Side curtain airbag system

An airbag and curtain technology, which is applied in the field of side curtain airbag systems, can solve the problems of different deployment times of curtain airbags, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

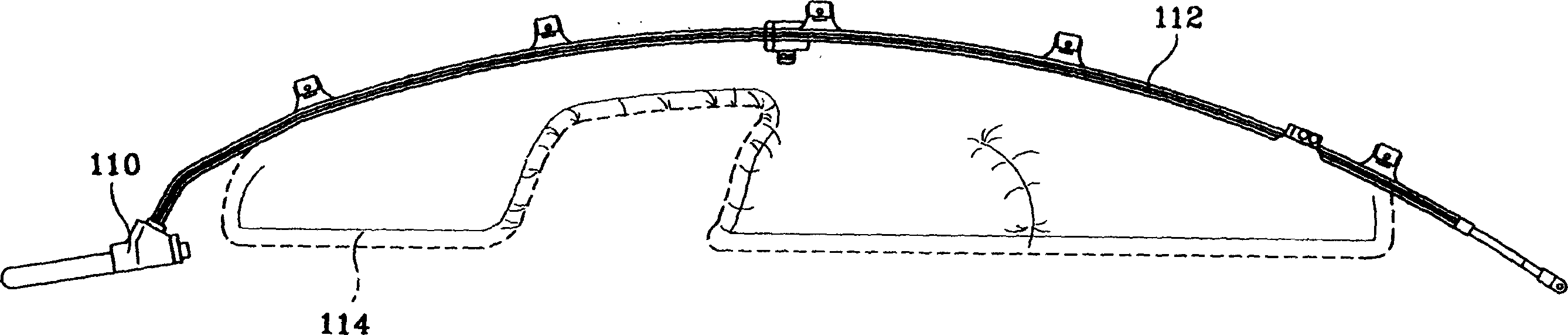

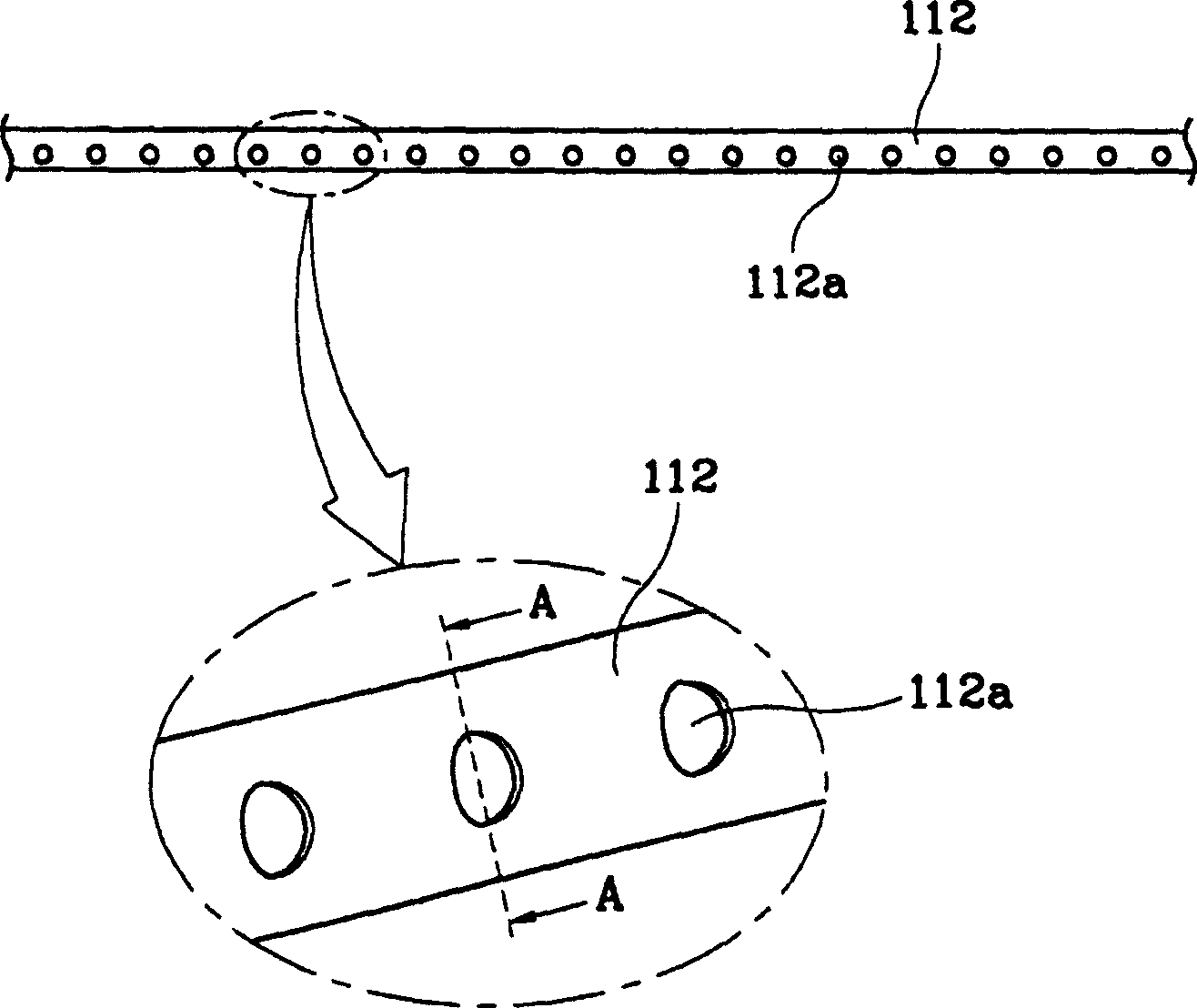

[0013] refer to figure 1 and 2 A side curtain airbag system for an automobile includes a gas pipe 112 that supplies gas generated from an inflator 110 to a curtain airbag 114 . The gas pipe 112 may be a hose, a tube, an aluminum pipe, or a steel pipe, and is formed with a plurality of injection films 112 a to supply gas to the curtain airbag 114 . The gas injection film 112 a is formed where the gas pipe 112 and the curtain airbag 114 are connected.

