Patents

Literature

104results about How to "Good ornamental value" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

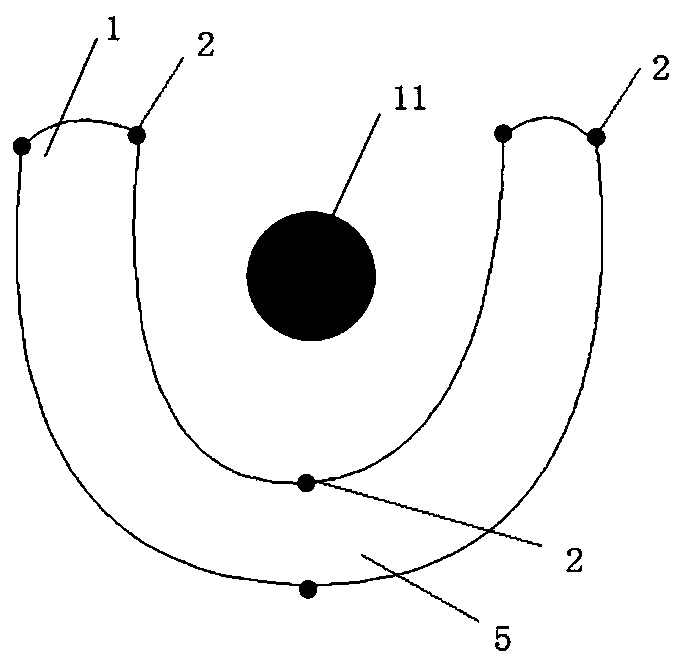

Method for grafting branch onto tree

InactiveCN103081732AImprove survival rateGood ornamental valueHorticulture methodsGraftingAgroforestry

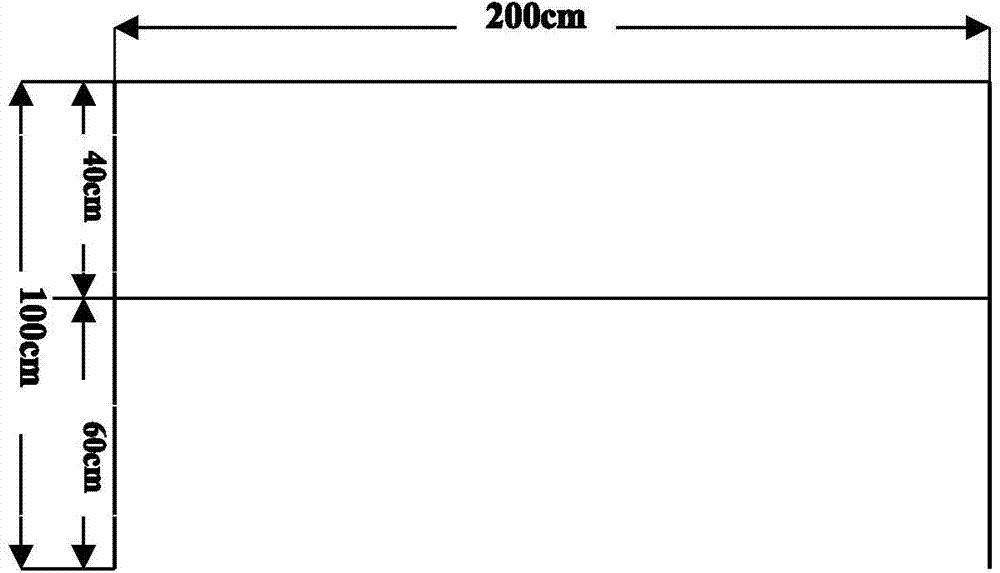

The invention discloses a method for grafting a branch onto a tree. According to the method for grafting the branch onto the tree, a scion tree which is in the same type as the tree where the branch is to be grafted is selected; the scion tree is transplanted beside the tree where the branch is to be grafted; the time of grafting is chosen to be in March to May, 60% to 70% of the skin of an inarching portion of the scion tree is stripped to expose the xylem of the scion tree, a groove where the inarching portion of the scion tree can be inserted is formed in an inarching portion of the tree where the branch is to be grafted, the groove is deep enough to reach the xylem of the tree where the branch is to be grafted, and after the inarching portion of the scion tree and the groove are sterilized, the inarching portion of the scion tree and the groove are bonded closely; nails are used for fixing the inarching portion of the scion tree and the groove, and then a grafting film is used for tying up the scion tree and the groove; the grafting film is untied after two to three months; in the inarching growing period, the situation that the scion three is provided with suitable soil, water and fertilizer for facilitating the growth of the scion tree is maintained; and if the scion tree is alive after the grafting, the portion, under the joint portion of the scion tree and the tree, of the scion three is cut and sealed with tree wound sealing glue, wherein the cutting time is chosen to be in October to November and at least one year after the grafting date.

Owner:长沙县奥景花卉苗木专业合作社

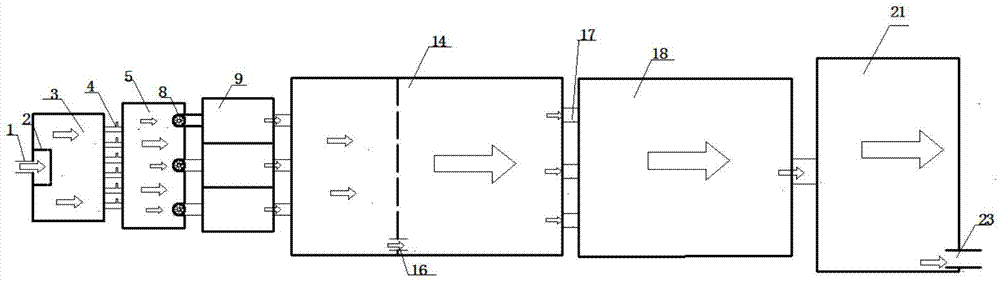

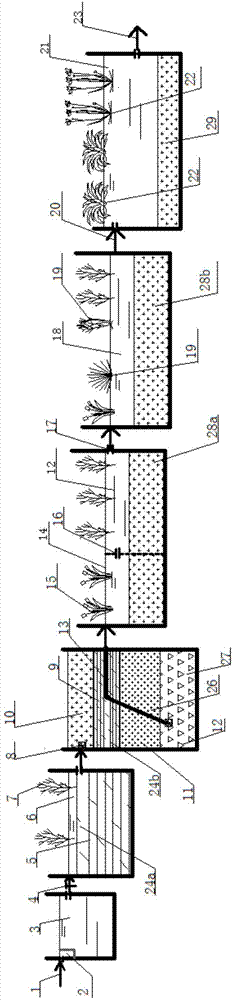

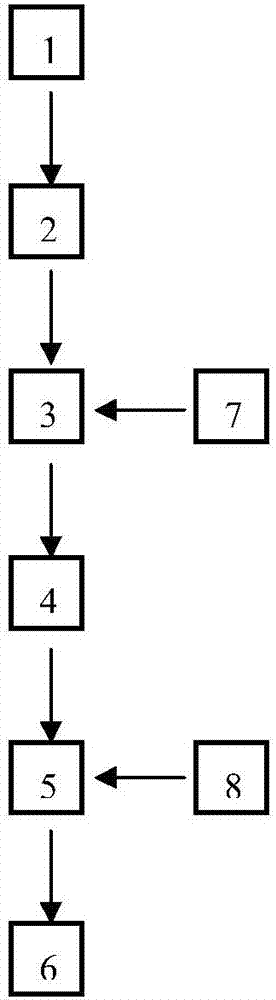

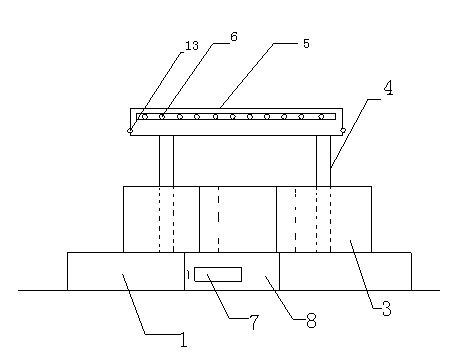

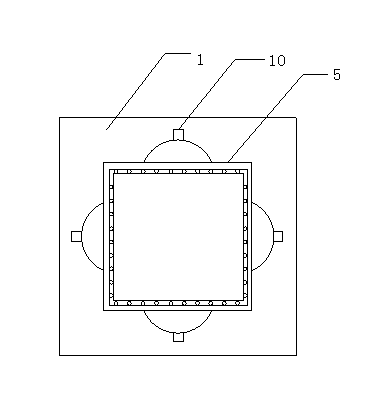

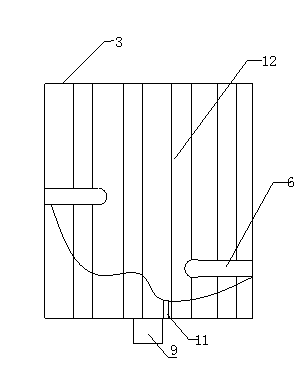

Ecological combined treatment method and device for rural distributed sewage

InactiveCN103880257AEfficient purificationImprove processing efficiencyMultistage water/sewage treatmentConstructed wetlandBiological filter

The invention discloses an ecological combined treatment method and device for rural distributed sewage. The method comprises the steps of A) rural sewage collection and pretreatment; B) treatment by a biological filter; C) treatment by an artificial wetland and a stabilization pond; D) ecological landscape configuration. The device is characterized in that a main water inlet pipeline is respectively connected with a lattice pool and a regulation pool, the regulation pool is connected with a horizontal flow biological filter through a water distribution pipe, the horizontal flow biological filter is connected with a vertical flow biological filter through a filter screen-water distribution pipe, the vertical flow biological filter is connected with a first-level artificial wetland via a perforated water collection pipe which is horizontally arranged, the first-level artificial wetland is connected with a second-level artificial wetland through an overflow weir, the second-level artificial wetland is connected with the stabilization pond through a straight flow water drain pipe, and a main water drain pipe is arranged at the tail end of the stabilization pond. According to the method, energy consumption is not required, the operation and the maintenance are simple and convenient, and the method further has the advantages of landscape effect, economic benefits, simple structure and low investment; high-efficient purification of rural distributed domestic and farming sewage is realized, and the removal rate of nitrogen, phosphorus, COD and the like in sewage is above 80% after treatment.

