Patents

Literature

42results about How to "Large production batch" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

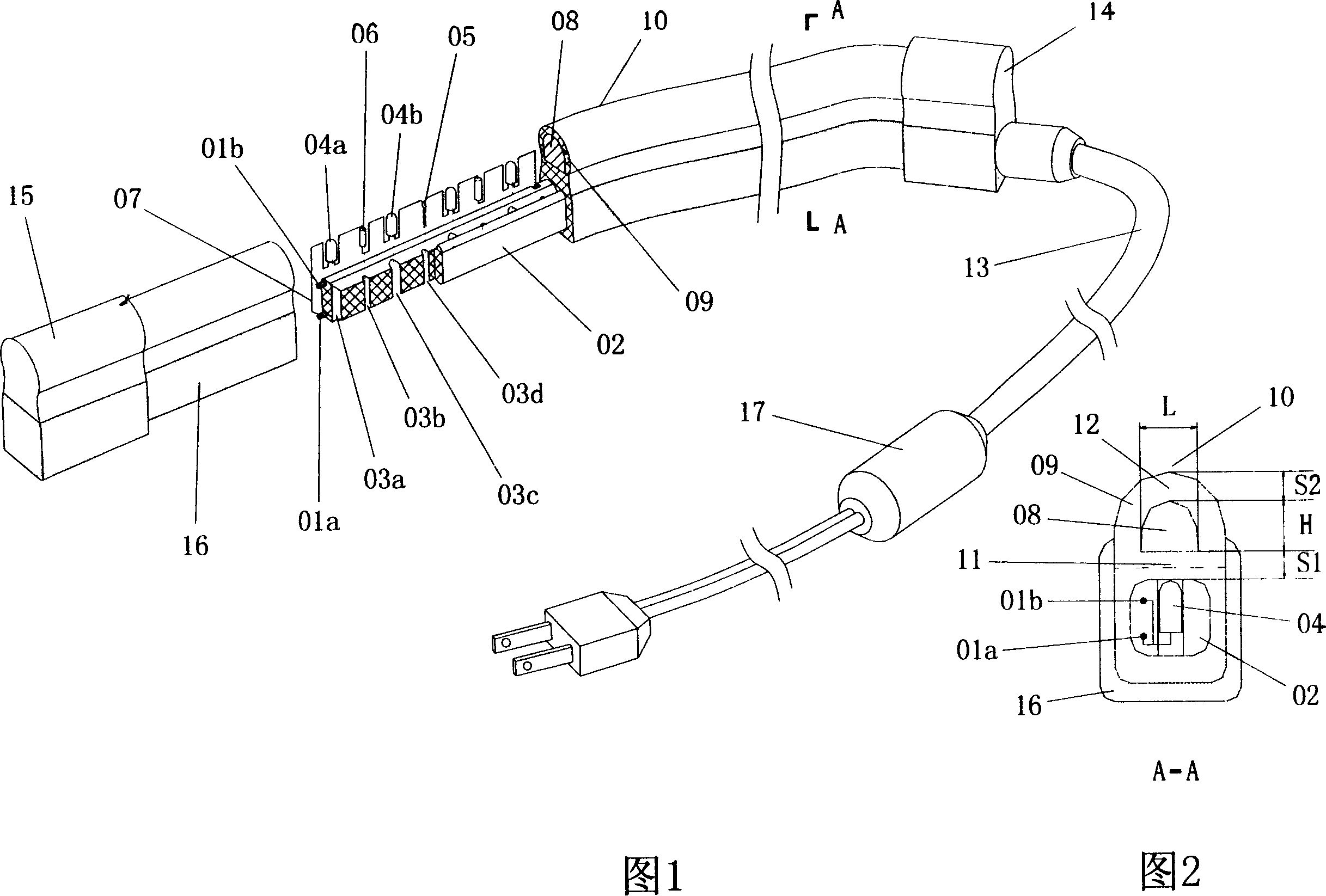

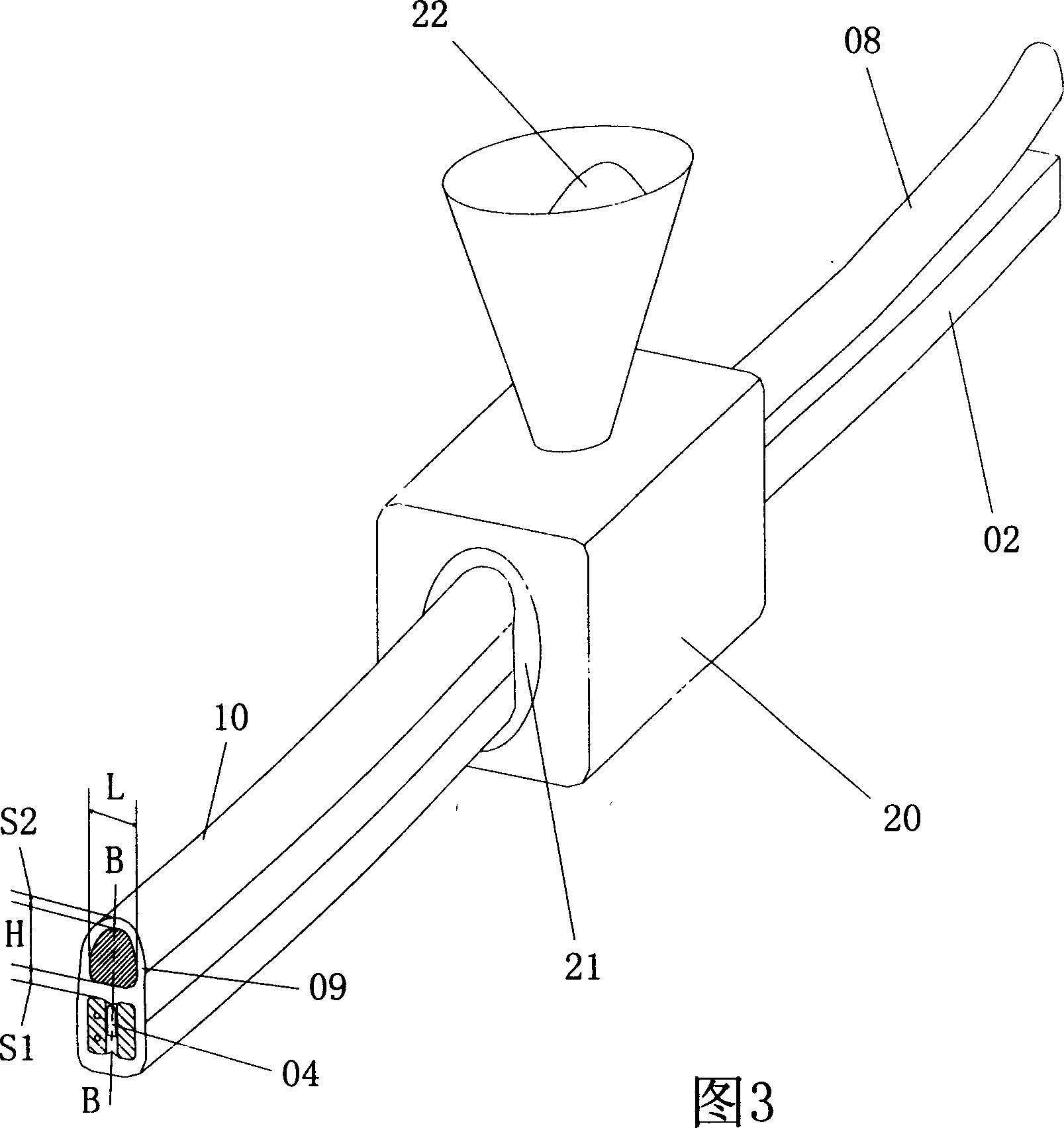

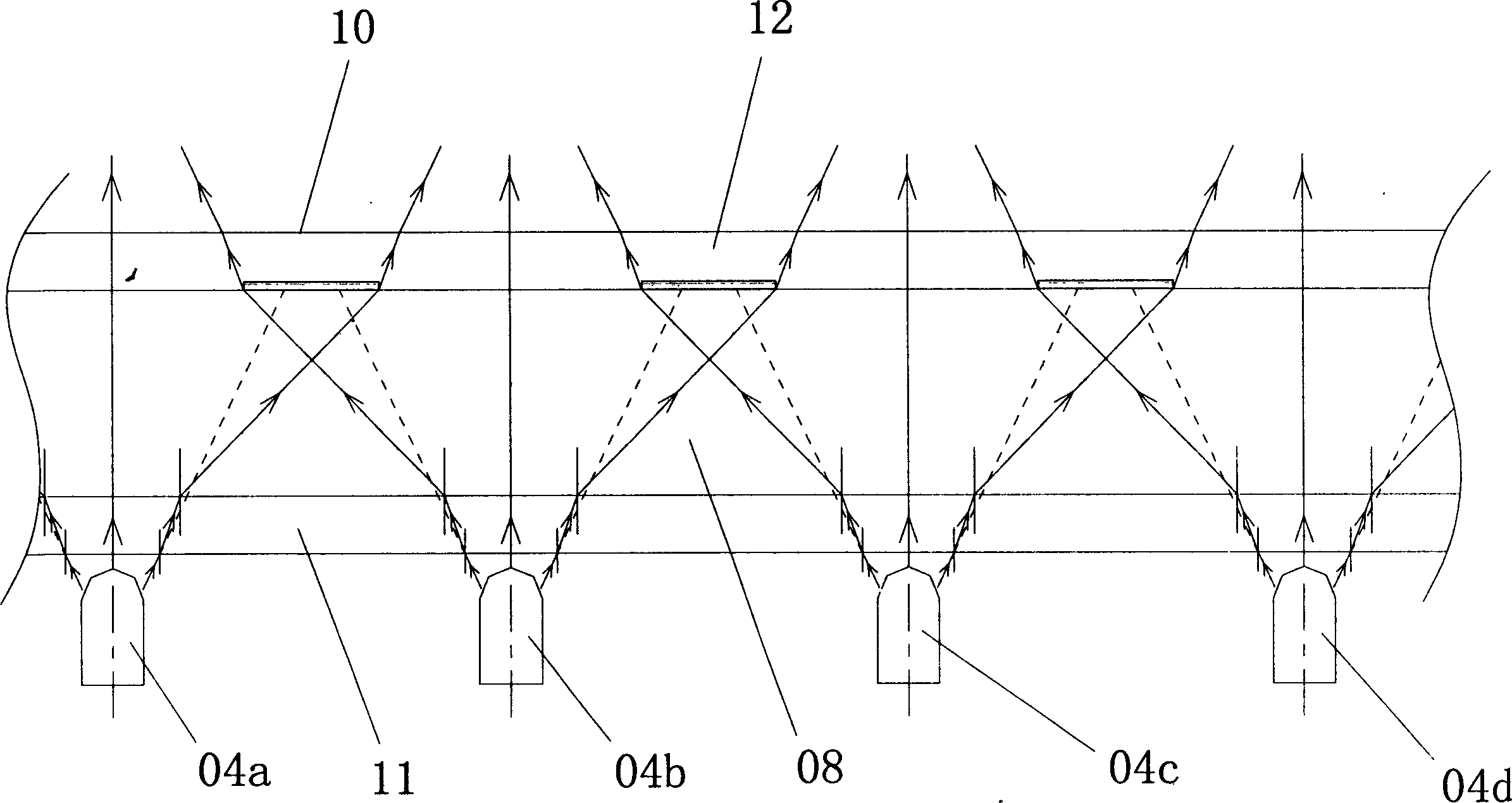

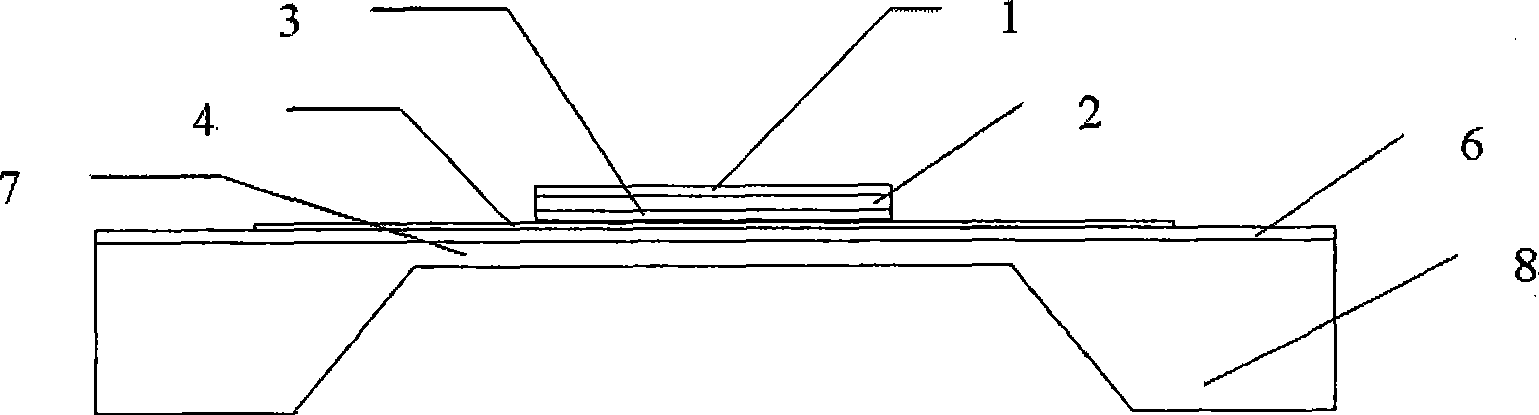

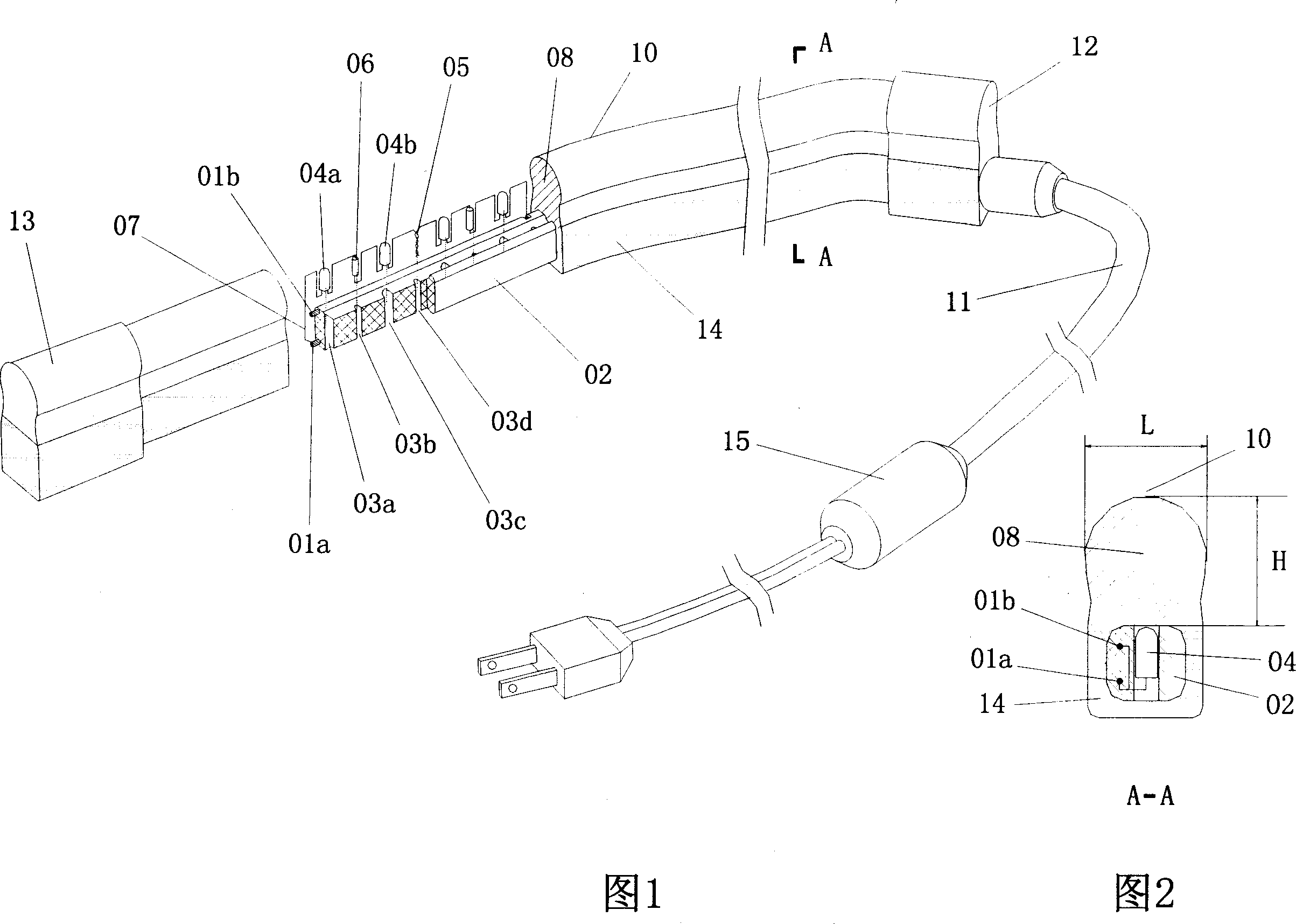

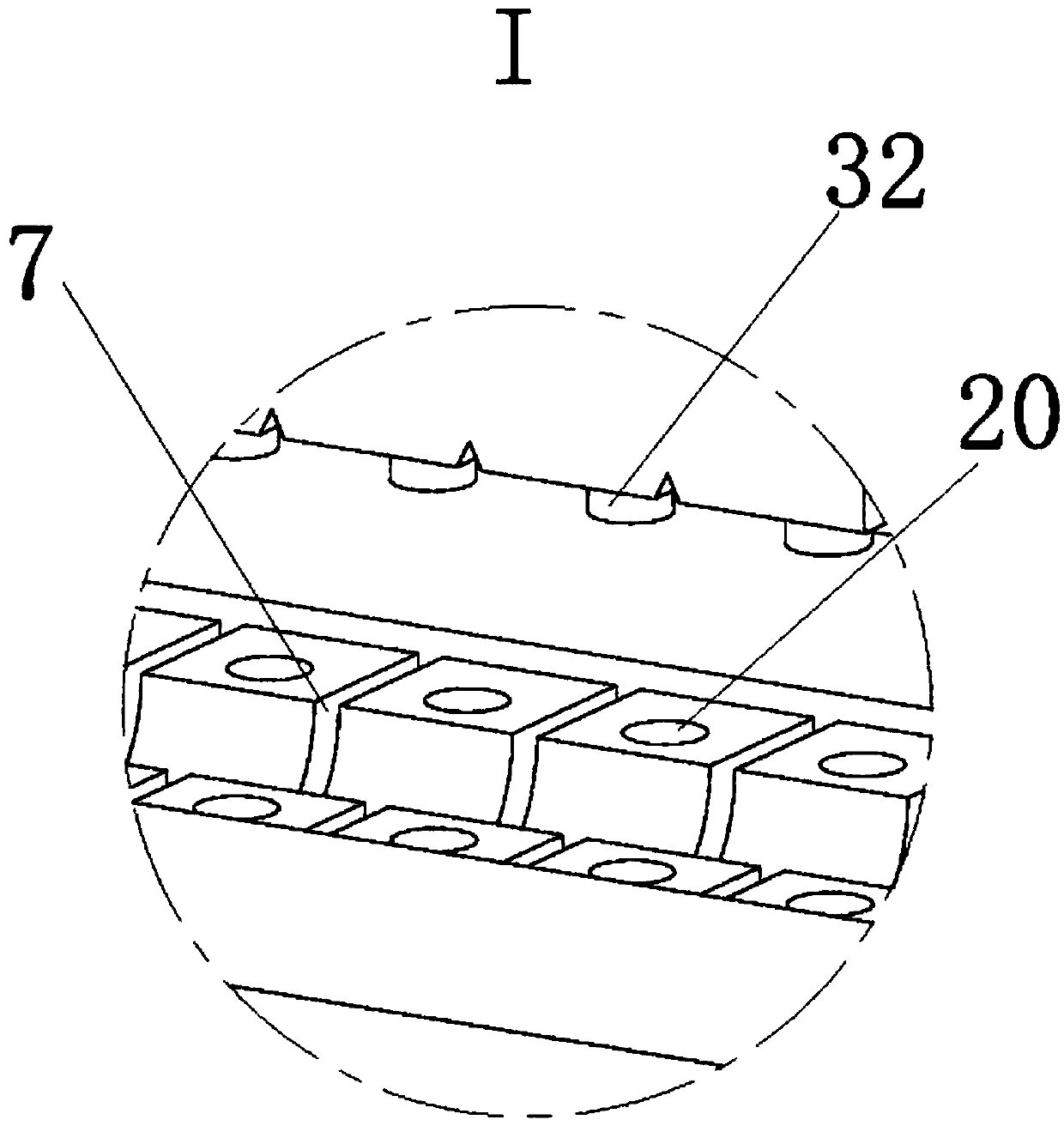

Improved structure of soft tube lamp

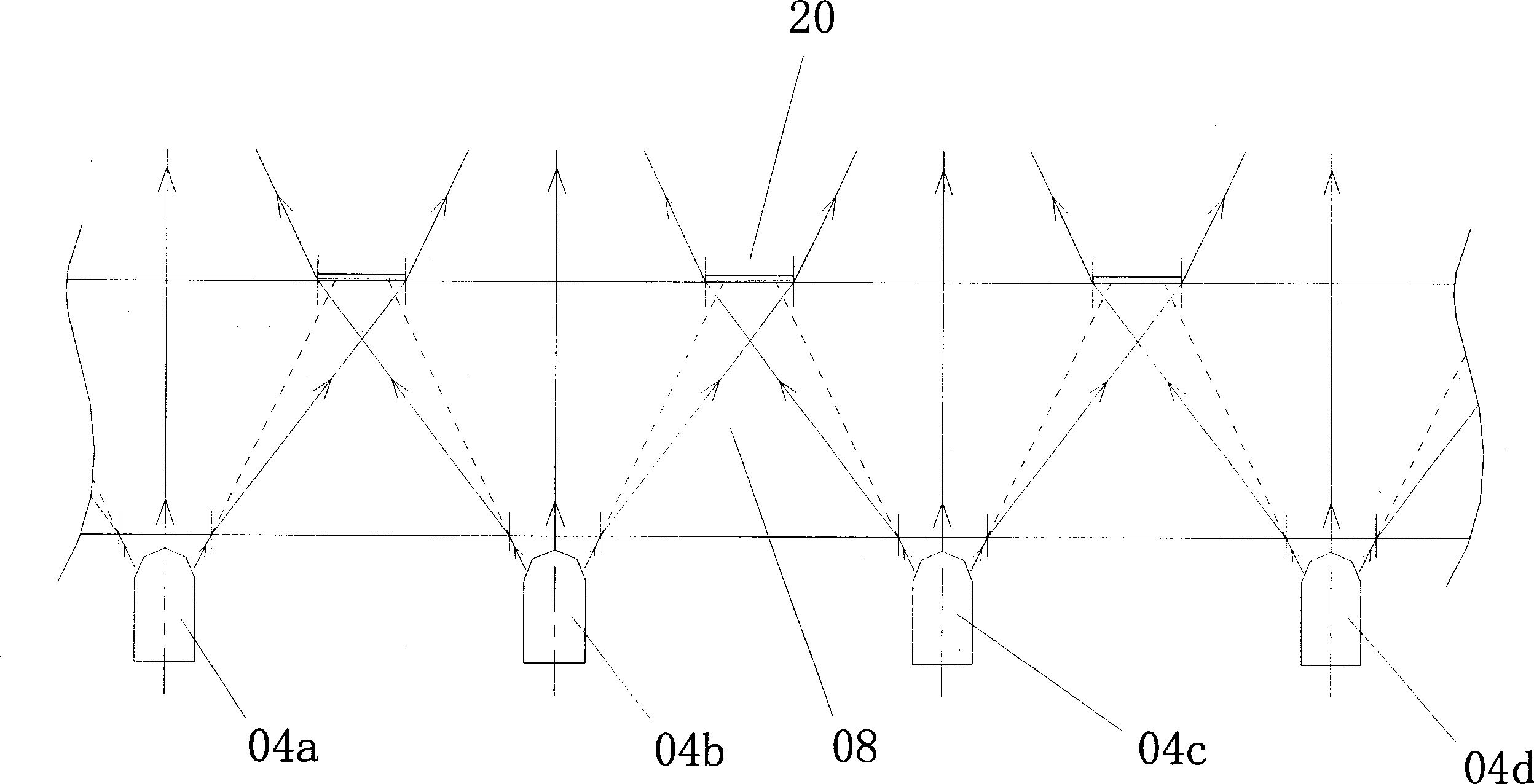

InactiveCN1641260AUniform continuous light effectLarge production batchPoint-like light sourceProtective devices for lightingContinuous lightSource lines

The invention discloses an improved structure of a soft tube lamp, including a core line, a plurality of LEDs arranged in the core line, a diffusing body with a length equal to the core line and provided above the LEDs, an envelopping layer with a length equal to the core line and envelopping the core line and the diffusing body, a joint for connecting the soft tube lamp with a power source line. The improved structure of the soft tube lamp according to the invention has an even and continuous light effect of an analog neon light, achieves an object desired and seeked in a soft tube lamp industry for a long time, realizes continuous and automatic mass-production of analog neon lights at the same time, thereby compared with the analog neon lights and soft tube lamps having other sturectures, the soft tube lamp of the invention has advantages of mass-production and low producing cost.

