Semiconductor manufacturing process

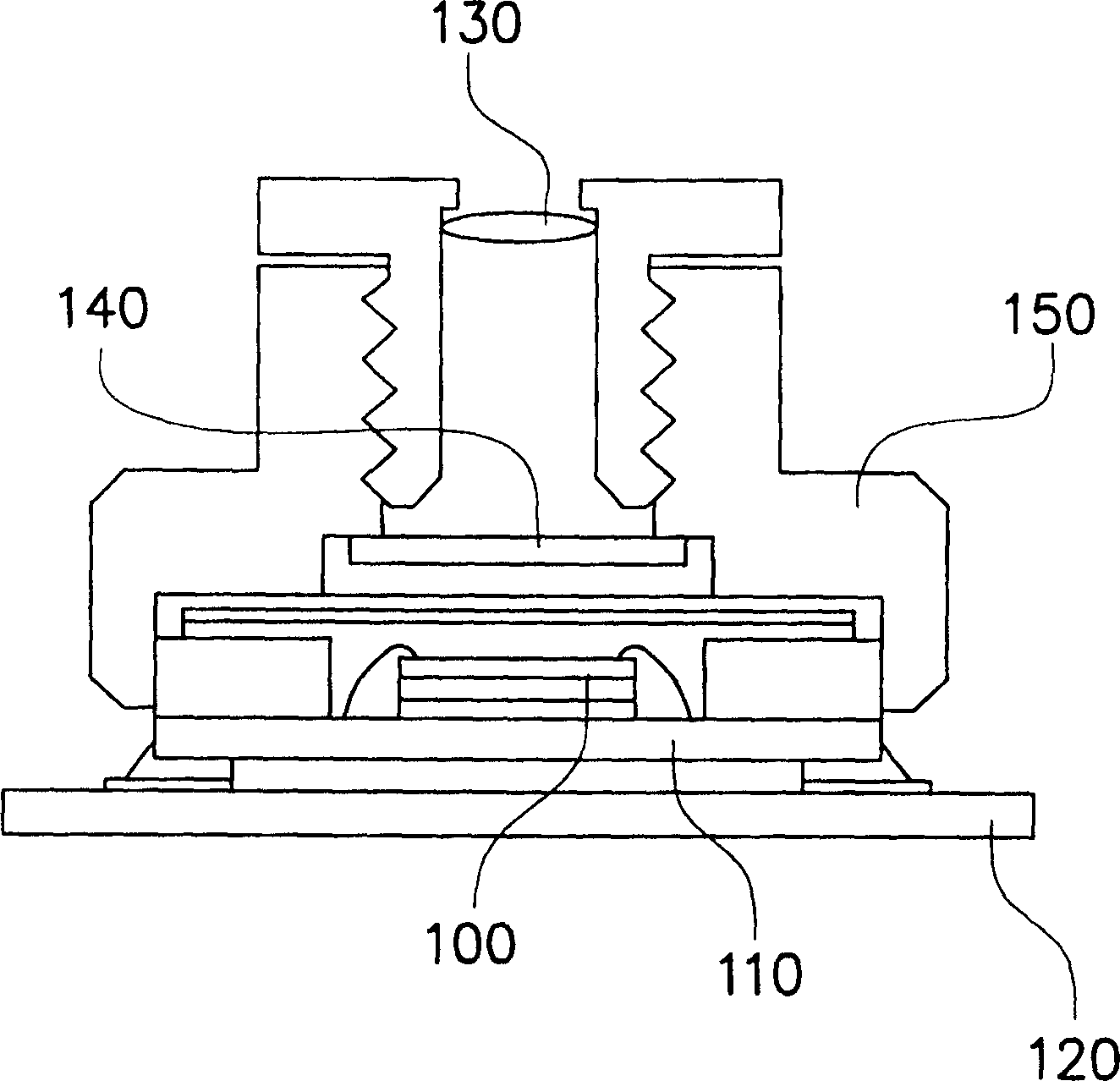

A manufacturing method and semiconductor technology, applied in semiconductor/solid-state device manufacturing, semiconductor devices, electric solid-state devices, etc., can solve the problems of lower packaging efficiency, large volume, lower pass rate of optical sensing modules, etc., to save time and cost , to avoid the effect of particle pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