Owner:大长江环境工程技术有限责任公司

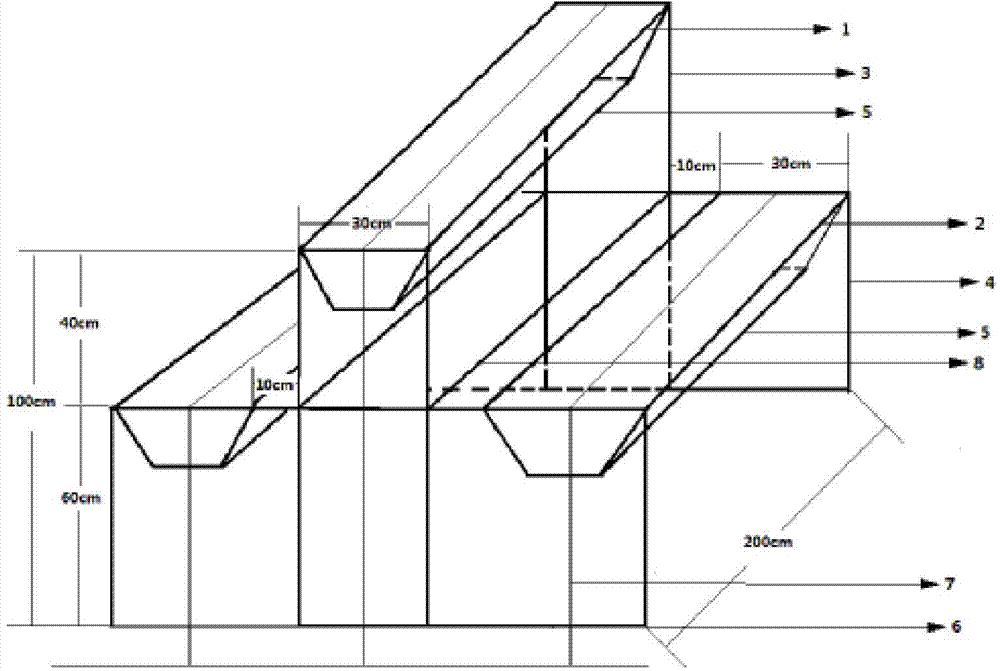

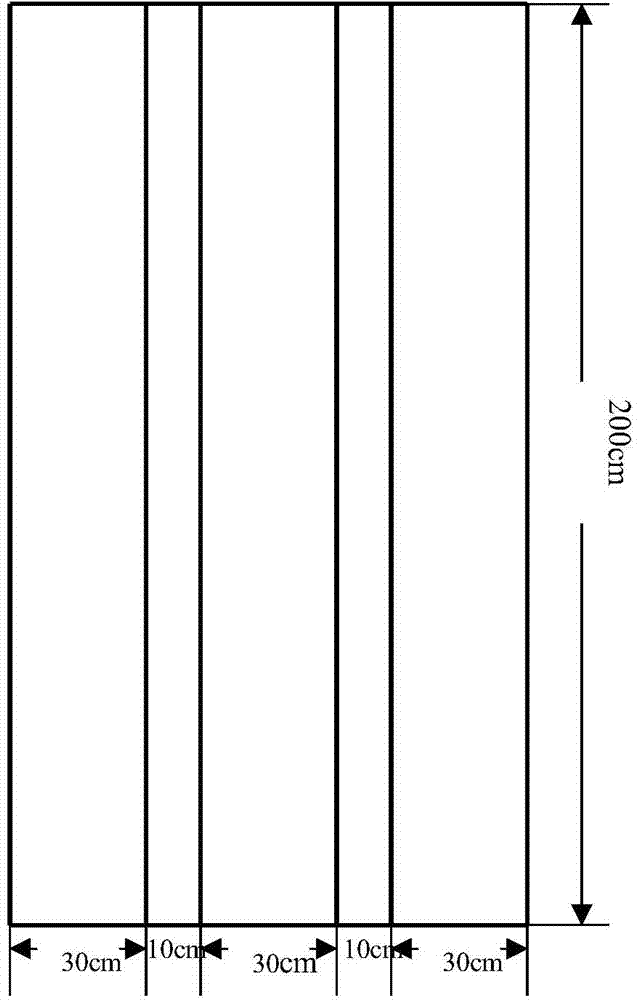

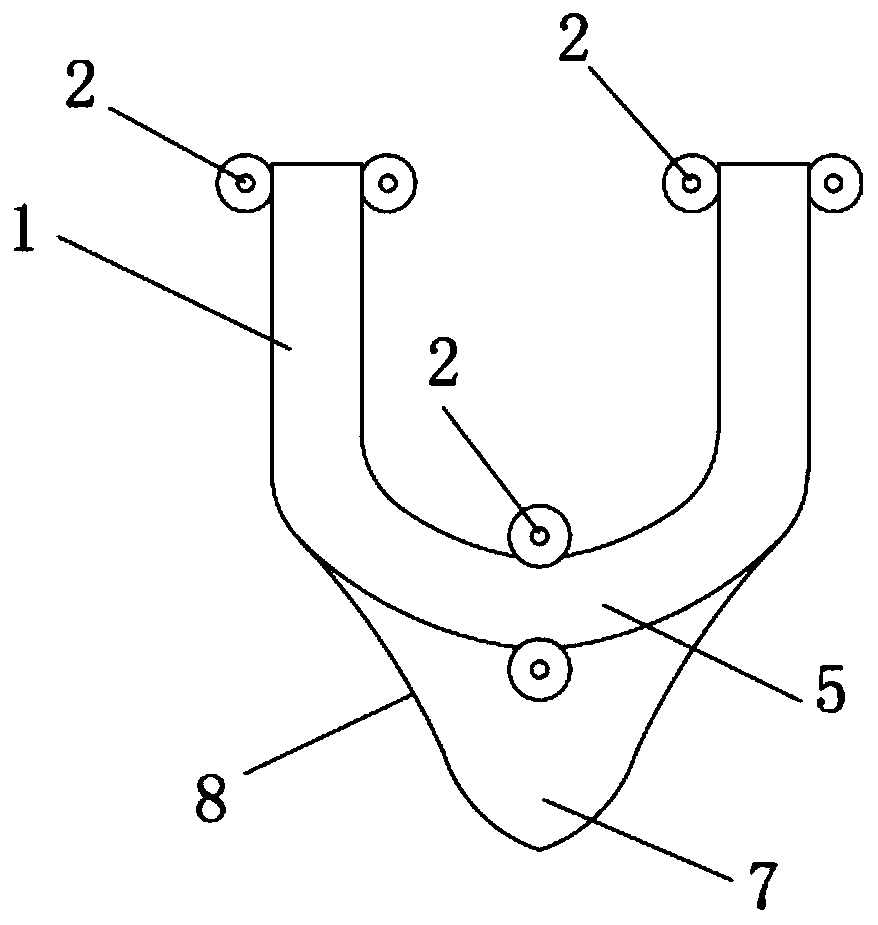

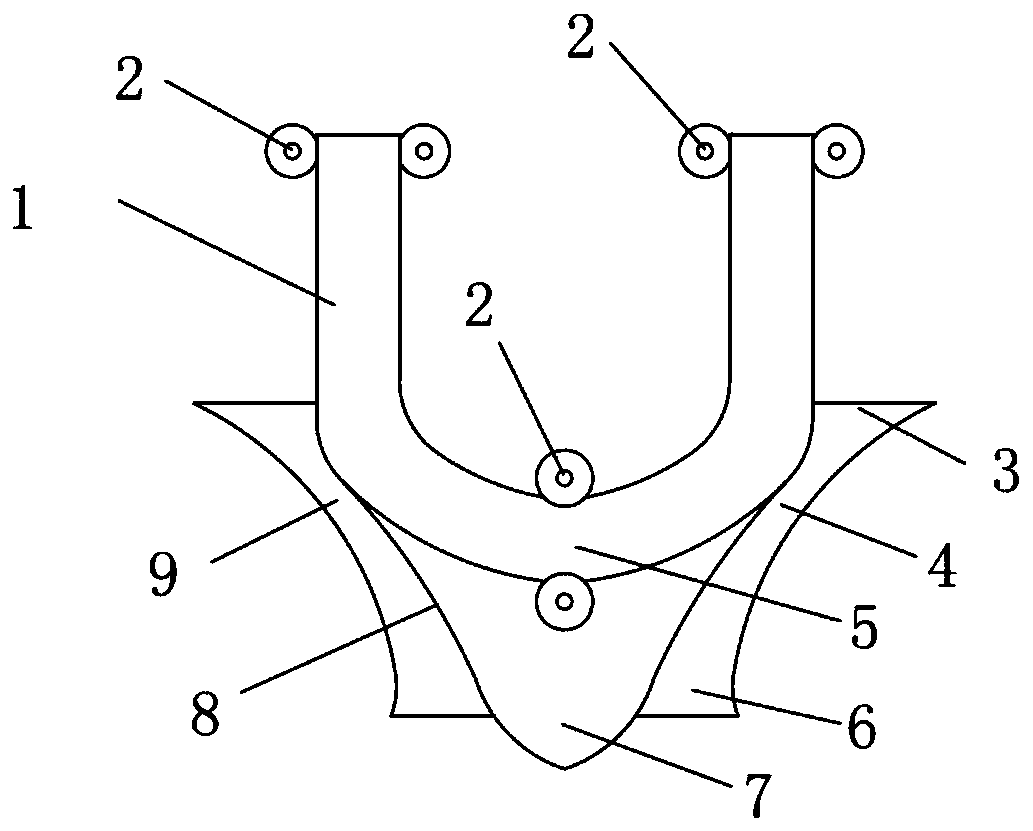

Method for cultivating frame type strawberries

InactiveCN103875428AConvenient for sightseeing and pickingBright colorsAgriculture gas emission reductionCultivating equipmentsFragariaWoven fabric

The invention relates to a method for cultivating frame type strawberries and belongs to the technical field of crop cultivation. According to the method for cultivating the frame type strawberries, a frame type strawberry cultivation device is adopted and is composed of cultivation grooves, cultivation groove supporting columns, a cultivation frame base, non-woven fabric and drip irrigation zones; through the suspension soilless cultivation of the strawberries, the labor intensity is relieved, the amount of labor is reduced, successive cropping obstacles are overcome, environmental growing conditions are effectively regulated, labor-saving, clean and high-quality cultivation is achieved, and high-quality strawberries can be produced. The natural environment and the production conditions are improved, the integration effect is utilized and performed, resources can be utilized more effectively, the resource utilization rate in unit area and unit time is increased, the potential productivity of an limited area is performed, and a remarkable effect is achieved. Along with the powerful development momentum of strawberry production and leisure picking, three-dimensional strawberry has a broad market, tourism picking can be more comfortable, and a novel mode is provided for the development of the urban leisure agriculture.

Owner:江苏丘陵地区南京农业科学研究所

Eggplant and big-flowered eggplant grafting method

The grafting method of eggplant and solanum wrightii includes the following steps: according to the requirements for shaping, selecting proper twig as stock in winter, selecting proper position on the section of the stock, cutting a slit, whose depth is 2cm-3cm and width is identical to that of scion, then selecting semi-lignified eggplant branch as scion, using cutter to cut its base portion into symmetrical oblique surfaces which are different in size, inserting the scion into the slit of stock, tightly binding said slit by plastic strip, and using a small plastic bag to cover the scion and slit together, after the new bud is grown from scion, removing said small plastic bag. Said invention can create the curious spectacle of that eggplant fruit can be grown on the big tree.