Owner:HE SHAN LIDE ELECTRONICS ENTERPRISE CO LTD

Freeze dried combination of Lansoprazole available for linjection and preparation method

InactiveCN1660091AImprove product qualityDoes not reduce efficacyPowder deliveryOrganic active ingredientsLansoprazoleFreeze-drying

A freeze-dried powder injection of lansoprazole is prepared from lansoprazole, cosolvent, alkaline amino acid and water proportionally.

Owner:龙蓓

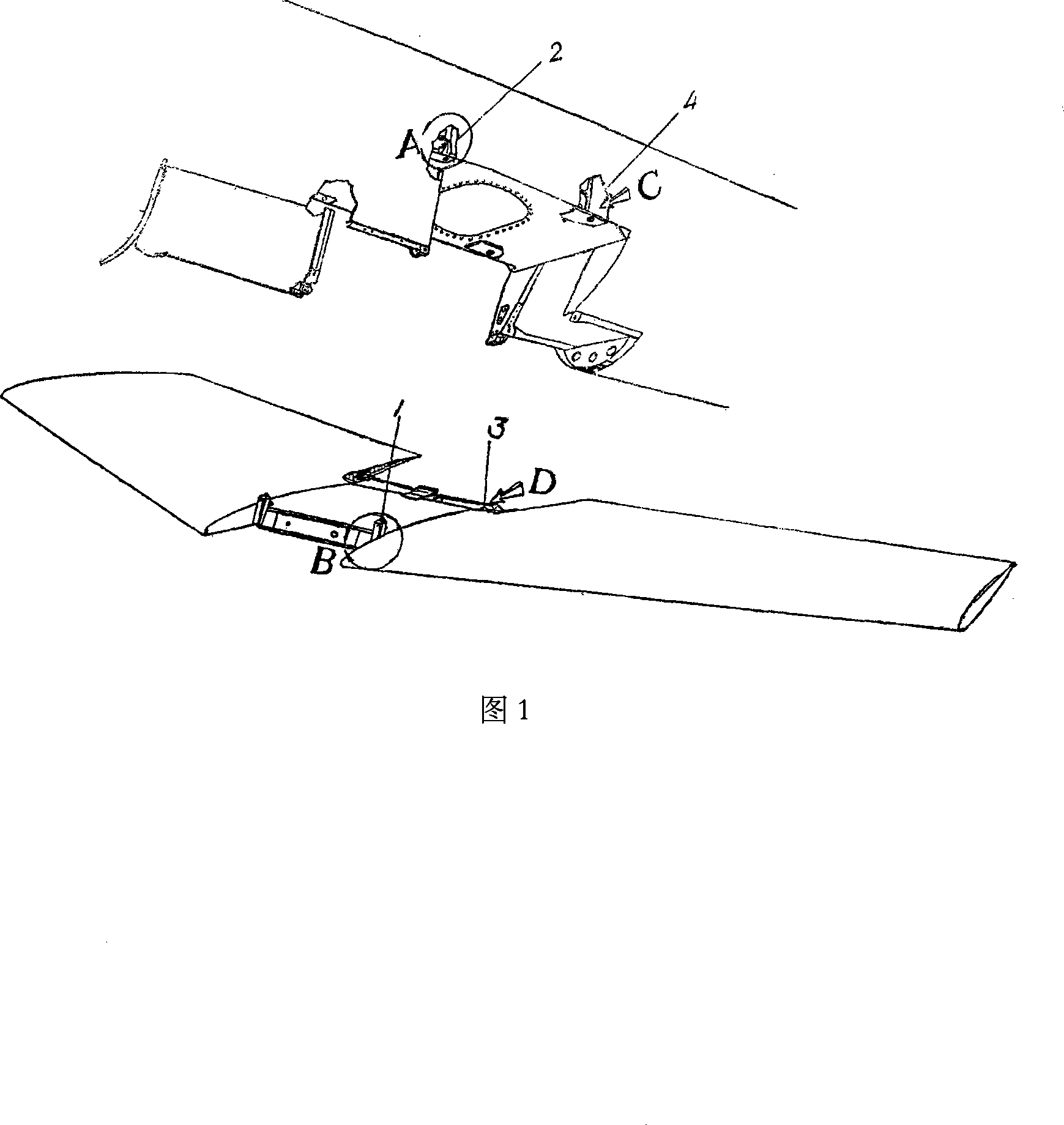

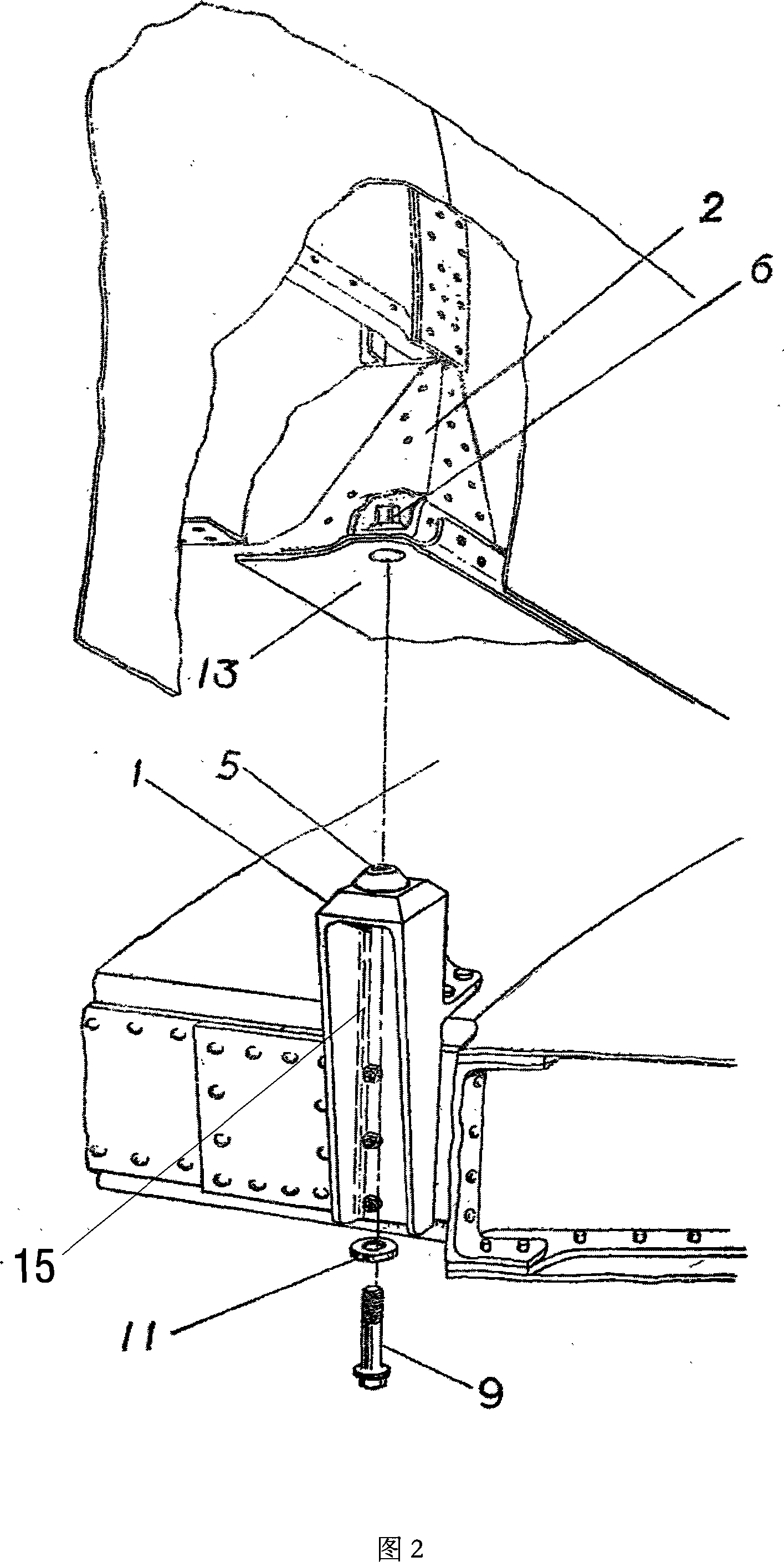

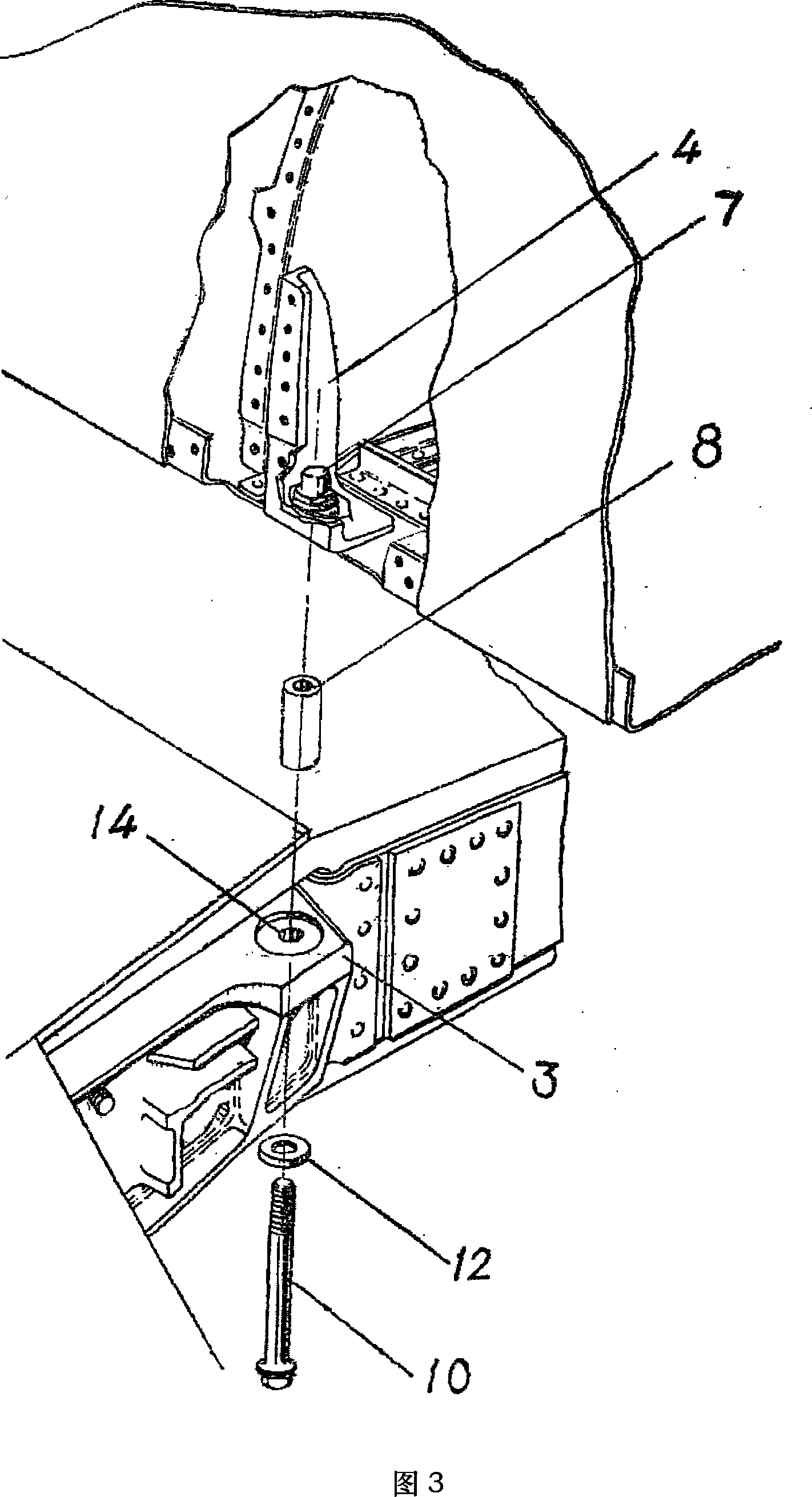

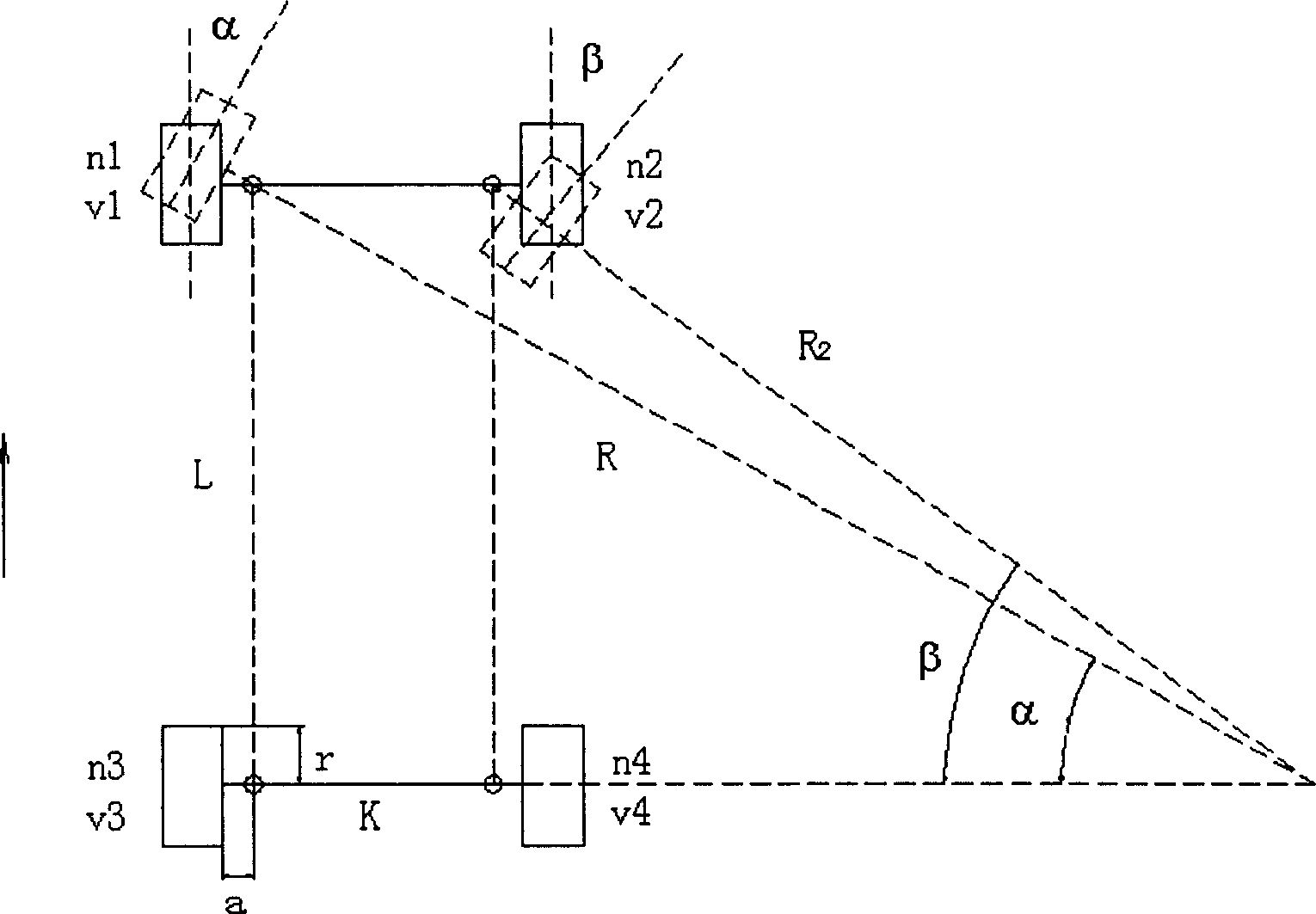

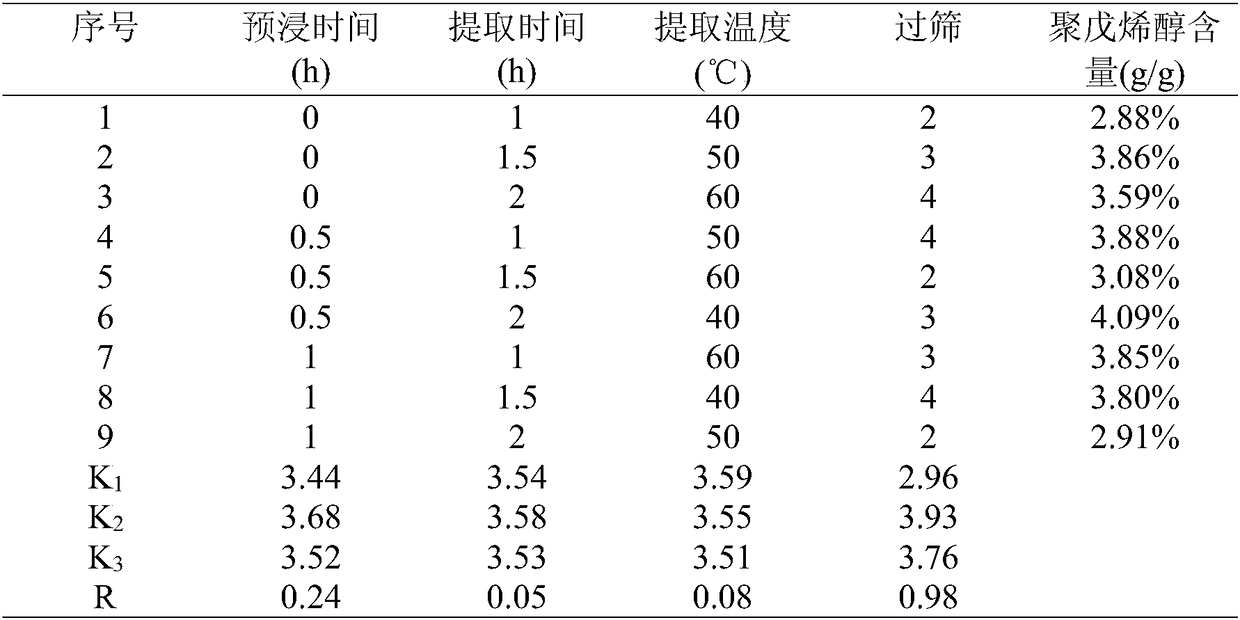

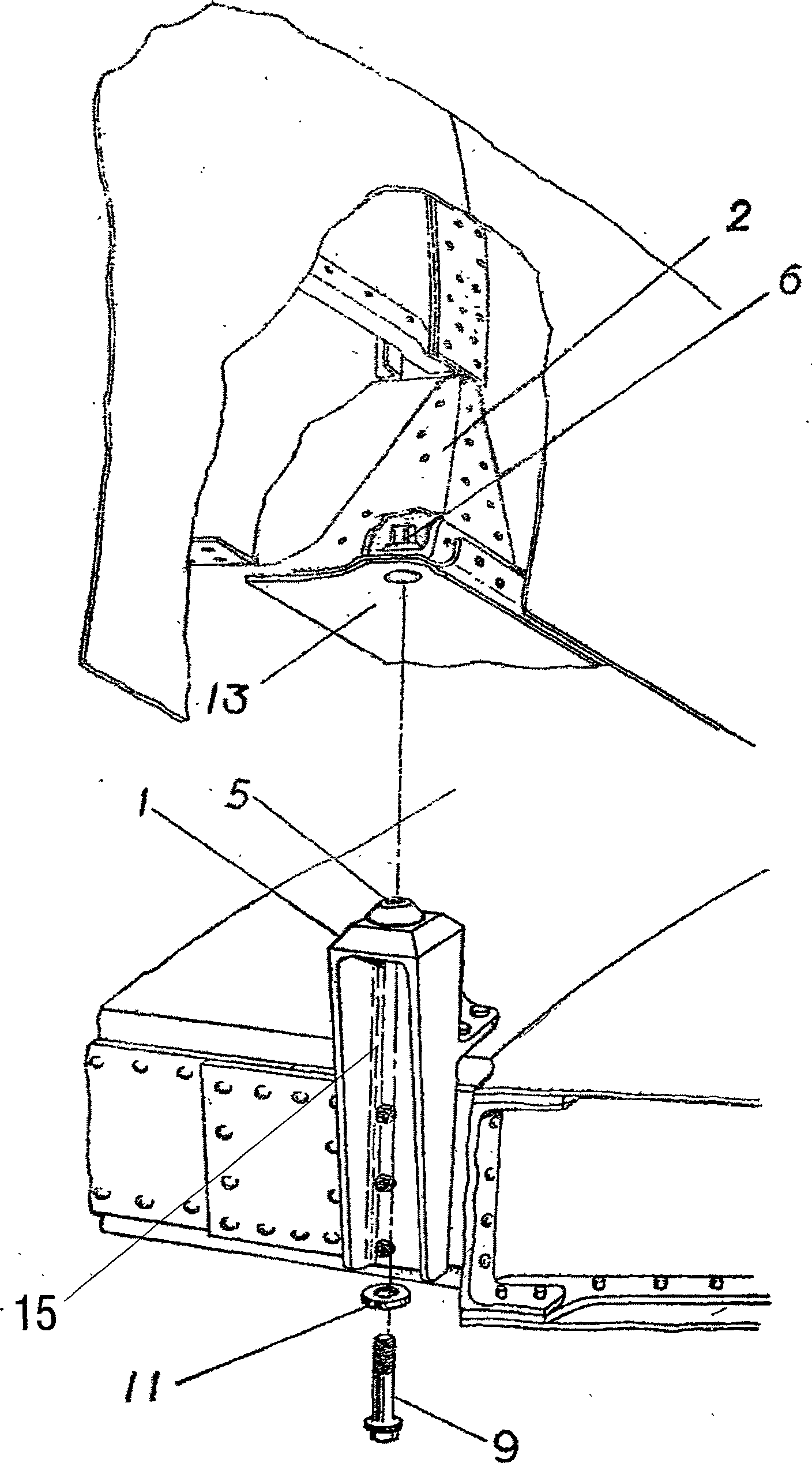

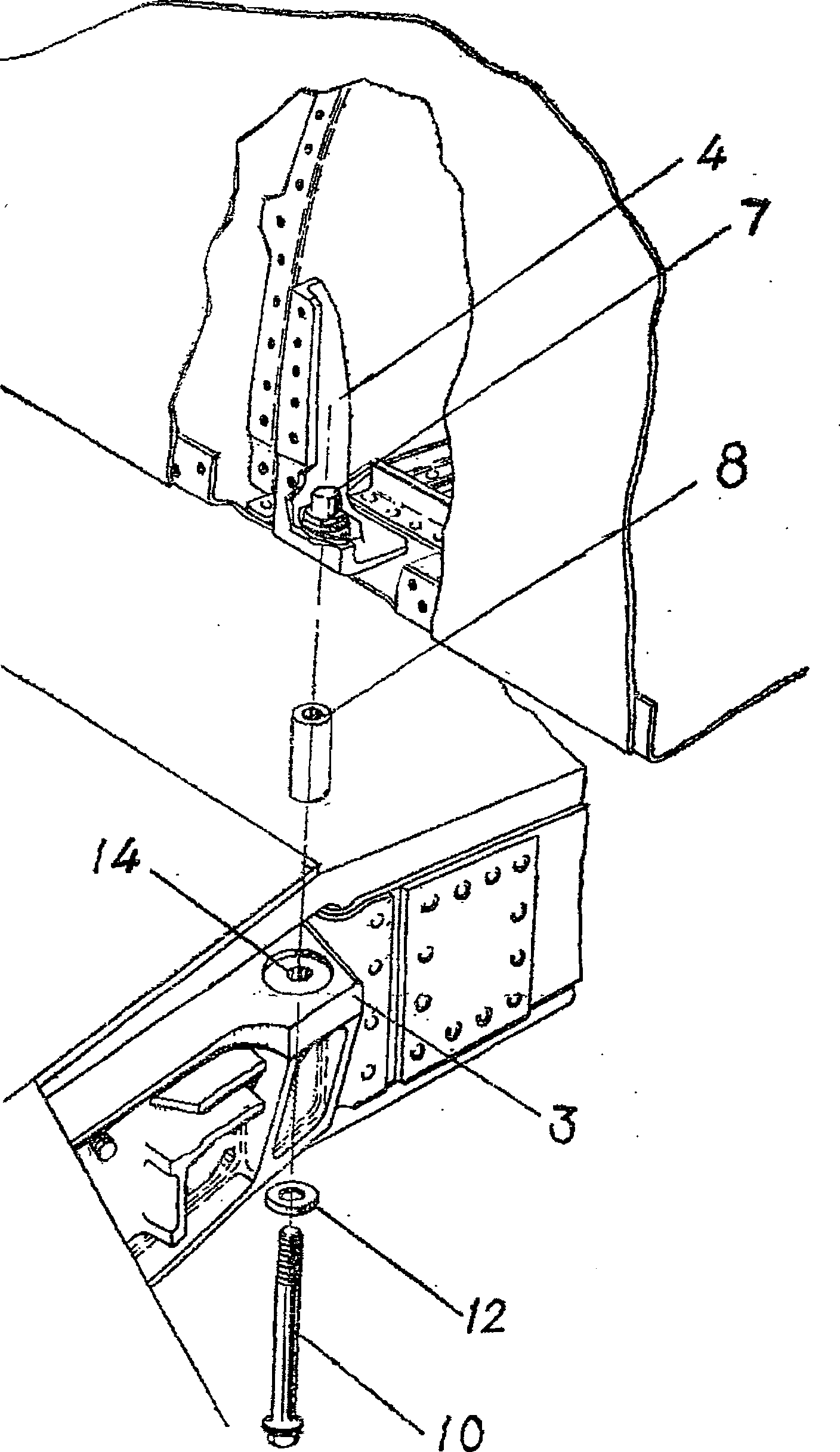

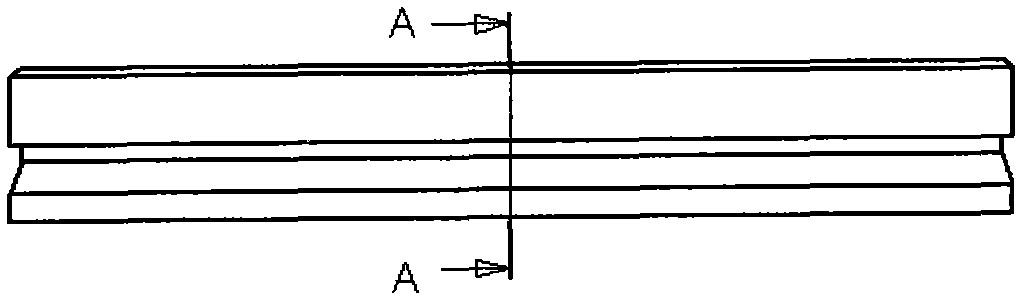

