Rapidly assembled and disassembled drone undercarriage structure

A landing gear and unmanned aerial vehicle technology, applied in the field of unmanned aerial vehicles, can solve the problems affecting the deployment time of the system, the long maintenance preparation period, and the complex disassembly process, so as to achieve convenient use, reduce flight preparation and withdrawal time, disassembly and assembly. convenient effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

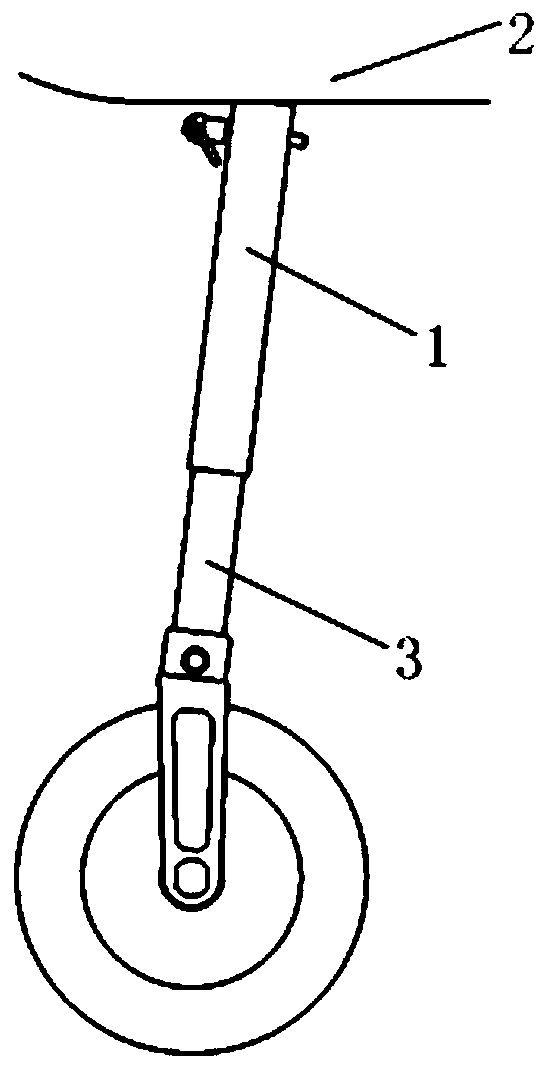

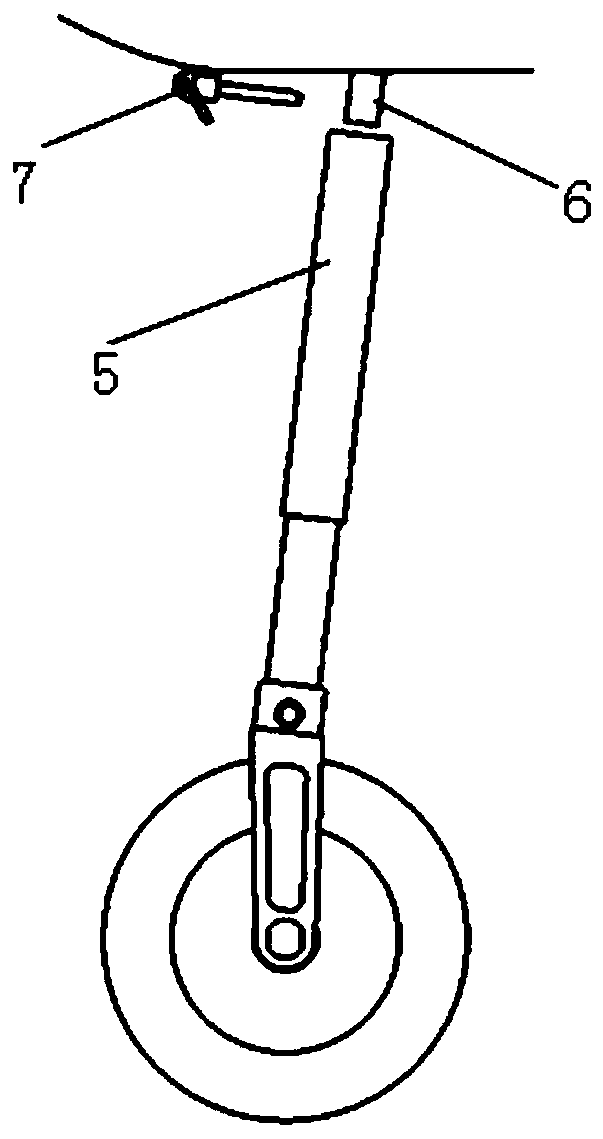

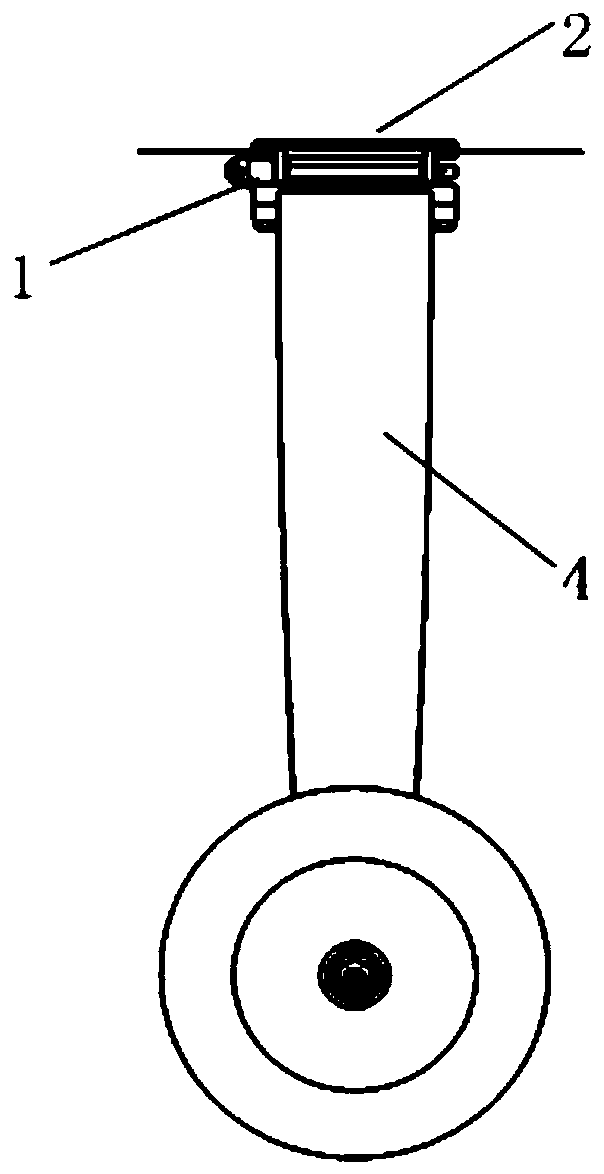

[0020] This embodiment is a structure for quickly disassembling and assembling the landing gear of an unmanned aerial vehicle.

[0021] refer to Figure 1 ~ Figure 4 , the rapid disassembly and assembly landing gear structure of the UAV in this embodiment is a quick disassembly and assembly structure of the landing gear connected by docking and quick release pins; the landing gear structure is composed of the front landing gear 3 and the main landing gear 4, wherein the front landing gear 3 includes the front landing gear support rod 5, the front landing gear fuselage pillar 6 and the first quick release pin 7; the main landing gear 4 includes the fuselage connection joint 8, the main landing gear joint 9 and the second quick release pin 10; the fuselage The connecting joint 8 is fixedly connected with the fuselage 2, and the main landing gear joint 9 is located at the upper end of the main landing gear 4 and is fixedly connected by bolts; Axial round hole, fuselage connectin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com