Owner:XISHUANGBANNA TROPICAL BOTANICAL GARDEN CHINESE ACAD OF SCI

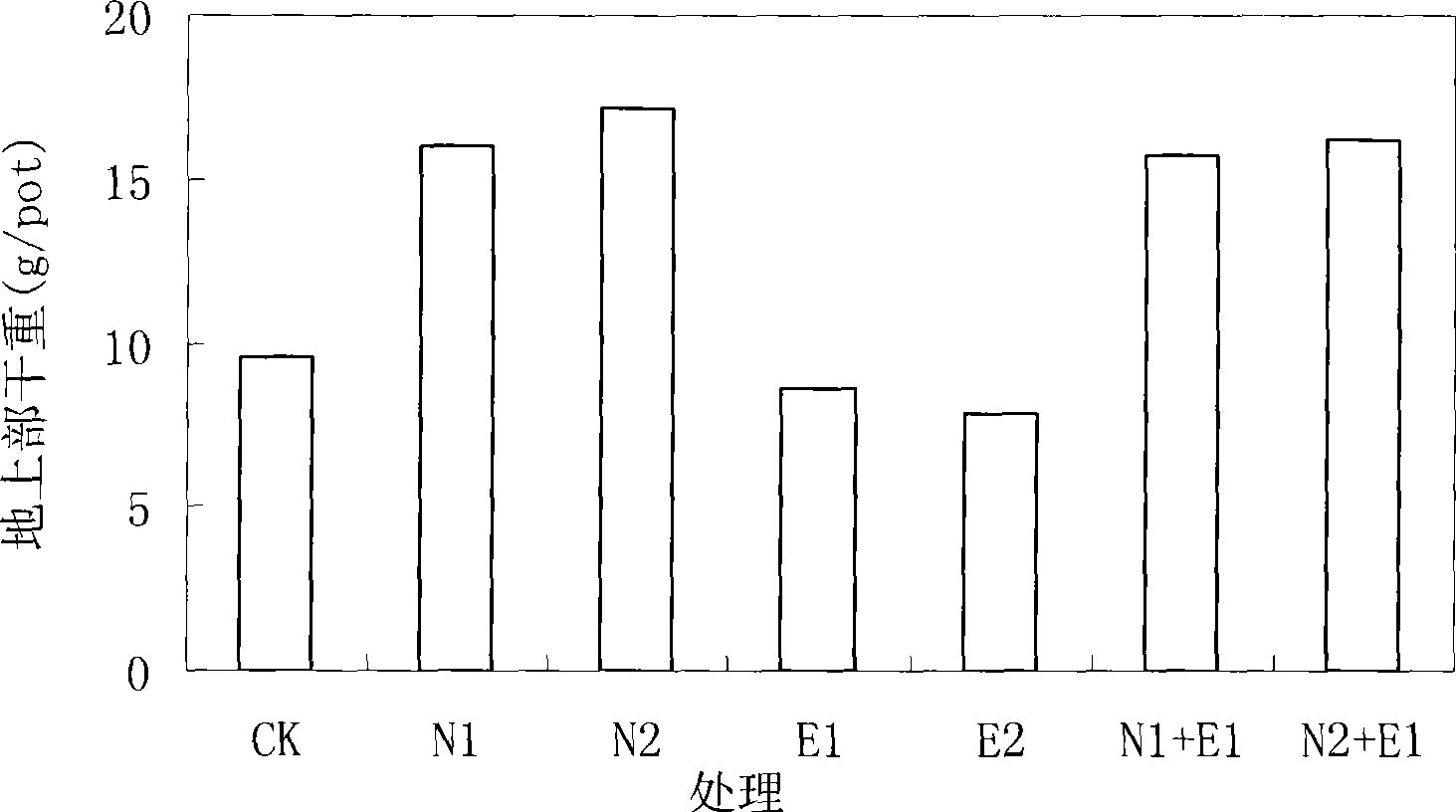

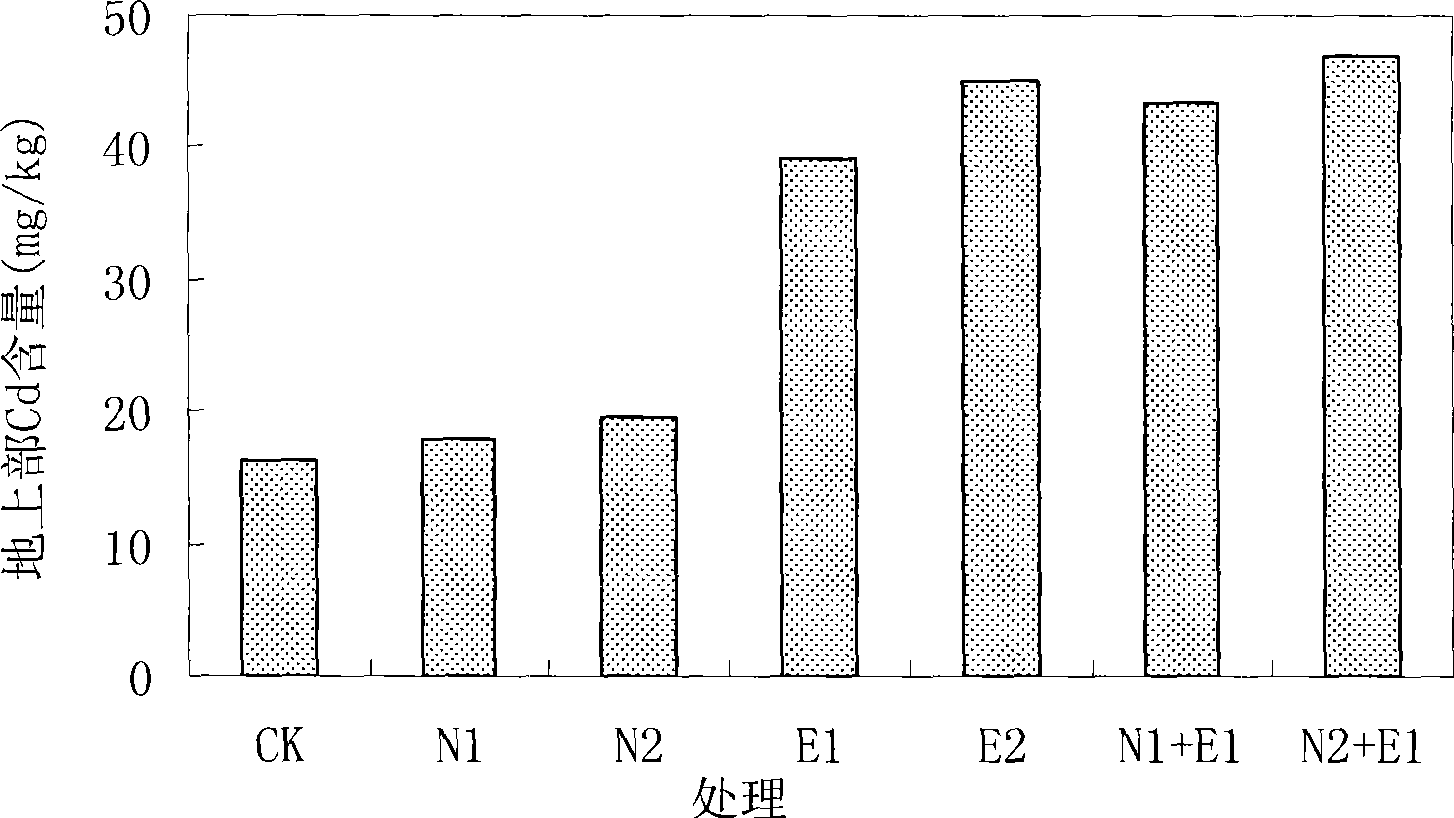

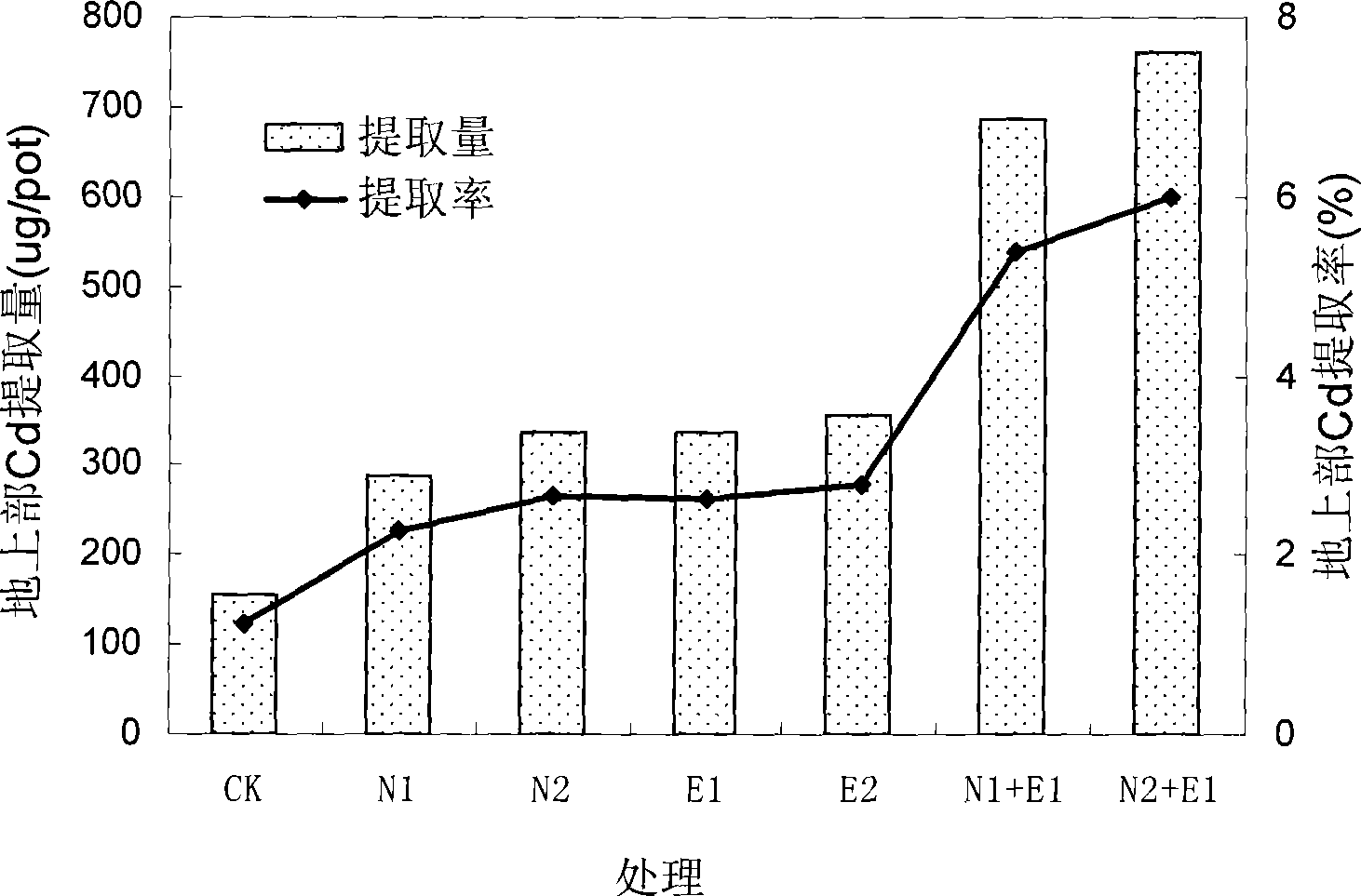

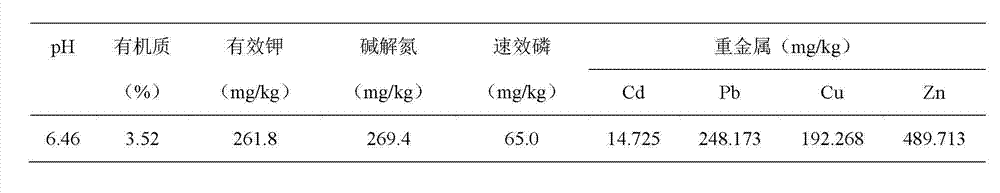

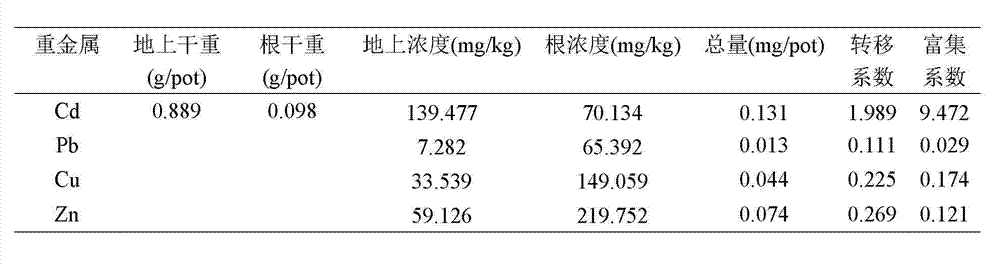

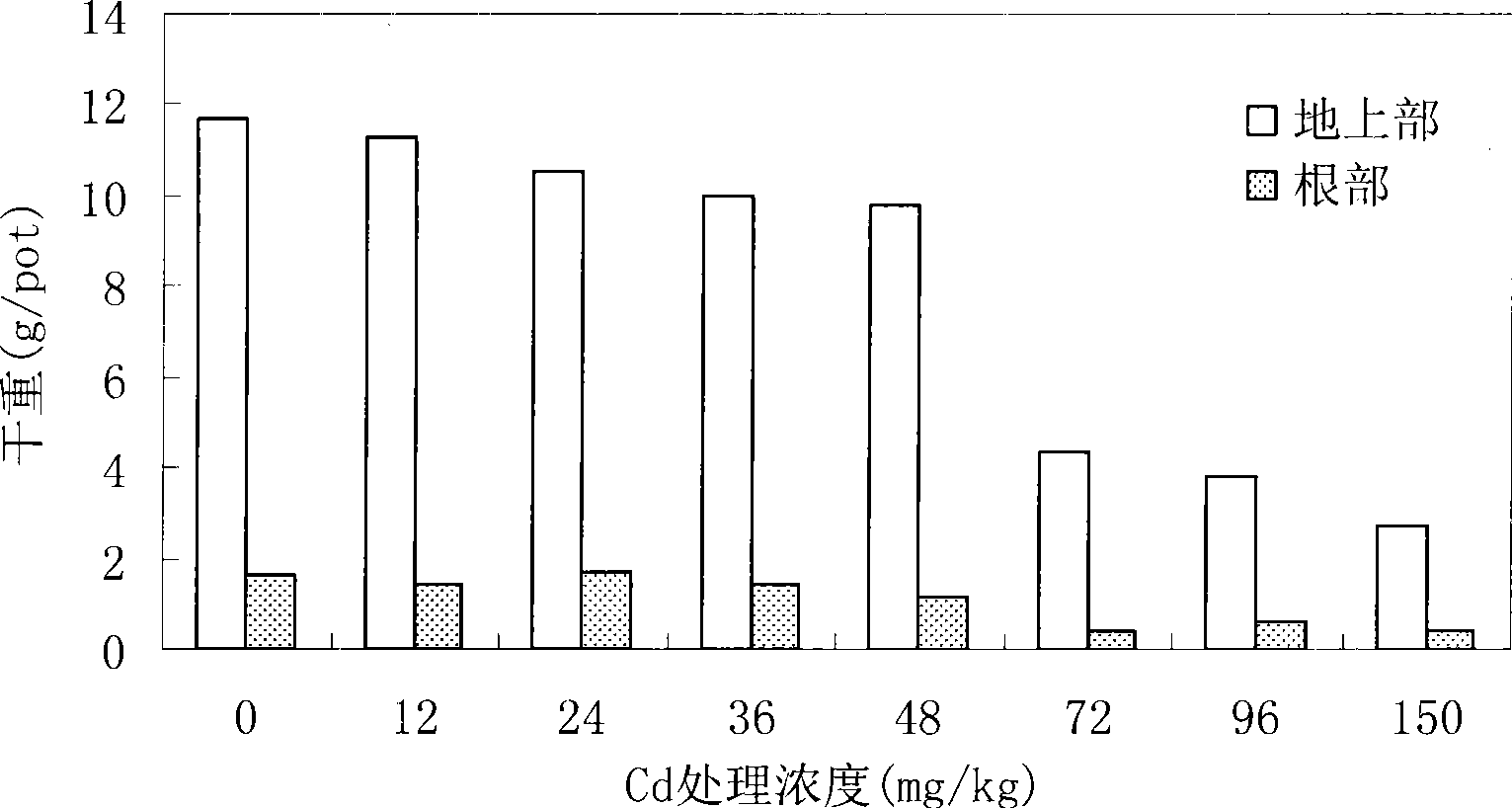

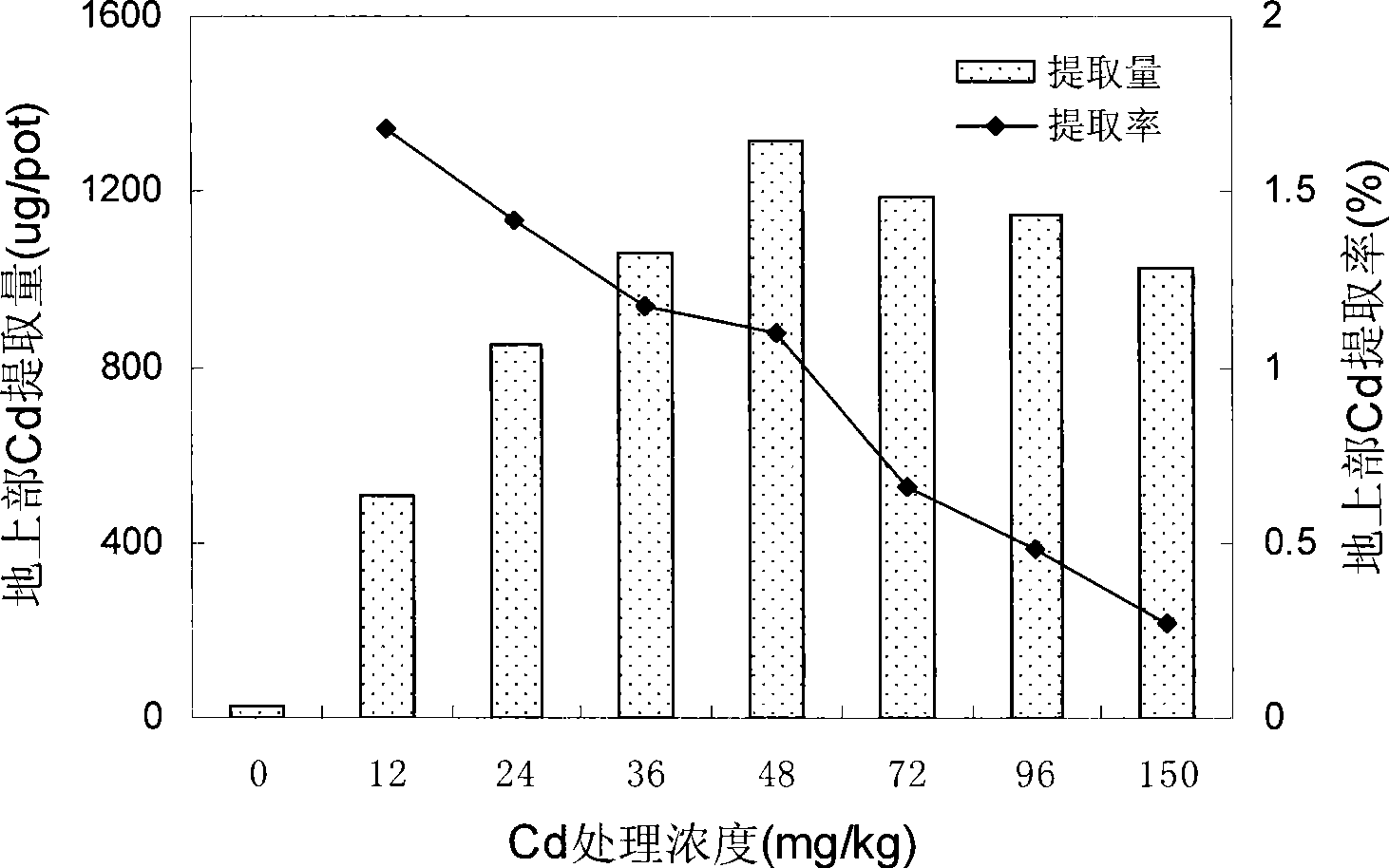

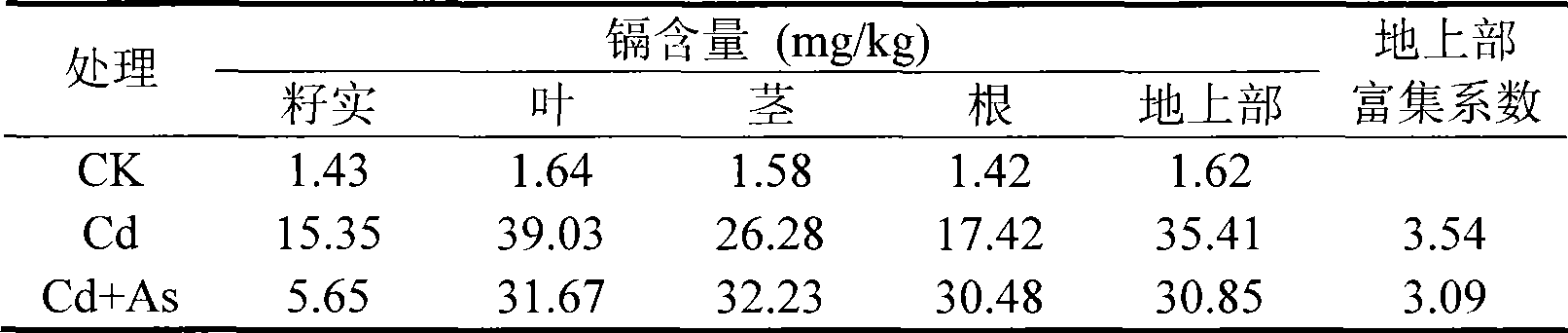

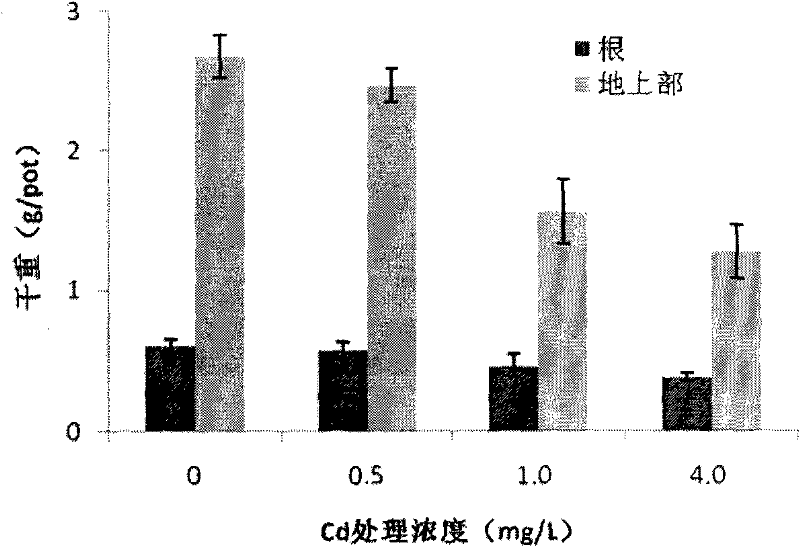

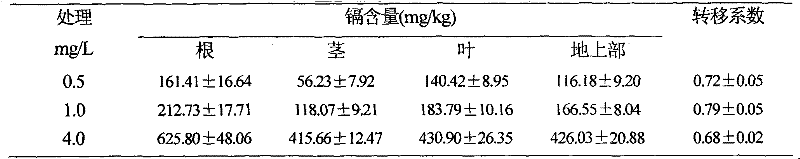

Combined reinforced method for repairing cadmium polluted soil

InactiveCN101462117AImprove repair efficiencyReduce repair costsContaminated soil reclamationPollution soilCadmium Cation

The invention relates to phytoremediation for heavy metal polluted soil, in particular to a method for utilizing combined reinforced measures to remedy cadmium-polluted soil. The method is to apply an ammonium fertilizer in the soil to be remedied, plant maidenhair, add a chelating agent into the soil when the maidenhair is grown to the flowering period or the maturation period, and completely remove the plants after the plants are grown for 10 to 15 days so as to achieve the aim of remedying the cadmium-polluted soil. The method not only can obviously relieve the harm of the chelating agent on the plants but also can obviously improve the reinforced remedying effect of the chelating agent by applying the acid fertilizer so as to accelerate the phytoremediation process of the cadmium-polluted soil. Moreover, the method has the advantages of low remediation cost, high remediation efficiency, strong maneuverability, small environmental risk and the like, and can beautify the environment when simultaneously treating the polluted soil.

