Filtered fabrics performance on-line detecting method

A detection method and filter cloth technology, applied in the direction of filtration and separation, separation methods, chemical instruments and methods, etc., can solve problems such as difficulty in use, high manufacturing cost, and insufficient economy, and achieve stable detection performance, reduce production costs, and improve production efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

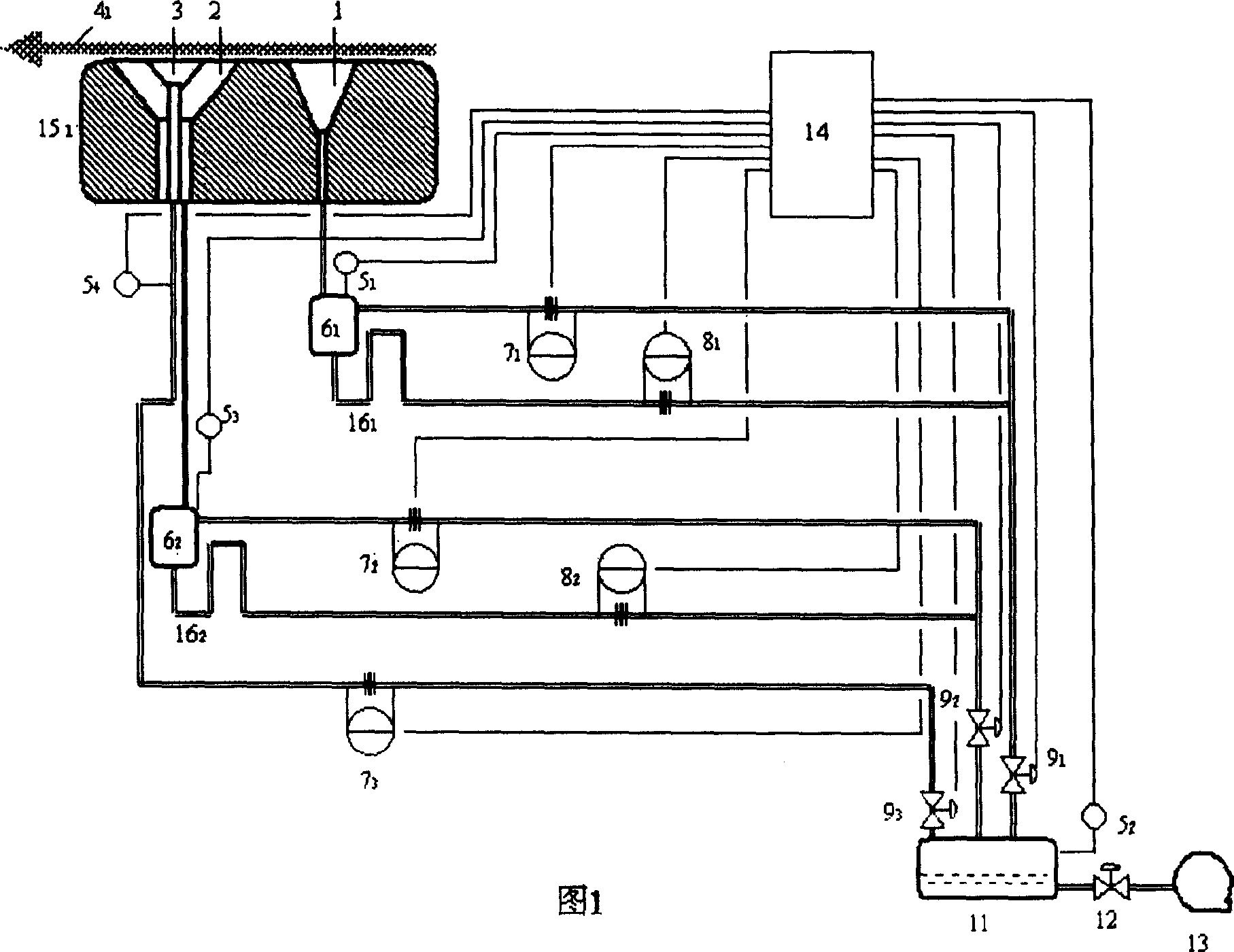

example 1

[0026] This example is the application of the present invention to the specification of 700G / M after the felt is separated from the wet paper on the papermaking press section. 2 felt 4 1 Conduct online comprehensive performance testing. Referring to Fig. 1, what this example adopts is to probe 15 1 Set up as a detection system with three detection areas 1-3. Detection areas 1 and 2 are respectively connected to the gas-liquid separation tank 6 1 、6 2 , gas-liquid separation tank 6 1 、6 2 Directly connected to the gas flow meter 7 1 、7 2 , respectively connected to the liquid seal tube 16 1 、16 2 Followed by liquid flow meter 8 1 ,8 2 , gas flow meter 7 1 、7 2 and liquid flow meter 8 1 ,8 2 Pressure regulating valve 9 controlled by controller 14 respectively 1 ,9 2 Connect vacuum tank 11, gas-liquid separation tank 6 1 、6 2 Respectively connected to the pressure sensor 5 1 、5 3 ; Detection zone 3 is connected to pressure sensor 5 4 , connected to the gas f...

