Cold-rolled strip steel electrostatic oiling chamber structure

A technology for electrostatic oiling and cold-rolling strip steel, which is applied to spray devices, liquid spray devices, etc., can solve the problems of rising production costs, environmental pollution, and pollution control costs, and achieves the effect of sensitive adjustment and uniform oil film thickness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings.

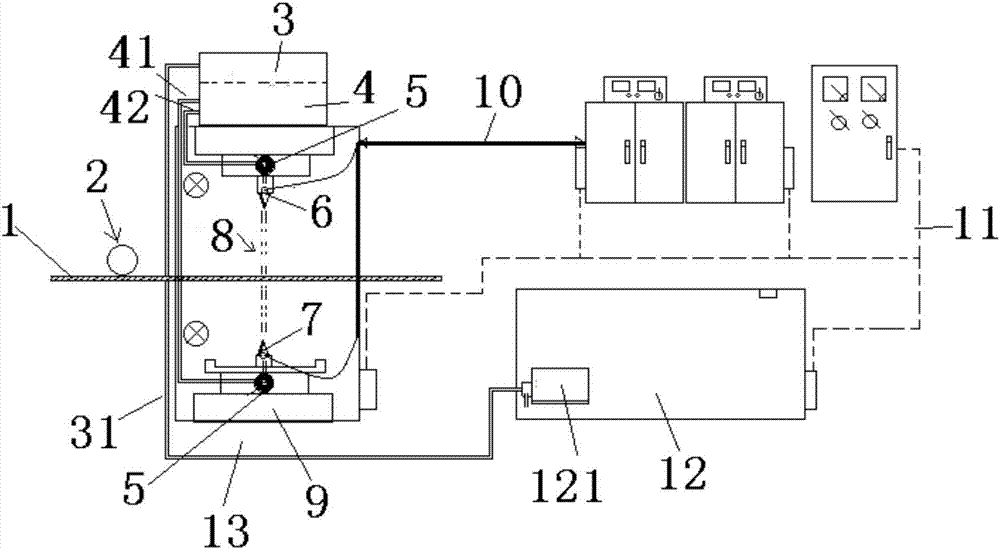

[0016] Such as figure 1 The structure of the cold-rolled strip electrostatic oiling chamber shown includes an oiling chamber 13, the upper knife beam 6 and the lower knife beam 7 are respectively arranged in the oiling chamber 13, and a heating oil tank is arranged on the top of the oiling chamber 13 3 and the knife beam oil supply servo adjustment system 4, the knife beam oil supply servo adjustment system 4 communicates with the upper knife beam 6 through the upper oil passage 42, and the knife beam oil supply servo adjustment system 4 communicates with the lower oil supply passage 41 The knife beam 7 is connected.

[0017] The production process of cold-rolled finished strip steel is mainly based on the cross-cutting unit, which mainly includes uncoiling, edge trimming, cross-cutting, oiling, stacking, etc. Among them, the existing method is too long due to the lon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com