Tread pattern structure capable of reducing rotative force

A pattern structure and tire surface technology, applied in tire tread/tread pattern, tire parts, transportation and packaging, etc., can solve the problems of large vehicle inclination and side roll

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in detail below in conjunction with example drawings.

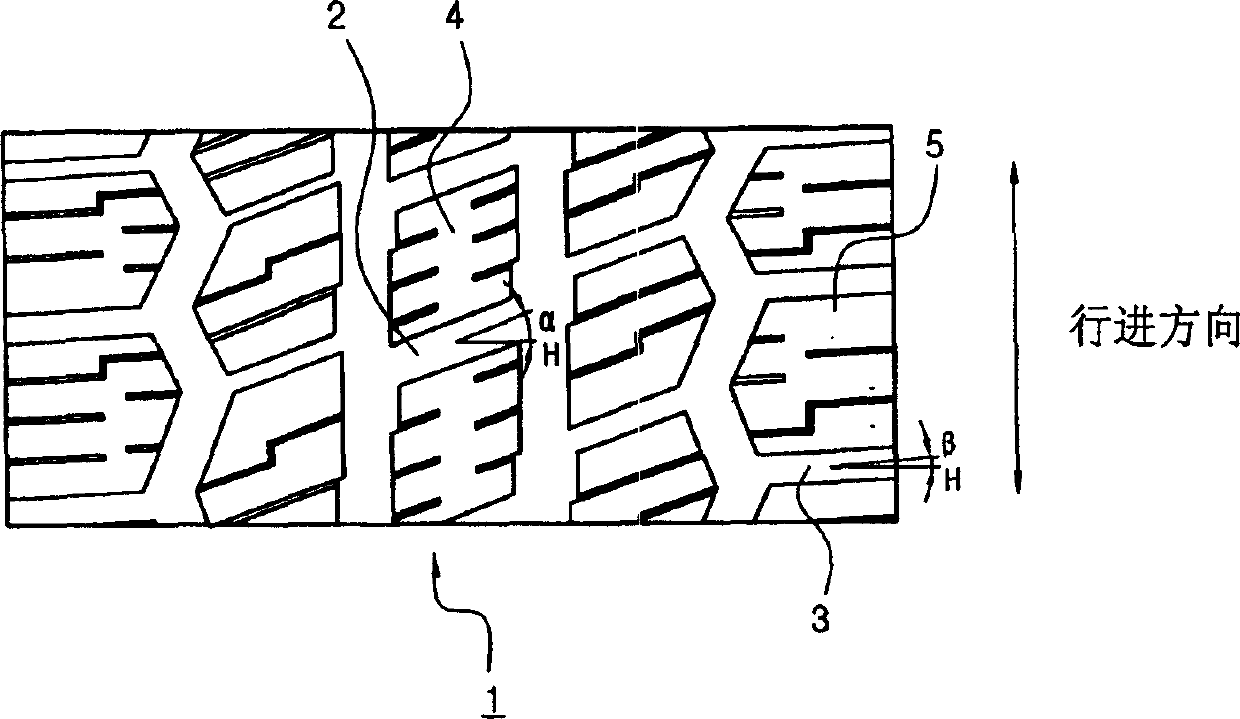

[0014] Fig. 1 is a partial plan view showing the tread structure of the tire tread of the present invention.

[0015] In the tread pattern structure for reducing the turning force of the present invention, the pattern has zigzag transverse grooves. The lateral grooves 2 in the central portion of the tread 1 and the lateral grooves 3 in the shoulder portion are inclined at a predetermined angle with respect to the horizontal transverse line H as a reference. Wherein, the angle α of the transverse groove 2 in the central portion 4 of the tire tread 1 is not less than 7° and not more than 15° based on the horizontal horizontal line H, and the angle β of the transverse groove 3 of the shoulder portion 5 is in the range of The horizontal horizontal line H is above 0° and below 5° of the reference.

[0016] Therefore, the actual contact area of the tire tread 1 accounts for 62-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com