Cooling water circuit system

A circuit system and cooling water technology, which is applied in the direction of engine cooling, coolant flow control, cooling device control device, etc., can solve the problem of poor warm-up performance of lubricating oil and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

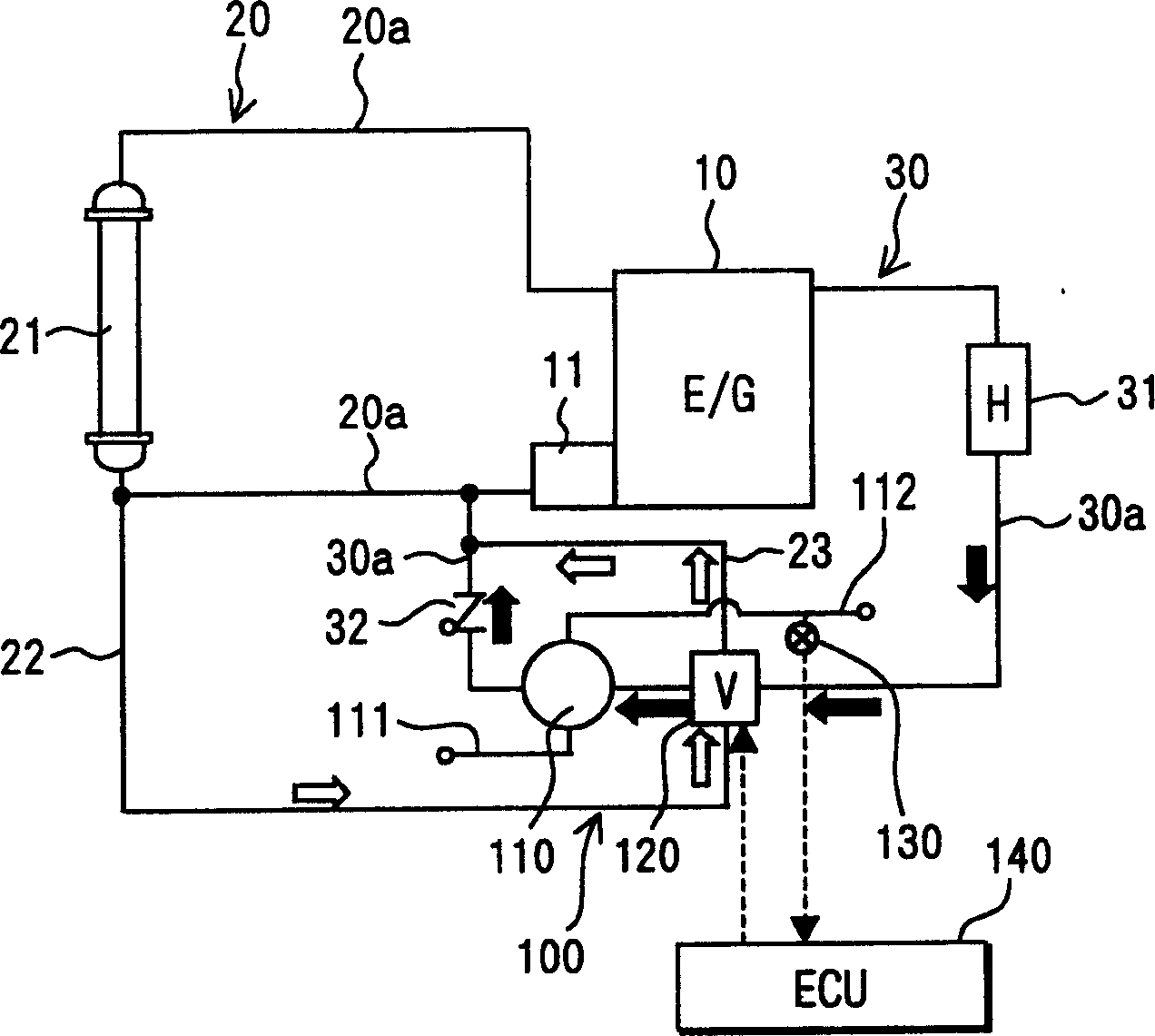

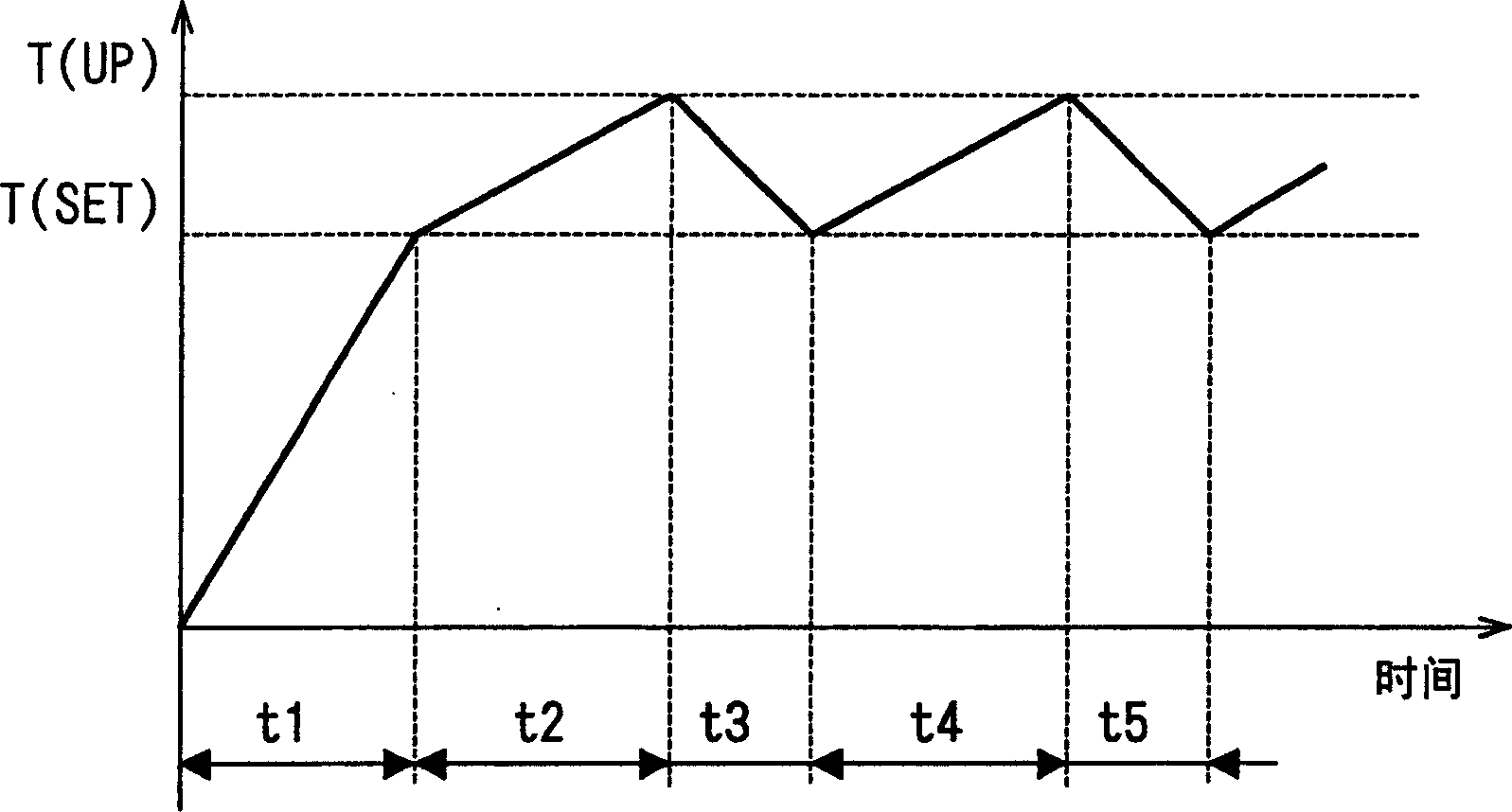

[0017] Refer to the following Figure 1-3 A first embodiment of the present invention is described. The vehicle engine 10 is provided in a cooling water circuit system in which cooling water (coolant) for cooling the vehicle engine 10 flows. The vehicle engine 10 includes an automatic transmission (not shown) provided with a torque converter for operating clutches and various gears of the transmission. Lubricating oil (ATF) is used as a power transmission medium in a torque converter. Cooling water 100 is provided to rapidly increase the temperature of the lubricating oil when the temperature of the lubricating oil is lower than the set temperature after the engine is started, and is also used to cool the lubricating oil to an appropriate temperature during normal operation of the engine.

