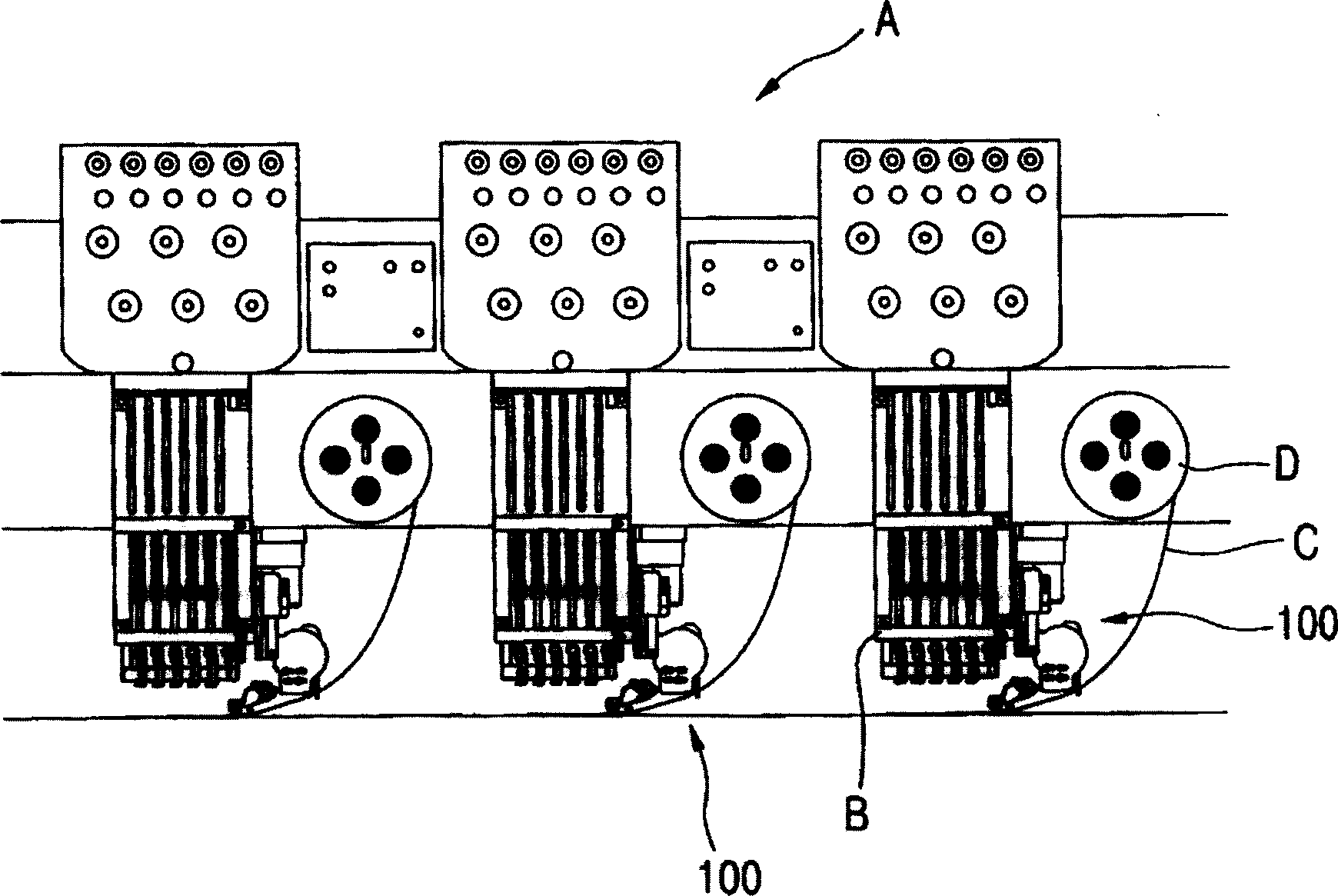

Metal plate duplex supplying device for embroidery machine

A supply device and metal sheet technology, applied to the mechanism of embroidery machines, embroidery machines, auxiliary devices, etc., can solve the problems of production efficiency degradation and prolongation of production time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

