Method for measuring wall thickness of aluminium alloy casting

An aluminum alloy casting and measured technology, which is applied in the field of chemical corrosion, can solve problems such as inaccurate local measurement, inability to accurately grasp the size of castings, and scrapping of castings in batches

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

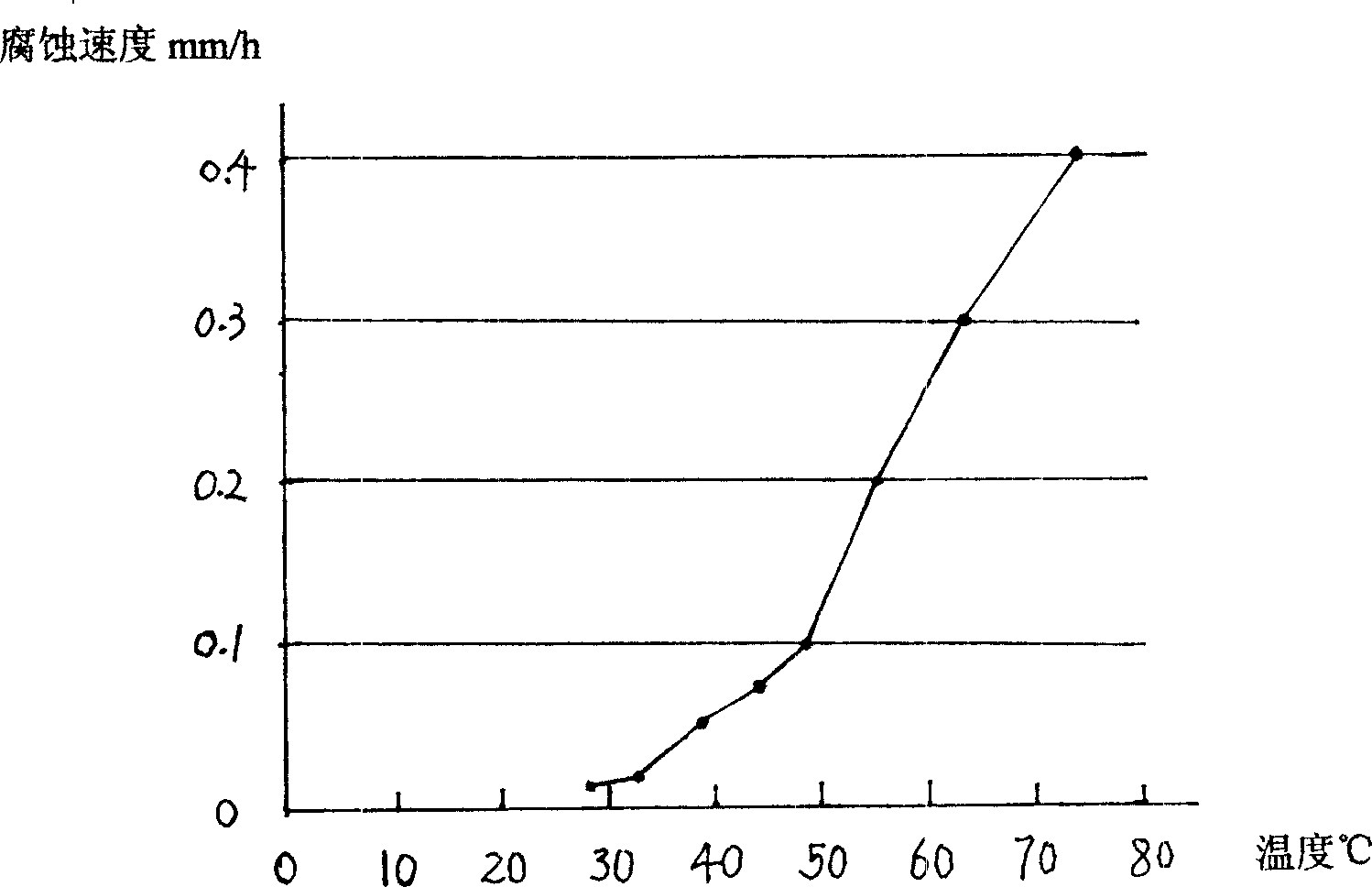

Embodiment 1

[0011] Measure the wall thickness of a part of the die-cast aluminum alloy casting during the mold test, and the designed wall thickness of the part that needs to be tested is 1 mm. First, select a measurement base point on the part of the aluminum alloy casting that is easy to measure the wall thickness, and measure the wall thickness of the base point to be 3 mm, as the reference value for measurement. Then the aluminum alloy casting is completely immersed in a NaOH solution with a temperature controlled at 73° C. and a concentration of 12% for chemical corrosion. According to the benchmark experiment, it takes 0.4 hours for a wall thickness of 1 mm to be corroded and penetrated. The production personnel began to carefully observe the parts to be inspected when it was close to 0.4 hours. When the first perforation is corroded on the wall of the aluminum alloy casting to be measured, measure the remaining wall thickness after the base point is corroded. If it is measured tha...

Embodiment 2

[0013] Measure the wall thickness of a part of the die-cast aluminum alloy casting during the mold test, and the designed wall thickness of the part that needs to be tested is 0.4mm. First, select a measurement base point on the part of the aluminum alloy casting that is easy to measure the wall thickness, and measure the wall thickness of the base point to be 3 mm, as the reference value for measurement. Then the aluminum alloy casting is completely immersed in a NaOH solution whose temperature is controlled at 35° C. and whose concentration is 70% for chemical corrosion. According to the benchmark experiment, it takes 2.1 hours for the wall thickness of 0.4mm to be corroded and penetrated. The production personnel began to carefully observe the parts to be inspected when it was close to 2.1 hours. When the first perforation is corroded on the wall of the aluminum alloy casting to be measured, measure the remaining wall thickness after the base point is corroded. If it is me...

Embodiment 3

[0015] Measure the wall thickness of a part of the die-cast aluminum alloy casting during the mold test, and the designed wall thickness of the part that needs to be tested is 1.5mm. First, select a measurement base point on the part of the aluminum alloy casting that is easy to measure the wall thickness, and measure the wall thickness of the base point to be 3 mm, as the reference value for measurement. Then the aluminum alloy casting is completely immersed in a NaOH solution with a temperature controlled at 95° C. and a concentration of 17% for chemical corrosion. According to the 1.5mm wall thickness obtained through the benchmark experiment, the corrosion penetration time is 1.5h, and the production personnel began to carefully observe the parts to be inspected when it was close to 1.5h. When the first perforation is corroded on the wall of the aluminum alloy casting to be measured, measure the remaining wall thickness after the base point is corroded. If it is measured ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com