Improved structure of soft tube lamp

An improved structure and hose technology, which is applied in the direction of lampshades, damage prevention measures for lighting devices, lighting and heating equipment, etc., can solve the problems of not seeing the effect of neon lights, achieve uniform and continuous light effects, large production batches, and production low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Below with reference to accompanying drawing, the present invention will be further described:

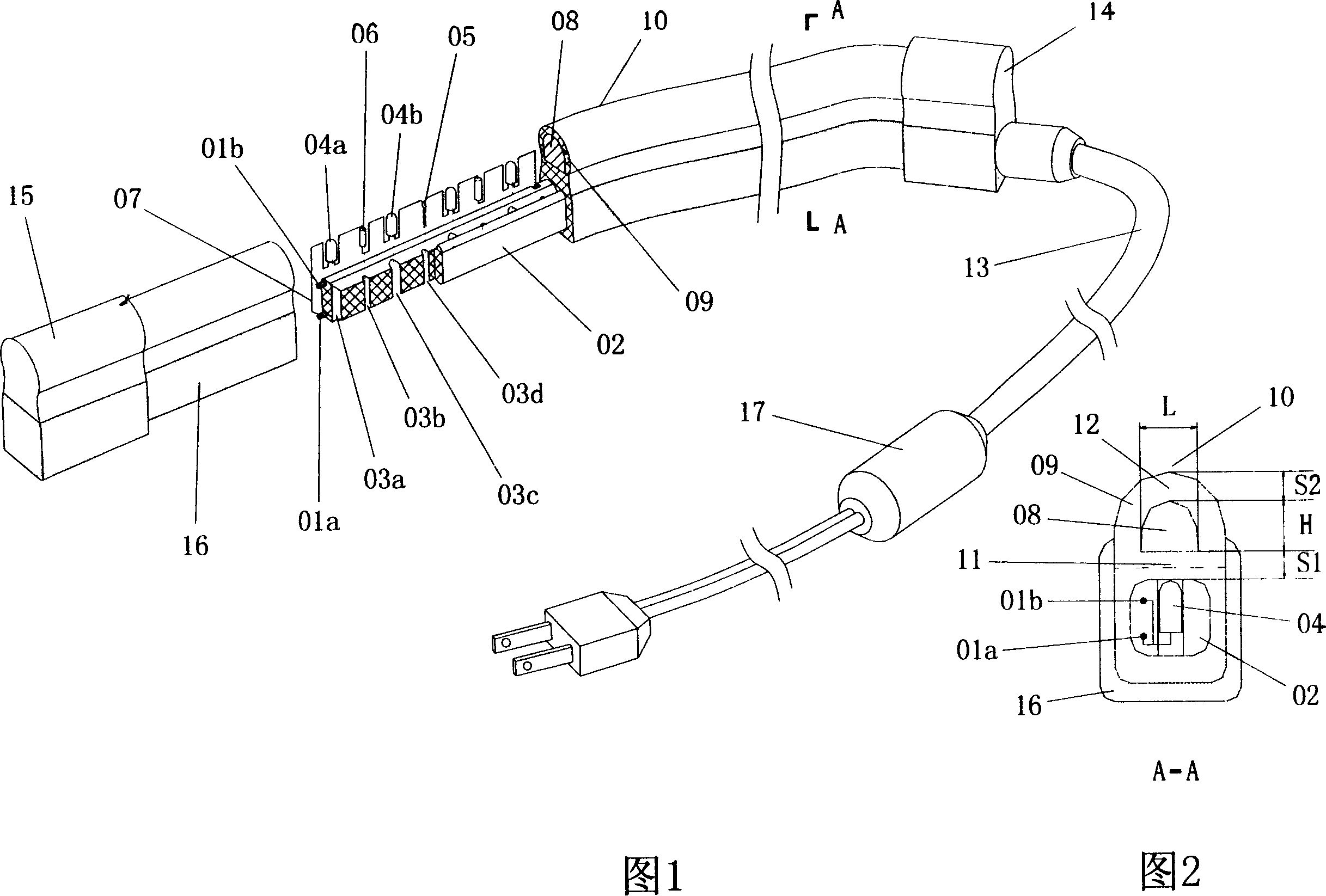

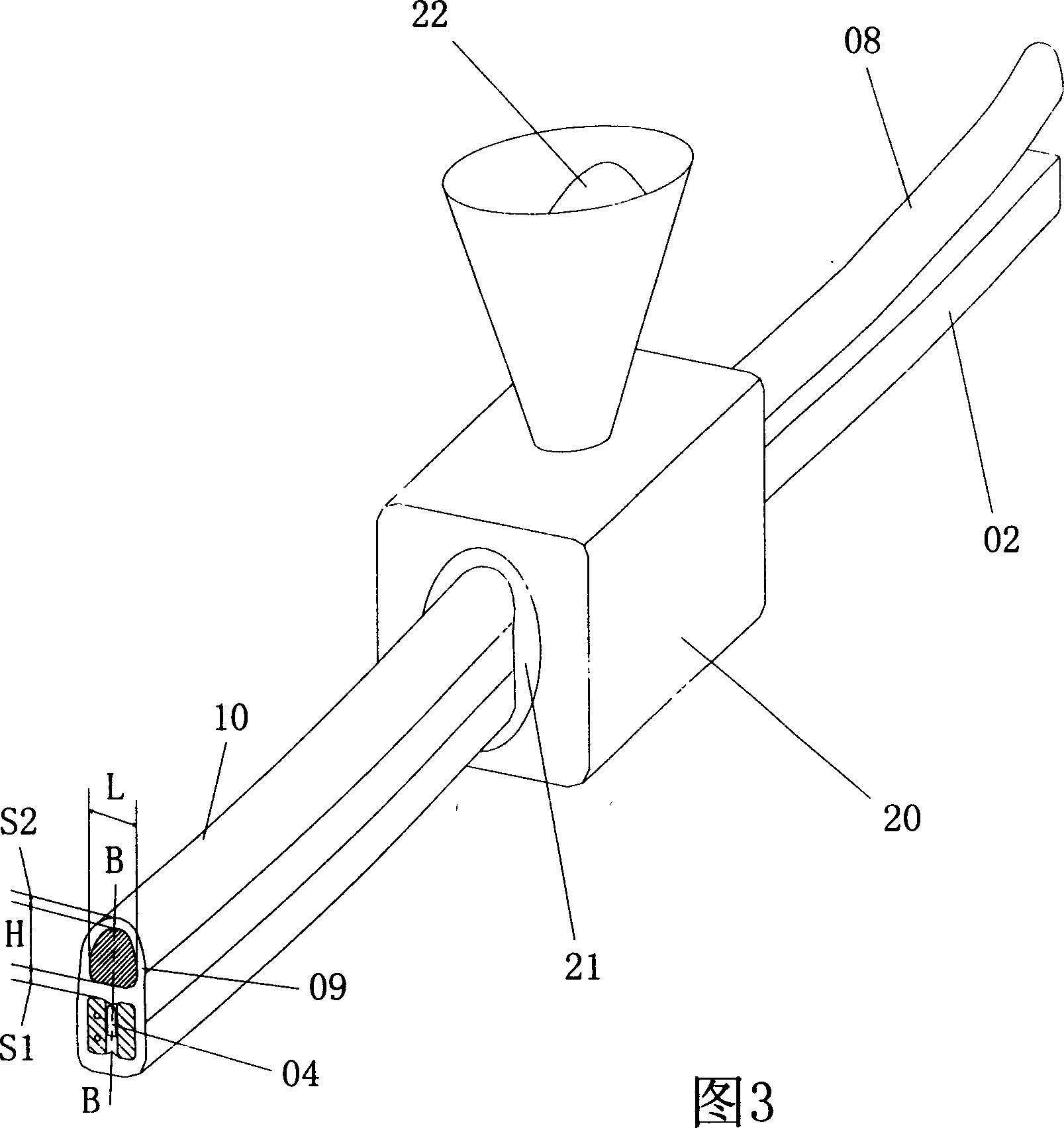

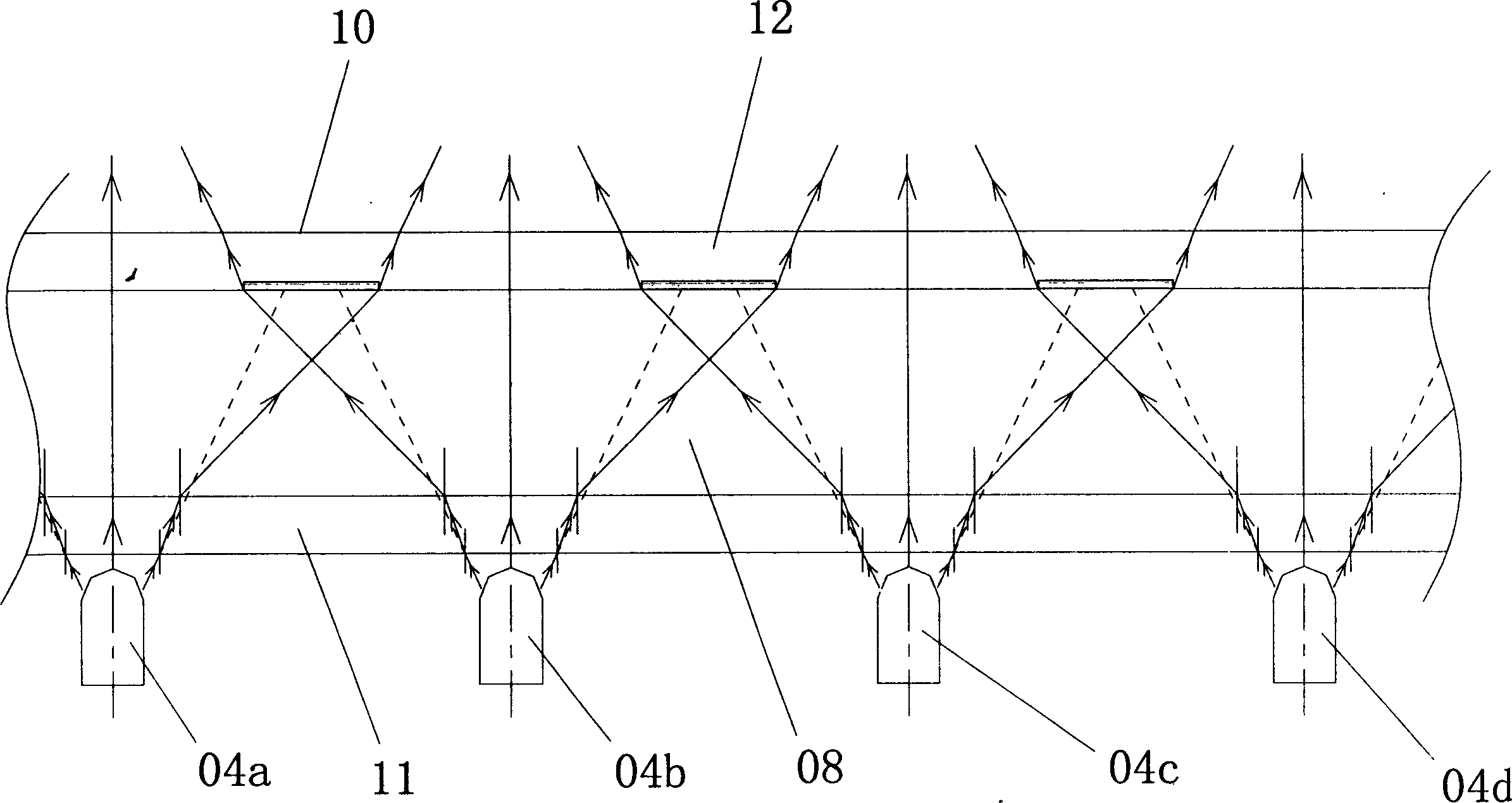

[0037] Referring to Fig. 1, it is a perspective view of the present invention, Fig. 2 is a sectional view of A-A in Fig. 1, and Fig. 3 is a schematic diagram of extrusion molding of the first preferred embodiment of the present invention.

[0038] An improved structure of a hose lamp according to the present invention, the first best embodiment, its production process includes: usually two copper twisted wires pass through the forming hole of the extrusion molding machine (not shown in the figure), and the automatic continuous extrusion is carried out by Flexible plastic, usually flexible PVC, is molded into a prefabricated length strip, which is the core wire 02 mentioned in this industry.

[0039] Then, on the entire longitudinal length of the core wire, a plurality of transverse through holes 03a, 03b, 03c, 03d parallel to the copper stranded wire are evenly punched out w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com