Impactless vibration steel rail

A shock vibration and rail technology, applied in the joints of rails, tracks, roads, etc., can solve the problems of affecting passengers' rest and physical and mental health, increased shock vibration and noise, large shock vibration and noise, and achieves simple structure and reduced impact Effects of vibration and noise, shock-free vibration and noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

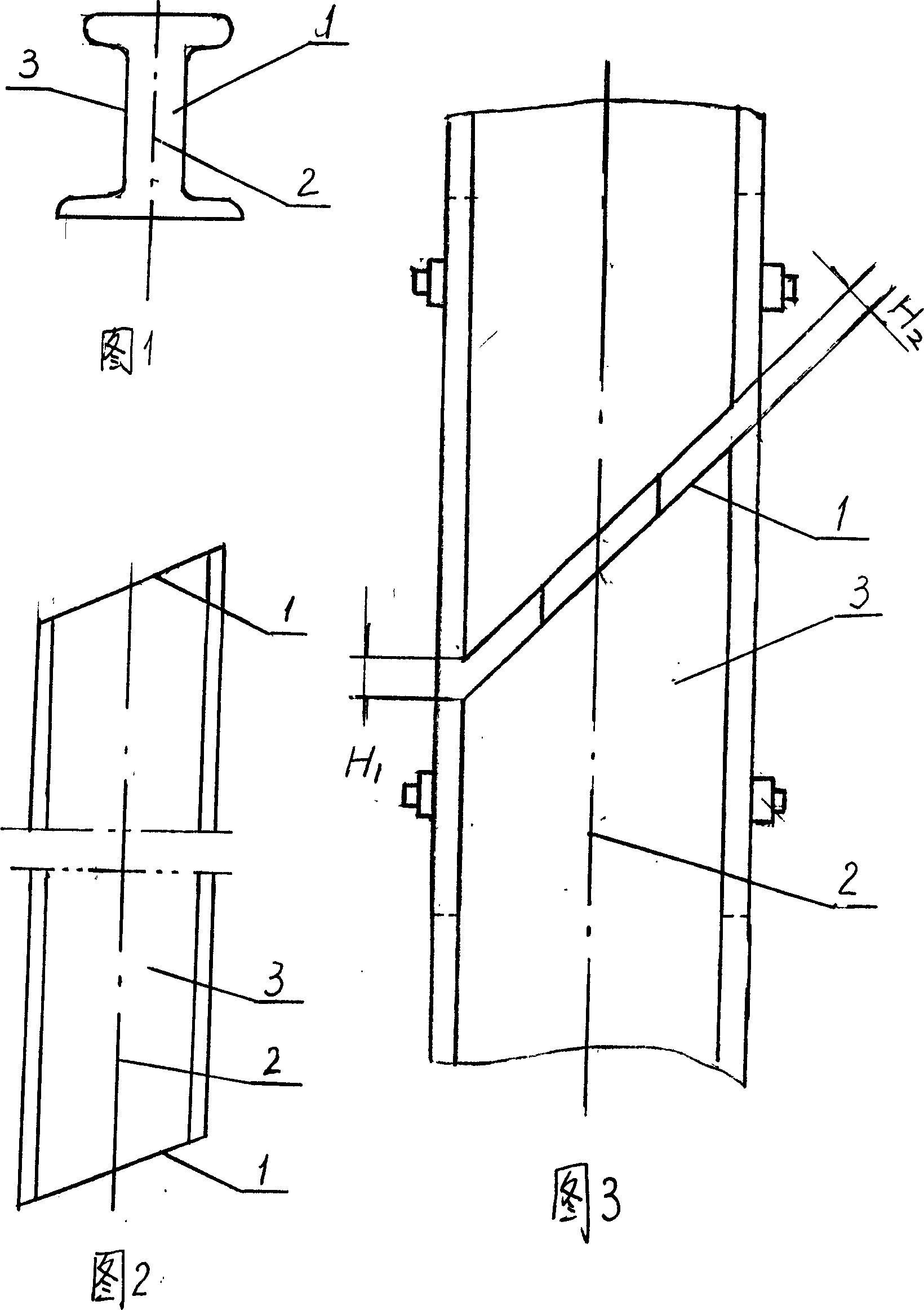

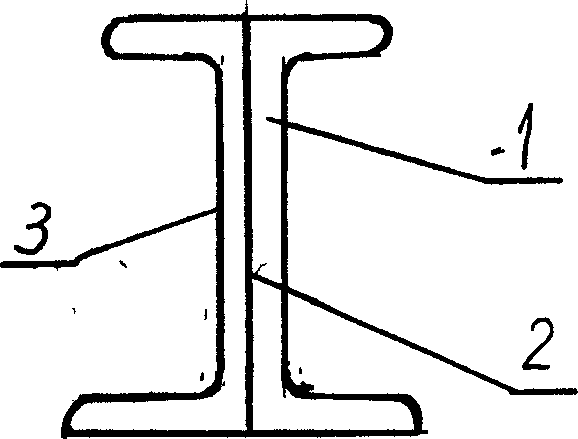

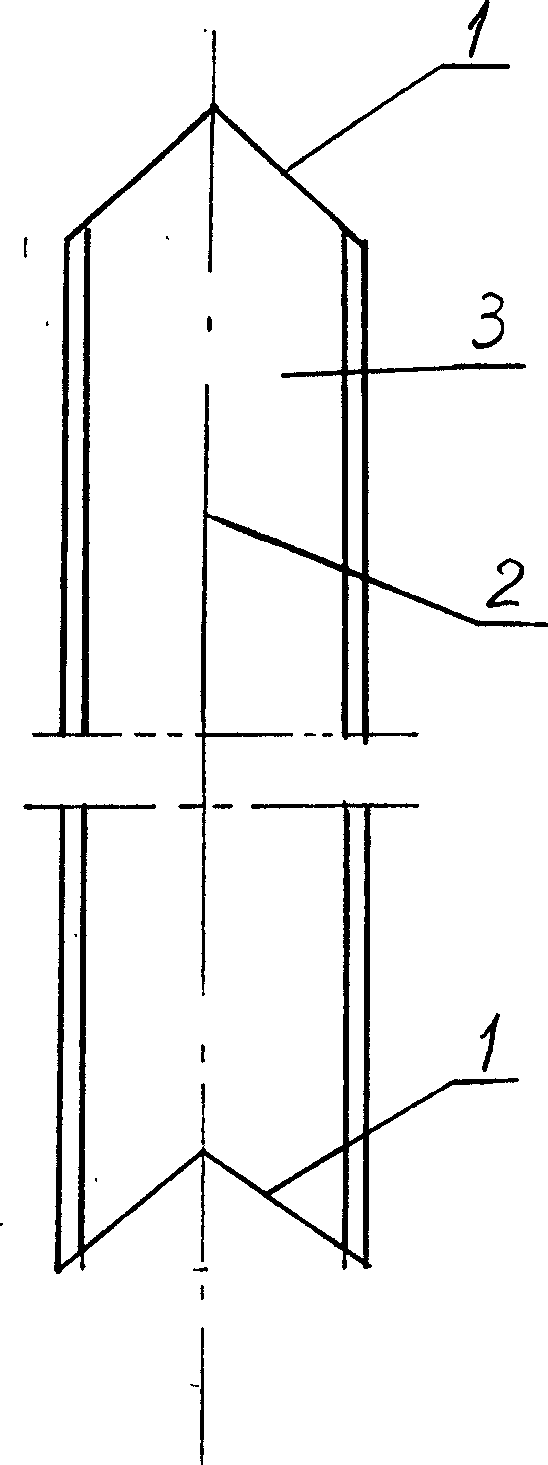

[0014] The best embodiment of the present invention will be described in detail below in conjunction with the accompanying drawings. A steel rail without shock and vibration, the end faces 1 of the two ends of the rail 3 are arranged in an inclined shape with respect to the longitudinal vertical surface 2 of the rail 3 in the horizontal direction, that is, the included angle is not equal to 90°, and the end faces 1 of the two ends are parallel to each other; or the rail The end faces 1 at both ends of 3 are respectively in the shape of a boss angle and a groove shape, and the size and angle of the boss angle end face and the groove angle end face are the same.

[0015] When the rail 3 is laid, the two ends of the rails with inclined end faces are connected, or the two ends of the rails with convex and concave angular end faces are matched, and the angular end faces of the convex platforms are located in the angular end faces of the grooves; the distance between the end faces is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com