Shape memory alloy spring driven manipulator control system

A technology of memory alloy springs and control systems, which is applied to manipulators and manufacturing tools, and can solve problems such as the control system of SMA-driven manipulators that have not been proposed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

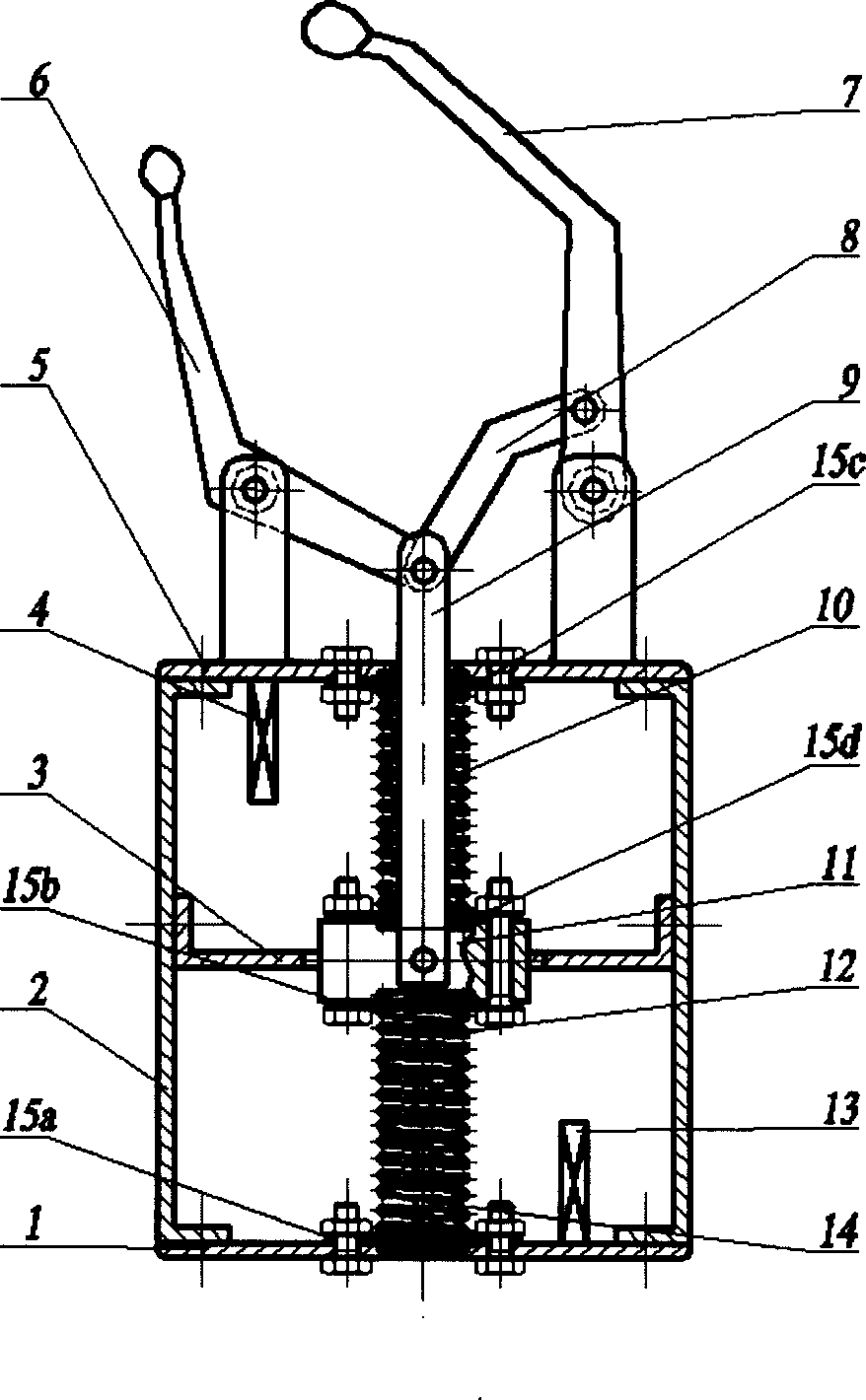

[0030] The specific embodiment of the present invention will be described with reference to the accompanying drawings.

