Tolerance deviation compensation element

A component and support component technology, applied in the field of span devices, can solve problems such as metal plate deformation, roof shell application, and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

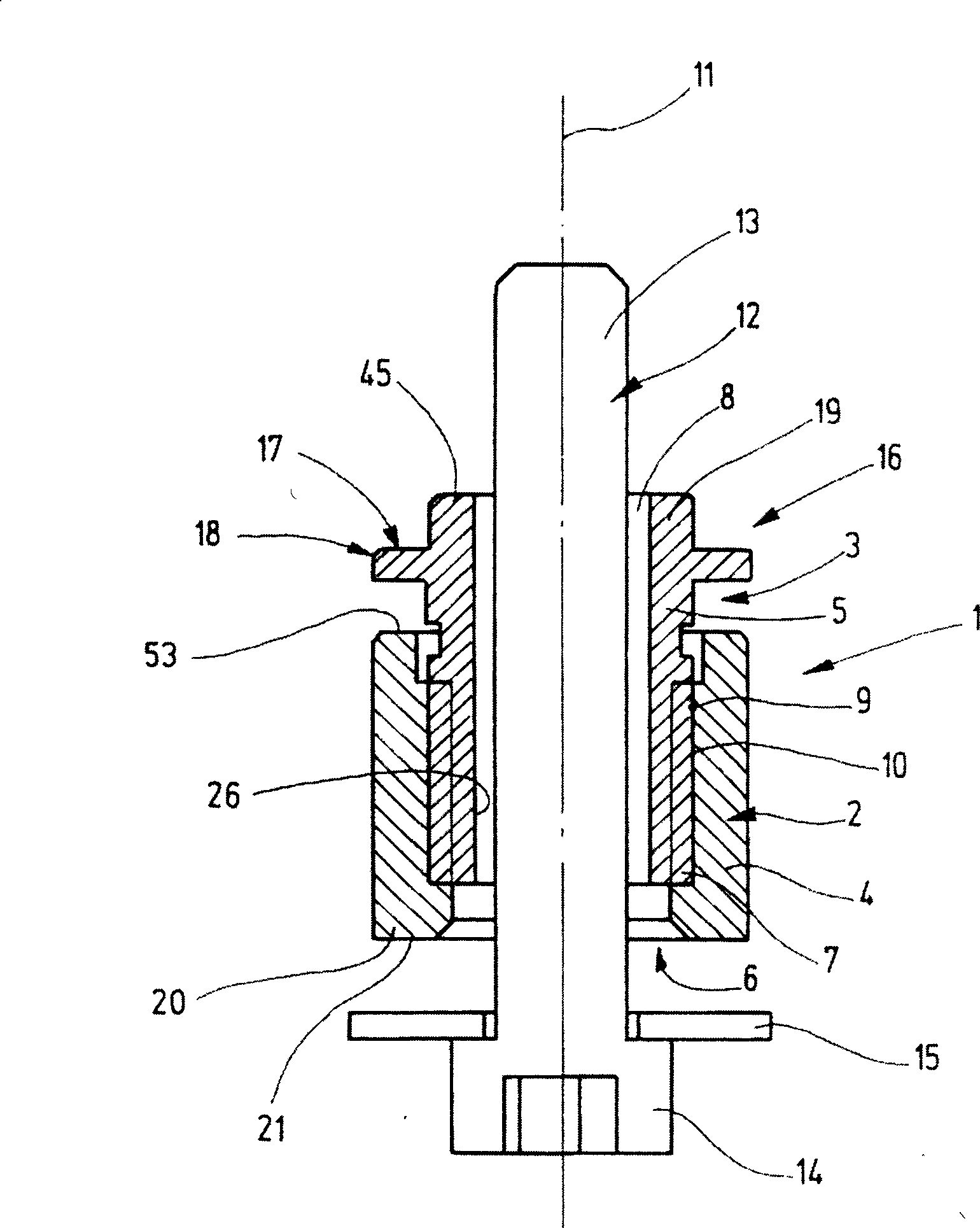

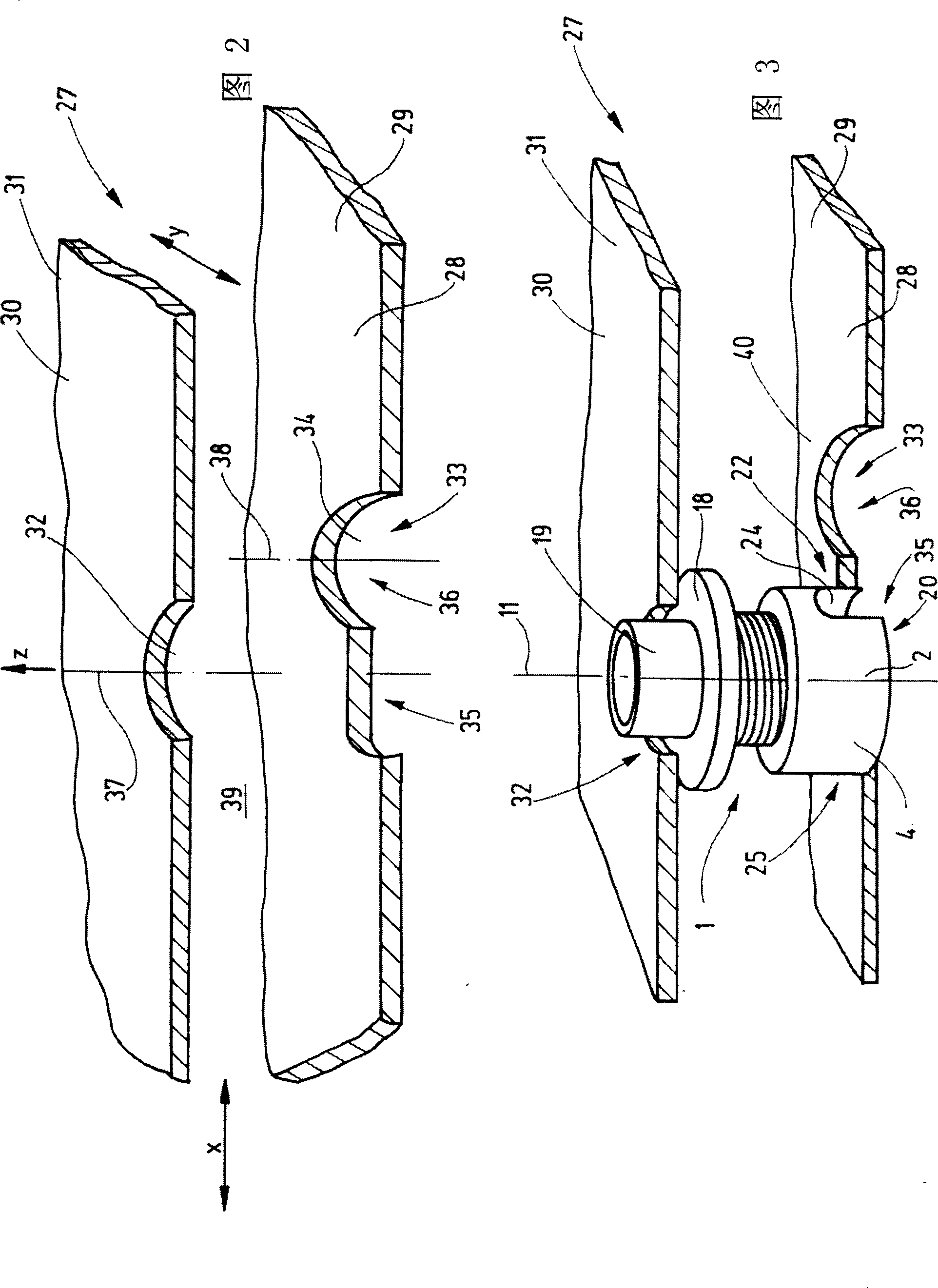

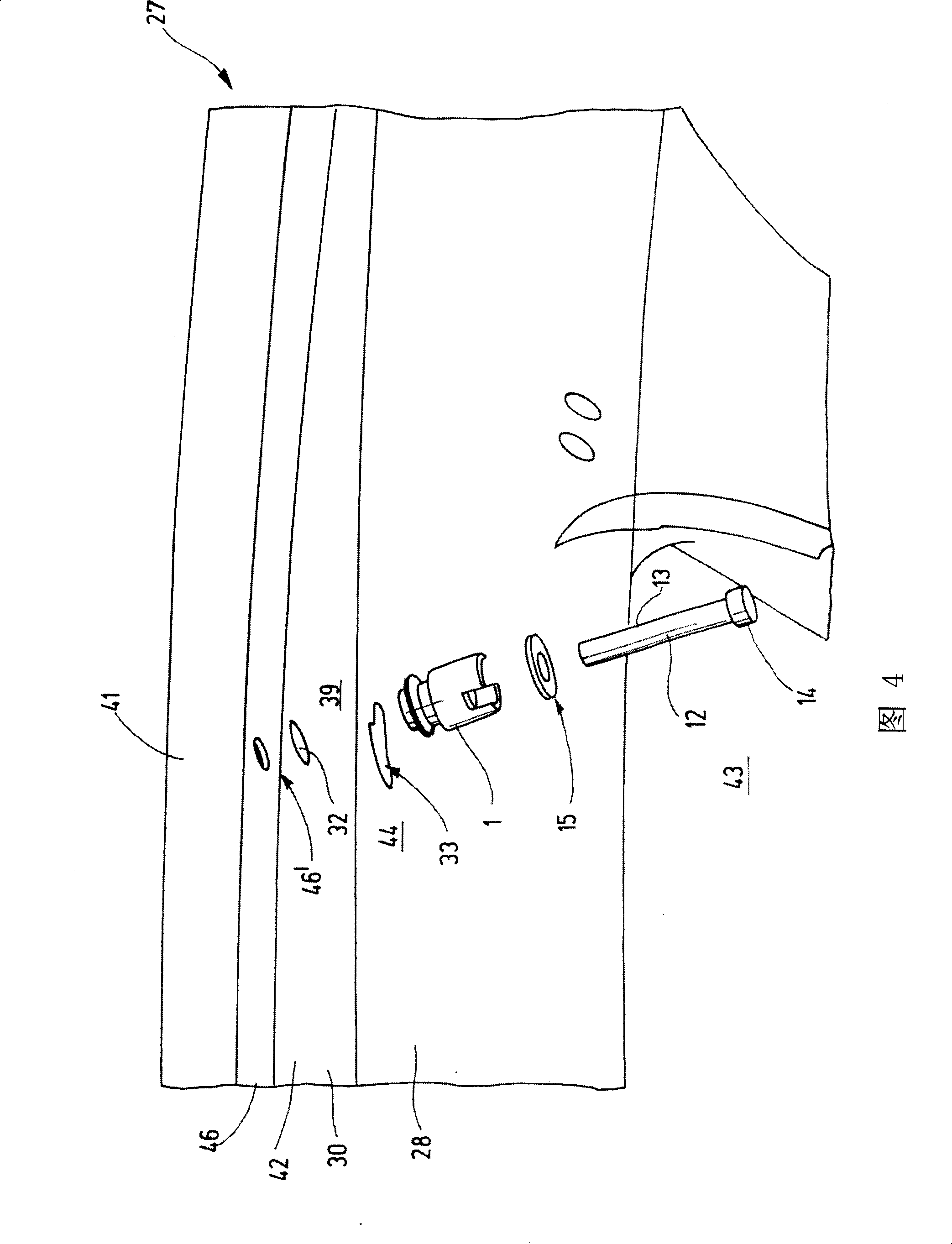

[0013] figure 1 A span device 1 is shown for mounting a roof strip on the roof of a vehicle. The span device 1 has a support part 2 and a counter support part 3 . The support part 2 is formed as an outer sleeve 4 and the counter-support part 3 is formed as an inner sleeve 5 . The outer sleeve 4 has an axial through hole 6 with an internal thread 7 . The inner sleeve 5 is equipped with an axial penetration groove 8 . An outer thread 10 is held on the outer surface 9 of the inner sleeve 5 . The inner thread 7 and the outer thread 10 are screwed together, ie the inner sleeve 5 is screwed axially into the outer sleeve 4 . Axial in figure 1 is marked with centerline 11.

[0014] From figure 1 It can be seen that a shaft section 13 with a thread 12 passes through the passage groove 8 and the corresponding part of the passage hole 6 . A washer 15 with a larger diameter is arranged at the head 14 of the thread 12 . From figure 1 It can be seen that the anti-support part 3 pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com