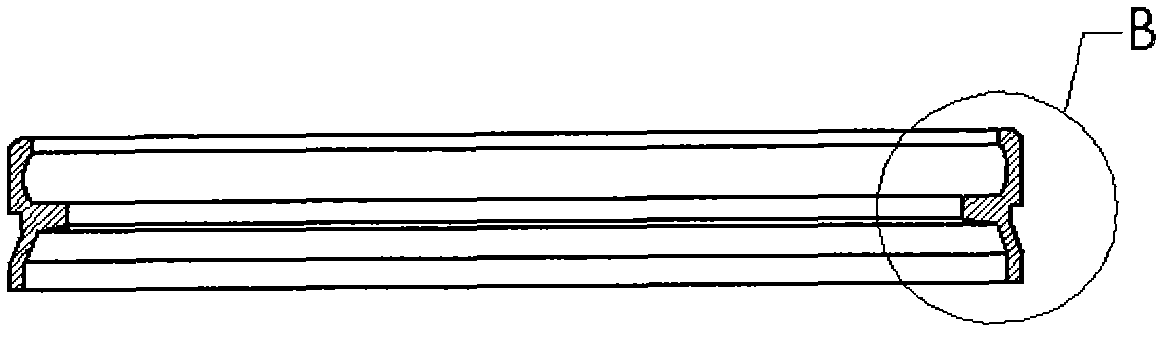

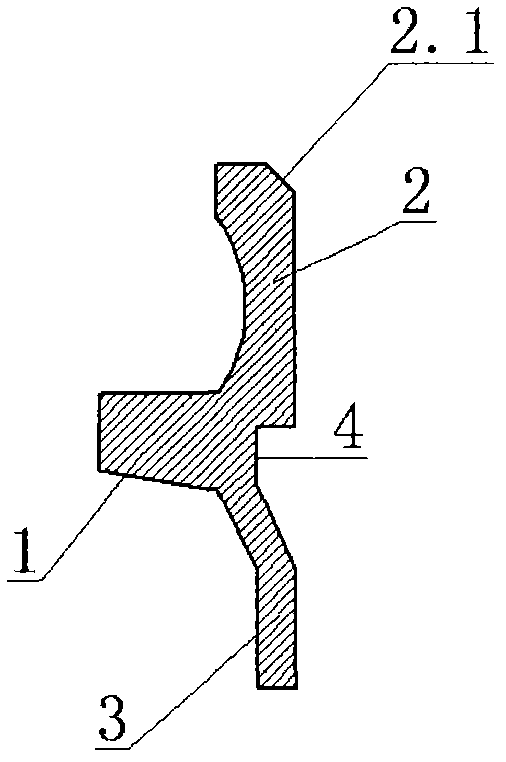

Connecting structure for unmanned aerial vehicle body and wing

InactiveCN101214852ASimple preparation processReasonable power transmissionToy aircraftsFuselagesStress concentrationUncrewed vehicle

The present invention discloses a connection structure of an airframe-airfoil of an unmanned aerial vehicle, which is realized by the connection of a pair of front and back joints of the airfoil and a pair of front and back joints at the oil box soleplate of the airframe that is the front joint of the airfoil is connected with the front joint of the airframe by bolts, and the back joint of the airfoil is connected with the back joint of the airframe by bolts. The airfoil and the airframe are linked just by four pairs of joints and four connection pieces, and the force transmission of the connection pieces is reasonable, which reduces the connection of joint parts and the concentration of stress; a majority of load is discharged during flying, which improves the anti-fatigue performance. The present invention has the characteristics of small size, good flexibility and large production batch. The structure can improve the rigidity of the joints to ensure the firm connection of the airframe and the airfoil and the high efficiency of the structure, and the structure belongs to the external connection, which has strong changeability and meets the requirement of combat readiness.

