Warp knitting machine

A warp knitting machine and drum technology, applied in the field of warp knitting machines, can solve problems such as difficulty in realizing yarn guide control and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

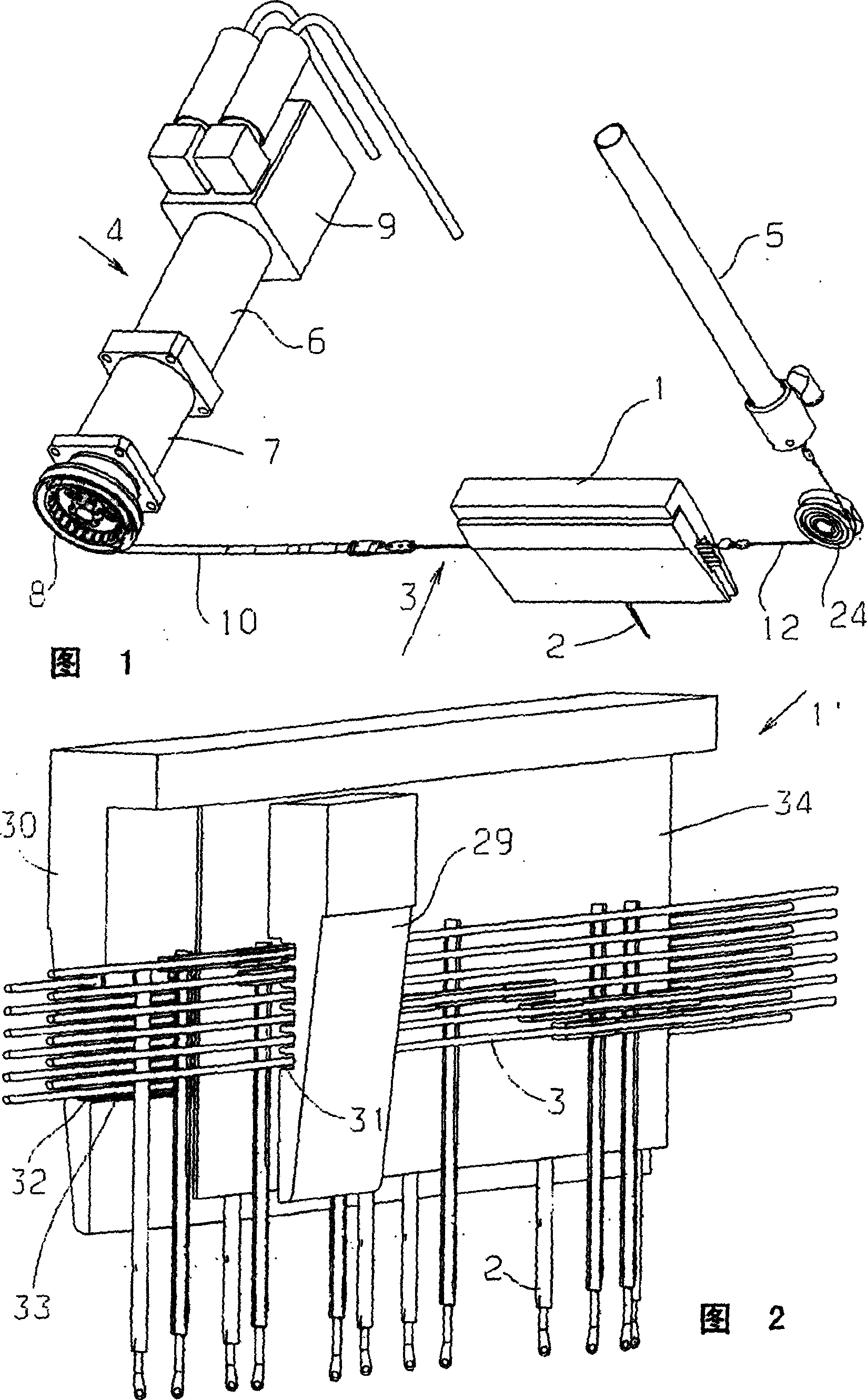

[0034] FIG. 1 schematically shows a flower bar 1 with a thread guide 2 . In practice, the flower bar is much longer and usually also has more than one thread guide 2 . This schematic is chosen for simplicity.

