Near-infrared radiation absorbing masterbatch, near-infrared radiation absorbing product made from the masterbatch, and method of making near-infrared radiation absorbing fiber from the masterbatch

A heat storage and masterbatch technology, applied in optics, melt spinning, optical components, etc., can solve problems such as poor heat absorption effect, poor far-infrared radiation efficiency, and no light absorption and heat storage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

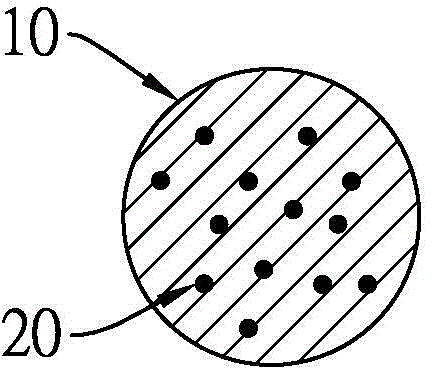

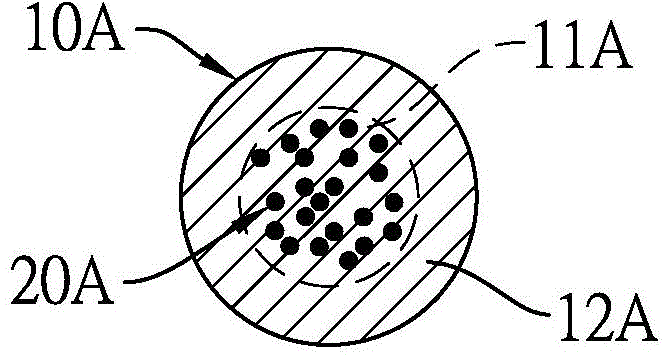

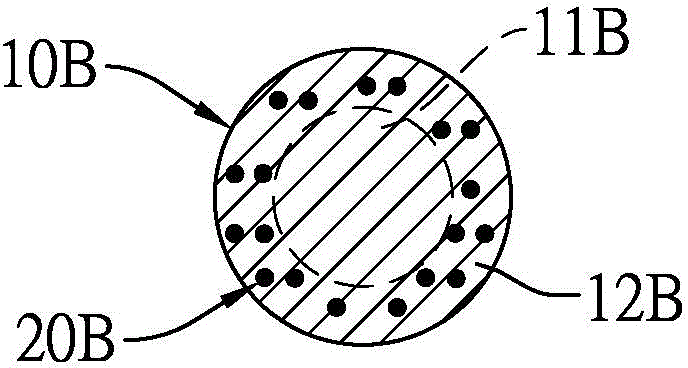

[0037] Embodiment 1 Preparation of light-absorbing heat-storing masterbatch, fiber and cloth

[0038]

[0039] After fully mixing a light-absorbing heat-storage powder, a dispersant and a first polymer with a high-speed mixer, a twin-screw extruder is used at a temperature of 220°C to 250°C to mix the light-absorbing heat-storage powder The powder, the dispersant and the first polymer are blended and extruded to prepare a light-absorbing heat-storage masterbatch.

[0040] In this embodiment, the light-absorbing heat storage powder is purchased from the antimony-doped tin oxide powder of Inframat Advanced Materials Co., Ltd. in the United States. The antimony-doped tin oxide powder in the antimony-doped tin oxide powder The ratio is 1:9, the secondary particle size of the antimony-doped tin oxide powder is between 40 nanometers and 100 nanometers, the far-infrared emissivity of the antimony-doped tin oxide powder is 0.94, and the antimony-doped tin oxide powder Tin oxide pow...

Embodiment 2

[0047] Embodiment 2 Preparation of light-absorbing heat-storing masterbatch, fiber and cloth

[0048] This embodiment is similar to Embodiment 1. This embodiment differs from Embodiment 1 in the following points.

[0049]In the preparation of the light-absorbing heat-storage masterbatch, the weight ratio of the light-absorbing heat-storage powder, the dispersant and the first polymer is 1:0.1:18.9, based on the total weight of the light-absorbing heat-storage masterbatch, the light-absorbing The content of heat storage powder is 5% by weight.

[0050] In the production of light-absorbing and heat-storage fibers, the weight ratio of the light-absorbing and heat-storage masterbatch to the second polymer is 1:4, and based on the total weight of the light-absorbing and heat-storage fibers, the light-absorbing and heat-storage fibers contain 1% by weight light-absorbing heat-storing powder.

Embodiment 3

[0051] Embodiment 3 Preparation of light-absorbing heat-storing masterbatch, fiber and cloth

[0052] This embodiment is similar to Embodiment 1. This embodiment differs from Embodiment 1 in the following points.

[0053] In the preparation of the light-absorbing heat-storage masterbatch, the weight ratio of the light-absorbing heat-storage powder, the dispersant and the first polymer is 4:0.4:5.6, based on the total weight of the light-absorbing heat-storage masterbatch, the light-absorbing The content of heat storage powder is 40% by weight.

[0054] In the production of light-absorbing and heat-storage fibers, the weight ratio of the light-absorbing and heat-storage masterbatch to the second polymer is 1:39, and based on the total weight of the light-absorbing and heat-storage fibers, the light-absorbing and heat-storage fibers contain 1% by weight light-absorbing heat-storing powder.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com