Method for straightening hot rolled reinforcing steel bar having ribs and equipment

A hot-rolled ribbed steel bar and straightening technology, applied in the field of wire straightening methods and equipment, can solve the problems of swinging and hurting people, twisting of longitudinal ribs of steel bars, damage to transverse ribs, etc. distorted effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

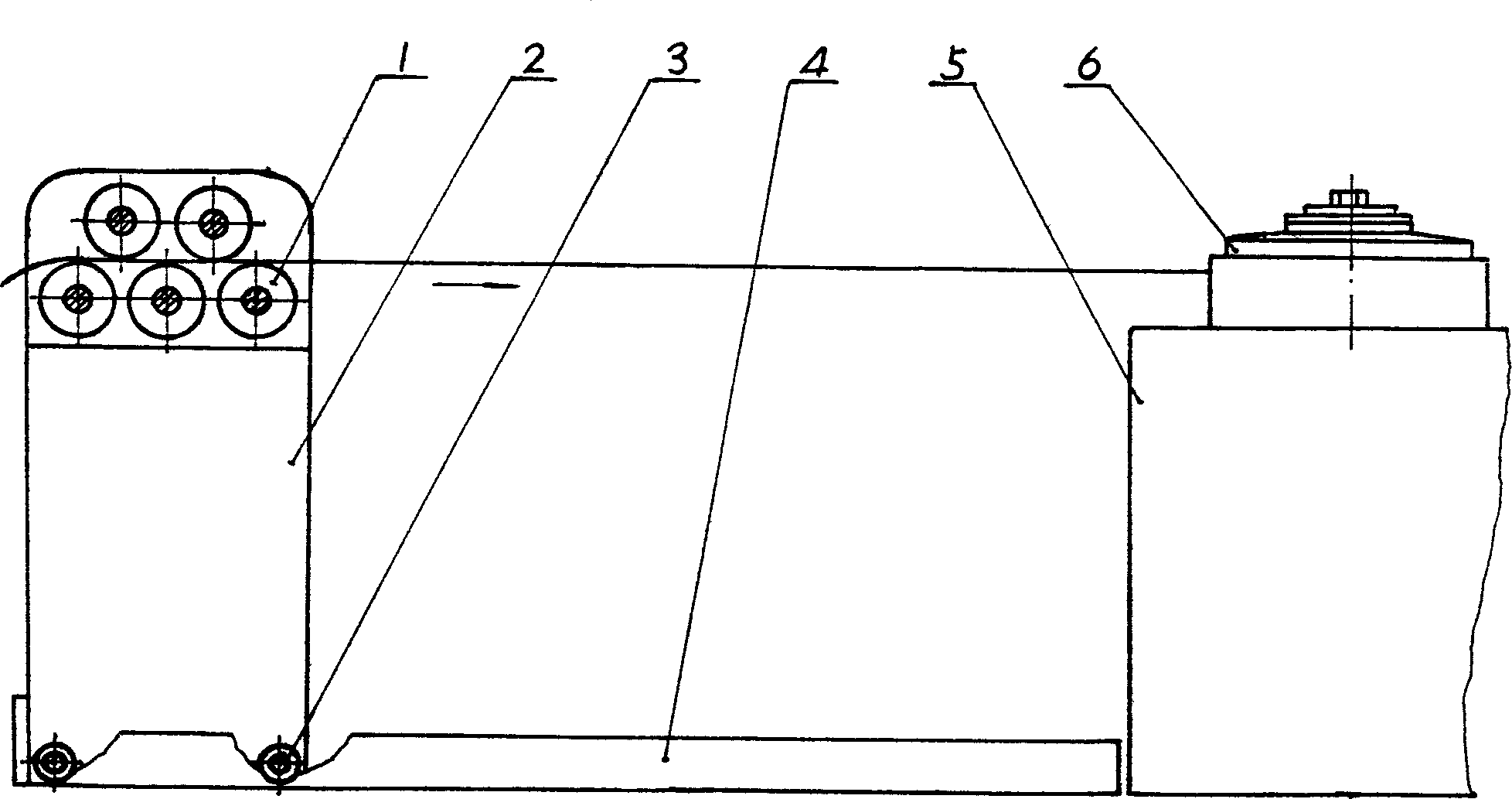

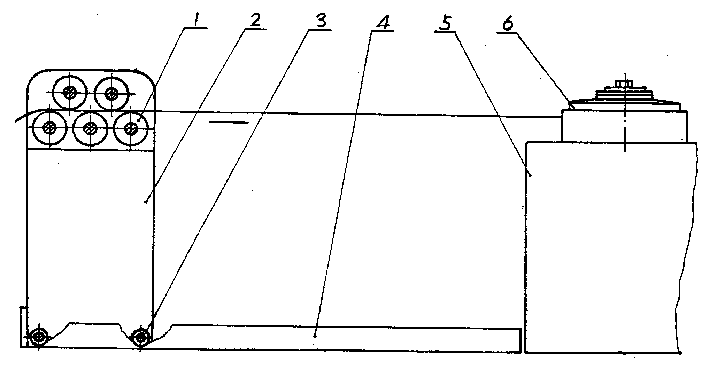

[0019] As shown in the attached figure: the hot-rolled ribbed steel bar straightening equipment includes a pre-straightening mechanism 2 and a longitudinal rib guiding mechanism 5, the pre-straightening mechanism 2 has a pre-straightening roller group 1, and the longitudinal rib guiding mechanism 5 has a guide roller 6. A roller 3 and a guide rail 4 are arranged between the pre-straightening mechanism 2 and the longitudinal rib guide mechanism 5, and the guide rail 4 leads from the bottom of the pre-straightening mechanism 2 to the longitudinal rib guide mechanism 5 on the rear side of the main machine. The pre-straightening roller group 1 can be one group, also can be more than one group, and its pressing roller axis can be parallel to the horizontal plane, also can be perpendicular to the horizontal plane.

[0020] When straightening the hot-rolled ribbed steel bars of Φ6-8 mm, the distance between the pre-straightening roller group 1 and the guide roller 6 is 0.7-1.5 meters....

Embodiment 2

[0022] Embodiment 2: When straightening the hot-rolled ribbed steel bar of Φ8-12 mm, the distance between the pre-straightening roller group 1 and the guide roller 6 is 1.5-3 meters. All the other are the same as embodiment one.

Embodiment 3

[0023] Embodiment 3: When straightening the hot-rolled ribbed steel bar of Φ12-16 mm, the distance between the pre-straightening roller group 1 and the guide roller 6 is 3-5 meters. All the other are the same as embodiment one.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com