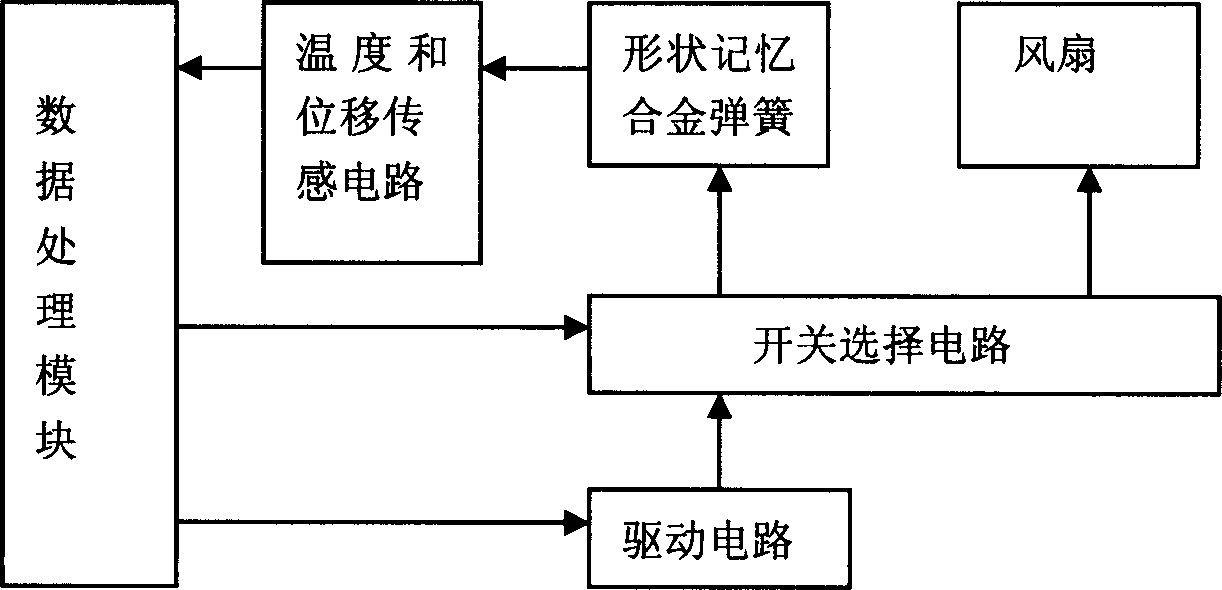

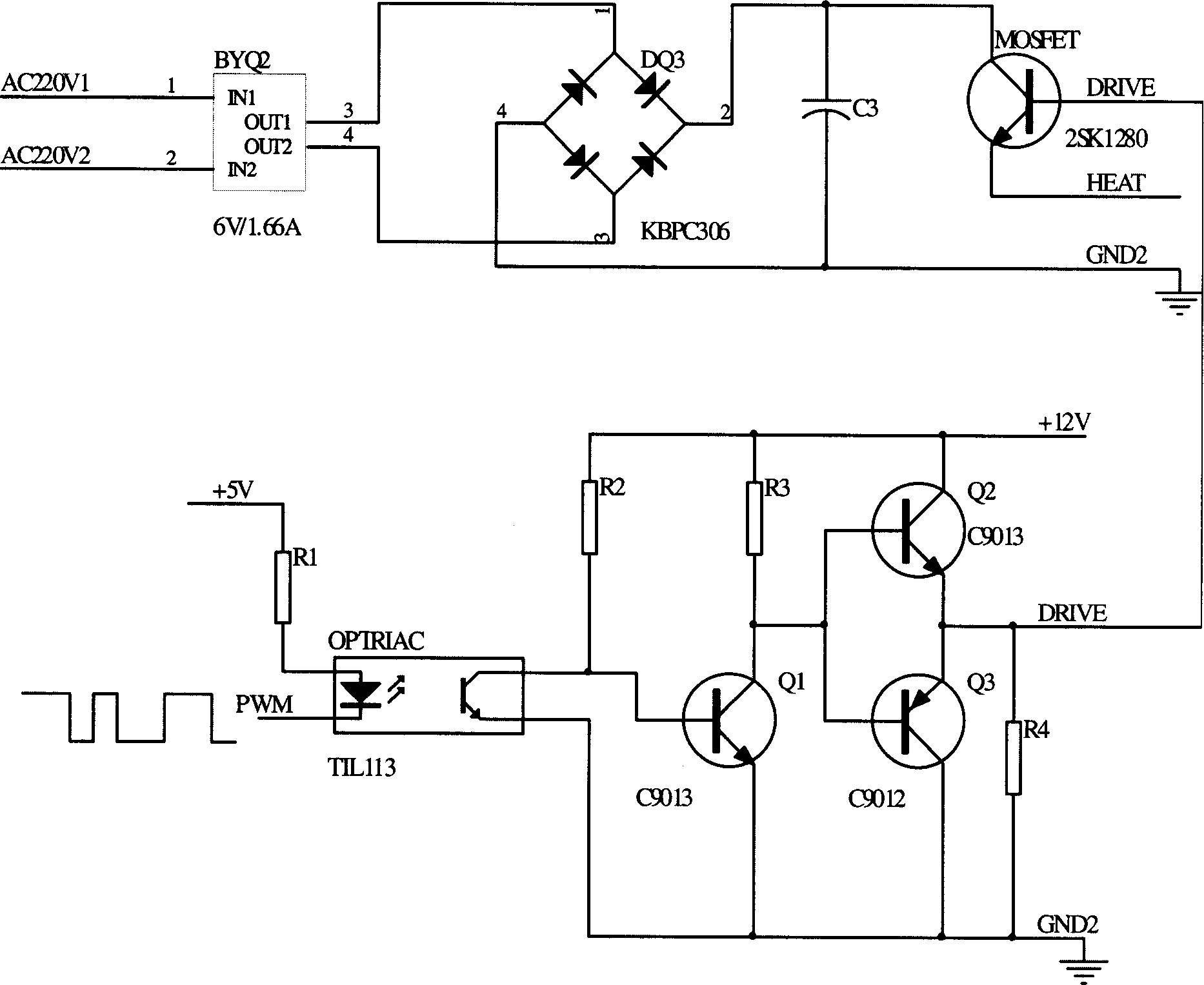

[0031] See figure 2 , temperature sensor (adopts AB glue to stick on spring 10 and 12 respectively) and displacement sensor (the present invention adopts slide wire rheostat, and its slide bar is connected with slide block 11) the temperature that detects and displacement data are sent into data processing module After data processing, the data processing module sends the output signal to the driving circuit and the switch selection circuit. One input terminal of the driving circuit is connected to the control signal output by the data processing module, and the other terminal is input with 220V grid voltage, and its output current is selectively added to the spring 10 or 12 through the switch selection circuit. The switch selection circuit receives the switch signal from the data processing module, and is used to selectively control the current on and off...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com