Owner:SHENYANG INST OF APPL ECOLOGY CHINESE ACAD OF SCI

Method for artificially propagating moon jellyfish

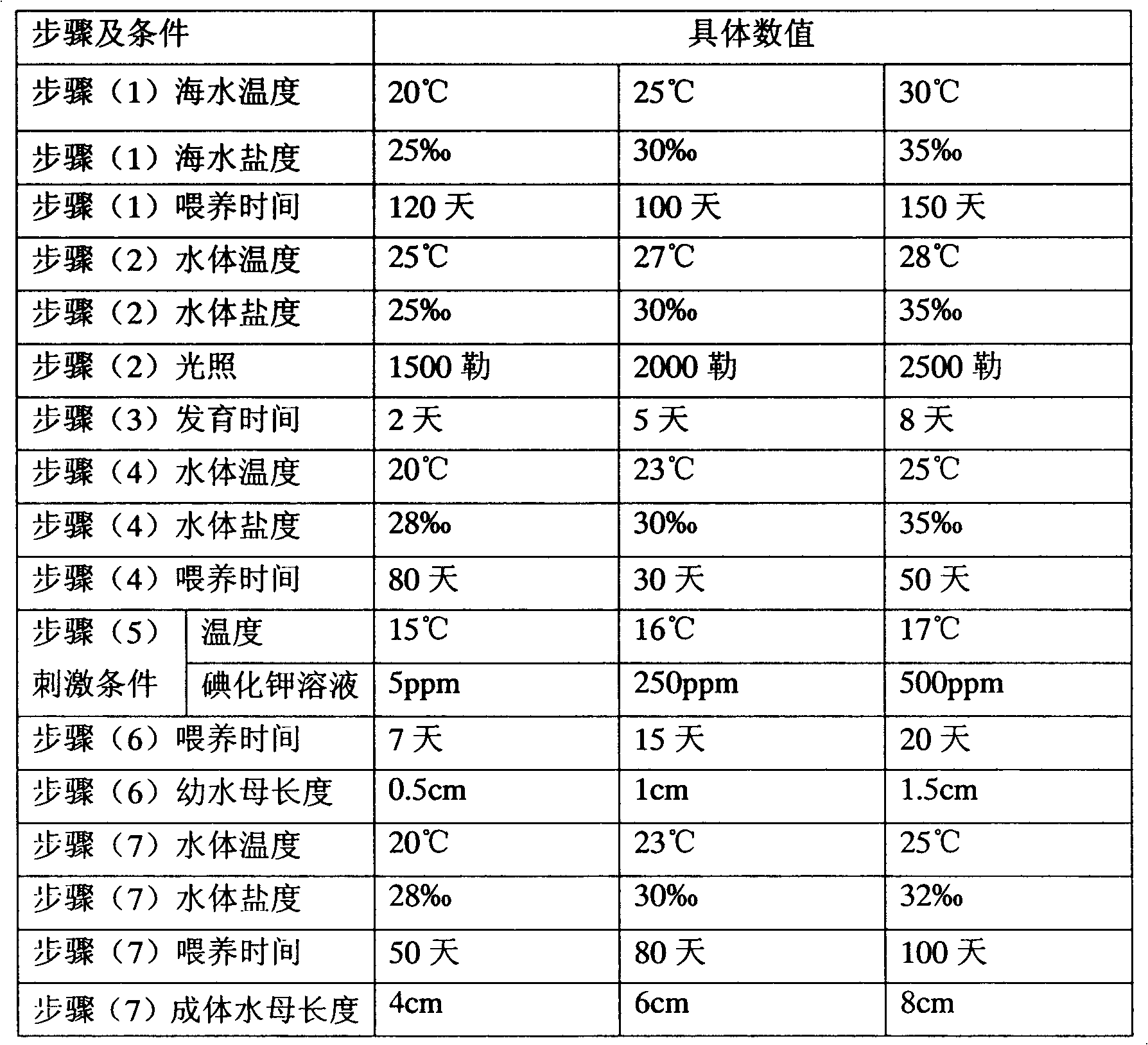

InactiveCN102524126AStabilize market supplyEasy to feedClimate change adaptationPisciculture and aquariaAurelia auritaLarva

The invention relates to a method for artificially propagating moon jellyfish and belongs to a propagating technology of marine organisms. The method comprises the following steps of: feeding female and male parents of the moon jellyfish in the same water body with stable temperature and salinity for 100-150 days; scratching the female parent and the male parent and changing the temperature, the salinity and illumination of the water body; respectively releasing ova and sperms from the female parent and the male parent, wherein the ova and sperms form fertilized eggs, the fertilized eggs develop to form larva plankton and the larva plankton develops for 2-8 days to form hydranths; separately culturing an attachment medium to which the hydranths are attached, keeping the water quality fresh as well as the temperature and the salinity stable; allowing hydranths to become hydranth adults after being fed for 30-80 days; under the conditioned stimulus, releasing a jellyfish larva from the hydranth adult; feeding the jellyfish larva in clear water quality and breeding the jellyfish larva by adopting soft bubbles; allowing the jellyfish larva to gradually grow into young jellyfish after being fed for 7-20 days; and transferring the young jellyfish into a young jellyfish culture tank, keeping the temperature and the salinity constant and allowing the young jellyfish to develop into an adult jellyfish after being fed for 50-100 days.

