Cooling fin structure of magnetron

A technology for cooling fins and magnetrons, which is applied in the field of cooling fin structures, can solve the problems that the cooling fins cannot fluently heat, cannot effectively radiate heat, etc., and achieve the effect of effectively radiating heat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in detail below with reference to the accompanying drawings and embodiments.

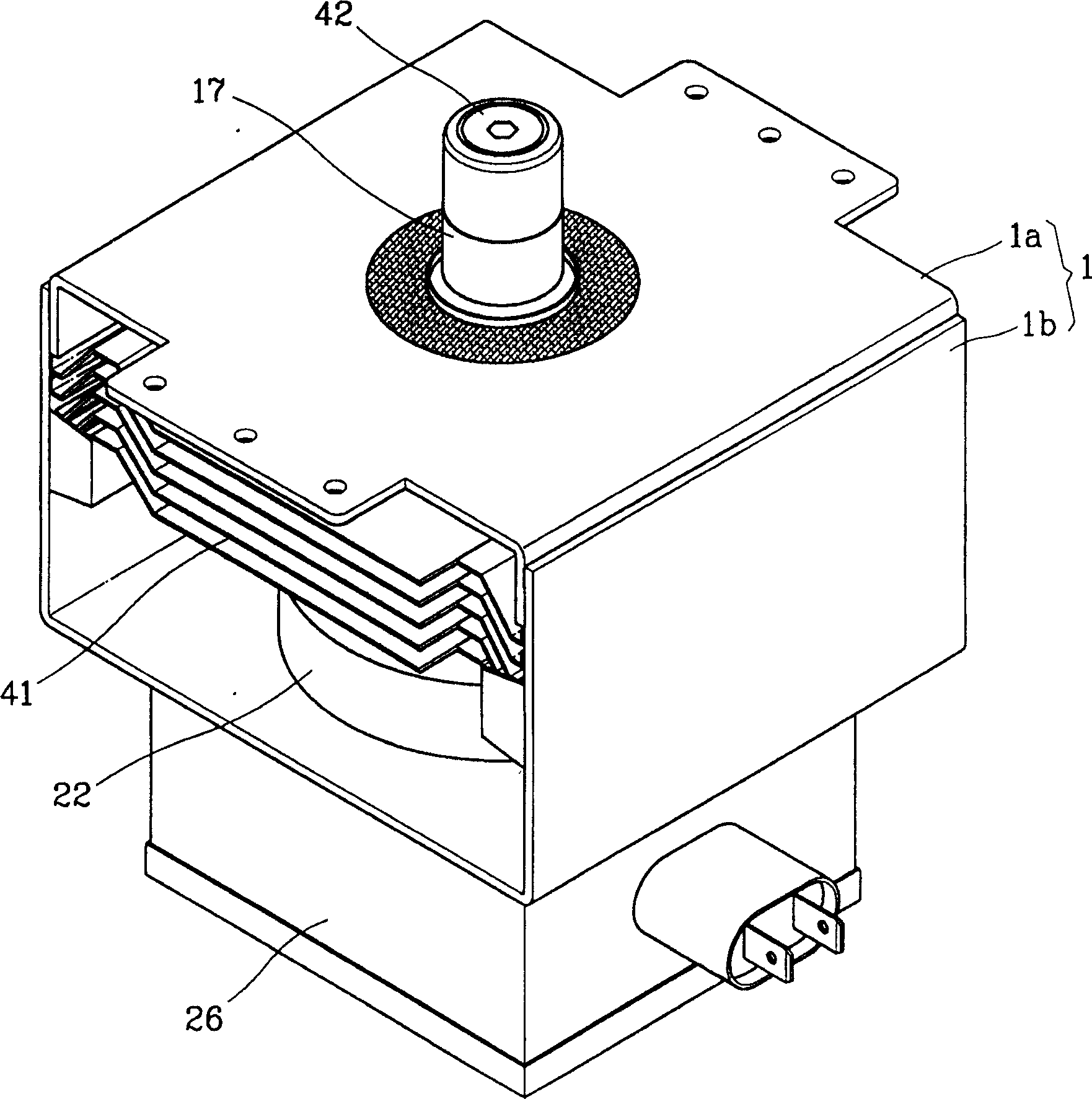

