Electric liquid processing device

A plasma treatment, plasma technology, used in circuits, discharge tubes, electrical components, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

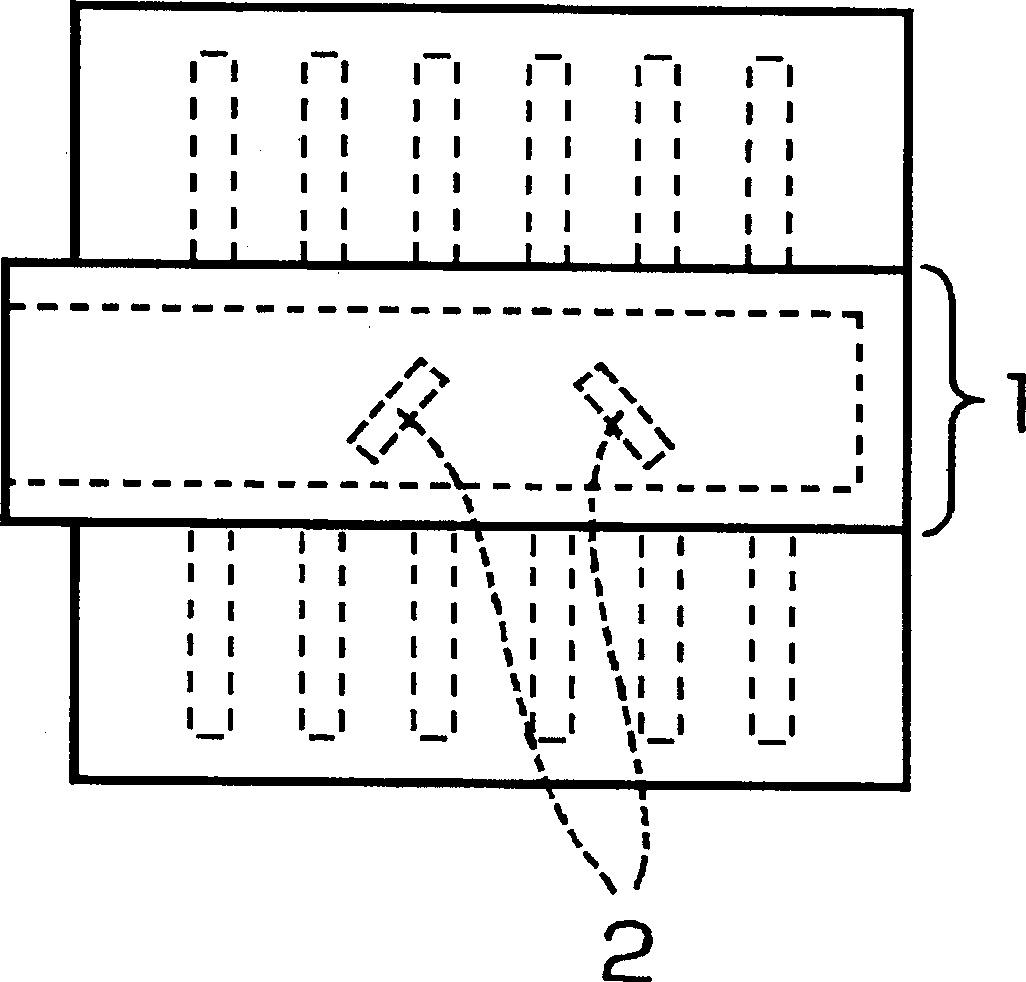

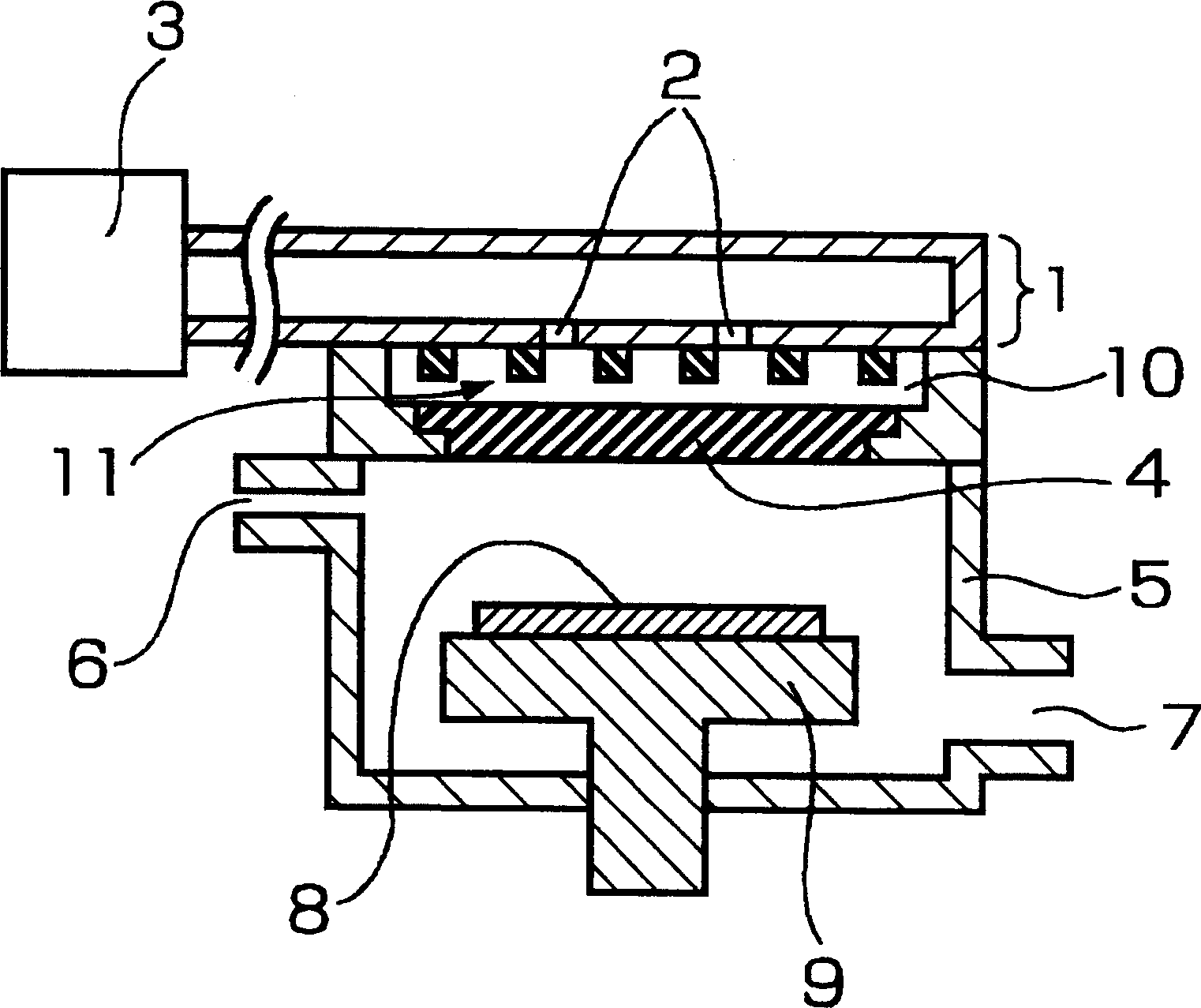

[0063] Fig. 1(a) is a plan view of the plasma processing apparatus of the first embodiment, and Fig. 1(b) is a cross-sectional view thereof.

[0064] Reference numeral 1 is a rectangular waveguide, 2 is a waveguide antenna, 3 is an electromagnetic wave such as a microwave source, 4 is an electromagnetic wave radiation window (electromagnetic wave introduction window) composed of a dielectric such as quartz, glass, and ceramics, and 5 is a Vacuum container, 6 is a gas introduction system, 7 is a gas discharge system, 8 is a substrate subjected to plasma treatment, 9 is a substrate mounting part, 10 is a dielectric sandwiched between the waveguide antenna 2 and the electromagnetic wave radiation window 4 The bulk space (for example, air) 11 is a concave-convex portion (concave-convex surface) provided on the surface of the waveguide 1 facing the electromagnetic wave radiation window 4 .

[0065] A gas introduction system 6 for introducing a source gas and a gas discharge system ...