Owner:李新书

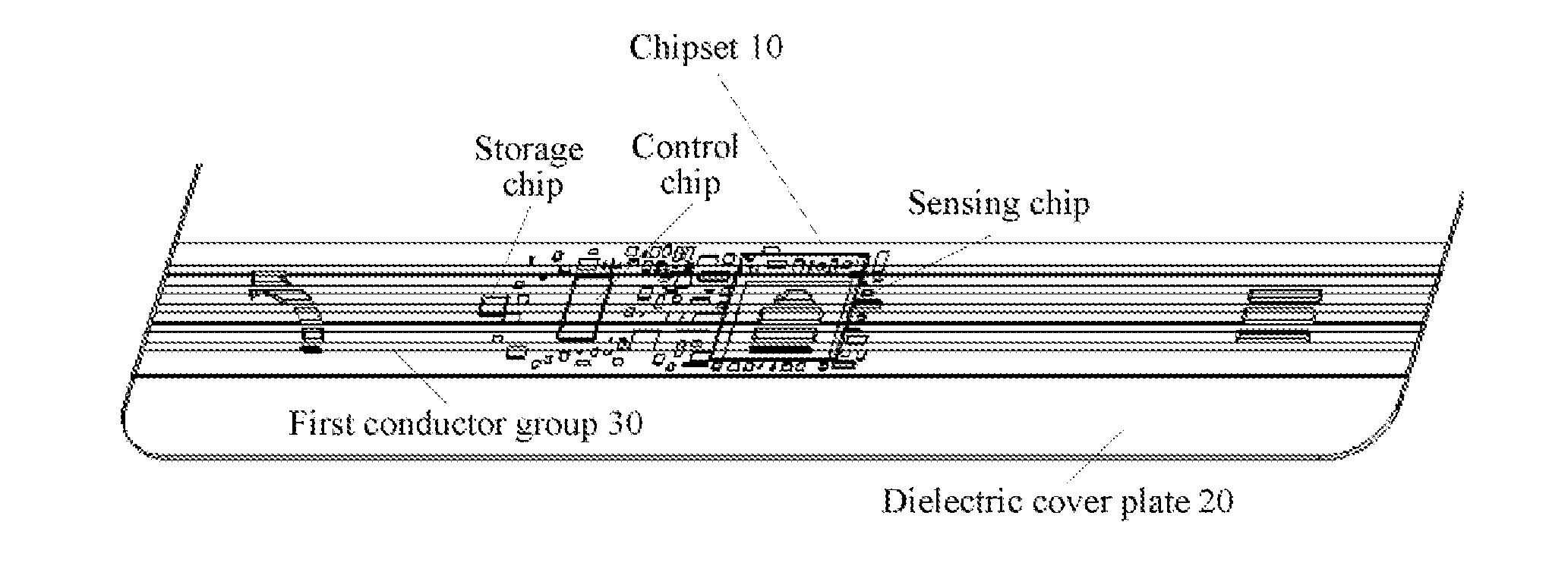

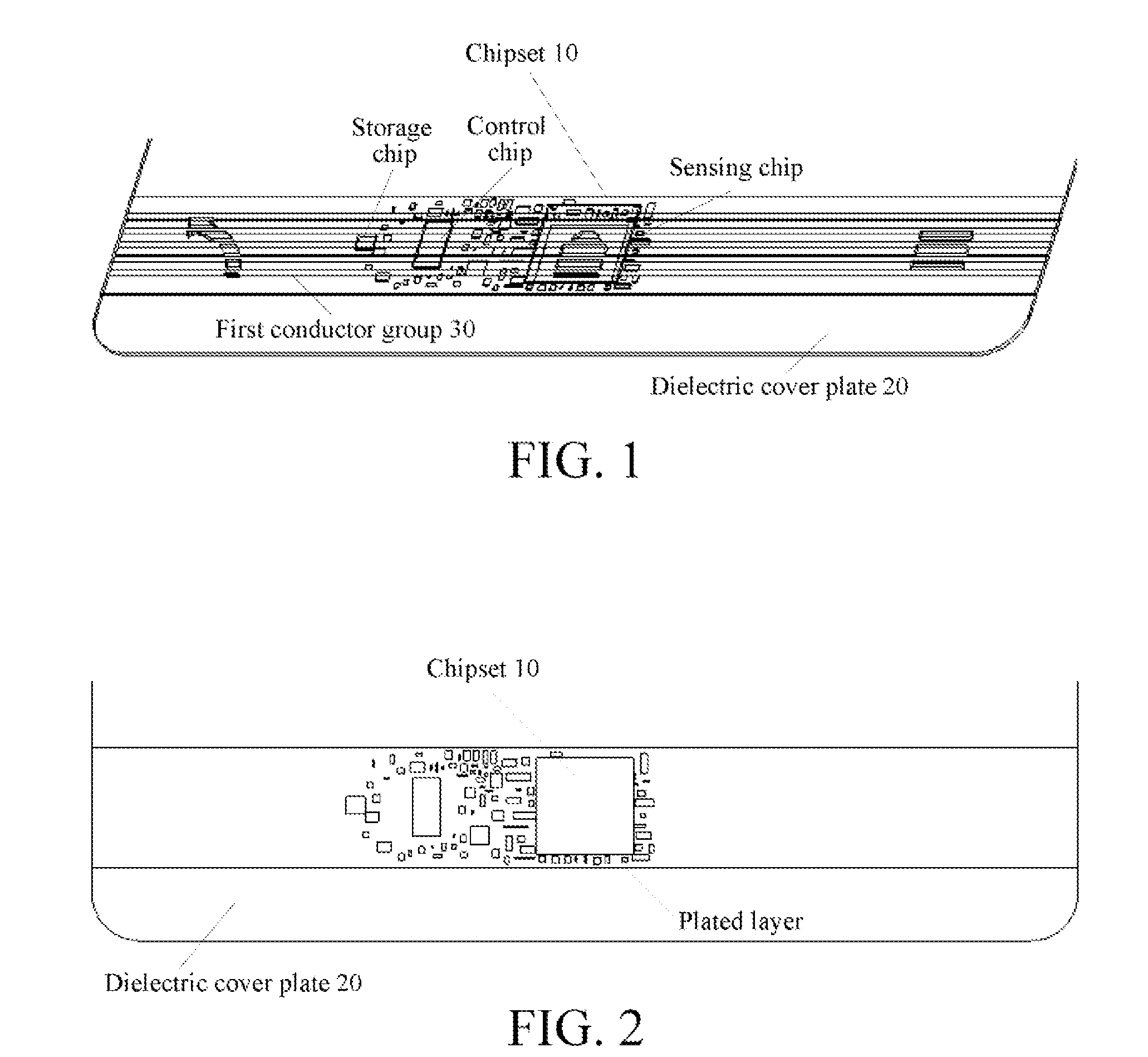

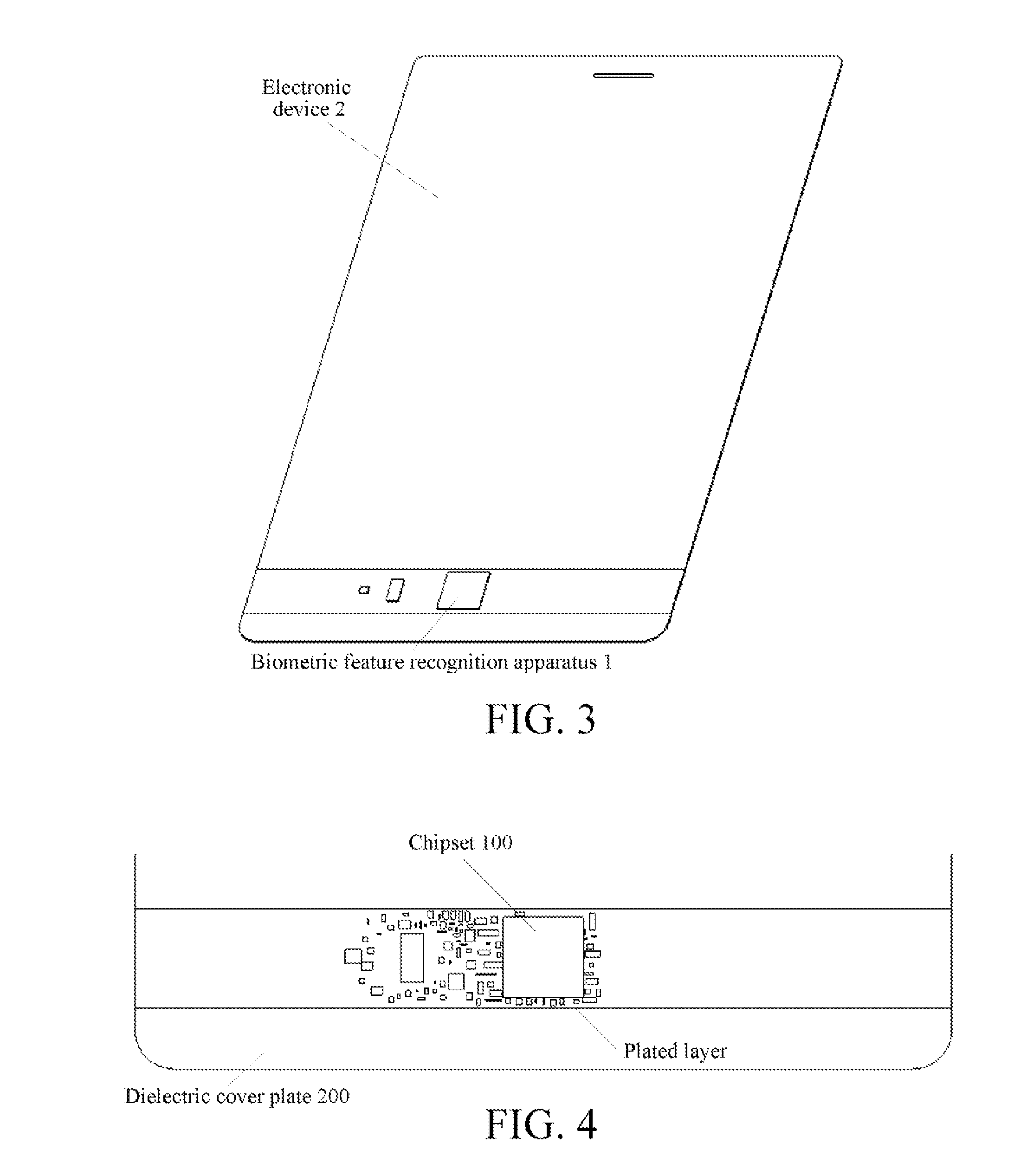

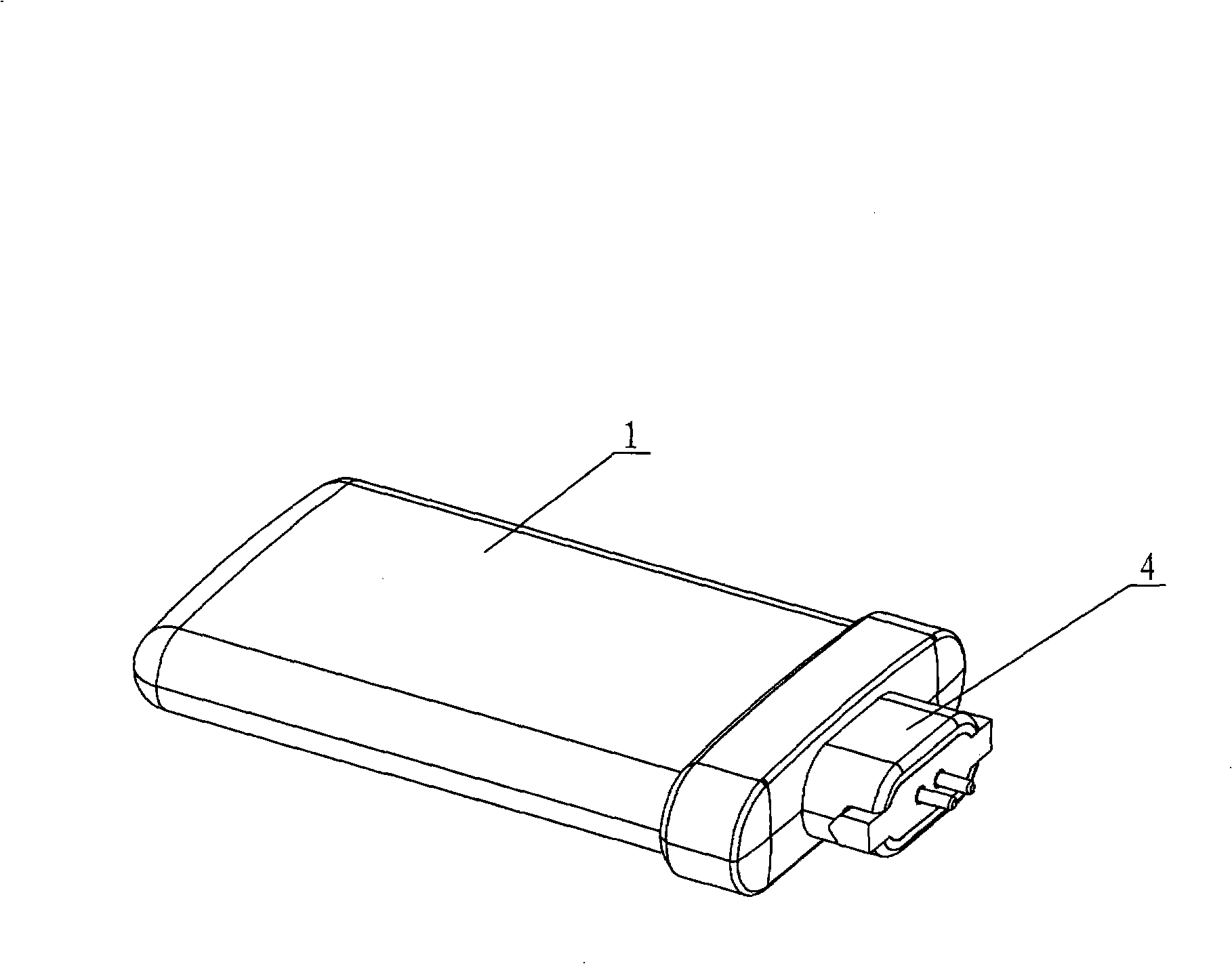

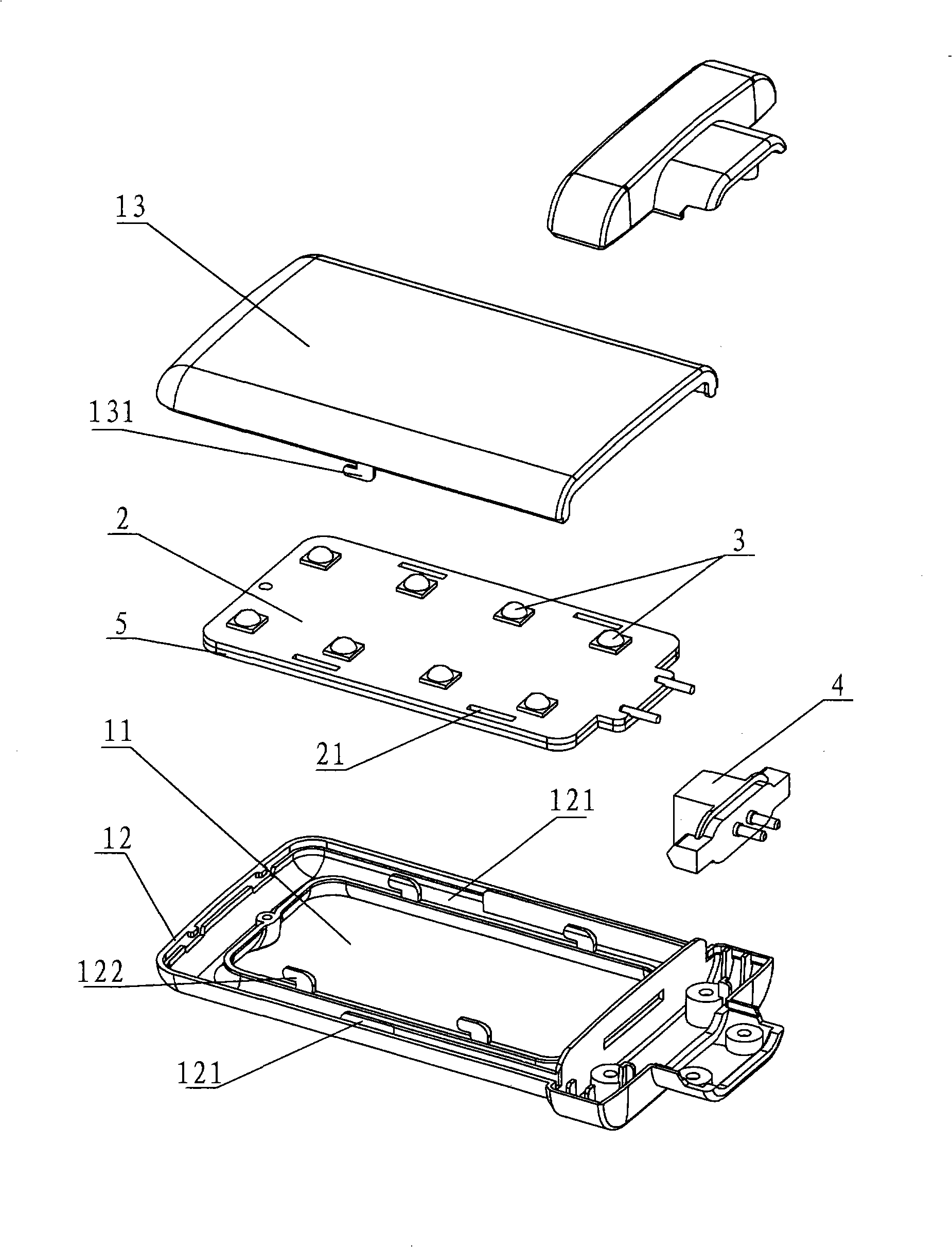

Biometric feature recognition apparatus and electronic device

InactiveUS20160379036A1Highly integratedLow subsequent manufacturing difficultyAutomatic exchangesPrint image acquisitionElectrical conductorChipset

A biometric feature recognition apparatus and an electronic device having the biometric feature recognition apparatus are disclosed. The biometric feature recognition apparatus includes: a chipset; a dielectric cover plate located above the chipset; and a first conductor group located above the dielectric cover plate, where the first conductor group and the chipset are interconnected, and the first conductor group provides a pulse signal to a user finger when the finger is in contact with the biometric feature recognition apparatus. The biometric feature recognition apparatus has advantages of a high integration density and low subsequent manufacturing difficulty, and can be made into a super thin structure and therefore has great ornamental value. Moreover, interior of the biometric feature recognition apparatus can be protected, and is highly secure.

Owner:SHENZHEN GOODIX TECH CO LTD

Dried silkworm cordyceps militaris and culture method thereof

The invention relates to dried silkworm cordyceps militaris. A preparation method of the dried silkworm cordyceps militaris comprises the following steps: infecting a host silkworm chrysalis with a cordyceps militaris fungus No.1, and carrying out artificial culture and conversion so as to form the dried silkworm cordyceps militaris, namely a complex of the dried silkworm chrysalis and the cordyceps militaris. The success rate of the dried silkworm cordyceps militaris in scale production is greater than or equal to 98%, the dried silkworm cordyceps militaris can be stored for 3 to 4 years, i.e., so that the storing period of the dried silkworm cordyceps militaris is longer than that of plumeria rubra acutifolia cordyceps militaris, and the content of nutritional ingredients in the dried silkworm cordyceps militaris is higher than that of the nutritional ingredients in the plumeria rubra acutifolia cordyceps militaris. In addition, the cultured dried silkworm cordyceps militaris is golden yellow in colour and lustre, i.e., the ornamental value is good. The cultured dried silkworm cordyceps militaris has obvious effects for treating high blood pressure, high blood fat, high blood sugar, kidney diseases, digestive system diseases, nervous system diseases and cardiovascular and cerebrovascular diseases. Thus, the dried silkworm cordyceps militaris is superior to cordyceps sinensis and natural cordyceps militaris.

Owner:李龙飞

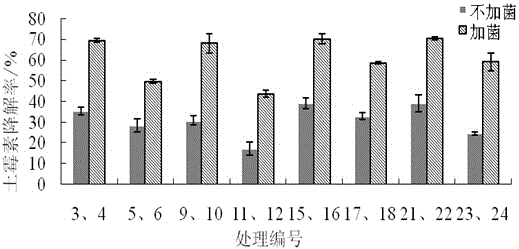

Method for restoring cadmium-terramycin combinedly contaminated soil through combination of plant and degrading bacterium

InactiveCN105195504AStrong enrichment abilityStrong plant growthContaminated soil reclamationMirabilis jalapaGreenhouse cultivation

