Tunable light wave guide dispersion compensator controlled by two-section erverse electrode oriented coupler

A technology of directional coupler and dispersion compensator, which is applied in the coupling of optical waveguide, electromagnetic wave transmission system, electrical components, etc., can solve the problems of unfavorable application, increase the circumference of optical microring, etc., and achieve the effect of great flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

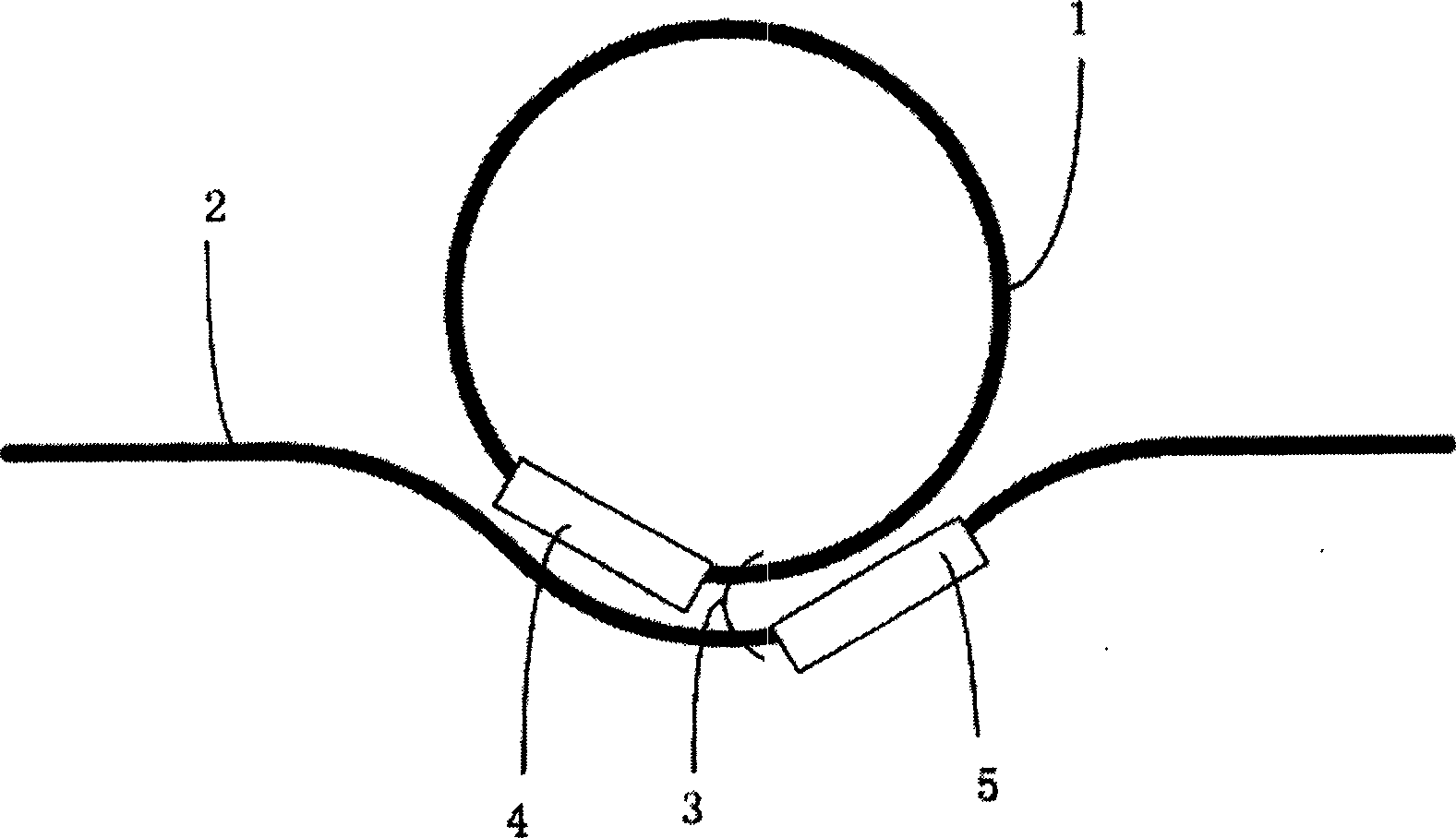

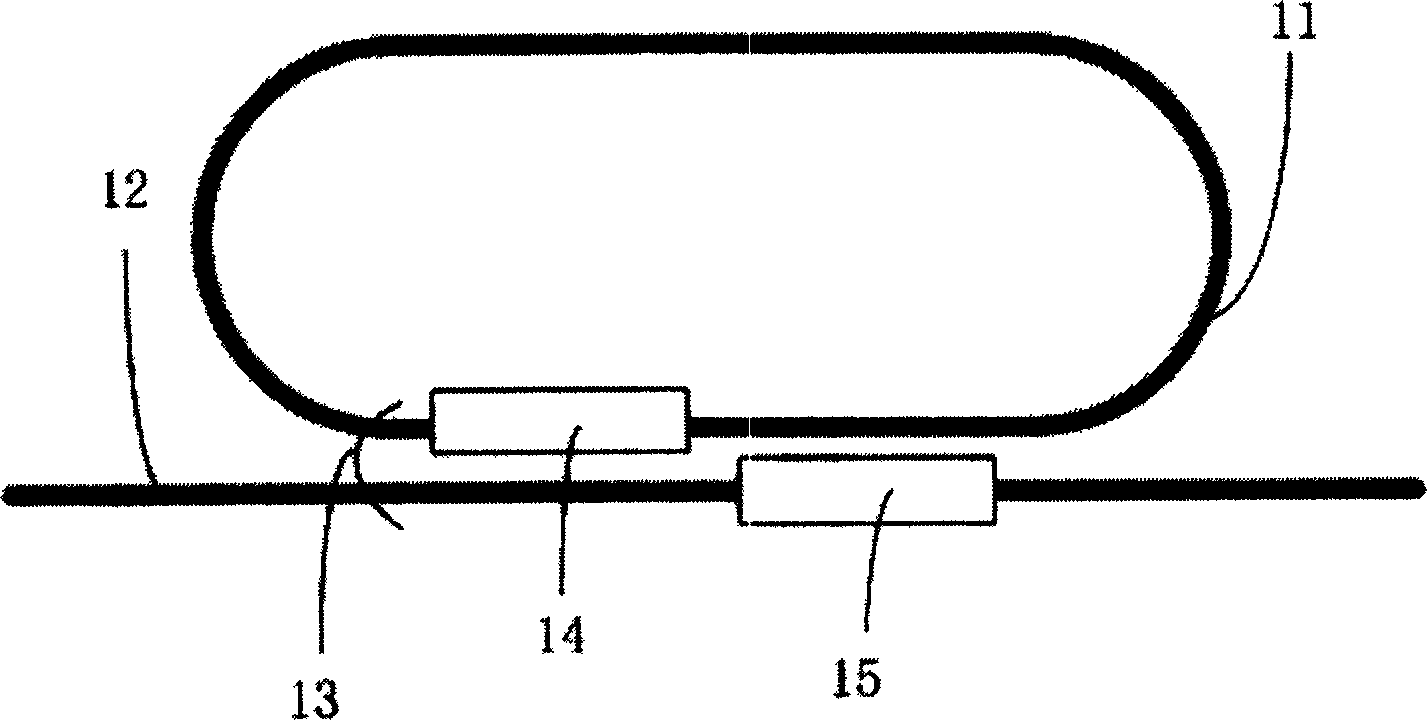

[0014] figure 1 and figure 2 It is an adjustable optical waveguide dispersion compensator controlled by a double-section reverse electrode directional coupler. figure 1 The optical waveguide microring 1 is circular, figure 2 The optical waveguide microring 11 is in the shape of a track and field track. Among them, 1 and 11 are optical waveguide microrings, 2 and 12 are input / output coupling optical waveguides, 3 and 13 are directional coupler parts with double-section inverted electrode structure, driving electrodes 4 and 14 and driving electrodes 5 and 15 The double-section reversed electrode parts are formed respectively. Of course, it should be explained here that the electrode structure is only schematic, and it will be specifically set according to the driving of the refractive index effect used.

[0015] There are many implementations of the present invention, and the silicon dioxide multilayer planar optical waveguide process is used as an example here, but it is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com