Electric vacuum cleaner

A vacuum cleaner and electric technology, applied in the direction of vacuum cleaners, cleaning equipment, household appliances, etc., can solve the problems of sudden closing, impact of the main body 15, etc., and achieve the effect of high performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

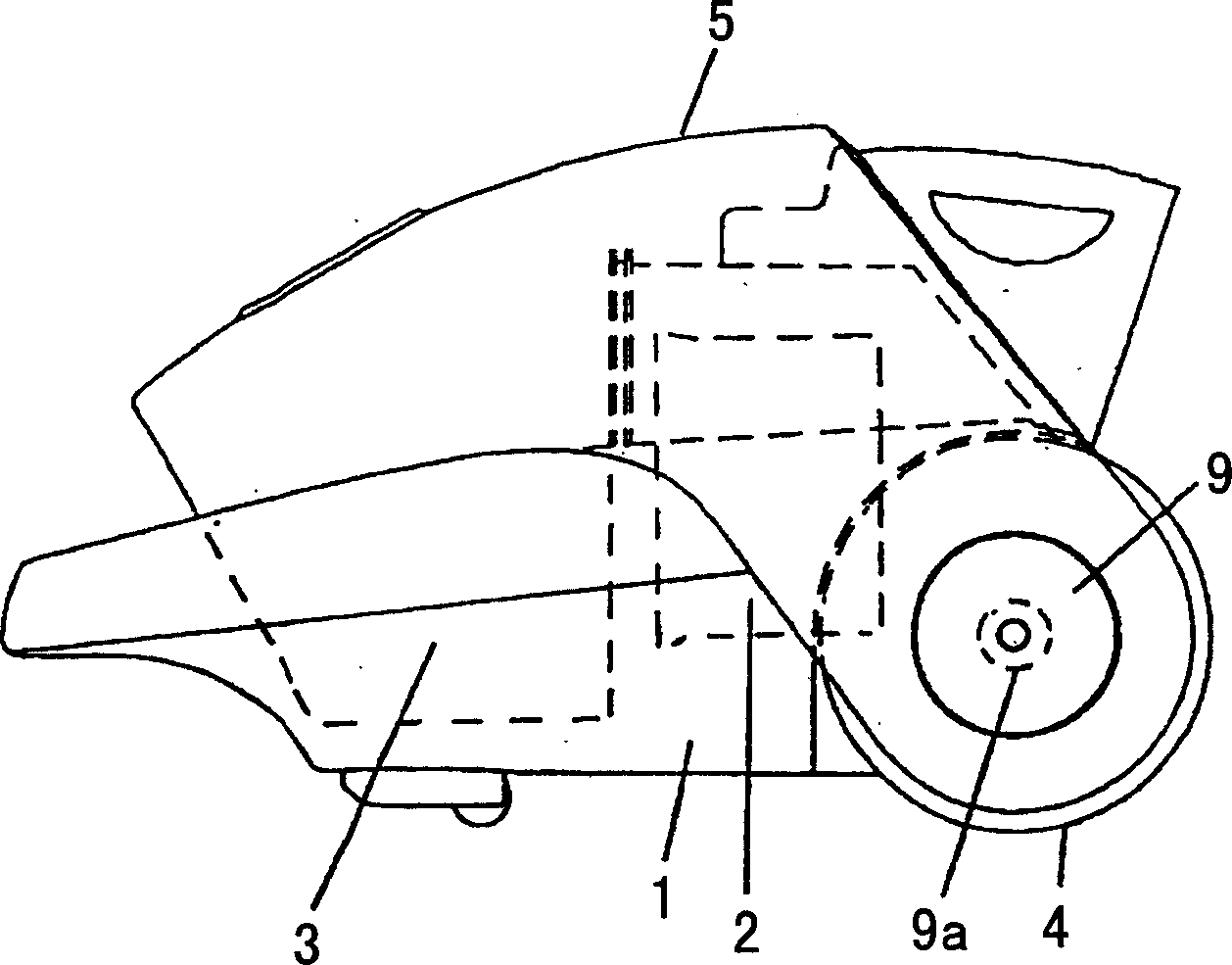

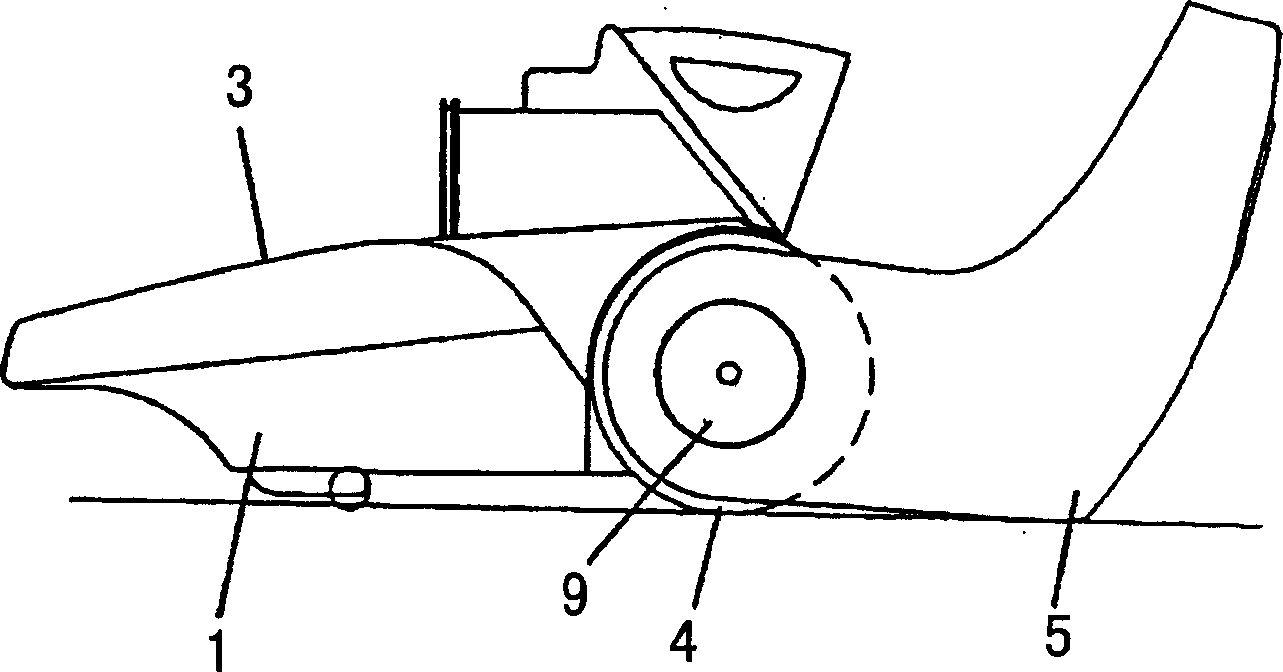

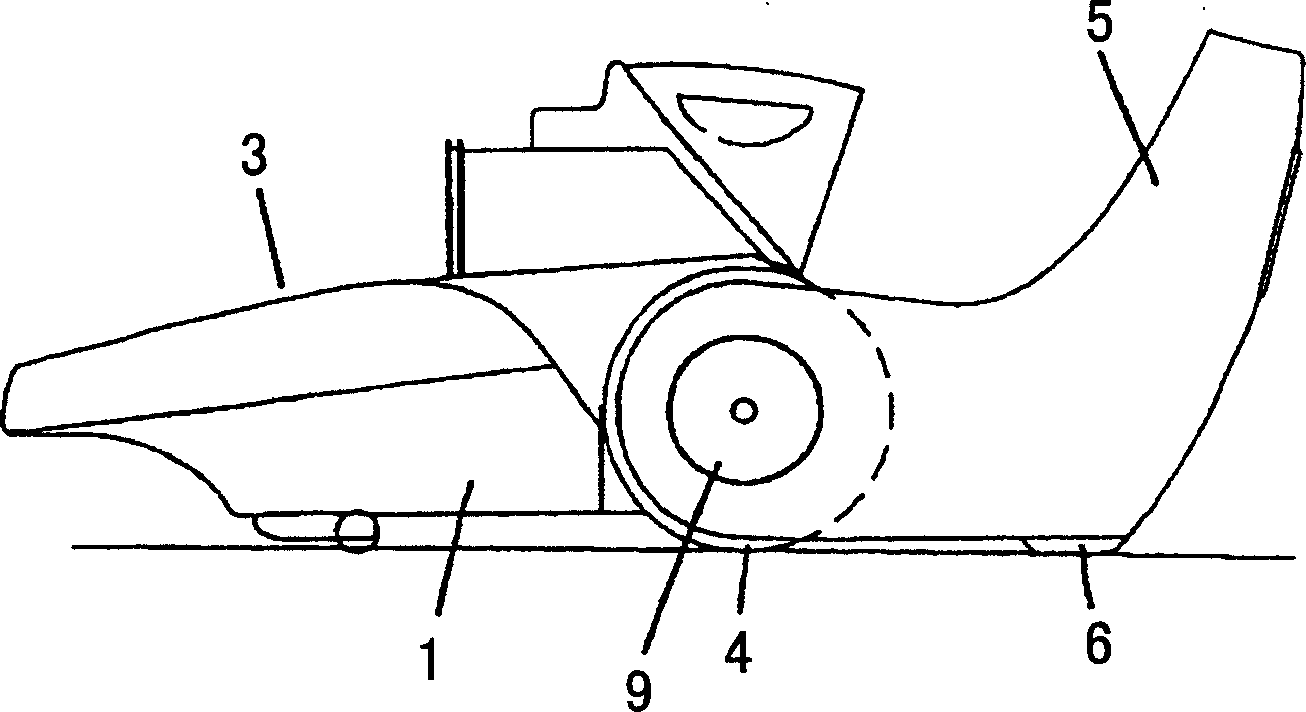

[0035] first pass Figure 1 to Figure 6 The first embodiment of the present invention will be described.

[0036] figure 1 Among them, the inside of the main body 1: there is an electric fan 2 for attracting dust, and a dust collection chamber 3 for collecting dust connected with the suction head for attracting dust, and the walking of the main body 1 is provided at the bottom