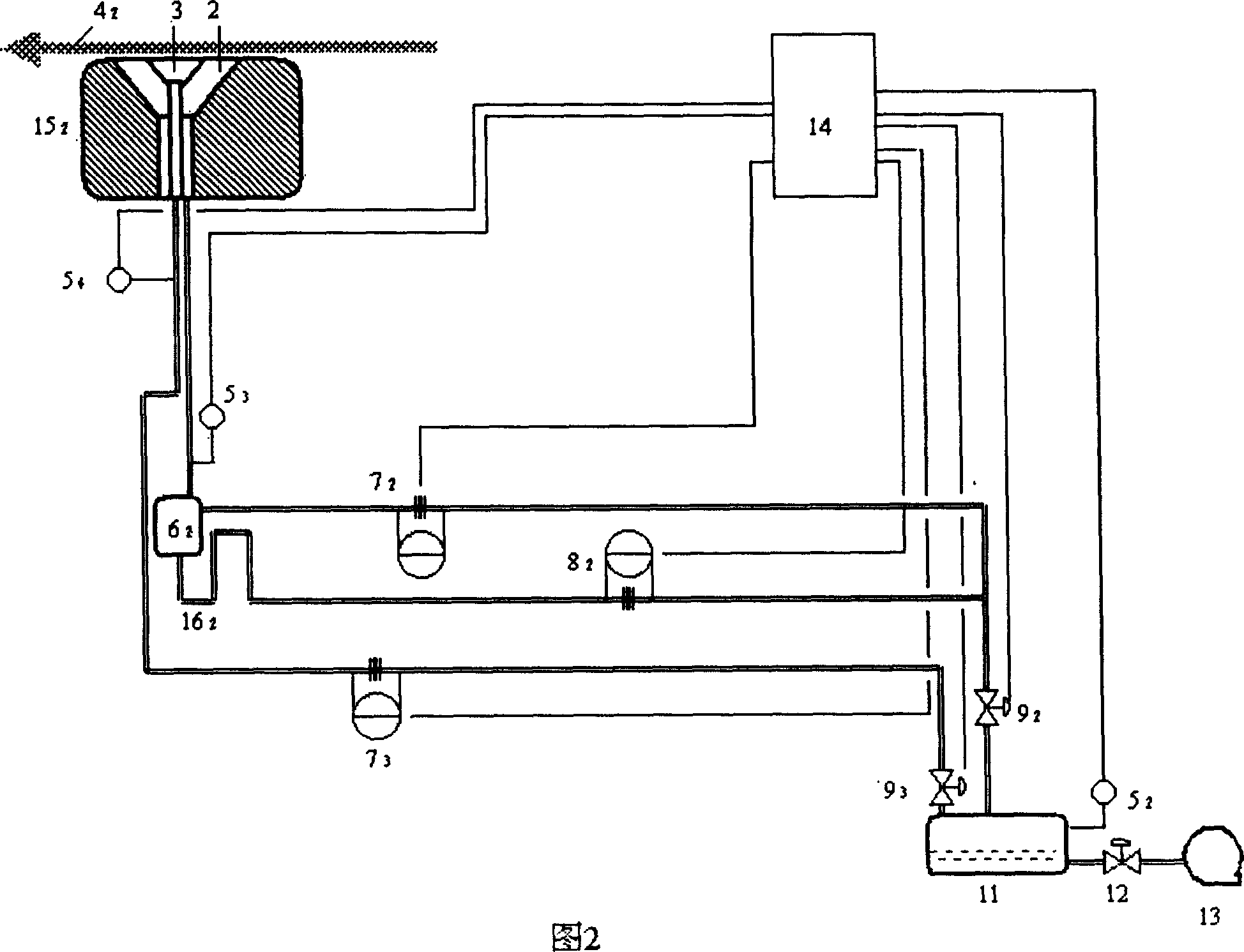

example 2

[0042] This example is the separation and filtration of calcium carbonate solid and sodium hydroxide solution used in the chemical industry in the present invention, the filter cloth 4 before the filter cloth enters the filter area 2 Air permeability, liquid content and filtrate detection. The filter cloth used in this process4 2 It is a monofilament rectangular mesh structure with a smooth surface. Referring to Fig. 2, what this example adopts is to probe 15 2 It is set up as a detection system with two detection areas 2 and 3. The vacuum degree used for the two detection zones 2 and 3 is all 0.015MPa vacuum degree, and the detection area is 314mm 2 . The detection system detection area 2 used in this example is connected to the gas-liquid separation tank 6 2 , gas-liquid separation tank 6 2 Direct connection to gas flow meter 7 2 , liquid seal pipe 16 2 Followed by liquid flow meter 8 2 , gas flow meter 7 2 and liquid flow meter 8 2 Pressure regulating valve 9 con...