The invention relates to a restoration method for contaminated soil and provides a method for restoring cadmium-terramycin combinedly contaminated soil through a combination of a plant and a degrading bacterium. According to the method, pot experiment is carried out; each pot is filled with cadmium-terramycin combinedly contaminated soil, and then seeds of maidenhair or Mirabilis jalapa are sowed in the soil; after germination of the seeds, root-irrigation and inoculation of a bacterial liquid of a high-efficiency terramycin degrading bacterium are carried out on soil where plate roots are located; greenhouse cultivation is employed, and when plants are in maturity period, the plants are totally removed from the contaminated soil; and the plants are repeatedly planted a plurality of times until pollutants in the soil reach soil environment safety standards. The restoration plants of maidenhair or Mirabilis jalapa grow vigorously, have a good ornamental value and shows good capacity in enriching cadmium; and the method has the characteristics of low cost, easiness in operation, no secondary pollution and capacity of beautifying the environment and is of important theoretical and practical significance to prevention and treatment of antibiotic and heavy metal contamination of soil and to safe production of agricultural products.

Owner:SHENYANG UNIV

Method for overseeding ryegrass in cynodon dactylon

InactiveCN105191658AGood ornamental valueHigh field application rateCultivating equipmentsPlant cultivationEconomic benefitsCynodon dactylon

The invention discloses a method for overseeding ryegrass in cynodon dactylon. The method comprises the steps of firstly, deeply plowing a target turf, and sowing cynodon dactylon; then, deeply shearing the cynodon dactylon on the turf in autumn and winter, and scarifying the surface layer of the turf; and finally, sowing ryegrass, and carrying out trimming, fertilizing, watering and other operations with different requirements on the cynodon dactylon and the ryegrass many times according to different times and states in the period of time. Through overseeding the ryegrass in the cynodon dactylon, the two crops can synergically grow to ensure that the same turf remains green throughout the year, so that the favorable ornamental value, relatively high field application ratio and relatively high economic benefit are brought.

Owner:YIBIN YUNCHEN ARBOR GARDEN

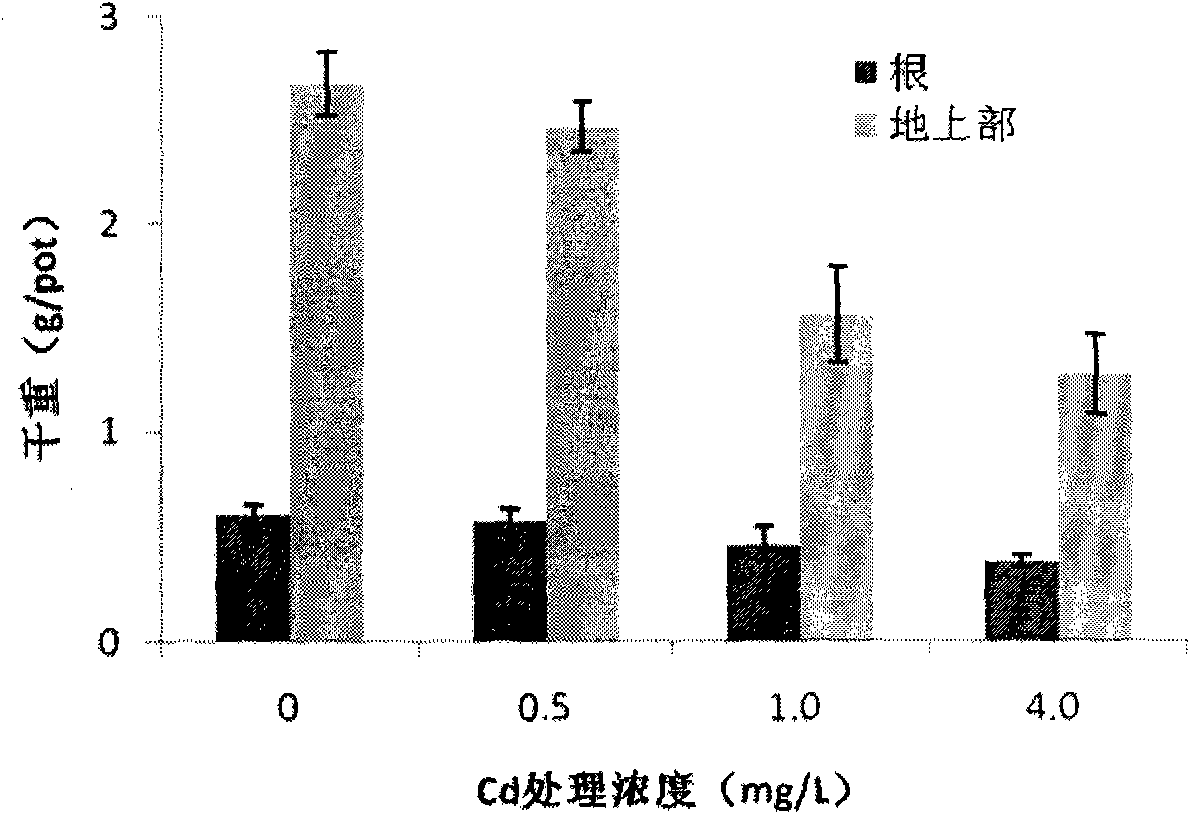

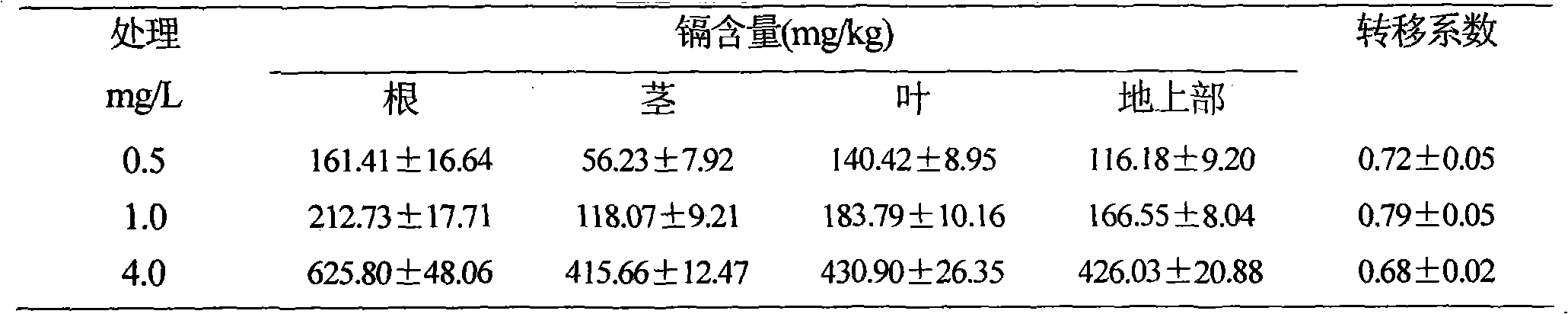

Method for repairing cadmium-polluted soil/bottom mud using beta vulgaris var.cicla l

InactiveCN102962246ALow costReduce leachingContaminated soil reclamationBiological sludge treatmentGreenhouseTherapeutic effect

The invention relates to a method for repairing cadmium-polluted soil / bottom mud using beta vulgaris var.cicla l. According to the method, beta vulgaris var.cicla l is planted in cadminum-polluted soil / bottom mud, and the plant is entirely moved out from the polluted soil / bottom mud when growing to the mature period to achieve the purpose of removing heavy metal cadmium in the soil / bottom mud; the planted vulgaris var.cicla l adopts the beta vulgaris var.cicla l with 4-6 true leaves which is transplanted into the cadmium-polluted soil / bottom mud; and the beta vulgaris var.cicla l planted in the cadmium-polluted soil / bottom mud is planted in a green house, and regularly watered to enable the soil water content to be kept at 60-70 percent of the field water capacity. The method can keep permanent treatment effect, in-situ treatment process, low treatment cost, environmental aesthetics and simple post-treatment.