of the rear Device is mobile wheel 4. The dust collection chamber cover 5 covering the dust collection chamber 3 can rotate around the same center as the rotation center of the moving wheel 4 .

[0037] In addition, in Figure 3 ~ Figure 5 Among them, 6 is a shock absorbing part arranged at the position where the dust collection chamber cover 5 is in contact with the ground when it is rotated, and 7 is a shock absorbing part arranged at the position where the dust collection chamber cover 5 is in contact with the ground when it is rotated. Approximately parallel surfaces at the point of contact. In...

Embodiment 2

[0044] Use below Figure 7 ~ Figure 13 A second embodiment of the present invention will be described. Here, the same components as those in the above embodiment are given the same symbols, and their descriptions are omitted.

[0045] The part 10 is a side protrusion of the dust chamber cover provided near the rotating part of the dust chamber cover 5 . The component 11 is a protrusion on the side of the moving wheel cover, and is provided at a position capable of contacting the protrusion 10 on the side of the dust collection chamber cover located inside the moving wheel cover 9 . When the dust collection chamber cover 5 rotates, the dust collection chamber cover side protrusion 10 and the moving wheel cover side protrusion 11 contact each other, thereby preventing the dust collection chamber cover 5 from further rotating. Additionally, if Figure 13 As shown in , the dust chamber cover side protrusion 10 is also pushed inward by the moving wheel cover side protrusion 11 t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com