Processing method of carrying out rotary forging on forge pieces with high precision of truck hub

A processing method and high-precision technology, applied to wheels, vehicle parts, metal processing equipment, etc., can solve problems such as low production efficiency, large metal consumption, and low forging precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The invention relates to a method for processing high-precision forgings of truck wheel hubs by rotary forging, such as figure 1 — Figure 4 As shown, it is characterized by:

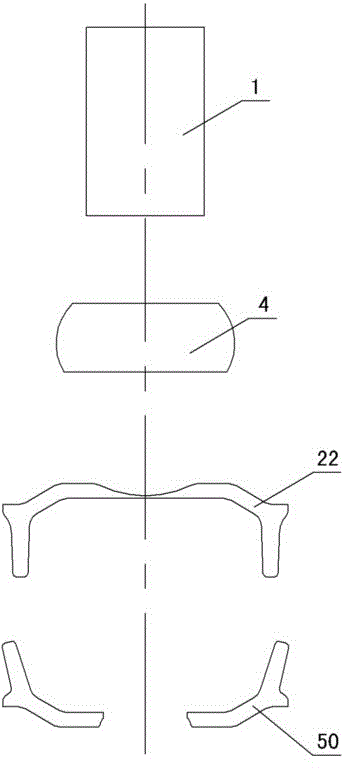

[0017] ①, aluminum rod heating, take aluminum rod 1, use the aluminum rod heating furnace to heat the aluminum rod for 3 hours, and heat it to 420°C-480°C;

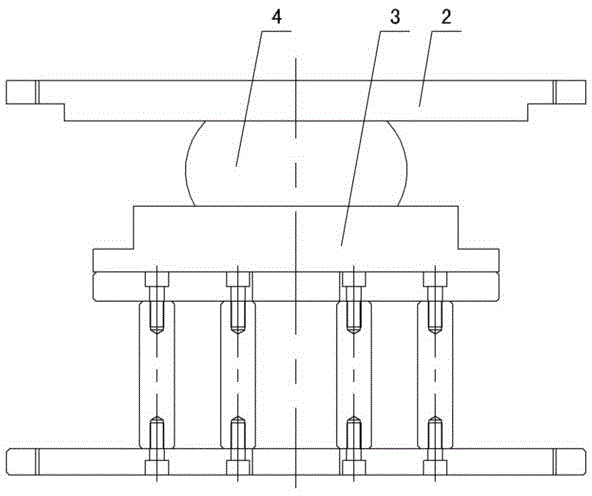

[0018] ② For upsetting the aluminum rod, take the oil press, which is equipped with the upper die pressing plate 2 and the lower die pressing plate (3), the preset height of the upper die pressing plate is 150 mm, and the pressure is 2000 tons, and the heated aluminum rod is molded and upset Get rough billet 4;

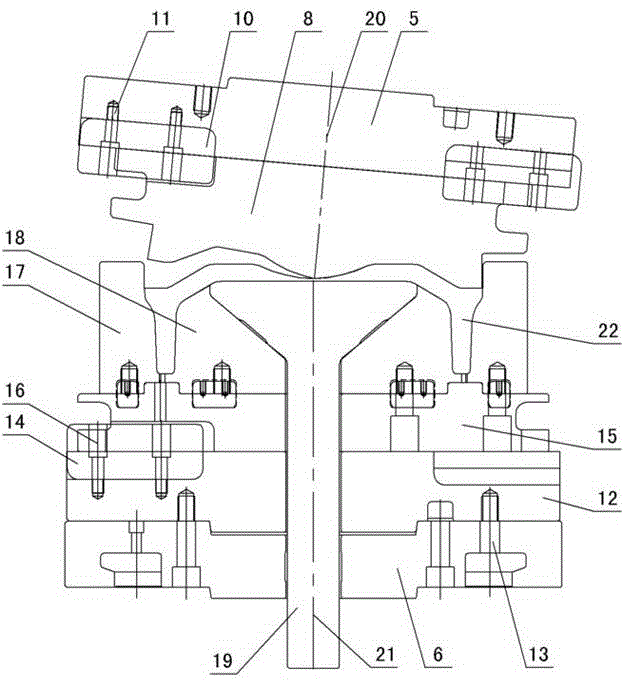

[0019] ③, turn forging, take the rough billet 4 and put it in the turn forging machine, the turn forging machine includes the first upper die holder 5 and the first lower die holder 6, the first upper die is installed under the first upper die holder 8. The first upper die base 5 and the first upper die 8 pass through the upper d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com