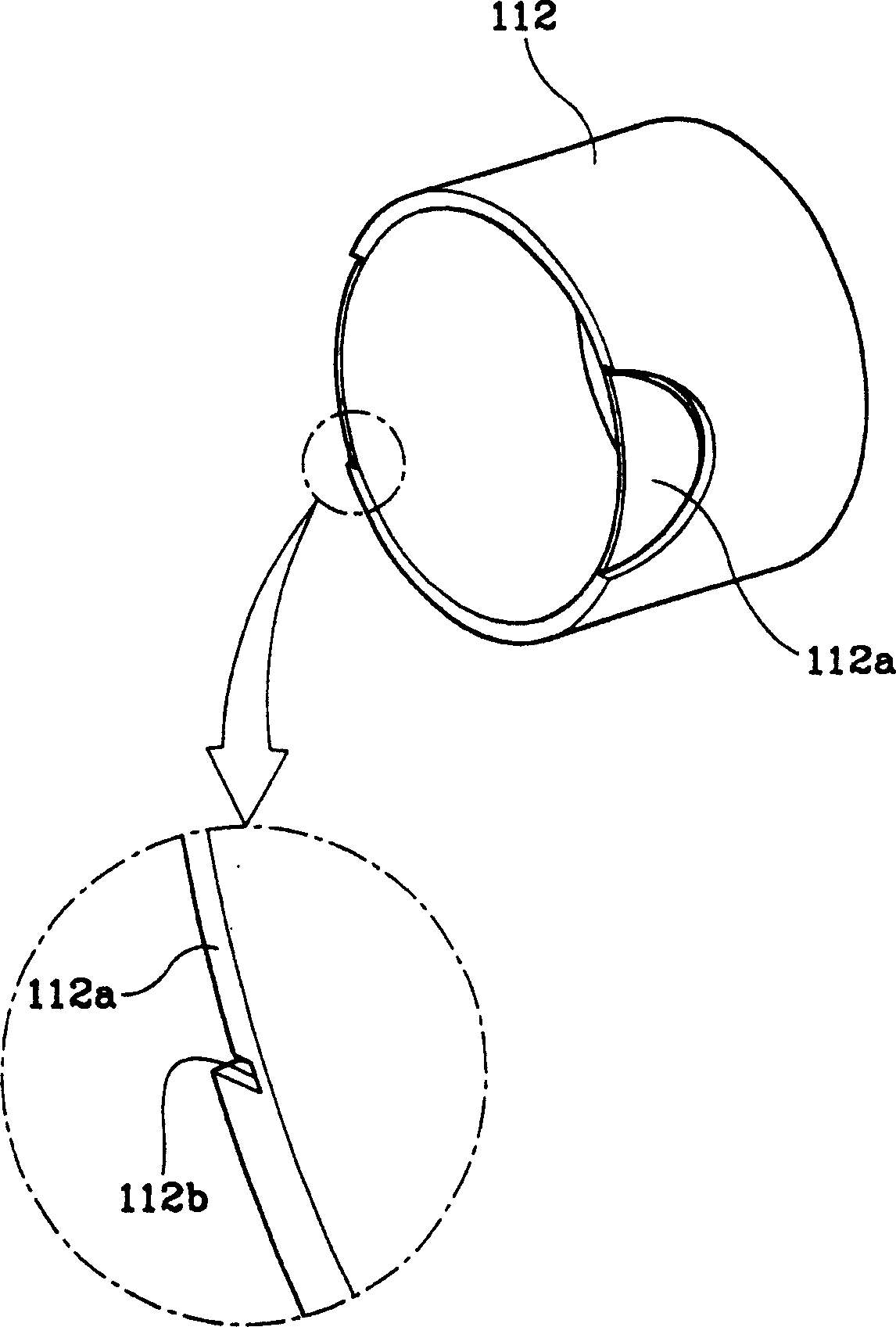

[0014] Such as image 3 and 4 As shown, gas injection film 112a is placed over gas tube 112 and may be composed of the same material as gas tube 112 . The gas injection film 112a may be made of a thinner film relative to the thickness of the gas tube 112 (ie, the difference between the thicknesses of the outer diameter and inner diameter of the gas tube 112). The outer shape of the gas injection film 112a is circular, but may also be elliptical, polygonal, or other shapes. The groove 112b may be formed at the boundary of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com