Process for rolling and forming external step section ring piece

A technology of outer steps and rings, applied in metal rolling, metal rolling, etc., can solve the problems of low material utilization, repeated heating of rings, large machining allowance, etc., to improve metal structure and performance, reduce heating The effect of increasing the number of times and increasing productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

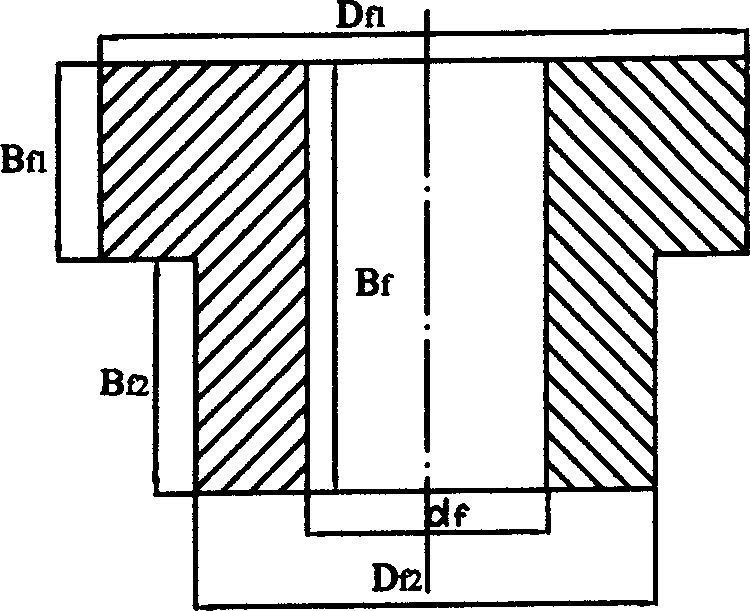

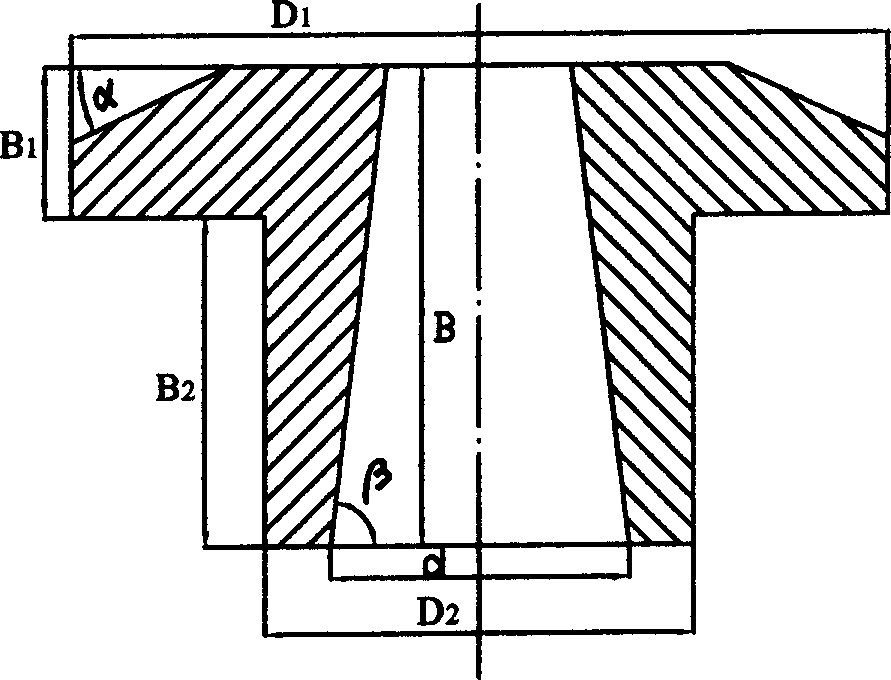

[0016] The method for rolling and forming the outer step cross-section ring is realized according to the following steps: 1). Cutting the material: sawing the bar into material sections, and the length of the material sections is L=(1~3)(B 1 +B 2 ), B 1 is the axial dimension of the large ring part of the blank, B 2 is the axial dimension of the small ring part of the blank.

[0017] 2). Billet making: uniformly heat the material segment from room temperature to the heat deformation temperature of high plasticity and low resistance, then upsetting, punching and punching the hot material segment to make a ring blank for rolling.

[0018] The material section is uniformly heated from room temperature to the heat distortion temperature of high plasticity and low resistance. The heat distortion temperature of the aluminum alloy ring is 550°C-350°C; the heat distortion temperature of the steel material ring is 1200°C-800°C.

[0019] The outer circular edge of the blank forms an ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Heat distortion temperature | aaaaa | aaaaa |

| Heat distortion temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap