Flatbottomed crawler belt travelling charger

A loading device and crawler technology, which is applied in the direction of measuring devices, instruments, and vehicle testing, can solve the problems that the detection section that cannot be crawled is placed on a straight line, cannot bear the crawler, etc., and achieves simple structure and reasonable detection results. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

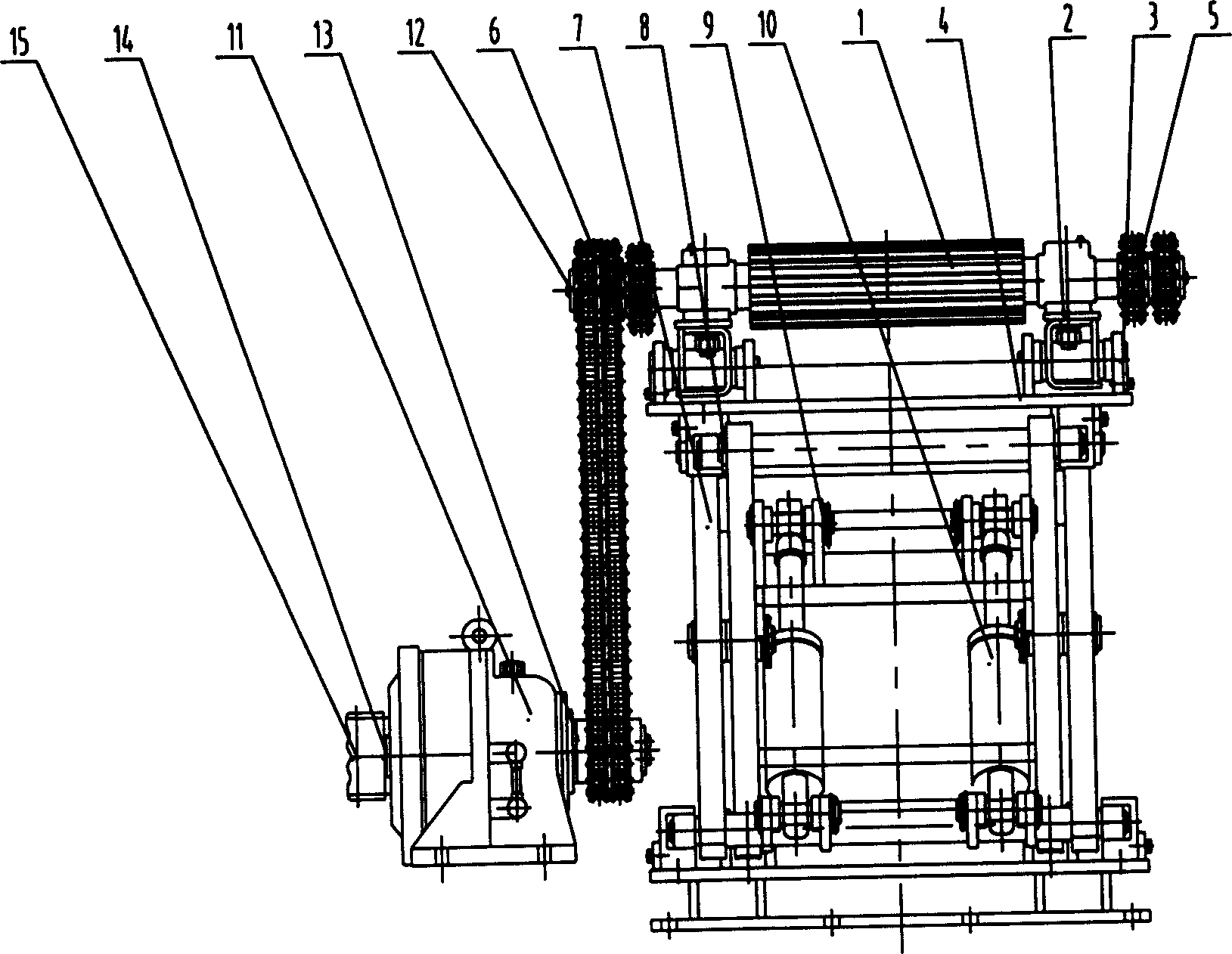

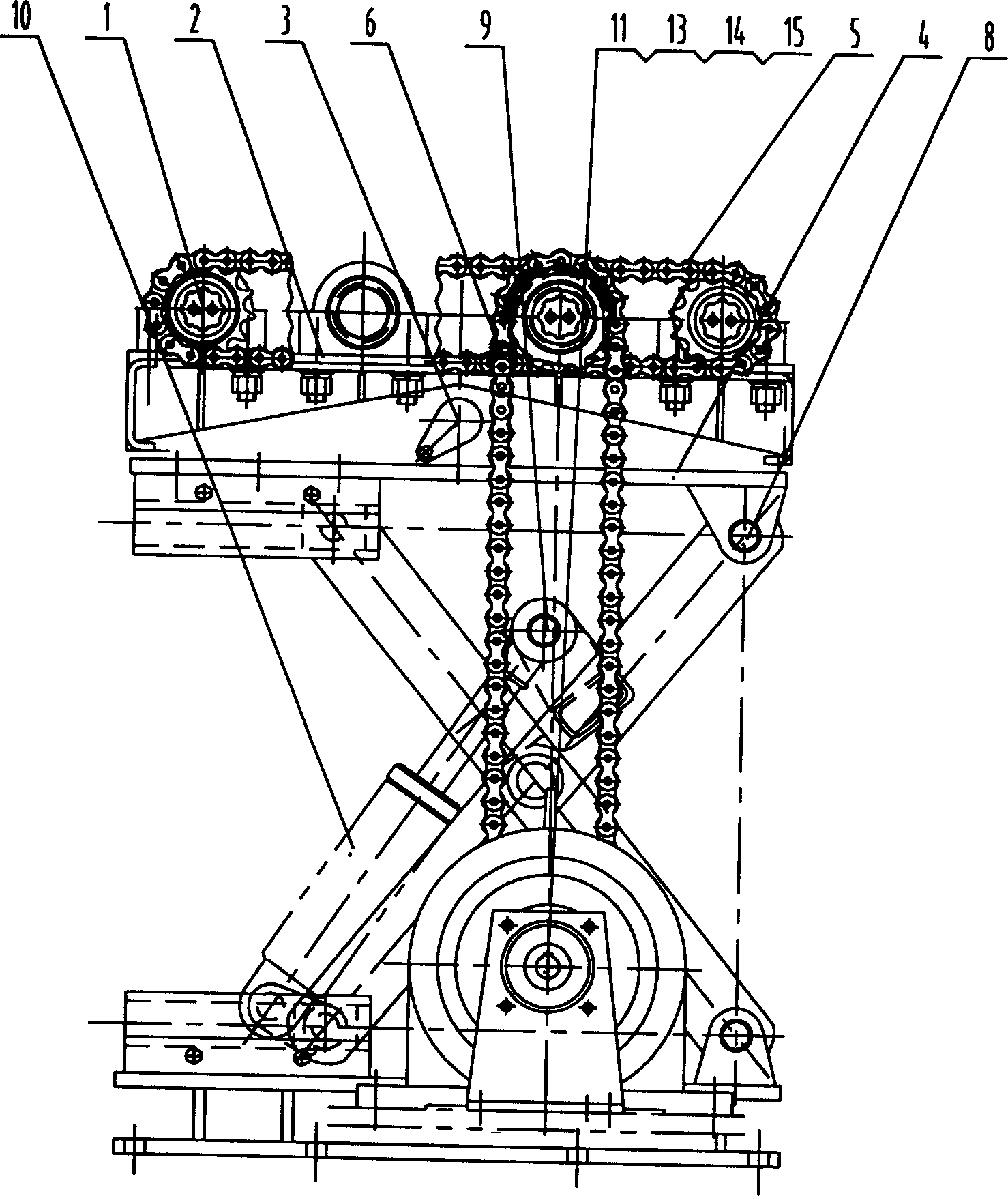

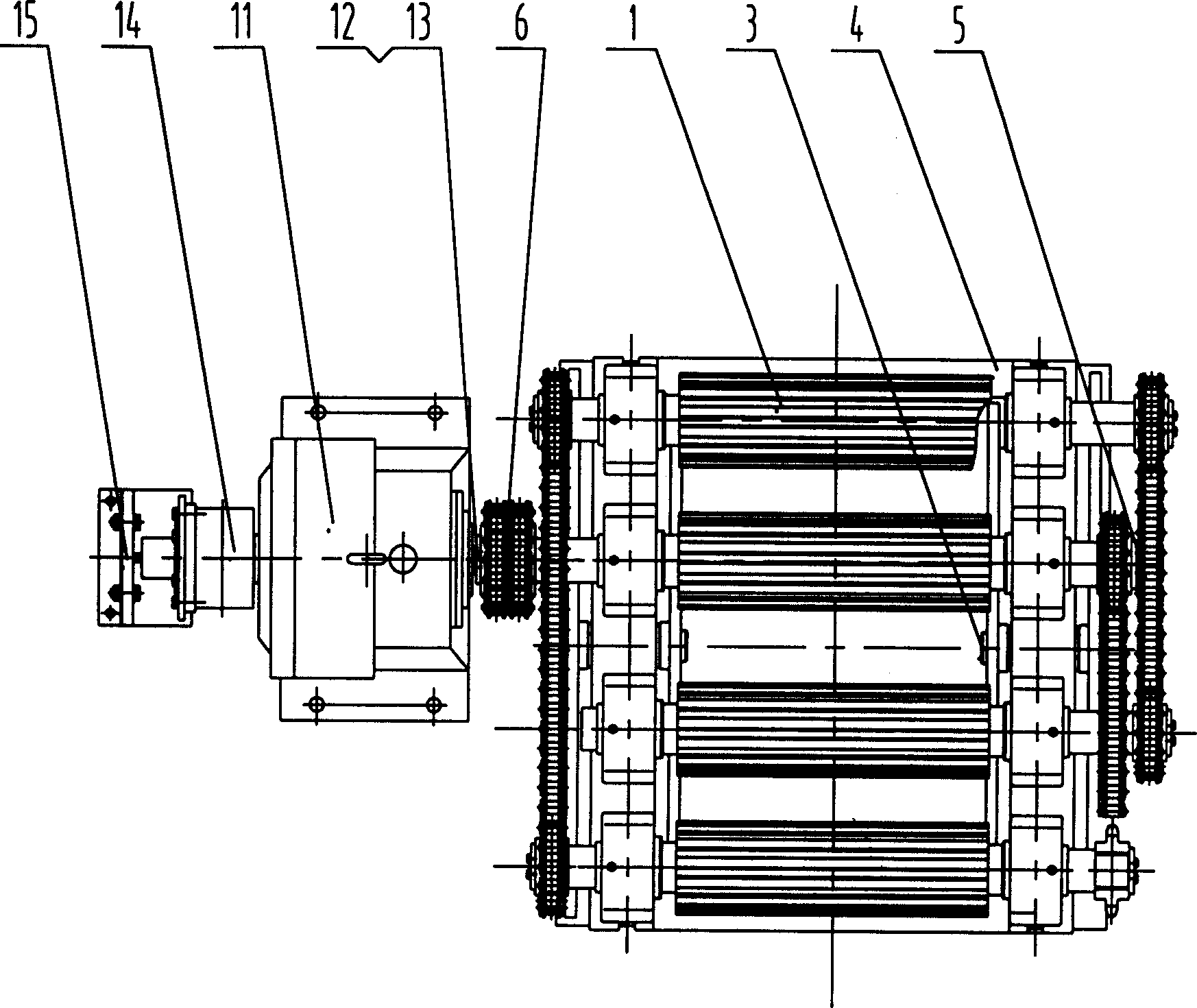

[0016] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

[0017] see Figure 1-Figure 3 , a flat-bottom crawler walking loading device, including: upper frame 4, two pin shafts 3, beam 2, idler roller 1 and idler driving chain 5, idler driven chain 6, the connection relationship between them is: two pin shafts 3 respectively The upper frame 4 and the two beams 2 are hinged, and at least four idler rollers 1 are fixed on the beam 2, and idler sprockets 12 are installed at both ends of the idler rollers, and any two idler rollers pass through the idler sprocket and the main chain of the idler Constitute a chain transmission, three groups of main transmission chains can be formed between the four idlers, and each idler group and auxiliary device form a secondary transmission through a driven chain. Ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com