Owner:BEIHANG UNIV

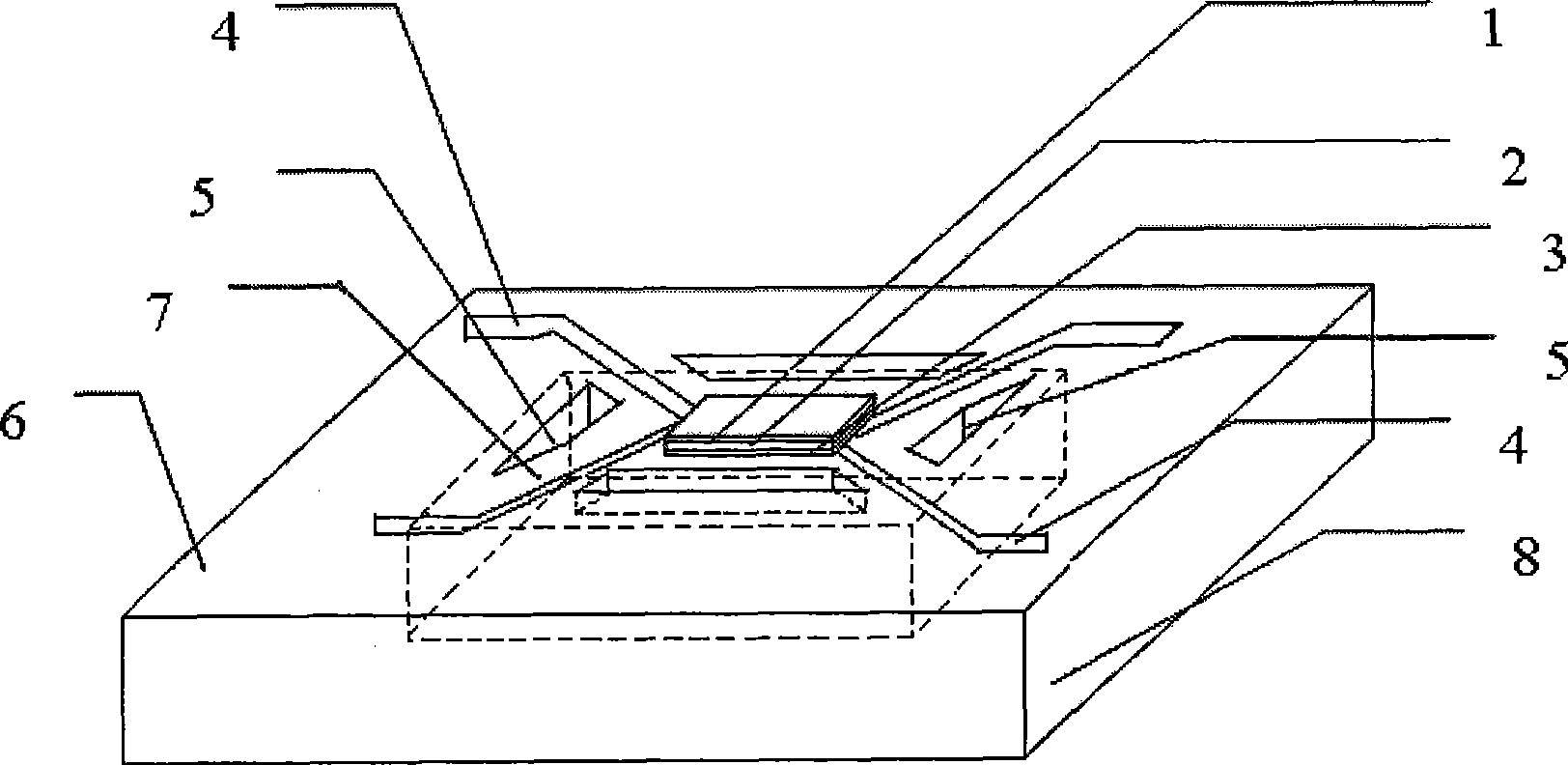

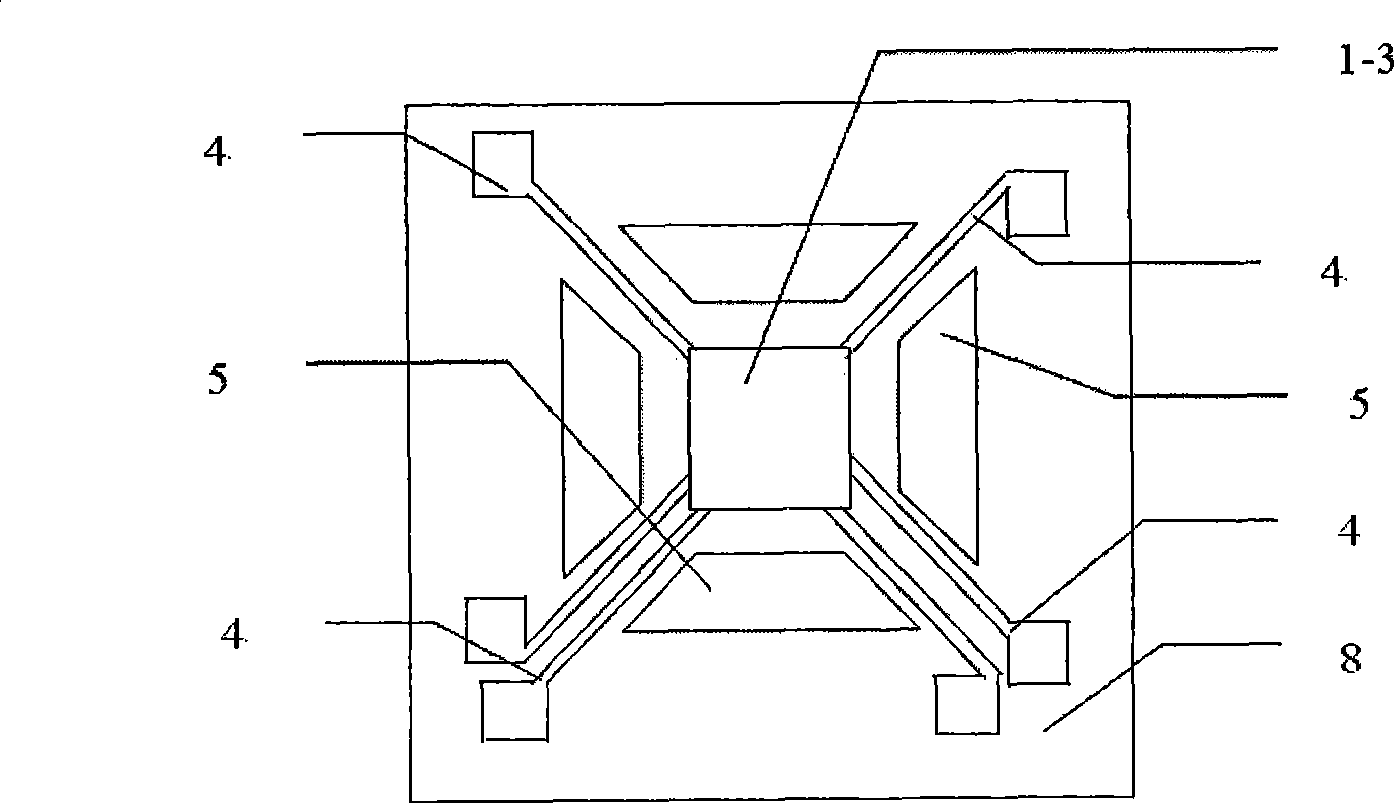

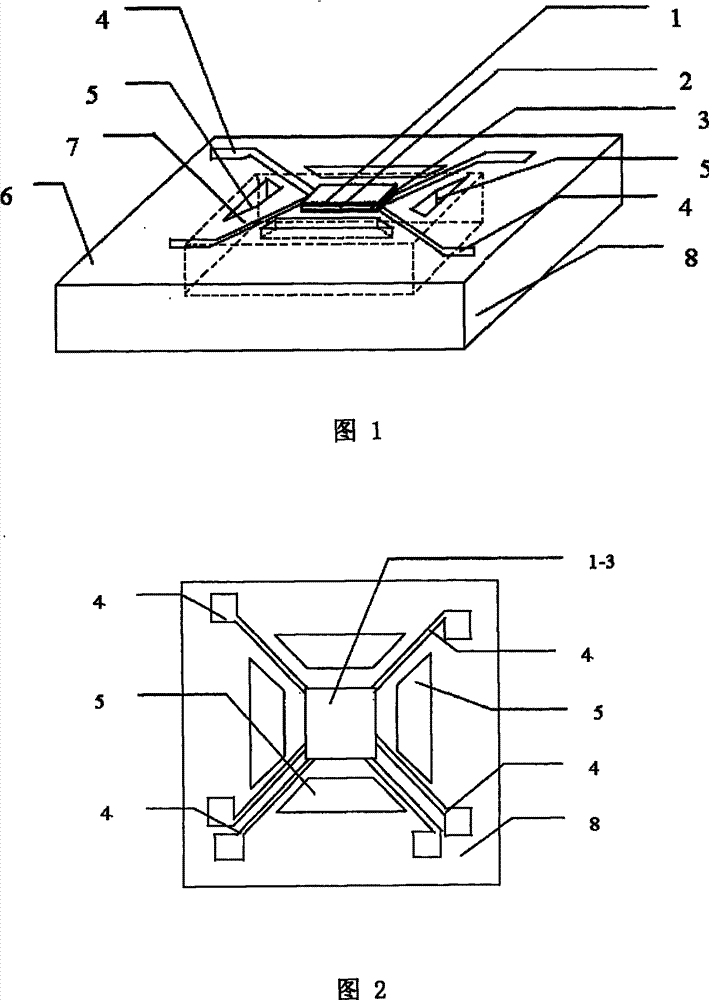

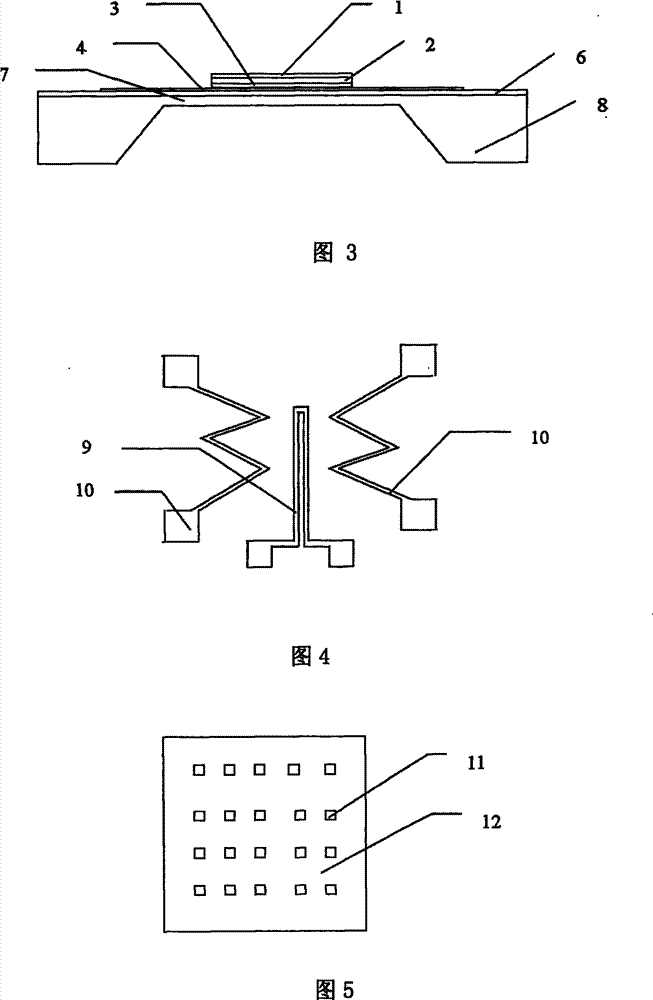

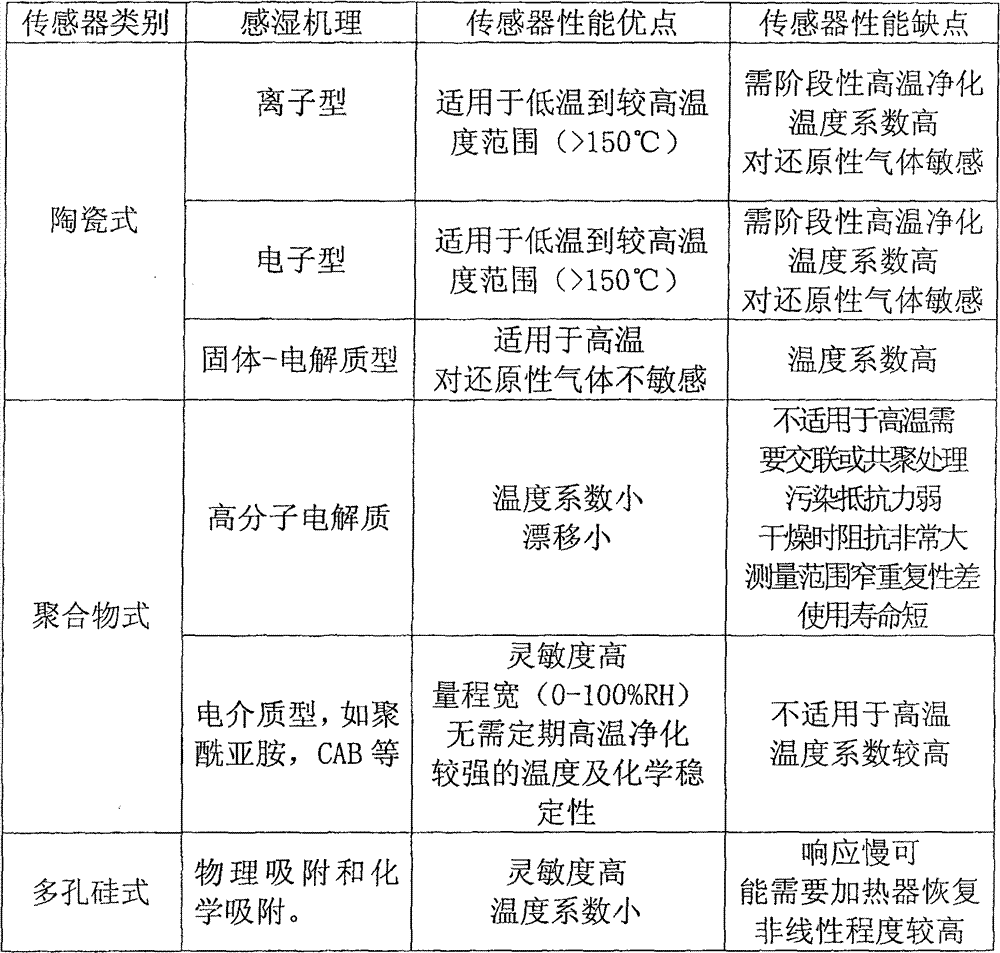

Constant temperature measurement-type micro humidity sensor and producing method thereof

InactiveCN101532975ASmall temperature coefficientLarge production batchMaterial impedanceCapacitanceEngineering

The invention discloses a constant temperature measurement-type micro humidity sensor and a producing method thereof, relating to the sensor technology; the sensor consists of a humidity sensitive film capacitor and a pedestal, wherein at least one electrode in the lower electrode of the humidity sensitive film capacitor acts as a capacitance or impedance measuring electrode and a constant temperature-control heating electrode and works with a temperature sensor in the lower electrode under the control of an external circuit of the sensor to cause the micro humidity sensor to measure humidityat certain constant temperature. A thin supporting film for supporting the humidity sensitive film capacitor in the sensor has through holes or clearance structures, thereby reducing heat loss and causing the sensor to realize constant temperature measurement under relatively low power consumption. The micro humidity sensor is not affected by the environmental temperature, has small temperature coefficient and good low-temperature performance, realizes the humidity measurement at negative temperatures and has a volume smaller than 2mm*2mm*2mm. The invention is applied to daily life, industrial production, weather forecast, environment monitoring, aeronautics, astronautics and other fields.