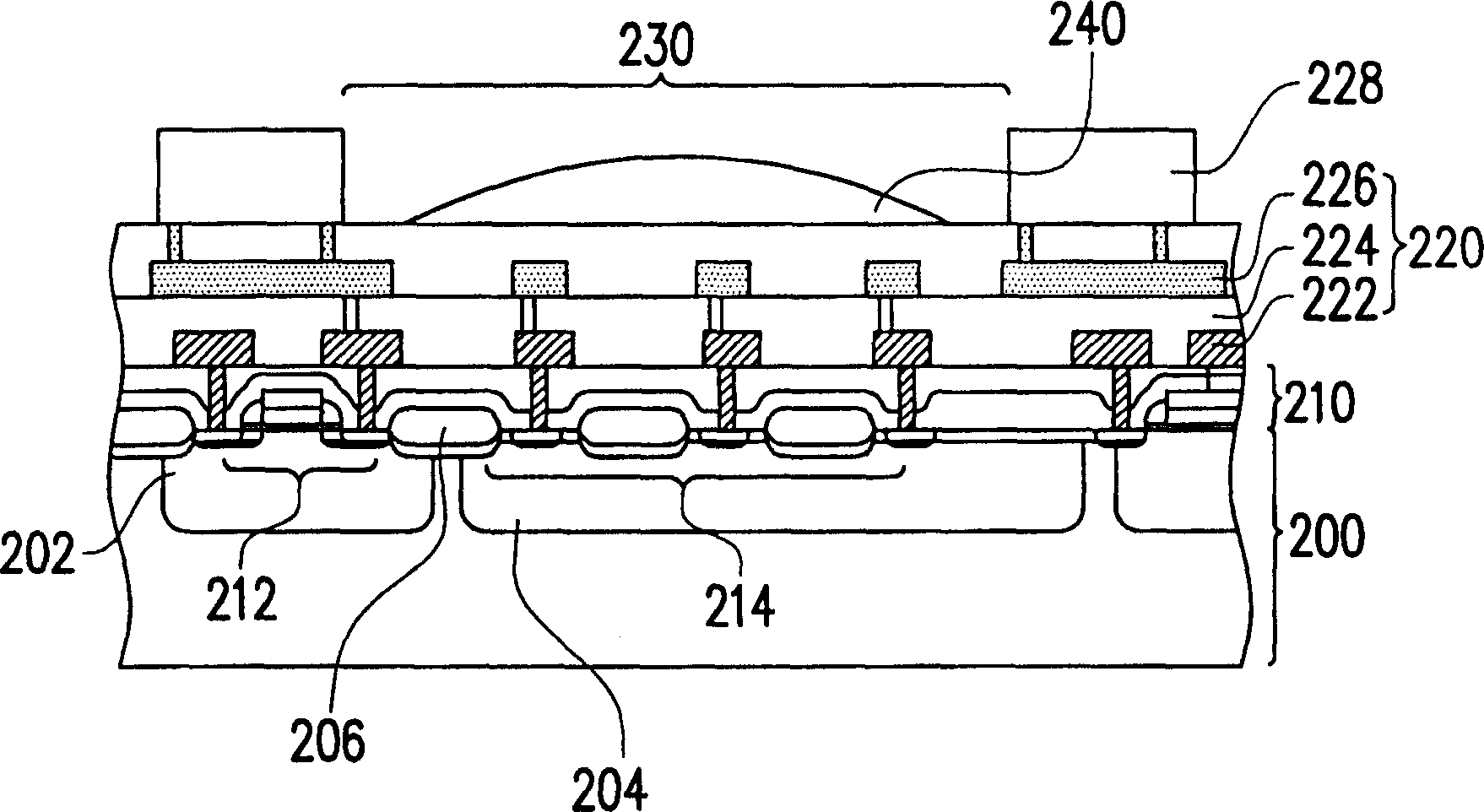

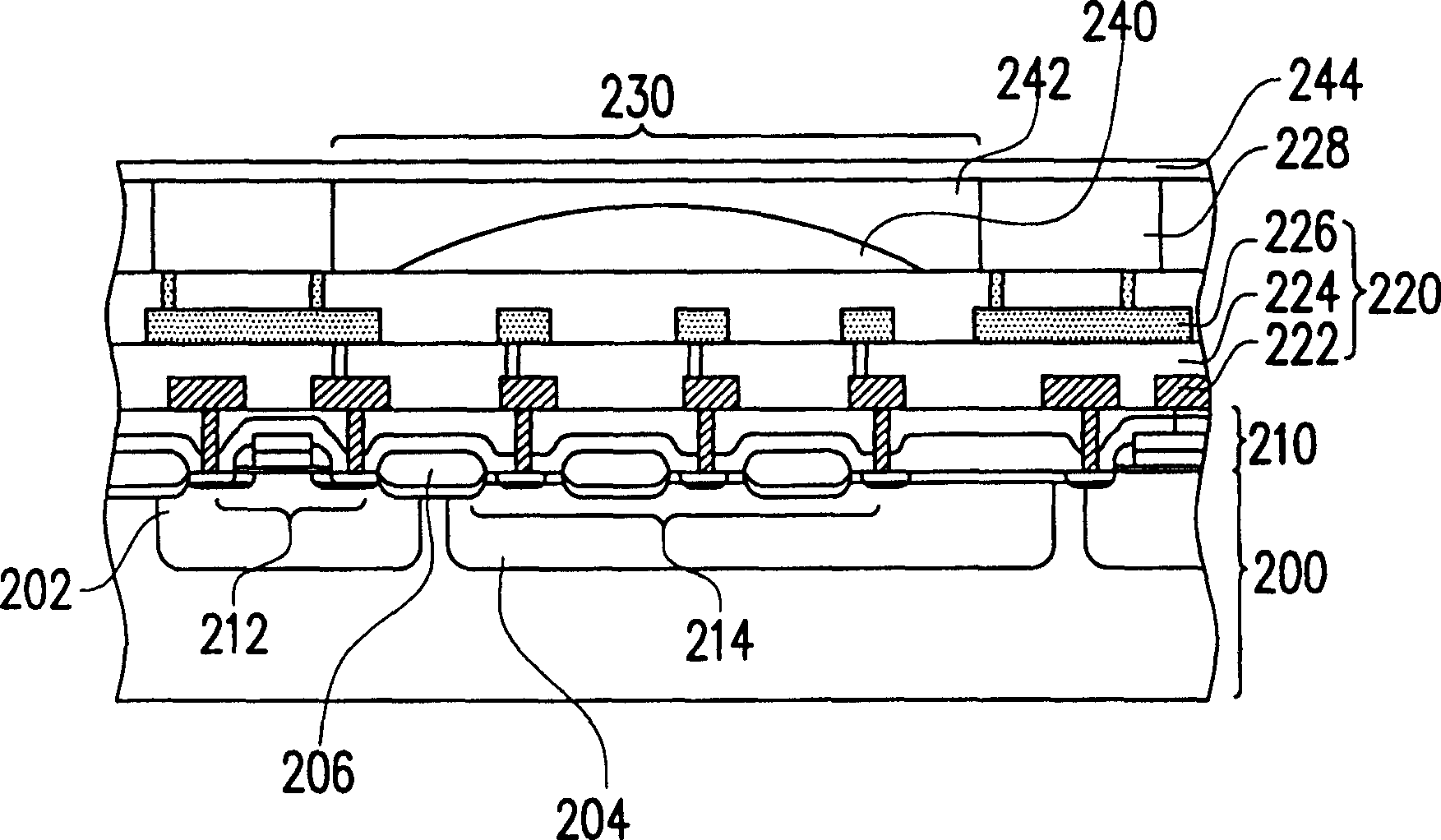

[0029] Please refer to Figure 2A ~2E, which sequentially show a schematic flow chart of a semiconductor manufacturing method according to a preferred embodiment of the present invention. Please refer to Figure 2A , a wafer 200 is provided, and the active element 212 and the photodiode array 214 of the active layer 210 are formed on the wafer 200 through a multi-channel mask process, wherein the active element 212 is, for example, a metal oxide semiconductor (MOS) transistor, which is commonly used There are PMOS transistors or CMOS transistors. The PMOS transistor is generally located on the surface of the silicon substrate (ie wafer) 200 of the N-type well 202, and the photodiode array 214 may be located on the surface of the silicon substrate 200 of the P-type well 204, and then a gate oxide layer ( gate oxide) 206 to separate the active device 212 from the photodiode array 214 . Then use the second masking process to determine the contact window of the gate (source and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com