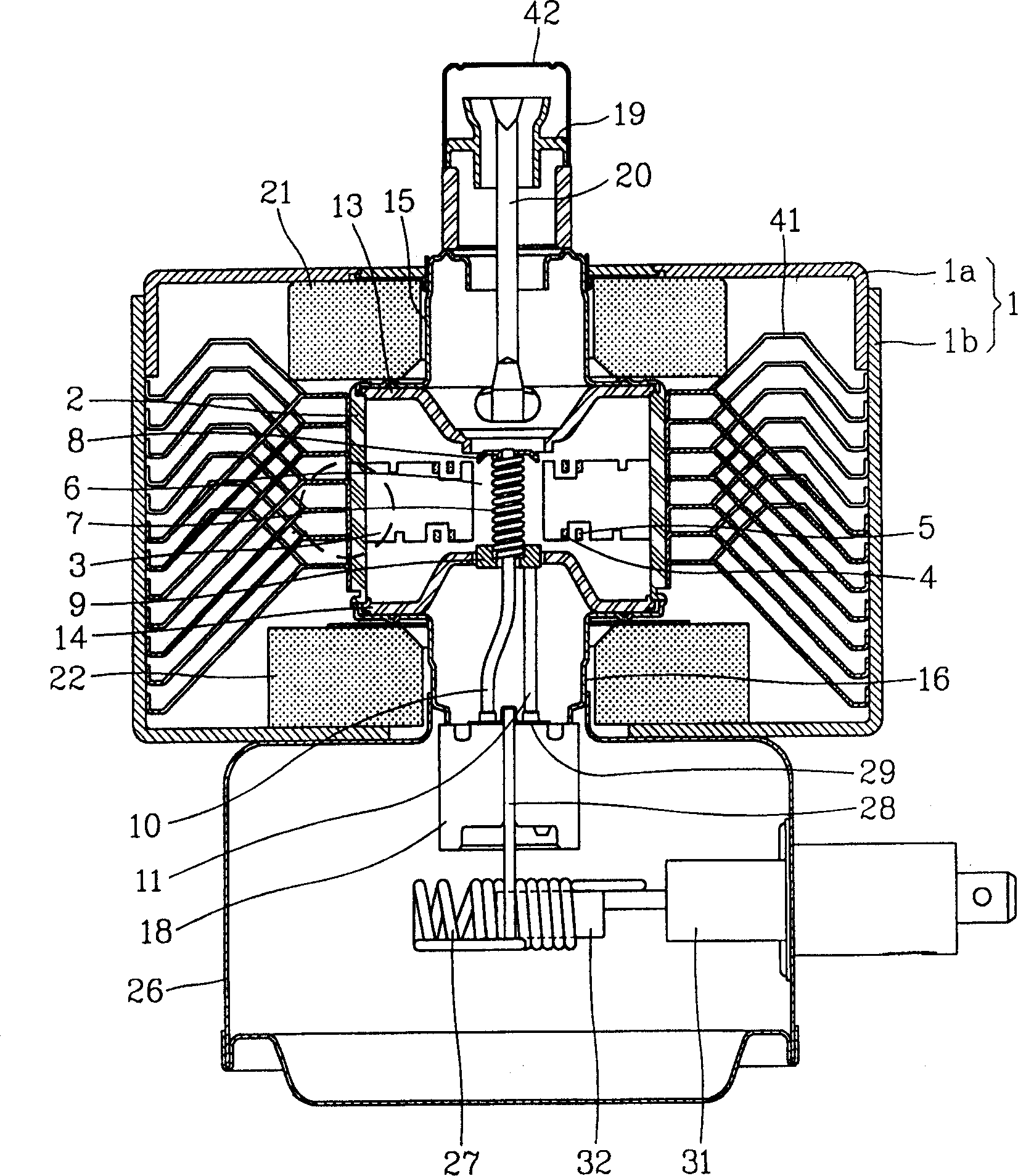

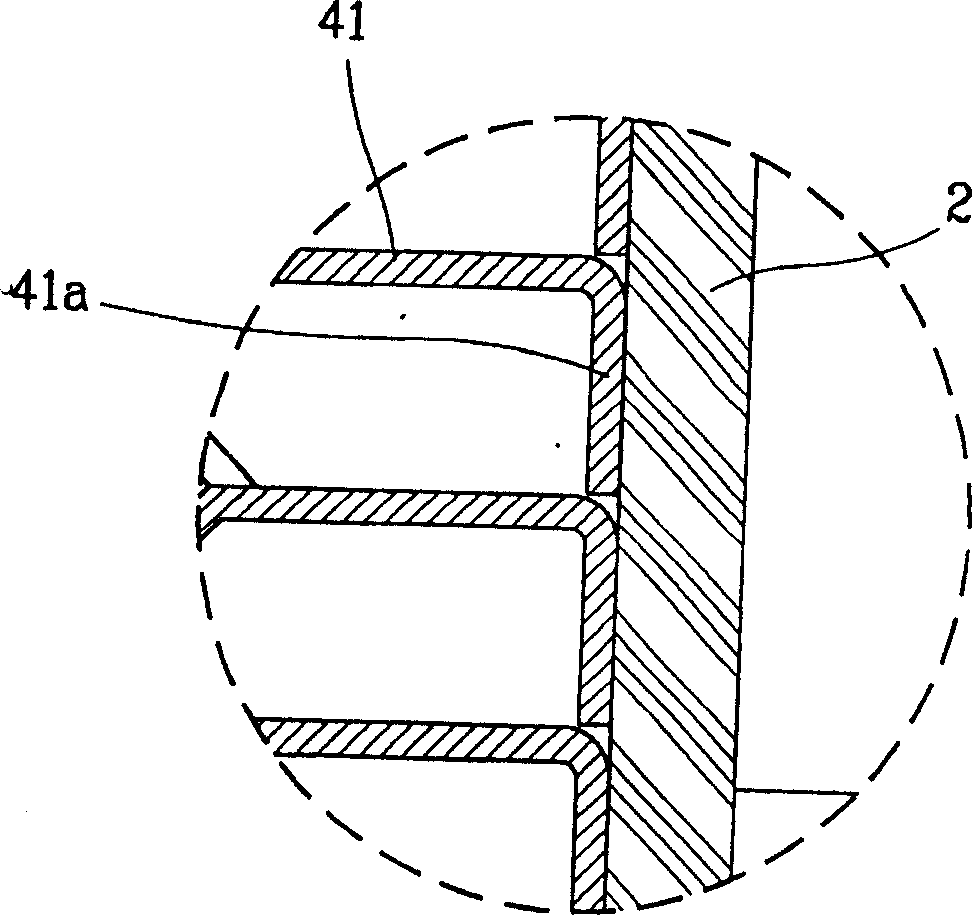

[0034] Figure 4 It is a longitudinal section structure diagram of the magnetron of the cooling fin structure of the present invention; Figure 5 It is a partial cross-sectional structure diagram of the cooling fin assembly state of the present invention.

[0035] As shown in the figure, the cooling fins (100) combined on the outside of the anode tank (2) of the present invention are formed by pressing into the body part (101) on the outer peripheral surface of the anode tank (2); The outer peripheral surface is integrally formed and constituted by a plurality of radiating fins (102) that transmit the heat transmitted by the body part (101) to the outside.

[0036] When the magnetron of the present invention constituted as above is in operation, the heat generated by the anode tank (2) is transferred to the body (101) of the cooling fin (100), and at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com