Helicopter without rotors

A technology of rotors and fins, applied in the field of active vertical lift vehicles, which can solve the problems of large energy loss, short helicopter range, and low quality factor of rotors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

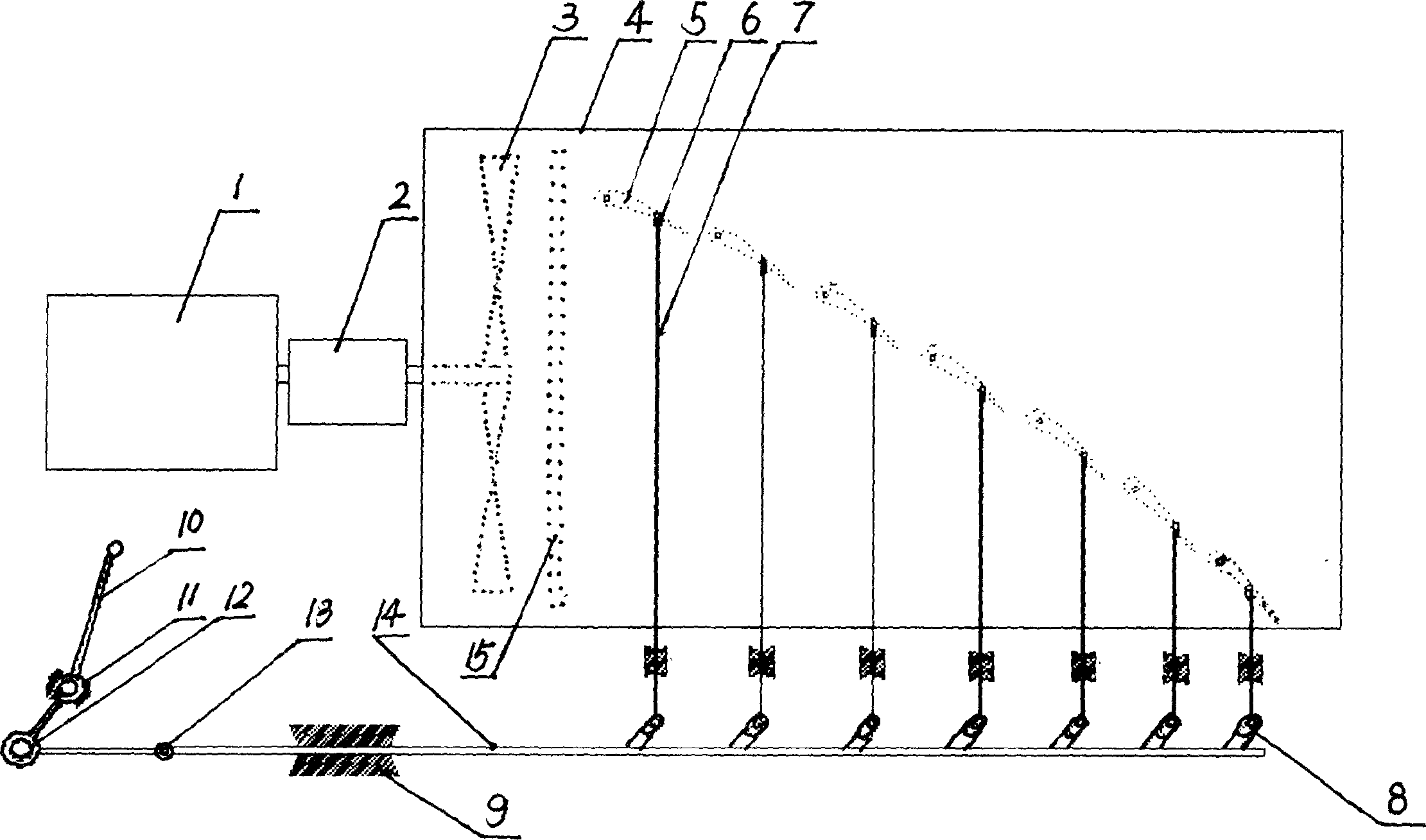

[0007] A specific embodiment of the present invention is given below in conjunction with the accompanying drawings. The non-rotor vertical lift-off device described in this embodiment consists of engine 1, gearbox 2, fan 3, windshield 4, wing 5, connecting rod shaft knot 6, attitude adjusting connecting rod 7, connecting rod hook 8, slide Rail 9, handle 10, fixed shaft wheel 11, attitude adjustment slipknot 12, alignment slipknot 13, movable connecting rod 14, rectifying grid mechanism 15 are formed, engine 1---be behind gearbox 2 with left and right ends windshield 4 (figure The left panel is shown in the middle, and the right panel is omitted) to form a semi-wind tunnel structure. The fan 3 is accommodated in the semi-wind tunnel structure. The airflow direction blown out by the fan 3 is provided with a gusset wing group mechanism composed of fins 5. Each wing The blades 5 are movably installed on the windshields 4 at the left and right ends through their end shafts. The bla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com