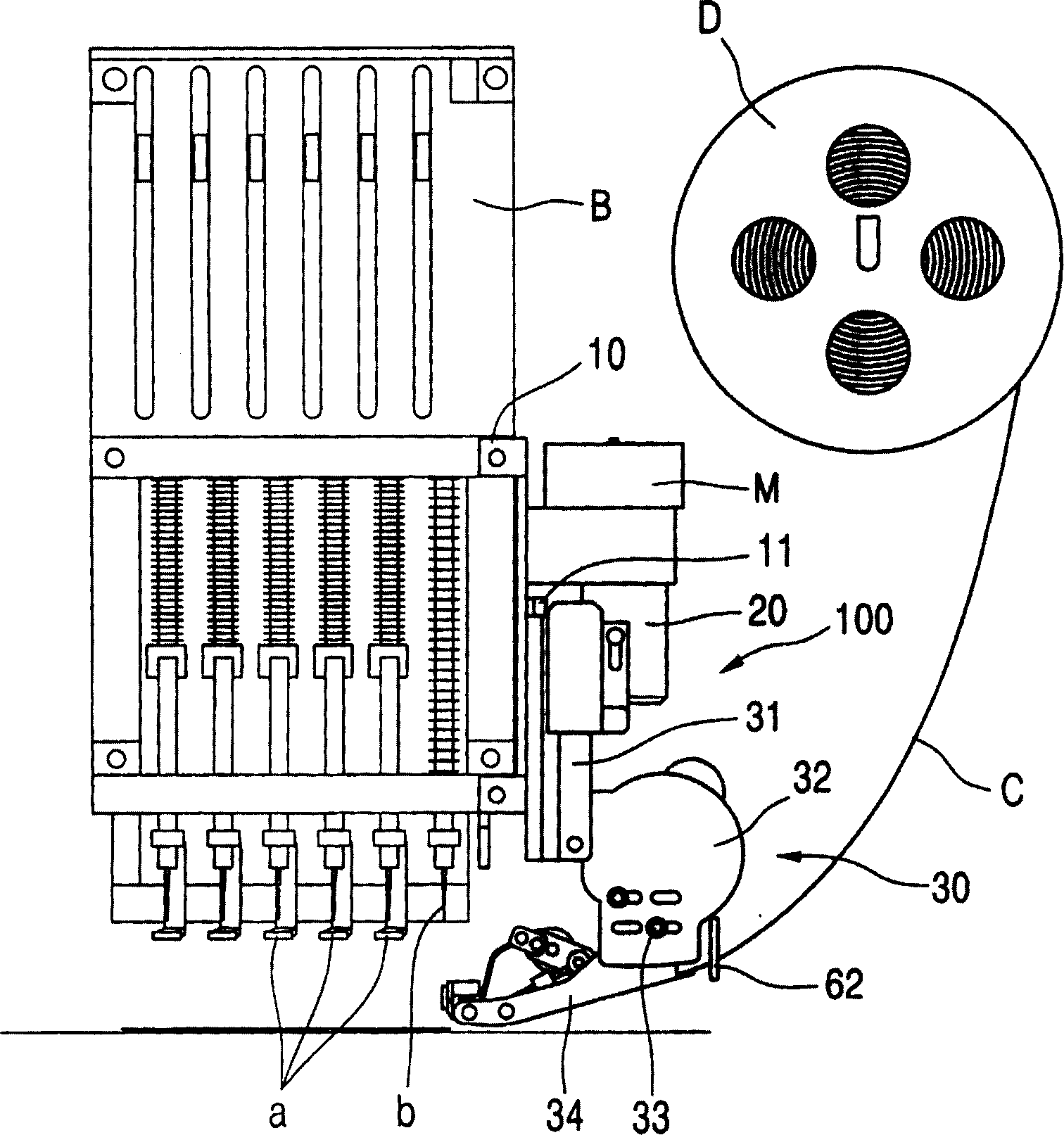

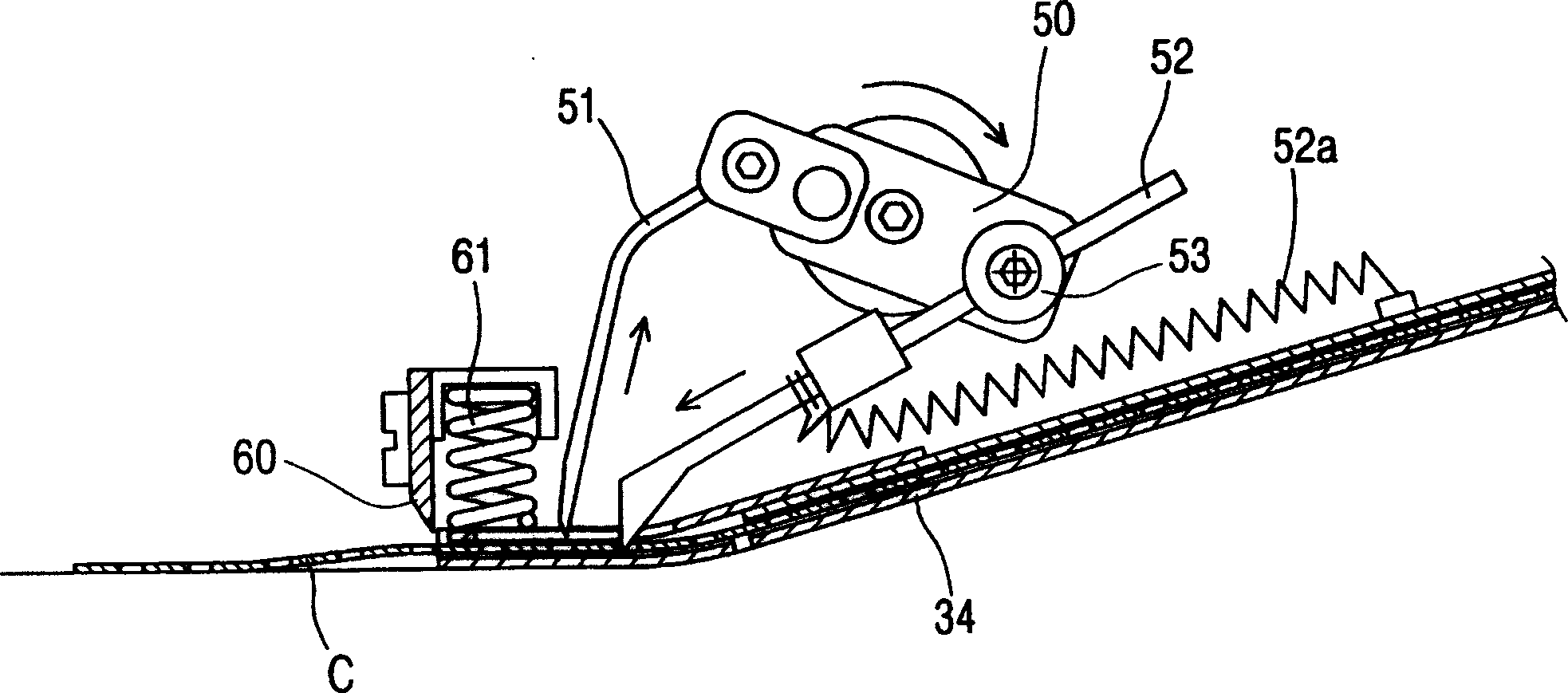

[0037] Hereinafter, an embodiment of the sheet metal double feeding device of the present invention will be explained in detail with reference to the accompanying drawings. In the drawings, the same reference numerals are used for the same elements, and detailed descriptions of related functions or elements are also omitted to avoid ambiguity.

[0038] Figure 4 is a front view of a sheet metal double feeding device according to the present invention, Figure 5 is a rear view of the sheet metal double feeding device according to the present invention. Figure 6 is the right side view of the metal sheet double feeding device according to the present invention;

[0039] The basic structure of the sheet metal supply device of the present invention is the same as that disclosed in Korean Application No. 367355 filed by the applicant of the present invention. The sheet metal feeding device of the present invention also includes elements for alternately driving two push rods moun...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com