Owner:INST OF ELECTRONICS CHINESE ACAD OF SCI

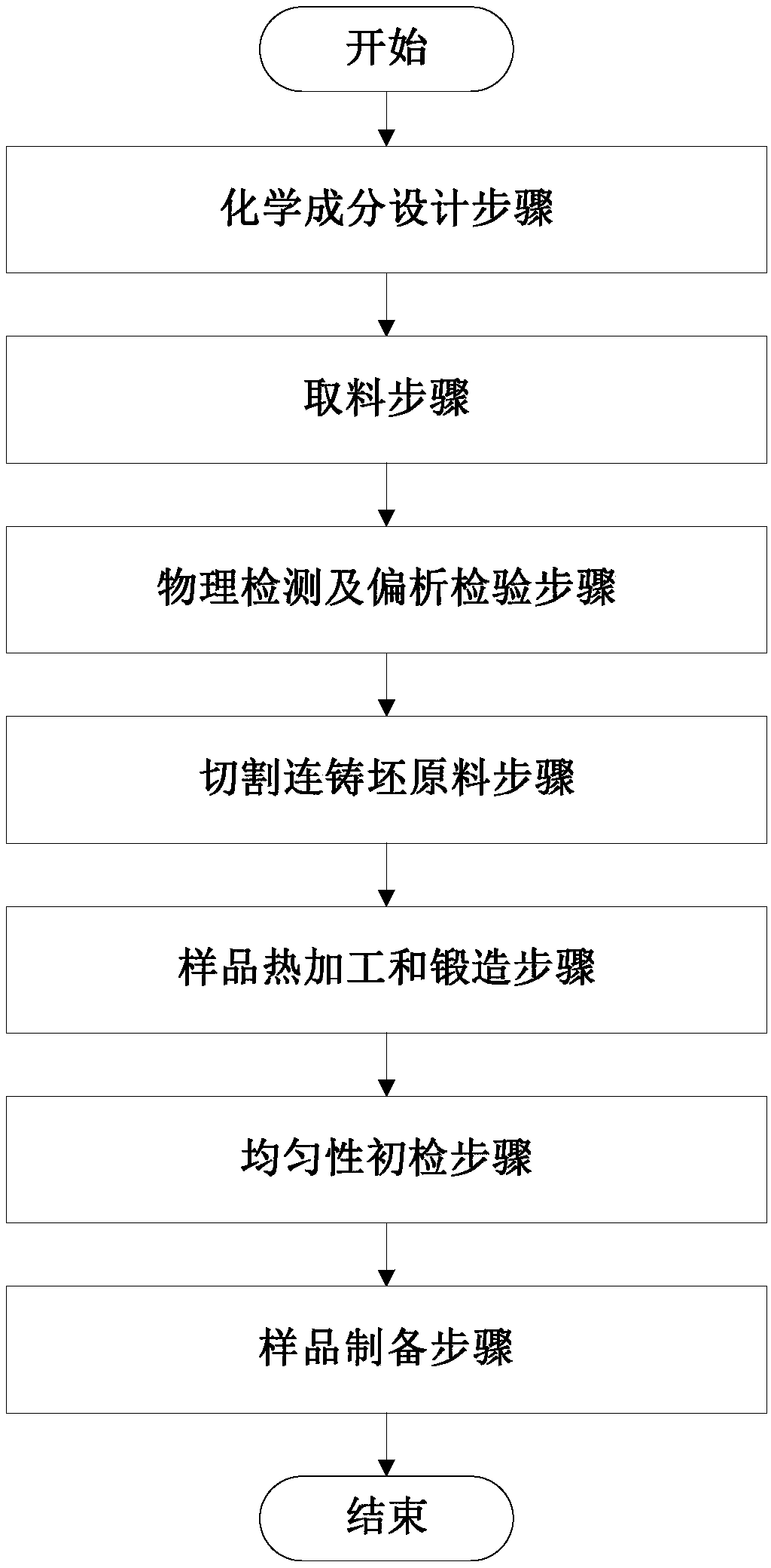

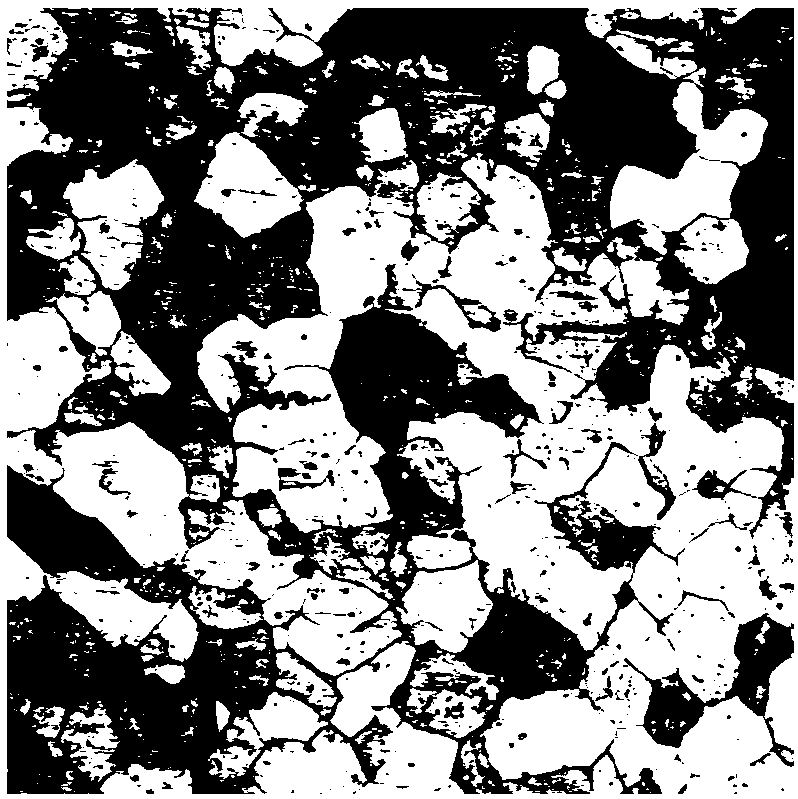

Preparation method of standard sample for spectral analysis of 400 series stainless steel, and standard sample

ActiveCN109030136AImprove cleanlinessThe composition is uniform and consistentPreparing sample for investigationForeign matterChemical composition

The invention discloses a preparation method of a standard sample for spectral analysis of 400 series stainless steel. The method comprises the following steps: a chemical component design step; a material extraction step; a physical detection and segregation inspection step; a continuous casting blank cutting; a sample thermal processing and forging step; a uniformity initial inspection step; anda sample preparation step. The invention further discloses a standard sample prepared according to the preparation method of the standard sample for the spectral analysis of the 400 series stainlesssteel. By adoption of the preparation method disclosed by the invention, it is ensured that the raw material used by the standard sample for the spectral analysis of the 400 series stainless steel islow in foreign matters, high in cleanness and good in component uniformity, the tissue compactness, fine grain, large batch and stable quality of the spectral standard sample are controlled by the thermal processing technology, and the requirements of various quality analysis control in the modern steel industry on the spectral standard sample are met.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

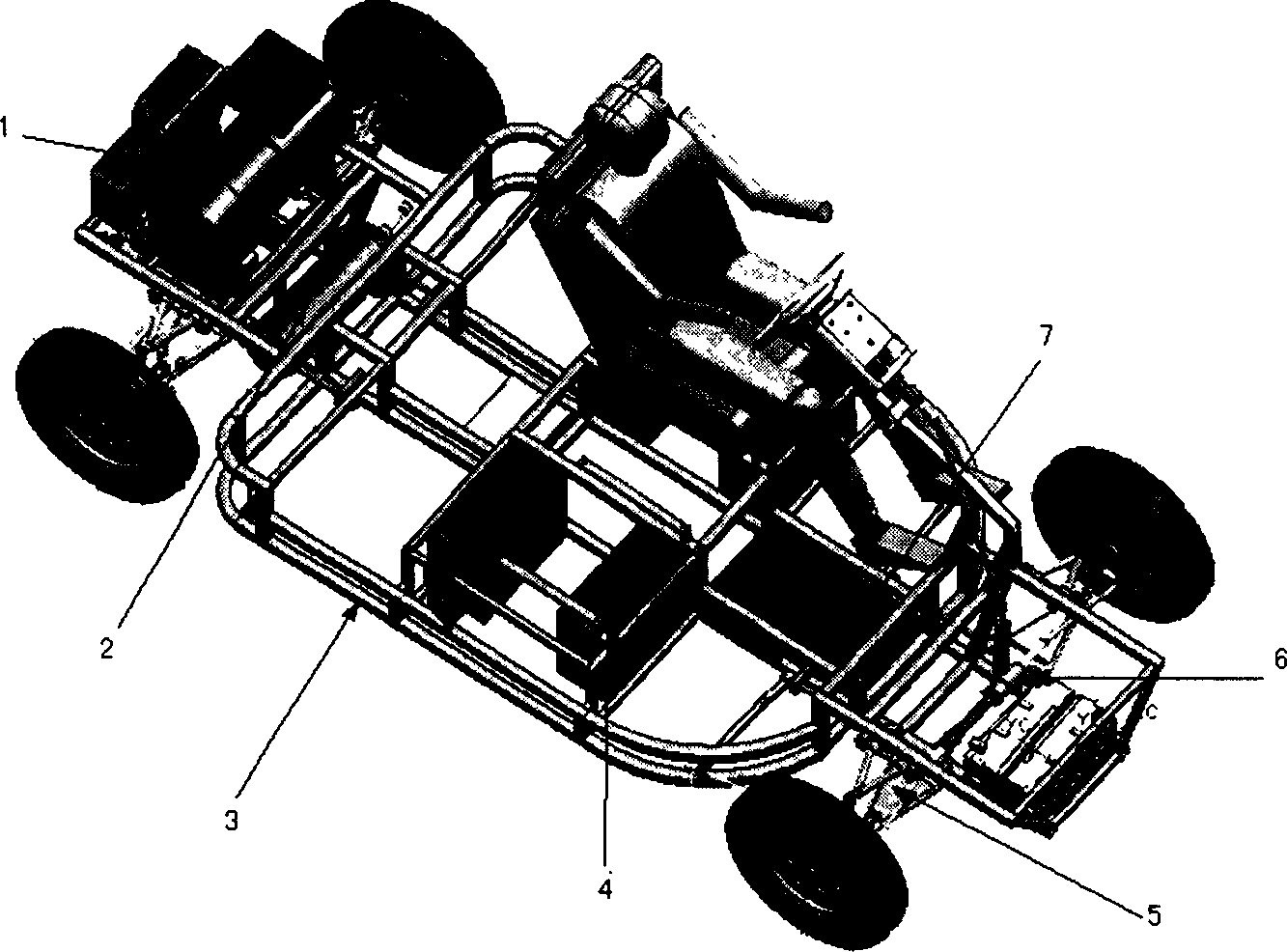

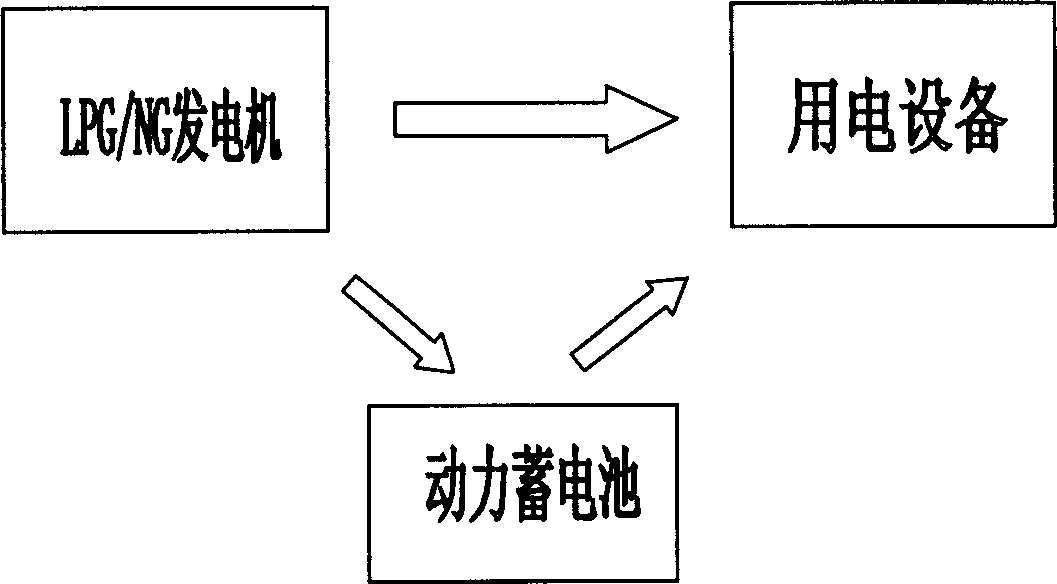

Four wheel driven mixed power mini-sized automobile

InactiveCN1765649AImprove energy efficiencyImprove battery lifeSpeed controllerVehicular energy storageHigh energyElectronic differential

The invention discloses a four-wheel drive mixed power mini-car comprising: wheels, power system, stirrup chassis, high-energy accumulator, a electrical driving wheel module, a gas tank, a redirector which connected to front wheel axle and direction controller, a steering displacement sensor, a electronic differential central controller which can decide if the generator charges the accumulator according to the driving condition and the SOC of accumulator, and a power management modular. The invention can effectively reduce the application cost and increase the endurance mileage with lower discharge; therefore, it can improve the industrialization of electrical car.