[0018] The cooling water circuit system of the engine 10 includes a water circuit 20 of the water tank to adjust the temperature of the engine 10 at an appropriate temperature. The water...

no. 2 example

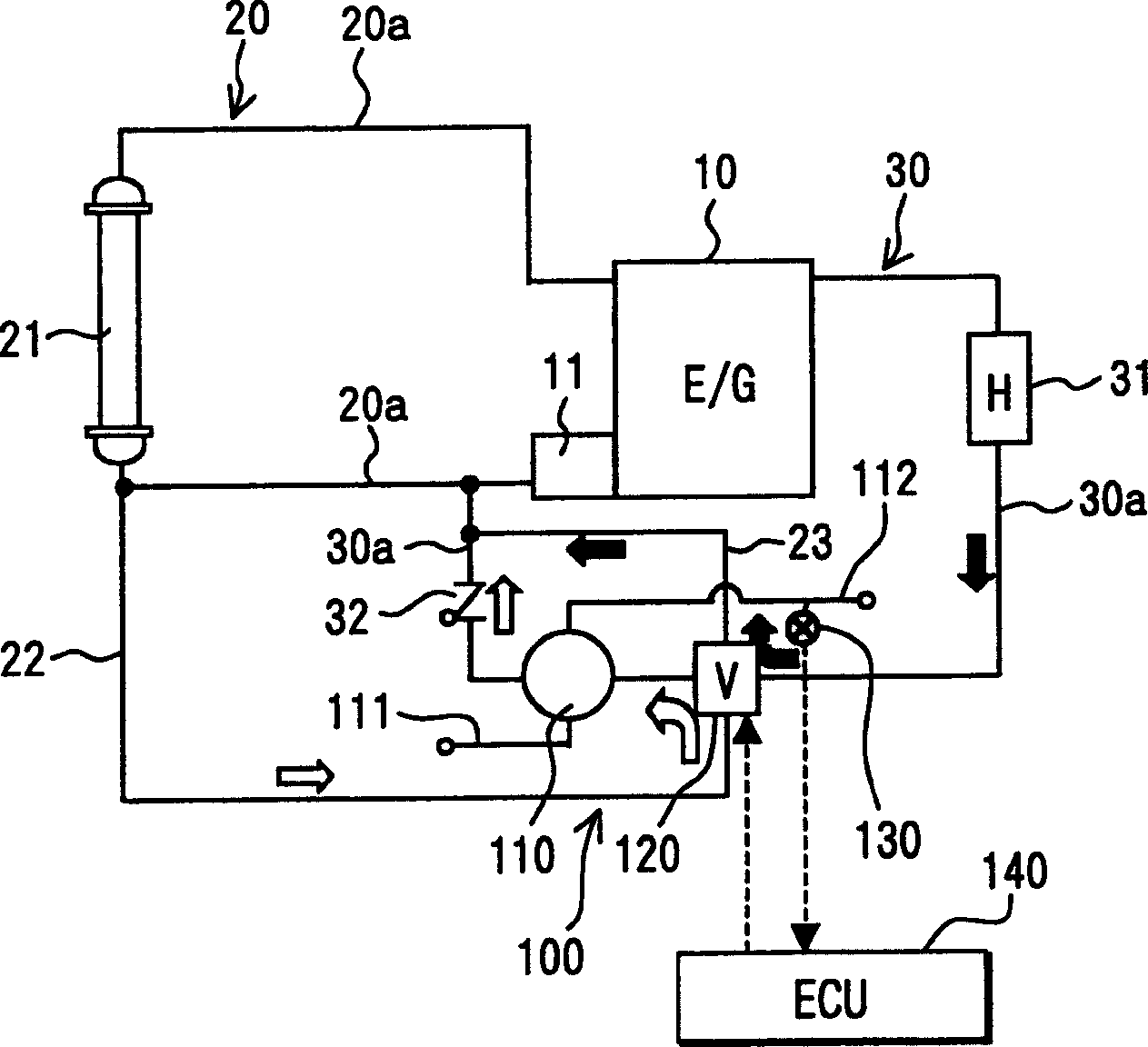

[0036] Refer to the following Figure 4 A second embodiment of the present invention is described. In the second embodiment, a water tank main bypass passage 24 is provided in the cooling water circuit system, through which the cooling water bypasses the water tank 21 . In addition, at the joint portion where the tank water passage 20a at the tank 21 is combined with the tank main bypass passage 24, a temperature controller 26 is provided.

[0037] A branch passage 25 branched from the tank main bypass passage 24 is provided. The refrigerant from the radiator main bypass passage 24 passes through the branch passage 25 and returns to the engine 10 after passing through the oil cooler 110 . A branch bypass circuit 40 is formed by the water tank main bypass passage 24 and the branch passage 25 , so that the refrigerant from the engine 10 returns to the engine 10 through the branch bypass circuit 40 while bypassing the water tank 21 . The branch bypass circuit 40 is the water t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com