Controllable profile vaneless diffuser for centrifugal compressor

A centrifugal compressor and diffuser technology, which is applied in the direction of machines/engines, mechanical equipment, liquid fuel engines, etc., can solve the problem that the shape of the inner wall of the diffuser cannot be adjusted according to the flow rate, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The specific embodiment of the present invention will be described with reference to the accompanying drawings.

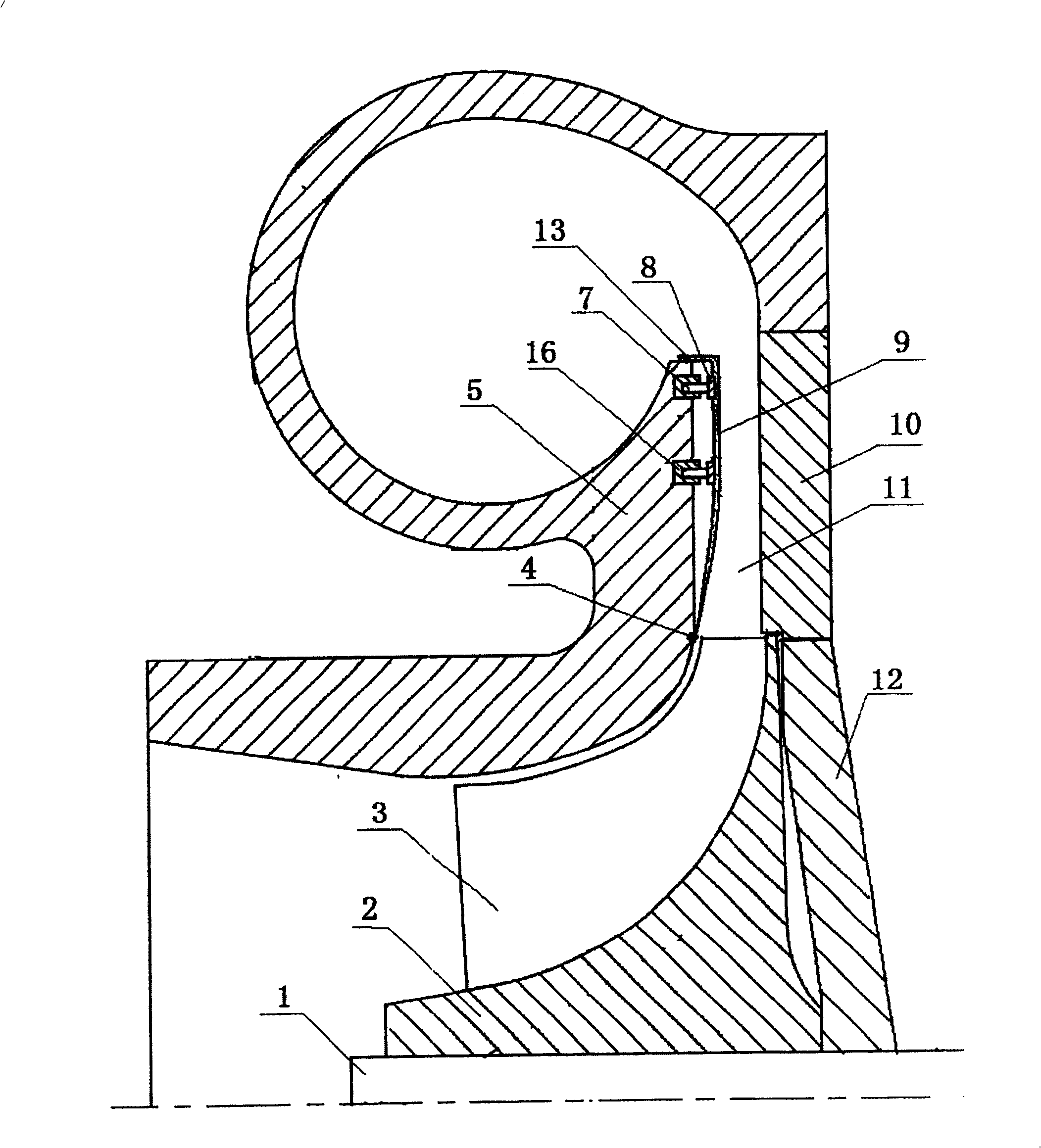

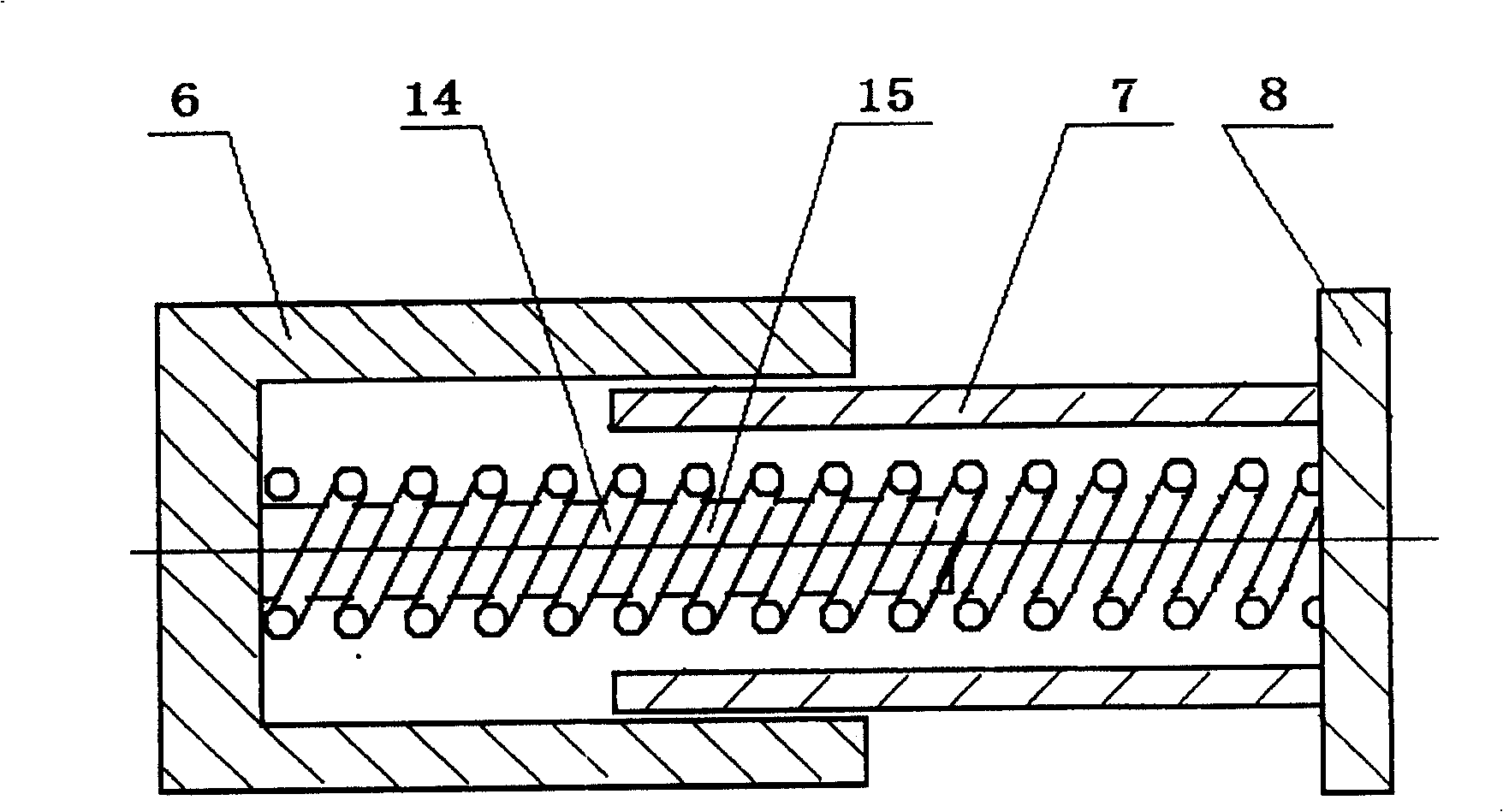

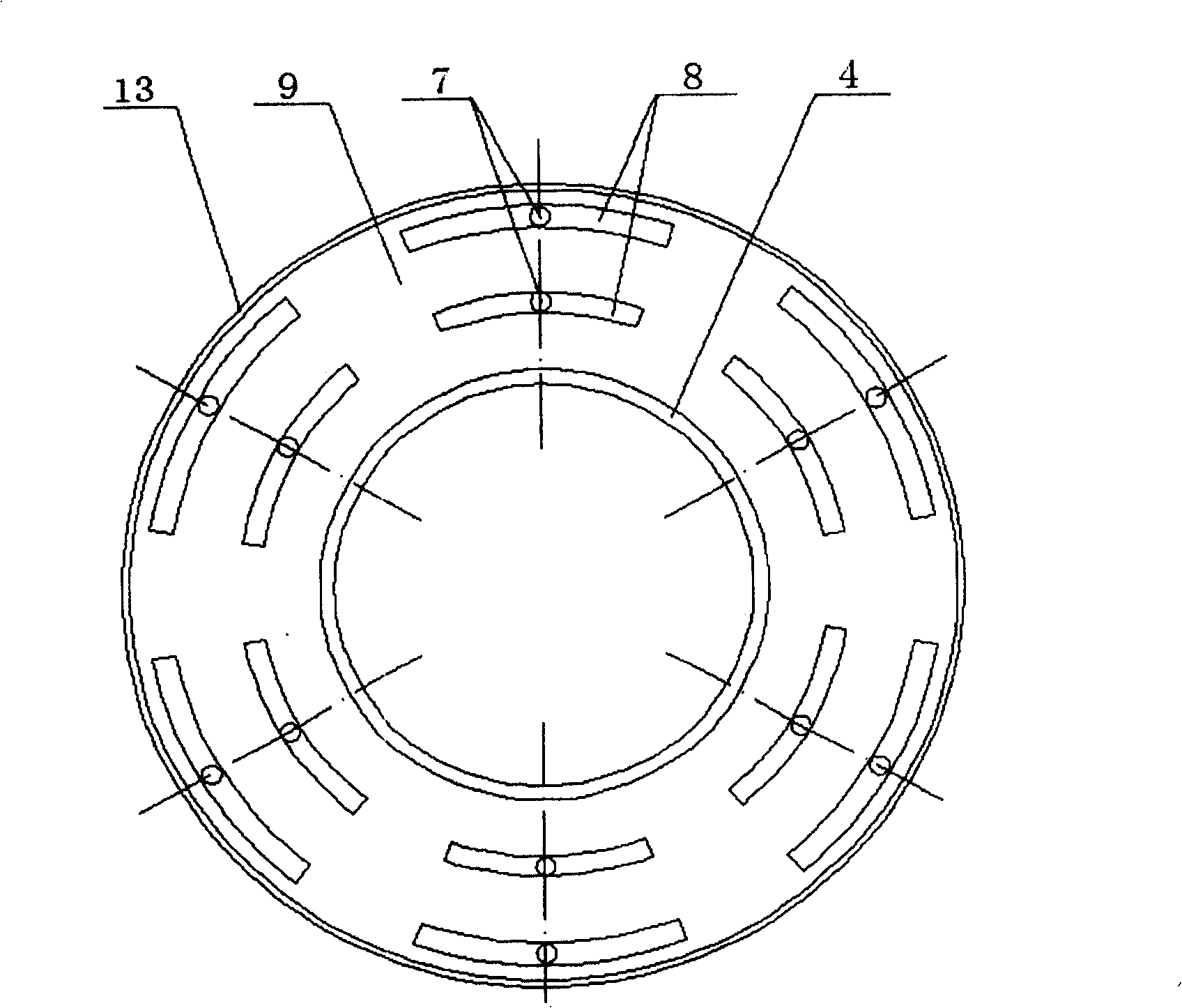

[0016] Such as figure 1 As shown, compressor rotating shaft 1, impeller disc 2, blade 3, outer wall diffuser wheel cover 5, diffuser disc 10 and impeller baffle 12 are all common parts of existing compressors, and 11 is a vaneless diffuser. Compressor flow channel. It is characterized in that, on the inner side wall of the diffuser wheel cover 5 on the outer wall, a flexible annular disc 9 is also installed, and the inner circumference of the flexible annular disc 9 is connected with the inner side of the diffuser wheel cover 5 on the outer wall. The walls are connected to form a junction 4, and at least two groups of radially distributed circular arc ring sheet groups are fixed on the circumferential surface of the flexible annular disk 9, and each group of circular arc ring sheet groups contains at least 3 circular arc ring sheet groups distributed along ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com