Decorative component, method of manufacturing a decorative component, timepiece, and decorated component

A technology for decorative parts and manufacturing methods, which is applied in clocks, clocks, mechanically driven clocks, etc., can solve the problems of monotonous appearance color and cannot correspond to diversified designs, and achieves promotion of design diversification, improved visibility, and setting The effect of increased degrees of freedom

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

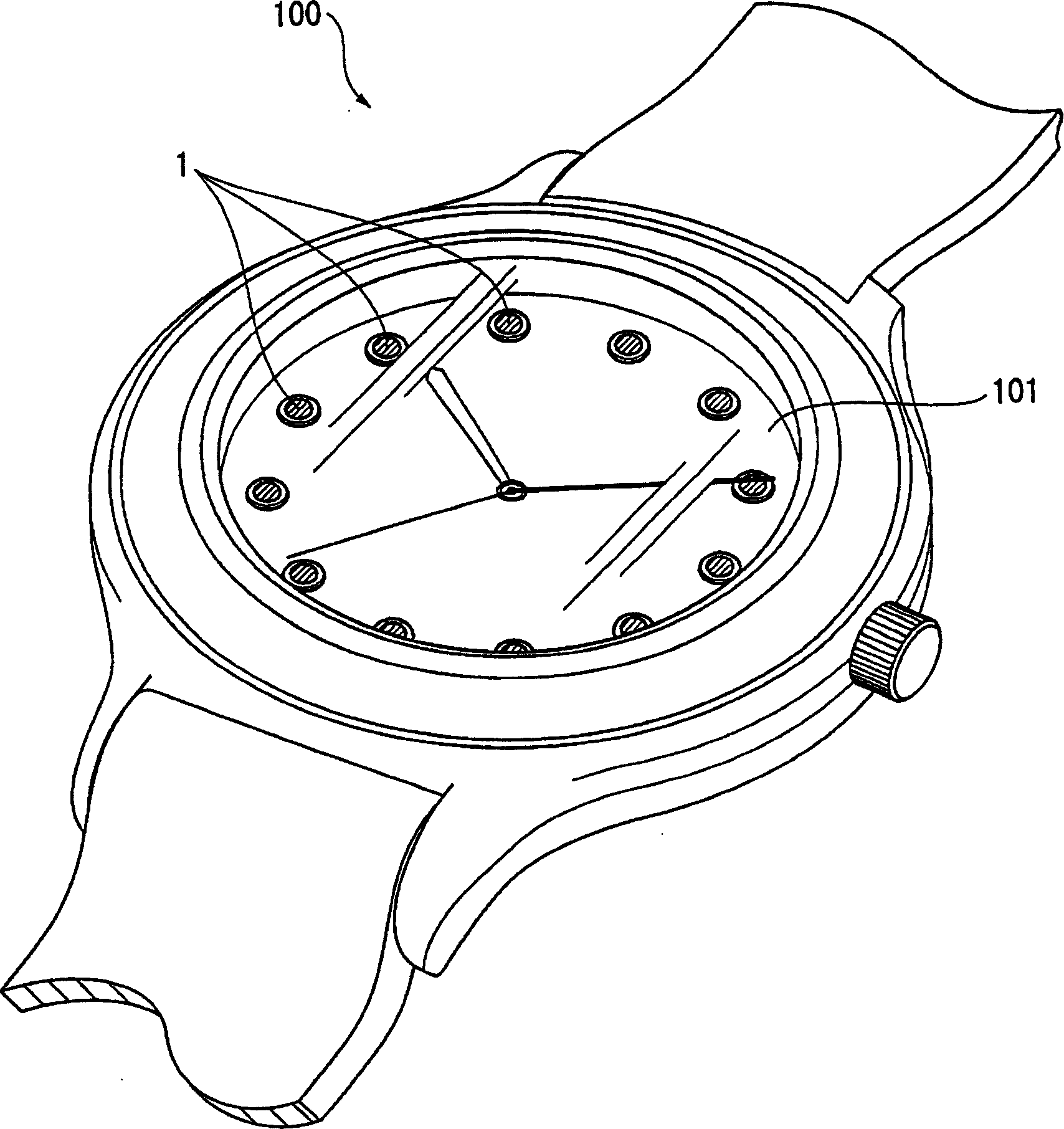

[0079] figure 1 A timepiece 100 using the scale member 1 as the decorative member according to the first embodiment of the present invention is shown. in the figure 1 Among them, the scale member 1 is pasted on a dial (base member) 101 of a watch 100 as a member to be decorated for decorating the clock 100 , and a plurality of scale portions are bonded to the dial 101 .