Embodiment 2

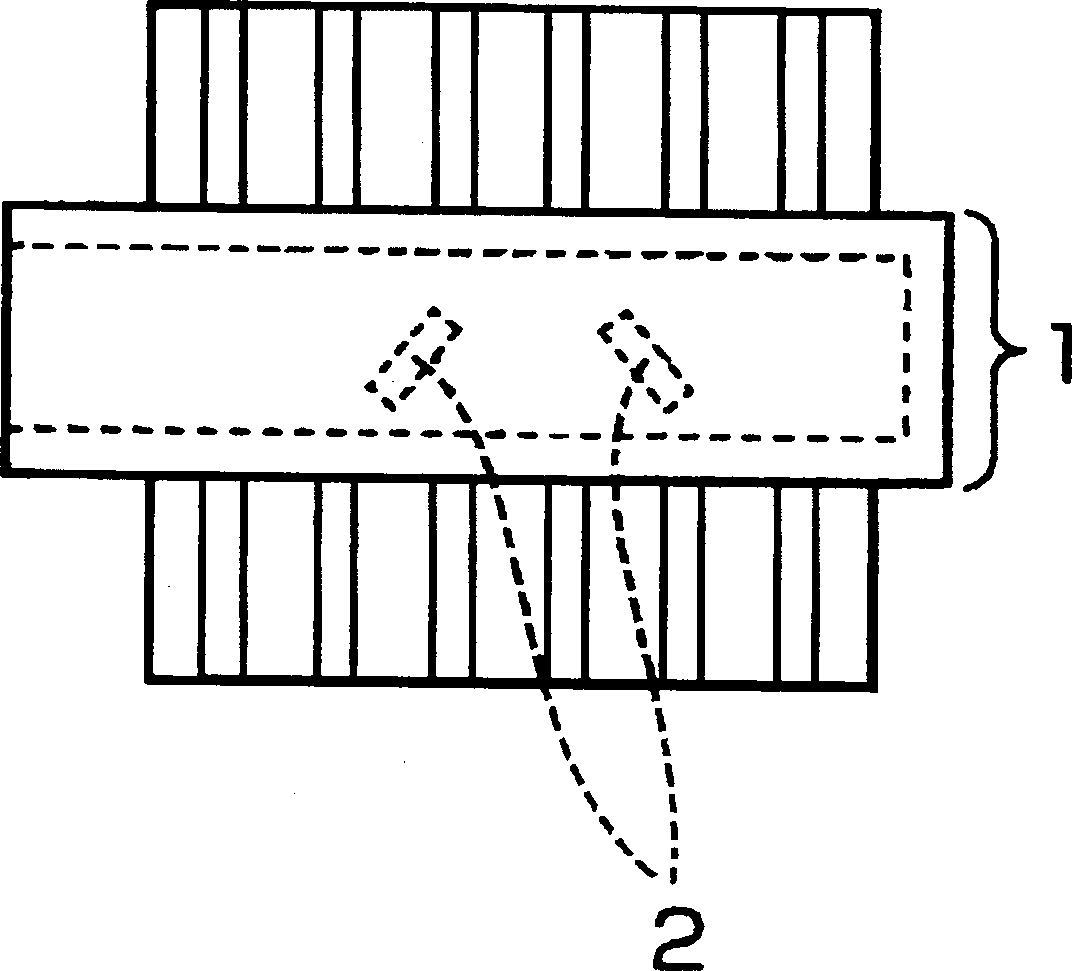

[0075] Fig. 2(a) is a plan view of the plasma processing apparatus of the second embodiment, and Fig. 2(b) is a cross-sectional view thereof.

[0076] Reference numeral 12 denotes a concavo-convex portion provided on the surface of the electromagnetic wave radiation window 4 facing the waveguide 1 .

[0077] In the second embodiment, on the surface of the electromagnetic wave radiation window 4 facing the waveguide 1 , elongated convex portions with a width of 10 mm and a depth of 5 mm are provided at intervals of 30 mm, thereby forming the concave-convex portion 12 .

[0078] The convex portion of the concave-convex portion 12 of the electromagnetic wave radiation window 4 is provided at a distance of 5 mm from the outer surface of the waveguide 1 on which the waveguide antenna 2 is provided. Furthermore, the surface of the electromagnetic wave radiation window 4 in contact with the plasma on the side opposite to the surface provided with the concave-convex portion 12 (that i...

Embodiment 3

[0084] Fig. 3(a) is a plan view of the electromagnetic wave radiation window in the plasma processing apparatus of the third embodiment, and Fig. 3(b) is a cross-sectional view thereof.

[0085] Reference numeral 13 is a glass plate constituting the electromagnetic wave radiation window 4 , and 14 is a mixing member made of spherical ceramics mixed with the glass plate 13 .

[0086] In Example 3, a glass plate (dielectric constant 4.7) 13 mixed with a mixing member 14 made of ceramics such as alumina (dielectric constant 9) is used as the electromagnetic wave radiation window 4 .

[0087] In addition, the diameter of the mixing member 14 made of spherical ceramics is 2.5 cm, and the thickness of the electromagnetic wave radiation window 4 is 5 cm. The diameter of the spherical mixing member 14 is larger than 1 / 8 of the wavelength of the microwave. Therefore, microwaves can be effectively dispersed due to reflection or scattering. As mentioned above, by using the electromagne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com