Slack-preventing connector

A connector and anti-loosening technology, which is applied in the direction of connection, parts of the connection device, device for joining/disconnecting the connection parts, etc., can solve the problems of the separation of the plug connector and the socket connector, and the unsatisfactory anti-loosening effect , to achieve the effect of eliminating gaps, ensuring reliability and ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

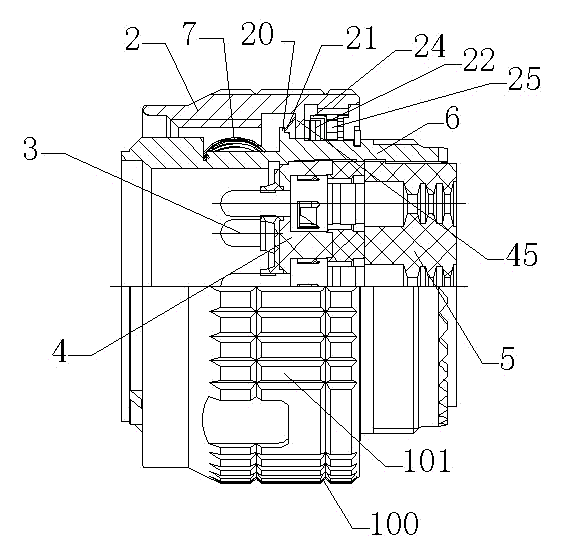

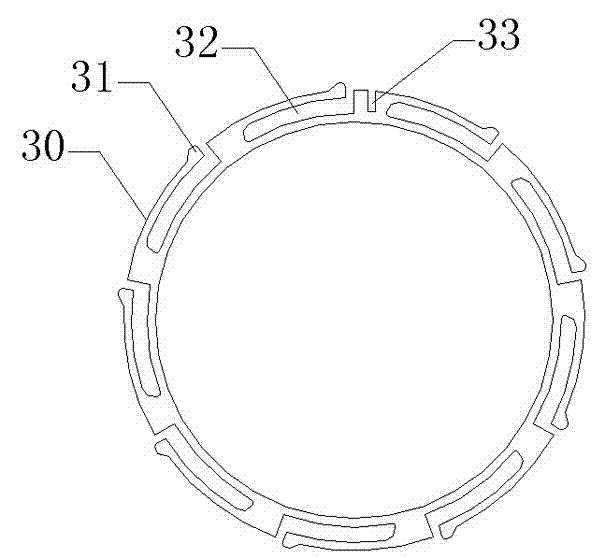

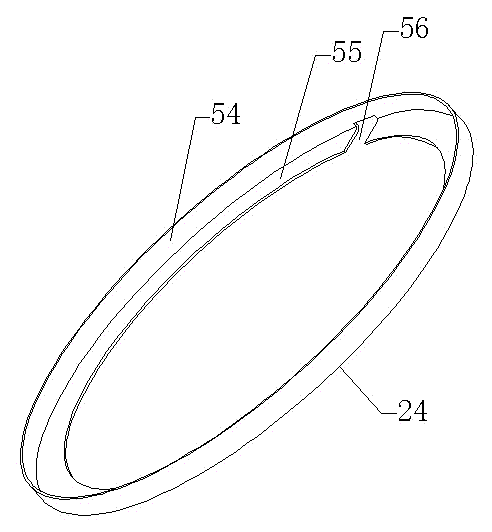

[0018] figure 1 , 2 , 3, and 4, the anti-loosening connector of the present invention includes a conductive connector housing 6, and the connector housing 6 has a cavity through the front and back, and the connector insulator 4 is installed sequentially in the cavity from front to back. , pressing plate and sealing line body 5, have coaxial connector contact installation hole in connector insulator 4, pressing plate and sealing line body 5, in connector contact installation hole, be fixedly installed with connector contact 3. A connecting nut 2 is set on the outer side of the connector housing 6, and two anti-skid ring grooves 100 are provided on the circumference of the connecting nut. , an arched grounding spring 7 electrically connected to the connector housing is also provided in the middle of the connector housing.

[0019] An anti-loosening mechanism is also provided between the connector housing 6 and the connection nut 2 to prevent the connection nut from being rever...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com