Owner:SHENYANG UNIV

Industrial cultivation method of spring dendrobium stem

ActiveCN101180942AImprove consistencyImprove qualityFertilising methodsCultivating equipmentsHigh elevationPhacus

The invention relates to a factorized-cultivation method of dendrobium nobile and pertains to the technical field of the flower cultivation, is characterized in that the method comprises the following steps: young seedlings after being properly conditioned are transplanted to plugs with 128 holes and then to nutrition pots of 8cm after cultivation of six to eight months, with illumination controlled below 35,000 Lux and temperature at 18-28 DEG C during cultivation; each plant is fertilized with 15 particles of Magamp when roots grow to the pot wall in the first year of cultivation, and is fertilized with rapeseed cake fertilizers by 0.5cm<3> in spring of the second year; flower forcing treatment is conducted in the third year of cultivation in nutrition pots of 8cm: flowering plants aretreated with low temperature at a high elevation and is forced for flowering with increasing temperature at a low elevation. The factorized-cultivation method of dendrobium nobile can adapt to climatic conditions in our country and solves the technical problem of the factorized-cultivation of dendrobium nobile, having simple technique, low production cost, good consistency of dendrobium nobile with high quality, good visual value and broad market prospects.

Owner:ZHEJIANG SENHE SEED

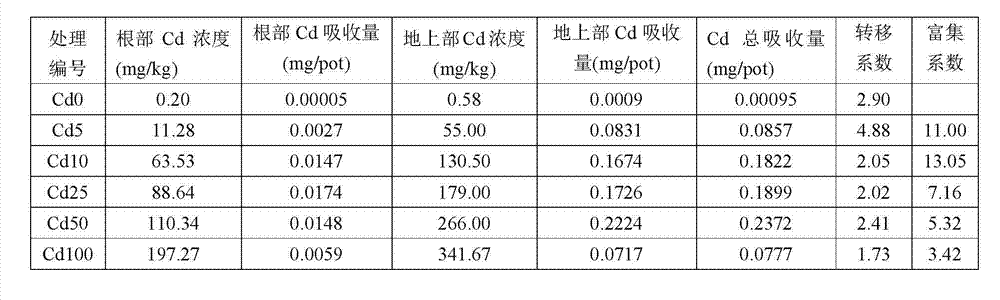

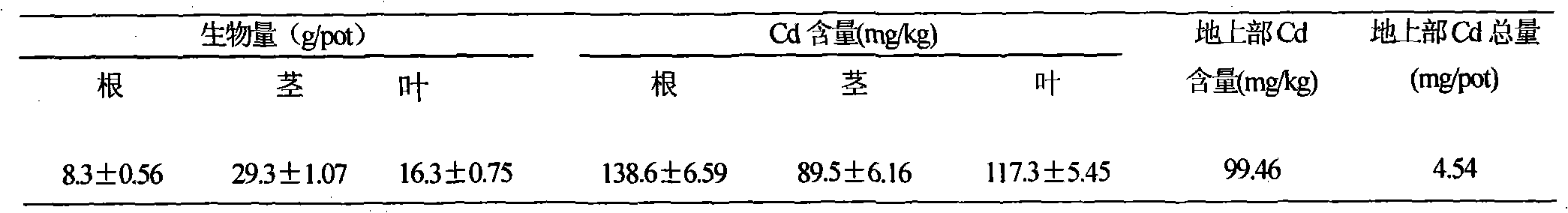

Method for remediating cadmium contaminated soil by using ornamental plant smooth joyweed

InactiveCN101941018AHigh enrichment factorLarge biomassContaminated soil reclamationProper treatmentGermplasm

The invention relates to phytoremediation technology in a heavy metal contamination environment, in particular to a method for remediating cadmium contaminated soil by using an ornamental plant smooth joyweed. In the method, the smooth joyweed (preserved in National Crop Germplasm Conservation Center, and the variety name is J589193) is planted on cadmium contaminated soil (including wet land), and a great amount of cadmium in the contaminated soil is absorbed through the root system of the smooth joyweed and is transferred to an overground part of the plant. When the plant grows to the end of the growing period or the biomass of the overground part is maximum, the overground part of the plant is moved away from the contaminated soil and is subjected to proper treatment, and the aim of continuously extracting and removing cadmium from the soil is fulfilled by repeatedly planting the plant and repeating the process. By remediating and treating the cadmium contaminated soil by using the enriched plant smooth joyweed, the method has the advantages of high efficiency, low cost, high operability, easy popularization and application, no damage to soil structure, no secondary contamination and the like, and also has good effect on soil erosion prevention and landscaping in contaminated fields.

Owner:AGRO ENVIRONMENTAL PROTECTION INST OF MIN OF AGRI +1

Method for repairing and treating soil with heavy metal pollution using daisy

InactiveCN101462118AImprove economic efficiencyAvoid secondary pollutionContaminated soil reclamationHorticultureBellis perennisRoot system

The invention relates to phytoremediation technology for treating polluted environment, in particular to a method for reparing cadmium-polluted earth by using a cadmium-enriched flower, namely Bellis perennis. The method utilizes root systems of the cadmium-enriched plant Bellis perennis to absorb cadmium enriched in the polluted earth in large amount, transfers the cadmium upward to the overground part, integrally removes the plant and properly treats the plant when the plant grows to the blossom time, thereby the plant absorbs and removes a large amount of the cadmium from the earth; and by repeatedly planting the plant and repeating the process, excessive cadmium in the earth can be continuously extracted until the content of the cadmium achieves the environment safety standards. The method has the advantages of small engineering quantity, no destruction to physicochemical property of the earth, no secondary pollution, beautifying the environment beautification while treating the polluted earth, and the like.

Owner:SHENYANG INST OF APPLIED ECOLOGY - CHINESE ACAD OF SCI

Planting method of oriental white oak

ActiveCN103329663AImprove germination rateGuaranteed growth qualityCultivating equipmentsSeed immunisationSurvival rateEcological Building

The invention discloses a planting method of oriental white oak, which particularly comprising the steps of: seed collecting, seed pretreating, sowing, seedling raising and transplanting to late fertilizer and water managing. The germination rate of oriental white oak seeds is effectively increased, the growth quality of nursery stocks is ensured due to the adoption of a sowing and seedling raising method, the transplanting survival rate of the oriental white oak is also improved due to the adoption of a reasonable transplanting method and late soil and fertilizer and water management in different periods, the cultured oriental white oak is developed in fibrous root systems and grows vigorously, a ripen tree is strong in appearance with luxuriant foliage, and has a good ornamental value; a strong promotion function is achieved for urban gardening utilization and popularization and forestry ecological building of trees with good varieties.

Owner:江苏汤氏园林有限公司

Flowering peach grafting and seedling method

InactiveCN105265274AVigorousPromote root developmentSeed and root treatmentGraftingWound healingRootstock

The invention discloses a flowering peach grafting and seedling method which comprises the steps of (1) mountain peach rootstock seedling cultivation, (2) scion preparation, (3) scion treatment, (4) scion grafting, and (5) post-grafting management. According to the invention, cultivated mountain peach rootstock seedlings are vigorous in growth, good in root development and high in drought resistance and cold resistance. In addition, the seedling method is simple, and the cost is low. A plurality of different kinds of flowering peach scions can be grafted on each mountain peach rootstock seedling, so that the single-plant grafting survival rate can be enabled to reach up to 99%. A cultivated grafted seedling has multiple species in one plant, so that better viewing values are brought when the cultivated grafted seedling is in blossom. Magnetic field treatment is carried out on the scions before grafting, division and differentiation of cells at a notch can be promoted, the wound healing ability is improved, the healing time is shortened, growth of the scions can also be promoted, and the grafting survival rate is improved. The method disclosed by the invention can complete grafting of flowering peach in the same year when the mountain peach rootstock seedling is cultivated, thereby greatly shortening the seedling time, and improving the efficiency and the market competitiveness.

Owner:阜南县田隆花木种植有限公司

Method for simulating wilds to cultivate lucid ganoderma under forest

The invention discloses a method for simulating the wilds to cultivate lucid ganoderma under forest. The method comprises the following steps: selecting species; preparing materials from planting matrix under forest of ganoderma lucidum; cultivating hyphae; planting lucid ganoderma; the like. The method and the steps are adopted to simulate wild to cultivate lucid ganoderma; the species are domesticated into a novel simulated wild high-quality variety; the lucid ganoderma is suitable for growth in a special moist environment in the Dabie mountain area; hyphae are white; pilei are russet, can reach 12-16cm in diameter, and can reach about 2cm in thickness; stipes are 12-16cm in length, can reach 2cm in diameter, and are hard; the temperature resistance of the hyphae can be expanded to 10-38 DEG C; the environment temperature suitable for growth can be 16-33 DEG C; the quality and the appearance of the fresh edible fungi are greatly improved; the cultivated lucid ganoderma has good medical care value and ornamental value.

Owner:安徽衡济堂药业有限公司

Artificial material-substitute imitative wild cultivation method for coriolus versicolor

InactiveCN107409743AAchieve sustainable useNeat edgesCultivating equipmentsMushroom cultivationIris versicolorArtificial materials

The invention relates to an artificial material-substitute imitative wild cultivation method for coriolus versicolor, and belongs to the field of domestication cultivation of rare wild medicinal fungi. The coriolus versicolor is a precious Chinese herbal medicine recorded in previous literature, and has efficacy such as tranquilizing, inflammation resistance and liver protection, just a few wild coriolus versicolor is adopted for a long time, and therefore demands of Chinese herbal medicines and people cannot be met. The method comprises fungus variety selection, stock preparation, cultivar preparation, cultivation bag production and coriolus versicolor cultivation. A collected mountain Tai wild coriolus versicolor sporocarp is utilized, and a tissue isolation method is adopted, thus a coriolus versicolor strain is obtained, then an original mother specie with high stability and yielding ability is cultivated through systematic selection, mother specie preparation is performed, stock preparation is performed, cultivar preparation is performed, cultivation bag production is performed, and environmental conditions are controlled for planting, thus the coriolus versicolor sporocarp is obtained. According to the invention, the specially-cultivated stock, a specially-cultivated cultivar and a prepared cultivation medium are utilized, the cultivation method provided in the invention is adopted, thus the cultivated coriolus versicolor is high in yield and good in quality, and the method disclosed by the invention is low in costs and easy in operation, and is a coriolus versicolor cultivation method which extremely has development and promotion value.

Owner:TAIAN ACAD OF AGRI SCI

Industrial cultivating method for cyclamen

ActiveCN1586110ASolve the technical problems of factory cultivationImprove qualityHorticulture methodsGerminationLow altitude

The present invention belongs to the field of flower planting technology. The industrial cultivating process of cyclamen includes the following steps: dot seeding and transferring to germination room; maintaining the germination room in the conditions of 15-20 deg.c, humidity of 94-96 % and complete dark; management in seedling stage; transplanting seedling; potting the seedling; hardening off before summer; management in summer, management in post-high temperature stage and management in flower stage. The said technological process is especially suitable for industrial cultivating process of cyclamen in subtropical zone and low altitude condition.

Owner:ZHEJIANG SENHE SEED

Flower ambroid accessory manufacturing method

ActiveCN105109263APrevent discolorationEasy to operateSpecial ornamental structuresFreeze-dryingUltraviolet lights

The invention provides a flower ambroid accessory manufacturing method. The flower ambroid accessory manufacturing method comprises the following steps: picking flowers and placing the flowers in a freezer for storage; placing the flowers in a pretreatment fluid to soak the flowers; performing freeze-drying treatment of the pretreated flowers to obtain freeze-dried flowers; placing the freeze-dried flowers into an aftertreatment fluid to soak the freeze-dried flowers for aftertreatment, wherein the aftertreatment fluid comprises 5-10 percent of a film-forming material, 0.1-1% of an ultraviolet light absorber and the balance of an aftertreatment solvent, the film-forming material comprises at least one of paraffin, polyethylene wax, polyethyleneglycol or silicone oil, and the aftertreatment solvent is at least one of ethanol, methyl benzene, gasoline or ethyl acetate; and performing resin embedding of the freeze-dried flowers subjected to aftertreatment. By the adoption of the technical scheme, the freeze-dried flowers can still maintain the original colors and shapes, the resin-embedded flowers still keep the original colors and shapes, and during the use of an accessory manufactured by embedding, the flowers cannot discolor or fade along with light irradiation.

Owner:NANNING MILLENNIUM ARTS & CRAFTS

LED (light emitting diode) lighting table-chair combination

InactiveCN103689926AGood ornamental valueEasy maintenanceLighting elementsStoolsElectric energyInfrared

The invention discloses an LED (light emitting diode) lighting table-chair combination which comprises a table arranged above a platform and four chairs, four table legs below the table are hollow solid-wood table legs; a table surface which is made of double-layer glass and is used for arranging an LED lamp is arranged above the four table legs, and the middle part of the table surface adopts a hollow structure; a wire of the LED lamp in the table surface is electrically connected with a controller in the platform through the four hollow table legs; a plurality of LED lamp are arranged in each chair; two LED lamps are arranged in each of the four chairs in an up-and-down staggering manner; after being connected in series with each other, the two LED lamps in each chair are connected with an infrared sensor. The LED lighting table-chair combination is simple in structure and reasonable in design; the lighting device of the table is arranged in the table surface, so that a good lighting effect is achieved; the chairs have the bearing capacity and also have an ornamental value; the LED lamps are switched on and switched off in a sensing manner, so that electric energy can be saved; the LED lighting table-chair combination is green, environment-friendly and good in heat dissipation effect; insulating substances are arranged on the outer sides of all circuits, thus the dangerousness is low.