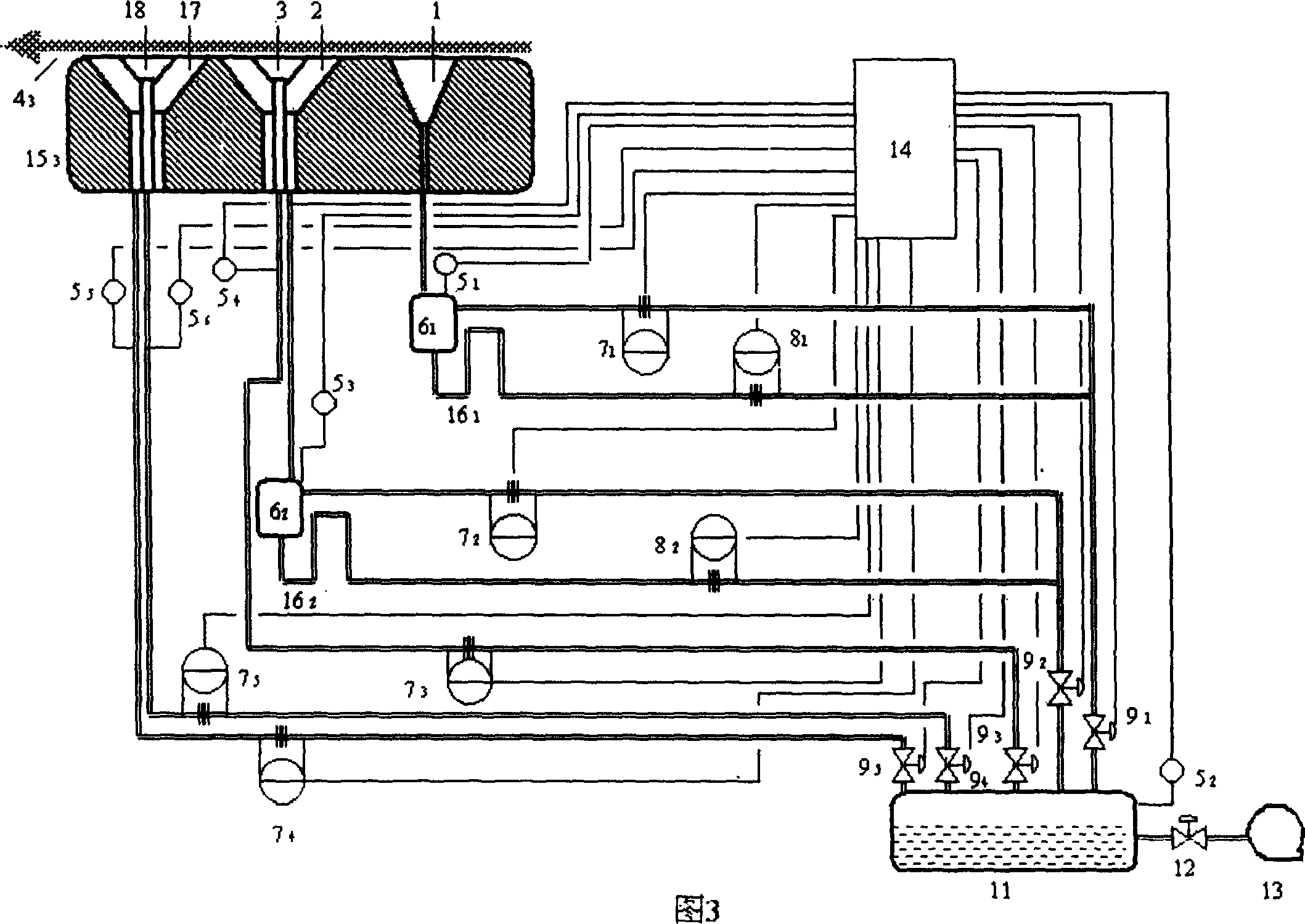

example 3

[0045] This example is the papermaking press part of the present invention used for the felt cloth and wet paper just after separation, and the specification is 900G / M 2 felt 4 3 Carry out online comprehensive testing. Referring to Fig. 3, what this example adopts is a probe 15 3 Inspection system with five inspection zones. Detection areas 1 and 2 are respectively connected to the gas-liquid separation tank 6 1 、6 2 , gas-liquid separation tank 6 1 、6 2 Directly connected to the gas flow meter 7 1 、7 2 , respectively connected to the liquid seal tube 16 1 、16 2 Followed by liquid flow meter 8 1 ,8 2 , gas flow meter 7 1 、7 2 and liquid flow meter 8 1 ,8 2 Pressure regulating valve 9 controlled by controller 14 respectively 1 ,9 2 Connect vacuum tank 11, gas-liquid separation tank 61 、6 2 Respectively connected to the pressure sensor 5 1 、5 3 . Detection area 3 is connected to pressure sensor 5 4 , connected to the gas flow meter 7 3 Followed by the pres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com