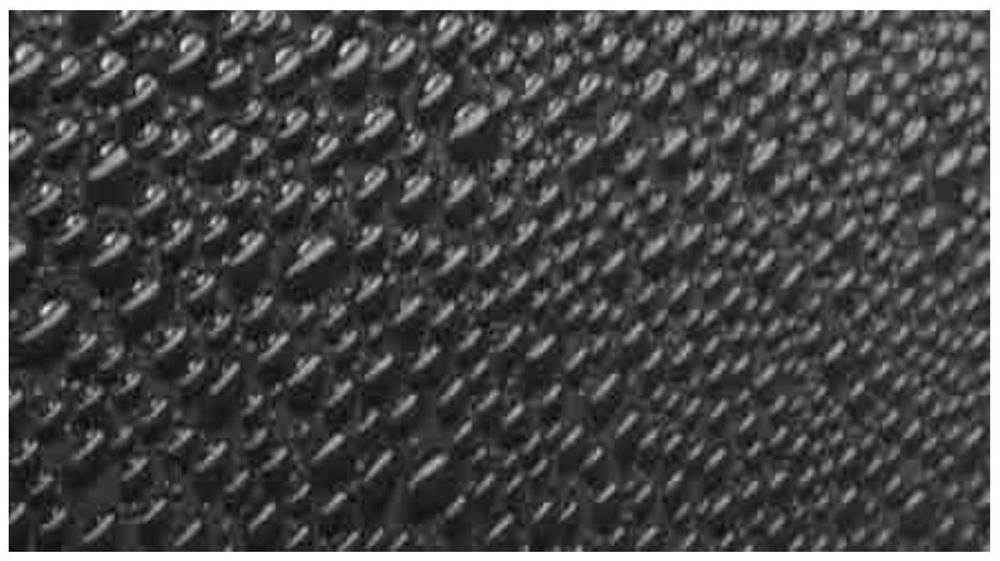

UV-cured water-drop-shaped effect coating and preparation method thereof

A drop-shaped coating technology, applied in anti-corrosion coatings, epoxy resin coatings, polyurea/polyurethane coatings, etc., can solve the problems of uncontrollable water droplet size, poor recoating adhesion, slow curing speed, etc., and achieve simplified formula Blending process, good ornamental value, fast curing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~4

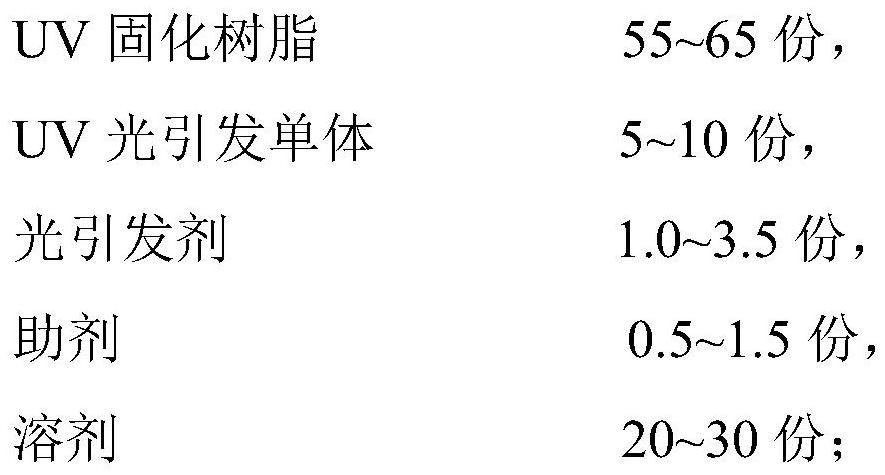

[0033] Prepare finish paint A according to the following table weight parts:

[0034] component name Example 1 Example 2 Example 3 Example 4 UV curable resin 55 65 65 60 Tripropylene glycol diacrylate 10 0 5 8 β-Hydroxyethyl Methacrylate 0 5 5 0 Photoinitiator BP 3.5 0 0 0 Photoinitiator 184 0 1.0 2.3 1.7 Photoinitiator TPO 0 0 1.2 0.8 Leveling agent Efka FL 3777 1.5 0 1.5 0.5 Leveling agent BYK-113 0 0.5 0 0 ethyl acetate 30 28.5 0 0 Butyl acetate 0 0 20 0 diisobutyl ketone 0 0 0 29

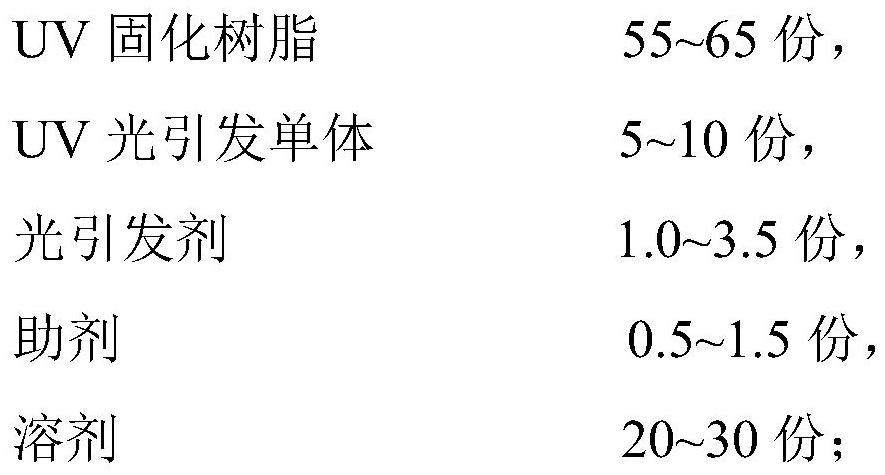

[0035] Prepare primer B according to the following table weight parts:

[0036] component name Example 1 Example 2 Example 3 Example 4 Topcoat A 85 100 90 90 Universal Black Paste 15 0 10 10

[0037] Spray the primer B on the substrate according to the construction standard, and form a film with a thickness of about 20 μm after it is com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com