A hydrogen selenide preparing method

A hydrogen selenide and hydrogen technology, applied in the direction of binary selenium/tellurium compounds, can solve the problems of blockage, impurity sulfur cannot be completely removed, and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0023] A preparation method for hydrogen selenide, comprising the steps of:

[0024] S1: Using the feeding device, add the selenium raw material containing 0.1-100ppm sulfur into the reaction furnace;

[0025] S2: using the hydrogen gas feeding path to feed the heated hydrogen gas into the reaction furnace;

[0026] S3: Under the heating condition in the reaction furnace, selenium and hydrogen are combined to form hydrogen selenide, and hydrogen selenide is mixed into the mixed gas;

[0027] S4: The mixed gas out of the reaction furnace is cooled to lower the temperature, and the selenium vapor is separated;

[0028] S5: The cooled mixed gas is condensed and liquefied in the condenser, and the uncollected hydrogen is returned to S2 through the circulating compressor to participate in the reaction with the newly introduced hydrogen;

[0029] S6: When 5-15% of the selenium raw material is consumed, the liquefied hydrogen selenide in the condenser is charged and collected to ob...

Embodiment 1

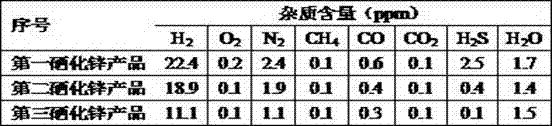

[0039] In a selenium reaction furnace, 500kg of selenium powder containing 0.1ppm of sulfur is dropped into by a feeding device, the air is replaced with hydrogen, heated and melted, then added to the hydrogen selenide reaction furnace. The reaction furnace is heated to 400°C, and hydrogen gas is introduced to react. The mixed gas generated by the reaction is cooled to 35°C to separate the selenium vapor, and then enters a condenser with a pressure of 8 atmospheres and a temperature of -50°C to condense and liquefy the hydrogen selenide and collect it. The uncondensed hydrogen is pressurized by the compressor and returned to the reaction furnace to participate in the reaction with the newly injected hydrogen. When 10% of the selenium raw material is consumed, the hydrogen selenide in the condenser is charged and collected for the first time to obtain the first hydrogen selenide product. When 50% of the selenium raw material is consumed, the hydrogen selenide in the condenser ...

Embodiment 2

[0043] In a selenium reaction furnace, utilize the feeding device to drop into 500kg of selenium powder containing 11ppm sulfur, replace the air with hydrogen, heat and melt and add it to the hydrogen selenide reaction furnace. The reaction furnace is heated to 500°C, and hydrogen gas is introduced to react. The mixed gas generated by the reaction is cooled to 50°C to separate the selenium vapor, and then enters a condenser with a pressure of 10 atmospheres and a temperature of -50°C to liquefy and collect hydrogen selenide. The uncondensed hydrogen is pressurized by the compressor and returned to the reaction furnace to participate in the reaction with the newly injected hydrogen. When 5% of the selenium raw material is consumed, the hydrogen selenide in the condenser is charged and collected for the first time to obtain the first hydrogen selenide product. When 40% of the selenium raw material is consumed, the hydrogen selenide in the condenser is filled and collected for t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com