Lifting support device for binding ring part of high-voltage-grade device body

A support device and high-voltage technology, applied in packaging and other directions, can solve the problems of less stress points, potential safety hazards, affecting surface quality, etc., and achieve the effect of convenient maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further elaborated below in conjunction with the accompanying drawings of the description.

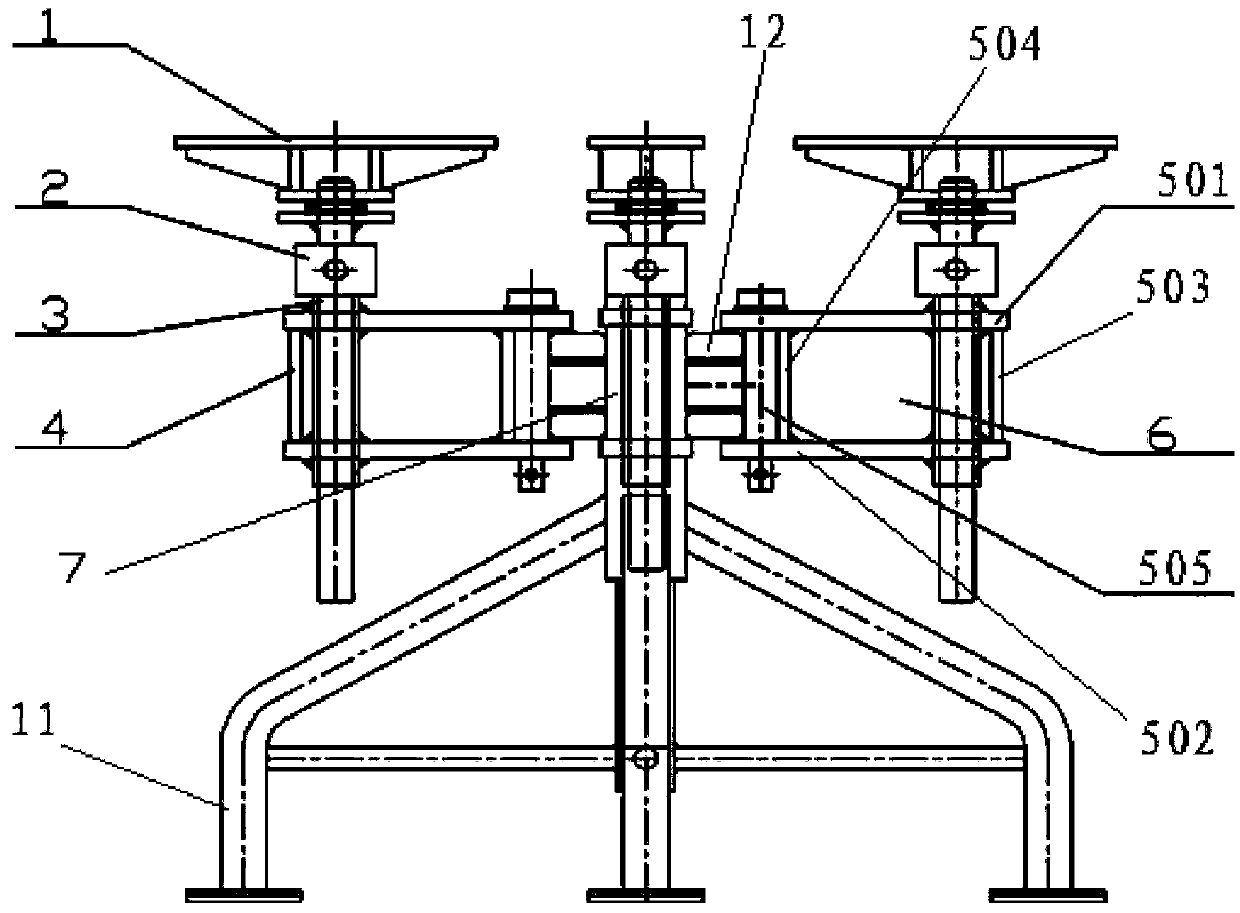

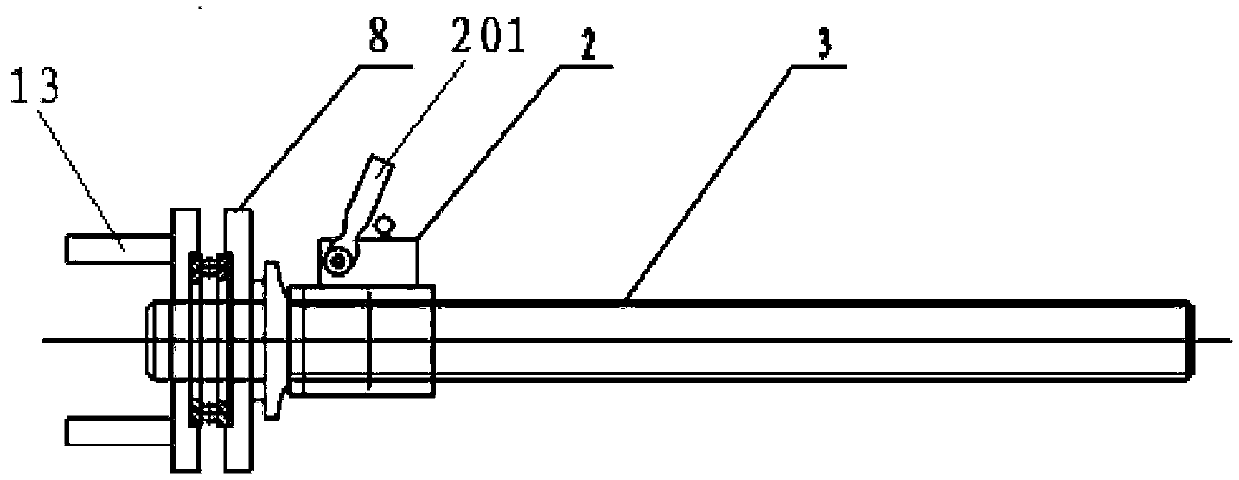

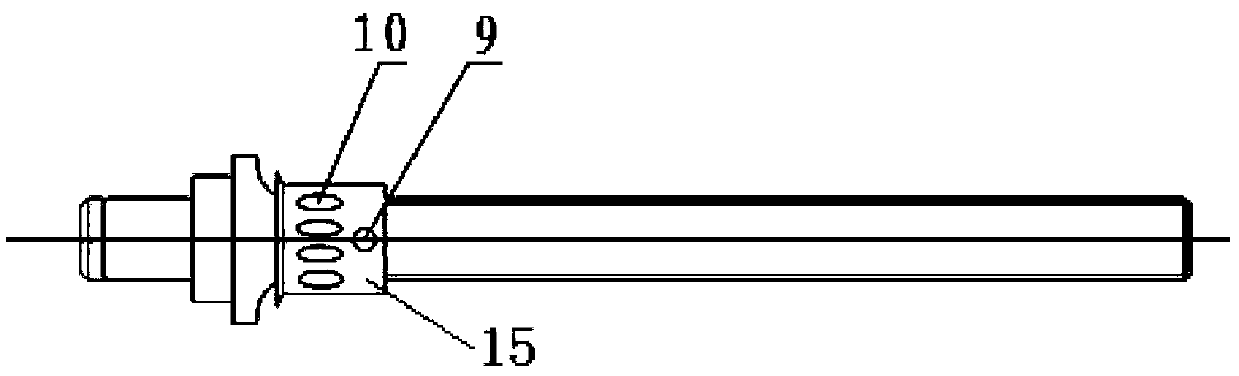

[0022] Such as figure 1 As shown, the present invention is a kind of lifting and supporting device for wrapping the ring part of the body of a large voltage class device, including a supporting structure, a rotating mechanism and a lifting mechanism, wherein there are four supporting structures, and the supporting surface of each supporting structure is equal to the body of the current transformer. It is in plane contact; each support structure is installed on a separate lifting mechanism, and each support structure has a separate rotation mechanism, and at least three plane support bodies of support structures are always guaranteed during the bandaging process.

[0023] The four support structures are installed on the overall base 11 in a manner that can be rotated independently through the bracket 4. The upper part of the overall base 11 has a rot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com