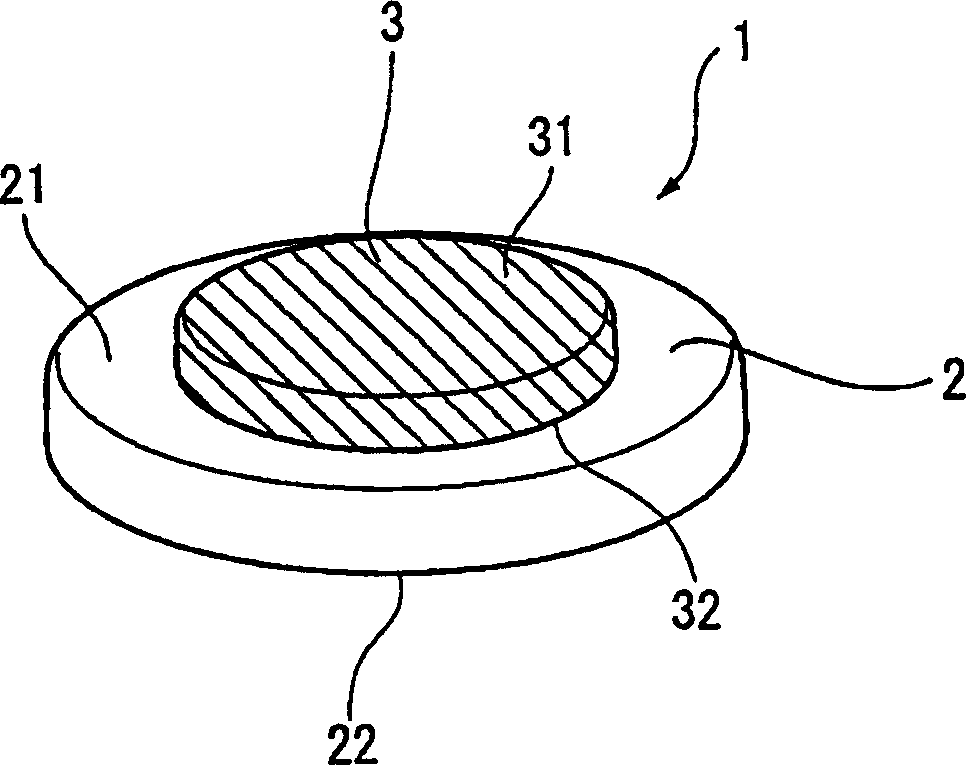

[0080] figure 2 A perspective view of the scale member 1 is shown. in the figure 2 Among them, the scale component 1 has: the first electroformed part 2 as the electroformed part pasted on the dial 101; and the second electroformed part as the decorative part formed on the decorative surface 21 of the first electroformed part 2 3.

[0081] The first electroformed part 2 is made by electroforming, and has an adhesive surface 22 that is attached to the dial 101 with an adhesive or the like; except for the adhesive surface 22 , the decorative surface 21 can be seen from the outside. The first electroform...

no. 2 approach

[0130] Next, a second embodiment of the present invention will be described. The structure of the decorative portion of the second embodiment is different from that of the first embodiment.

[0131] Figure 12 A perspective view showing a scale member 1A as a decorative member according to the second embodiment of the present invention. Such as Figure 12 As shown, the scale member 1A has: an electroformed part 2A pasted on the dial 101; and an electrodeposition sprayed part 3A as a surface treatment part (decorated part) formed on the decorative surface 21A of the electroformed part 2A.

[0132] The electroformed part 2A is formed in the same shape as the first electroformed part 2 of the first embodiment.

[0133] The electrodeposition sprayed part 3A is formed on the electroformed part 2A by electrodeposition spraying, and has: a fixed surface 32A fixed on the decorative surface 21A of the electroformed part 2A; Decorative surface 31A. The electrodeposition spraying pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com