[0035] The yarn guide 2 is fixed on the drawing member 3 . The tensile element 3 is tensioned between the transmission 4 and the tensioning device 5 . The tensioning device 5 produces a constant tension force on the tensioning element 3 independent of the position of the tensioning element 3 . For this purpose, the tensioning device is for example in the form of a compressed air cylinder.

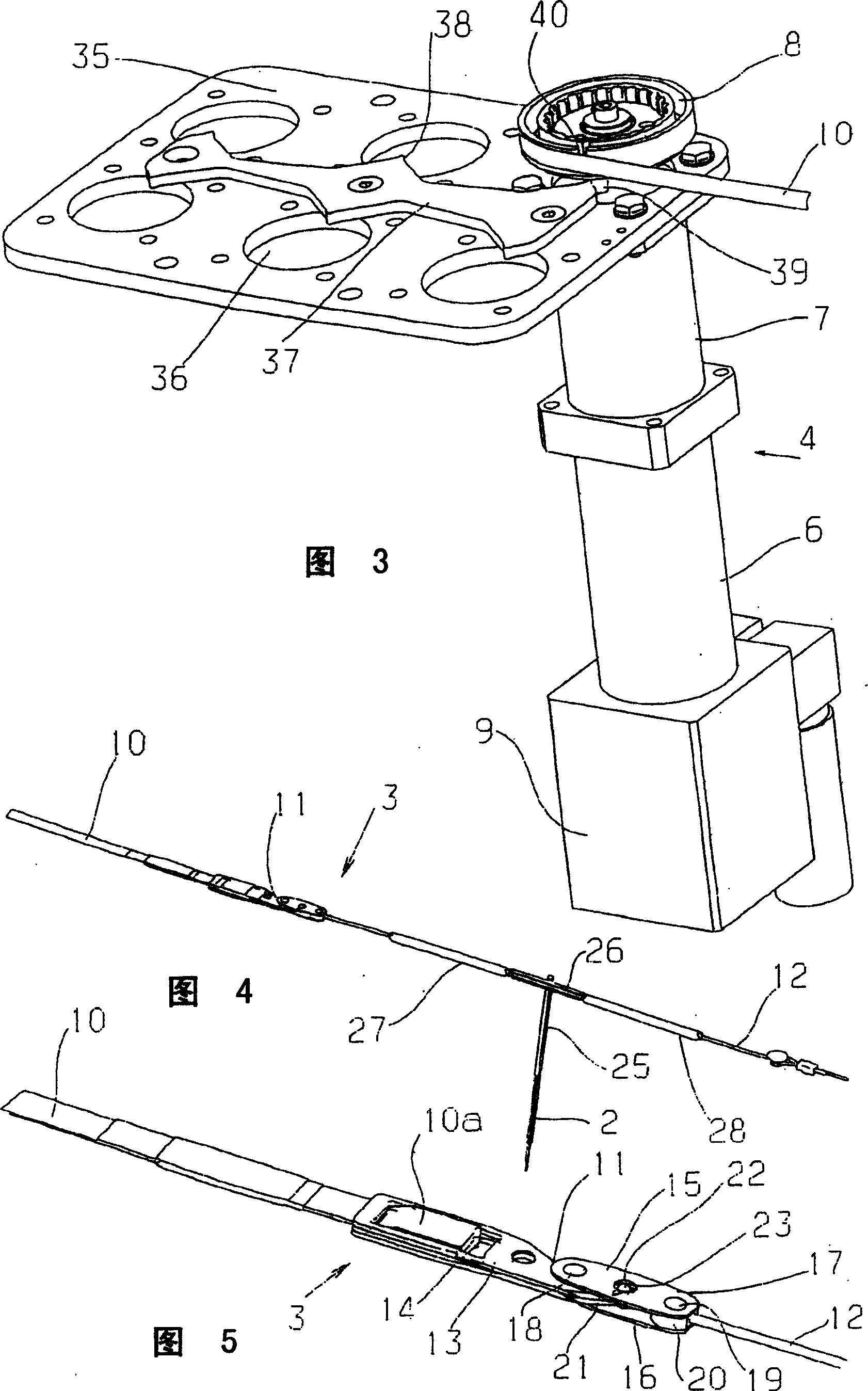

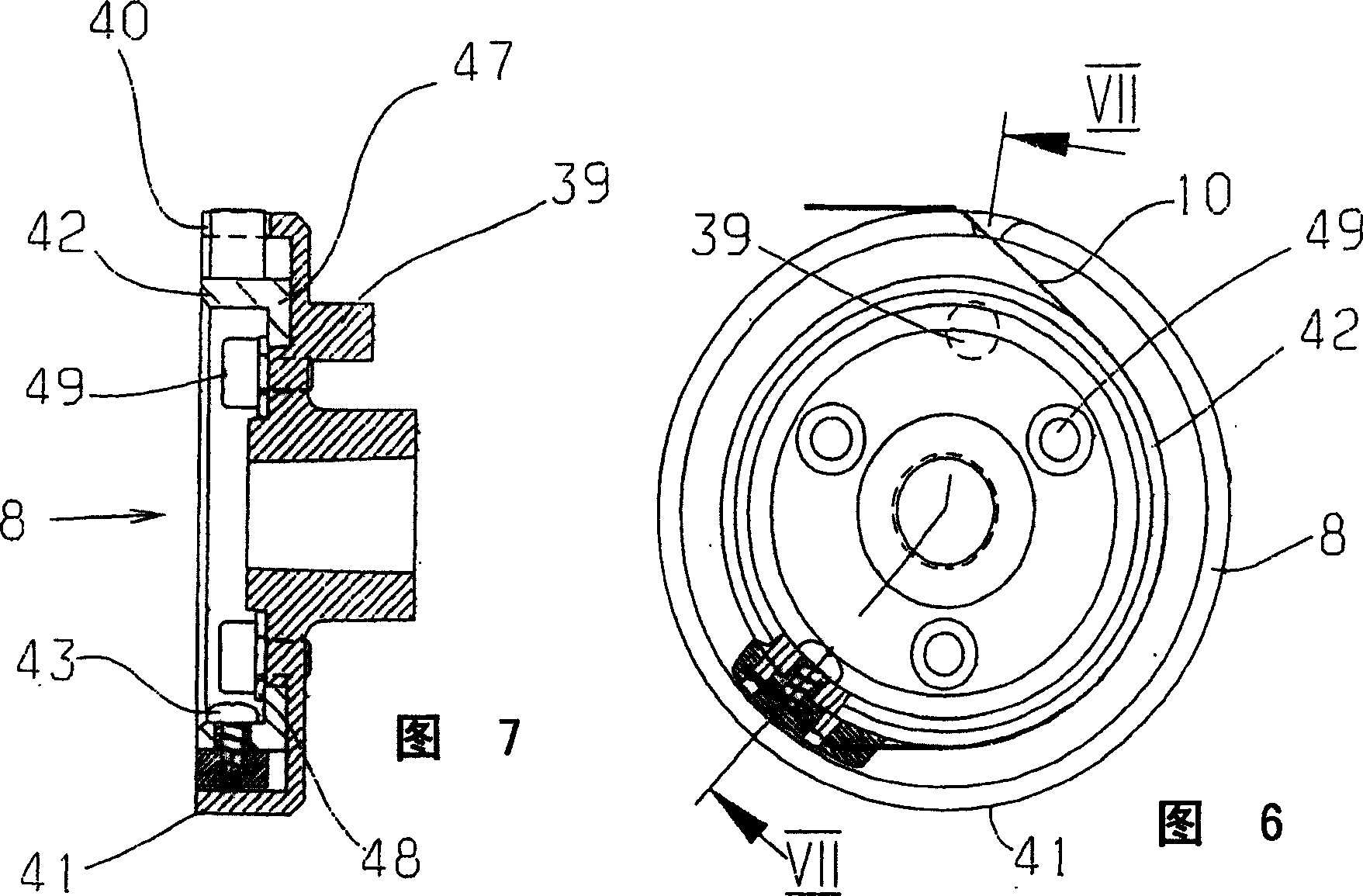

[0036]The transmission 4 has an electric motor 6 which drives the drum 8 via a reduction gear 7 . The electric motor 6 also has a sensor 9 which determines the angular position of the electric motor 6 . The motor 6 may be in the form of a servomotor, ie it has a permanent magnet excited rotor and a rotating field winding. It can also be called a permanent magnet excitation type...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com