Owner:SUZHOU CHENGTENG ELECTRONICS TECH

Method for remediating cadmium contaminated soil by using ornamental plant smooth joyweed

InactiveCN101941018BHigh enrichment factorLarge biomassContaminated soil reclamationProper treatmentGermplasm

Owner:AGRO ENVIRONMENTAL PROTECTION INST OF MIN OF AGRI +1

Method for remediating cadmium pollution of soil with red-spotted stonecrop

The invention relates to the technical field of soil remediation, and particularly relates to a method for remediating cadmium pollution of soil with red-spotted stonecrop. The method comprises the following steps: step A: applying a biomass charcoal improver to the polluted soil; step B: planting red-spotted stonecrop in the polluted soil; step C: after growing for 60-150 days, cutting overground plant parts of the red-spotted stonecrop and then applying a nutrient solution; and step D: after repeating the step C for 1-4 times, removing the whole red-spotted stonecrop. The method provided by the invention uses the red-spotted stonecrop and the biomass charcoal improver for joint remediation; the biomass charcoal improver provides a relatively good growth environment for the red-spotted stonecrop, plays a role of promoting growth of roots of the red-spotted stonecrop, and enhances vitality of the red-spotted stonecrop; the red-spotted stonecrop can enrich the heavy metal cadmium efficiently; the content of cadmium in the polluted soil can be reduced greatly under double action of the red-spotted stonecrop and the biomass charcoal improver; the method can achieve the purpose of complete remediation after three to six years and has good social and economic benefits and popularization and application values.

Owner:FOSHAN UNIVERSITY

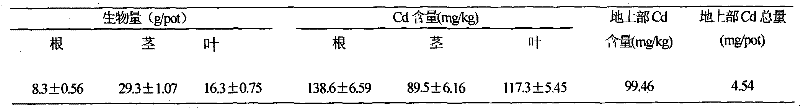

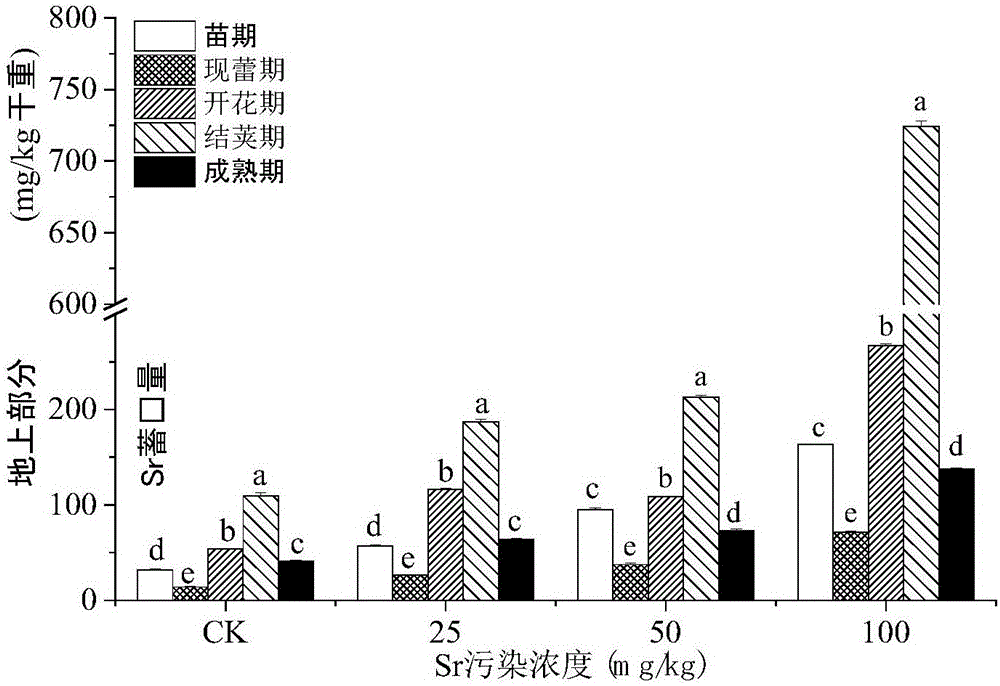

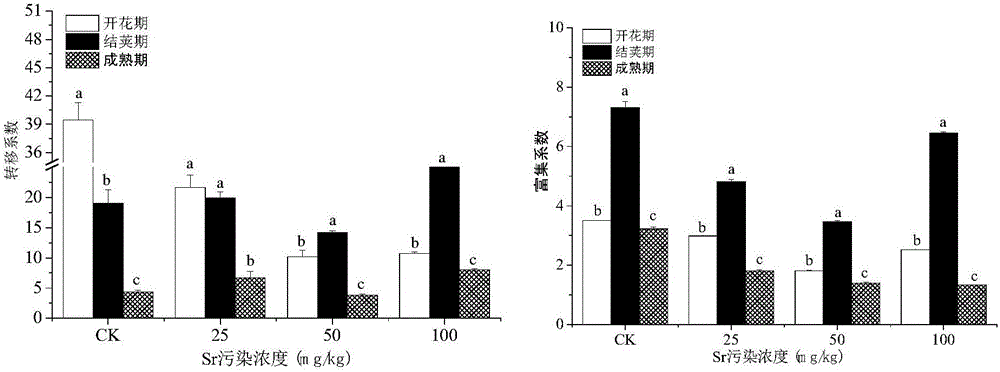

Method for restoring strontium-contaminated soil through oilseed rape

The invention provides a method for restoring strontium-contaminated soil through oilseed rape. The method includes the following steps that the oilseed rape is planted in the strontium-contaminated soil, and the overground part of the oilseed rape is harvested or the whole oilseed rape is moved away from the flowering period of the oilseed rape to the fruiting period of the oilseed rape. According to the method, the restoration and treatment efficiency of the strontium-contaminated soil is high, operation is simple, treatment cost is low, management is convenient, the in-situ restoration effect is good, the method can be used for restoration and treatment of the large-area strontium-contaminated soil, a new choice is provided for removing soil strontium contamination, and high application and popularization value is achieved.

Owner:SICHUAN NORMAL UNIVERSITY

Oriental cherry cuttage cultivation method

InactiveCN107333614AImprove fertilityIncrease contentBiocideCalcareous fertilisersFlowering seasonEconomic benefits

The invention discloses an oriental cherry cuttage cultivation method, and relates to the technical field of oriental cherry cultivation. The method comprises the steps of soil improvement, selection of cutting wood, processing of cutting wood, cuttage seedling, cuttage management, transplanting and field planting and daily management. According to the oriental cherry cuttage cultivation method, after seedlings are transplanted, the survival rate is high, the flower season is prolonged, and the oriental cherry has better economic benefits and ornamental values.

Owner:HFEI PUBANG AGRI TECH CO LTD

Ecological restoration method for performing warping on ecological bags in riparian water and land ecotone by using ecological bags

PendingCN109892133AHas the effect of blocking and anti-shockProtected SurvivalReceptacle cultivationBiological water/sewage treatmentRevegetationDry season

The invention relates to the technical field of riparian vegetation restoration and greening, in particular to an ecological restoration method for performing warping on ecological bags in a riparianwater and land ecotone by using the ecological bags. According to the ecological restoration method, the ecological bags have effects of blocking and scour prevention, can protect plants to survive inthe rainy season under the situation of water impact, and achieve the effect of ecological restoration; the ecological bags can also intercept silts brought by the partial water flow to achieve the effect of soil and water conservation; the ecological bags and the planted plants can play a warping role, thereby promoting natural restoration and growth of vegetations; the plants absorb many harmful elements in a water body in the flood season, thereby eliminating pollution, purifying the water quality, improving the quality of the water body, and restoring the ecological function of the waterbody; after the plants grow up, the water and land ecotone can also have good ornamental value in the dry season. The ecological restoration method has the advantages that the survival rate and preservation rate of vegetation planting in the water and land ecotone can be increased, and the method provided for the vegetation restoration of the water and land ecotone is simple and convenient, can beimplemented in a large area, and is low in cost.

Owner:BEIJING FORESTRY UNIVERSITY

LED integrated lamp tube

InactiveCN101349403AImprove luminous brightnessUniform lightPlanar light sourcesLight source combinationsElectricityEffect light

The invention discloses an integral lighting tube of light emitting diodes, which comprises a casing, a printed circuit board, a plurality of light emitting diodes and a universal electric socket, wherein the printed circuit board is arranged in the casing, the plurality of light emitting diodes are arrayed and mounted on the printed circuit board, and the printed circuit board is connected with the universal electric socket. The integral lighting tube integrally uses the plurality of light emitting diodes, and has the advantages of high lighting brightness, uniformly light and the like, and the integral light tube utilizes the universal electric socket, can be engaged with various lamps, and is extremely convenient in use. The integral lighting tube can be designed into variously beautiful shapes, and has well viewing value and decorative action. The integral lighting tube is in dismountable engagement with the lamps, and the body of the lighting tube is also a dismountable structure, when the light emitting diodes are burnt out, the lighting tube can be used again only with needing to change new light emitting diodes but the integral lighting tube of light emitting diodes or the overall lighting fitting, thereby largely saving the using cost for consumers.

Owner:陈少藩

Precision casting method for metal objects

The invention discloses a precision casting method for metal objects. The method includes the following steps that A, model making is performed, beewax is used for making a casting model, and an outline and a clay core are combined in a sleeving mode to form a cavity; B, preheating is conducted, the outline and the clay core are combined in the sleeving mode to be heated with small fire at first, slow cooling is performed, and then the outline and the clay core are put into a furnace kiln to be heated at a high temperature; C, pouring is carried out, molten copper is poured into a pouring gate, and after the molten copper is solidified and cooled, the outline and the core can be removed to take out a copper billet casting; D, a copper billet is polished; and F, decorating and surface coloring are carried out, the polished product is decorated, surface coloring is conducted after the product is decorated, and accordingly a finished product can be obtained. By the adoption of the method, rupture and sand holes cannot happen to the casting formed through the outline and the clay core easily, molten copper mobility can be improved by preheating the outline and the clay core, and therefore the molten copper injected into the cavity can be evenly filled, and the density and hardness of the finished product are improved; and in addition, through the reasonable technology, manufactured copper ware is fine and smooth in surface, delicate in modeling, dainty and exquisite and good in ornamental value.

Owner:五星机械(镇江)有限公司

Saline-alkali soil improvement and bioremediation method

ActiveCN107980269ASalinity stableImprove adsorption capacityCultivating equipmentsSoil-working methodsAmorpha fruticosaAlkali soil

The invention belongs to the field of environmental protection, and specifically provides a saline-alkali soil improvement and bioremediation method. According to the specific technical scheme, the method includes the steps that a soil amendment is prepared; saline-alkali soil is conditioned, and greening cultivation soil is prepared; a greening cultivation area is established; greening nursery stocks are cultivated, longitudinal and transverse isolation areas are arranged through the establishment of the greening cultivation area, and it is ensured that the saline-alkaline degree of the cultivation area is stable; fraxinus chinensis and amorpha fruticosa are screened and interplanted; soil improvement with organic fertilizer, longitudinal and transverse isolation and selection of improvedtree species are conducted at the same time so that the soil saline-alkaline degree can be effectively reduced, the effect is achieved that EC is smaller than or equal to 0.3% and pH is greater thanor equal to 7.2, the structure of the soil is improved, and soil hardening is prevented.

Owner:TIANJIN REDSUN WATER IND

Potted cultivation method for centella asiatica

InactiveCN105409525AGuaranteed hydrophobicityGuaranteed water retentionAnimal corpse fertilisersBioloigcal waste fertilisersAspirinBetula platyphylla

The invention relates to the technical field of planting industry and particularly relates to a potted cultivation method for centella asiatica. The method comprises the steps of scissoring creeping stems of wild centella asiatica in March every year, adding 2-5 parts of glucose, 0.01-0.03 part of magnesium sulfate and 3-5 parts of aspirin into every 100 parts of silver birch juice so as to obtain a rooting solution, soaking cuts of the creeping stems of the wild centella asiatica in the rooting solution for 10-15 days, mixing garden soil, coarse sand, sawdust, humus soil, egg-shell meal, feather meal and plant ash according to the weight ratio of 5: 1: 1: 3: 1: 1: 1 so as to obtain soil for cultivation, spreading the soil for cultivation and sphagnum moss, which are in the volume ratio of 4: 0.5, into each cultivation pot in a layered manner from bottom to top sequentially, planting the creeping stems of the wild centella asiatica in cultivation pots according to a ring shape in a manner that the spacing among rings is 5-7cm and 5-10 creeping stems of the wild centella asiatica are subjected to stem planting per 0.01 square meter, and placing the cultivation pots at a shady place with the cultivation shade rating of 50-70% after stem planting.

Owner:QUANJIAO TAOHUAWAN FRUIT & VEGETABLE PLANTATION SPECIALIZED COOP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com