Owner:SHANGHAI FUEL CELL VEHICLE POWERTRAIN +1

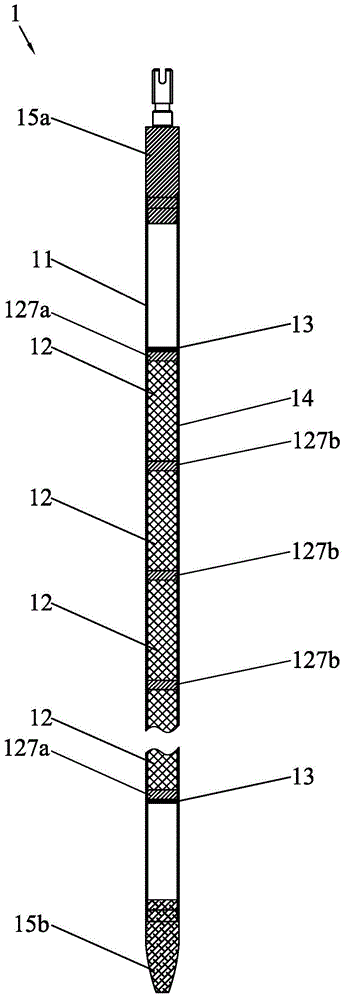

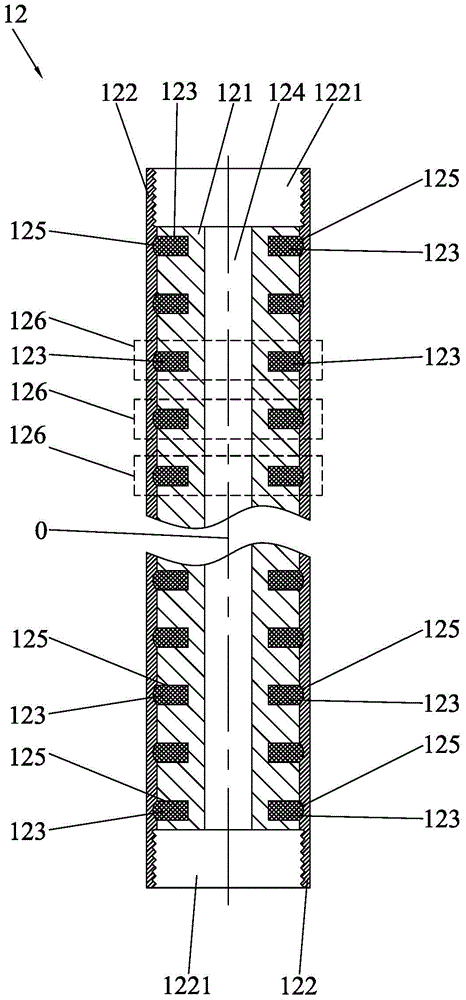

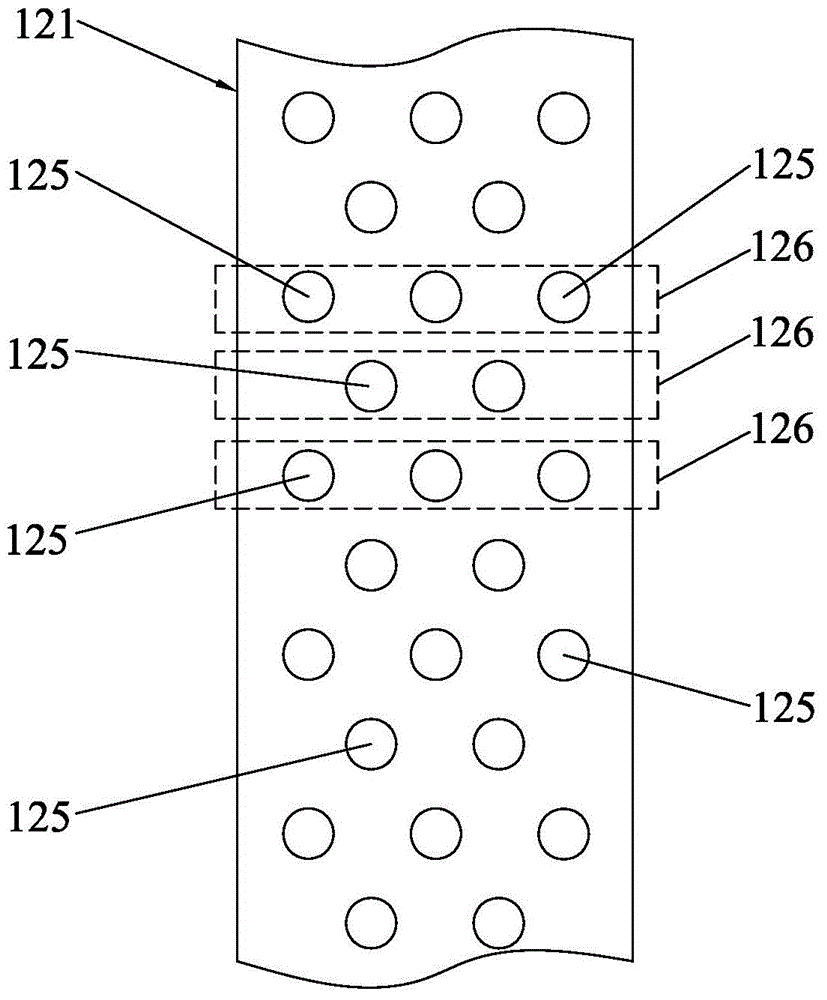

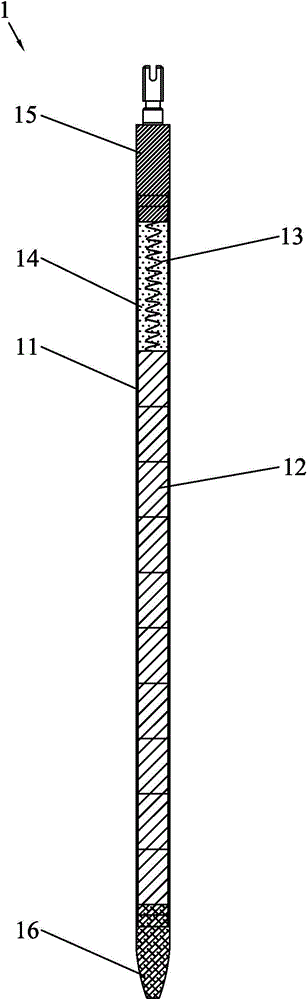

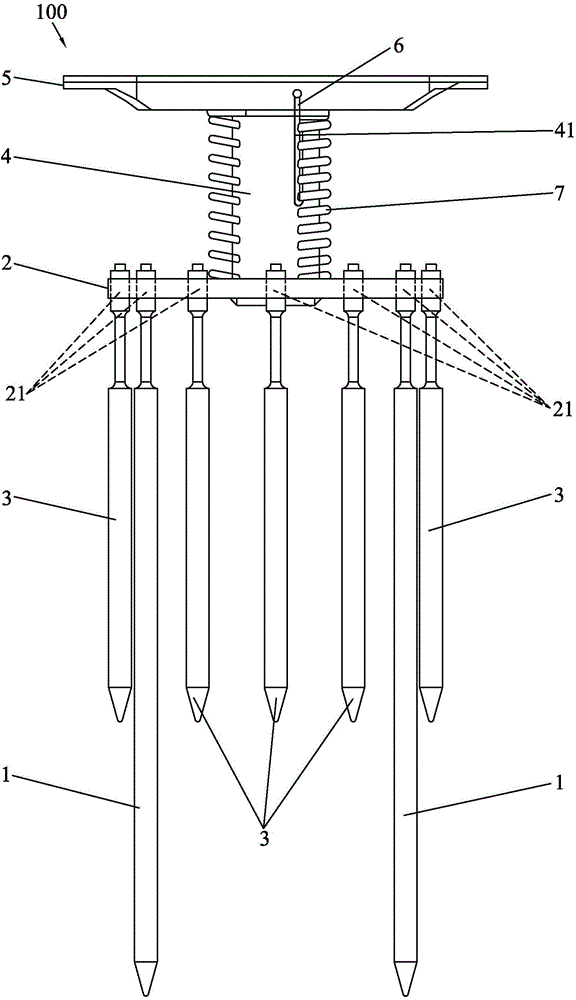

High-specific-activity radioactive source core target, radioactive rod and novel thimble plug assembly

InactiveCN105244069AImprove qualityImprove utilization efficiencyNuclear energy generationConversion in nuclear reactorNuclear reactor coreIsotope

The invention discloses a high-specific-activity radioactive source core target. Neutrons are absorbed in a nuclear reactor core so as to generate radioactive isotopes. A matrix, a casing pipe and radioactive source needle which absorbs the neutrons so as to generate the radioactive isotopes are included. The matrix presents a hollow structure and forms a gas chamber. Source needle grooves are uniformly arranged around a radial direction of the matrix and an irradiation source layer is formed. The source needle grooves on the same irradiation source layer surround and form a circle. A center of the circle is located on a central axis of the gas chamber. An axial direction of the matrix possesses at least two irradiation source layers and the layers are arranged in parallel with an equal interval. Source needles are symmetrically inserted into the source needle grooves of the same irradiation source layer. The matrix is arranged into the casing pipe in a sealing mode and helium is filled into the gas chamber. The invention also discloses a radioactive rod possessing the high-specific-activity radioactive source core target and a novel thimble plug assembly. The assembly can restrict a reactor core coolant bypass flow and can generate the radioactive isotopes. Economic benefits are remarkable and industrial, agricultural and medical demands can be satisfied.

Owner:CHINA NUCLEAR POWER TECH RES INST CO LTD +4

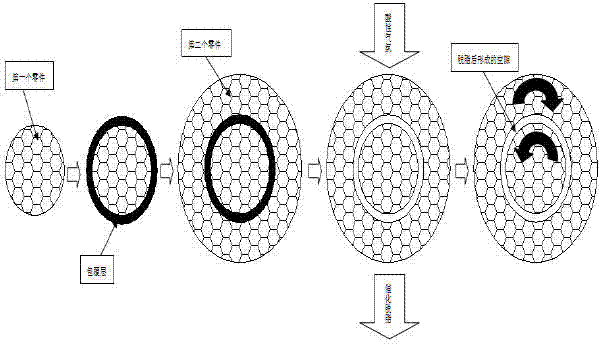

Powder injection molding technology for producing micro-size hinged parts

The invention relates to a powder injection molding technology for producing micro-size hinged parts. According to the technology, a polymer cladding layer which can be catalytically decomposed is formed in an injection molding mode on the surface of the first injection molding part or the interface of the first part and the second part which are hinged by adopting a first rubber coating mold, injection molding is performed again on a mold cavity containing an injection blank through a second rubber coating mold, powder of the second part is fed in an injected mode, an interlayer part set with a middle polymer capable of being catalytically decomposed is finally obtained, and no contact point exists between the first part and the second part. The middle polymer cladding layer which can be catalytically decomposed is completely removed in the following-up degreasing stage, a gap where the first part and the second part move relatively is formed, and therefore the inseparable hinged parts with the size controllable are manufactured. The technology is simple in production process, it is avoided that a linkage system is assembled additionally, overall cost is reduced, production efficiency is high, and the powder injection molding technology can be widely used in the fields of production of micro electro mechanical system, manufacturing of medical instruments and artificial limbs and the like.

Owner:CHANGSHA UNIVERSITY

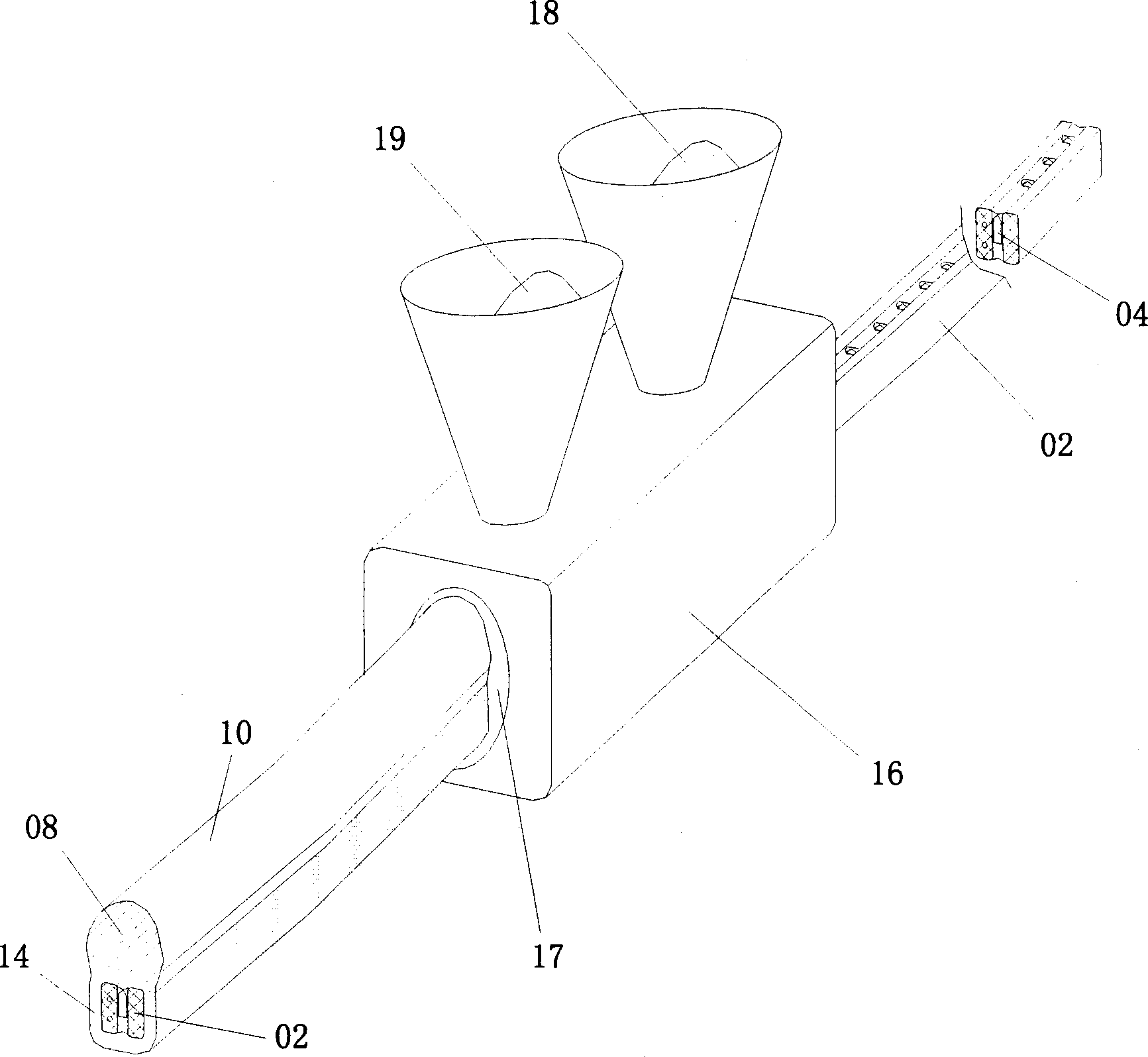

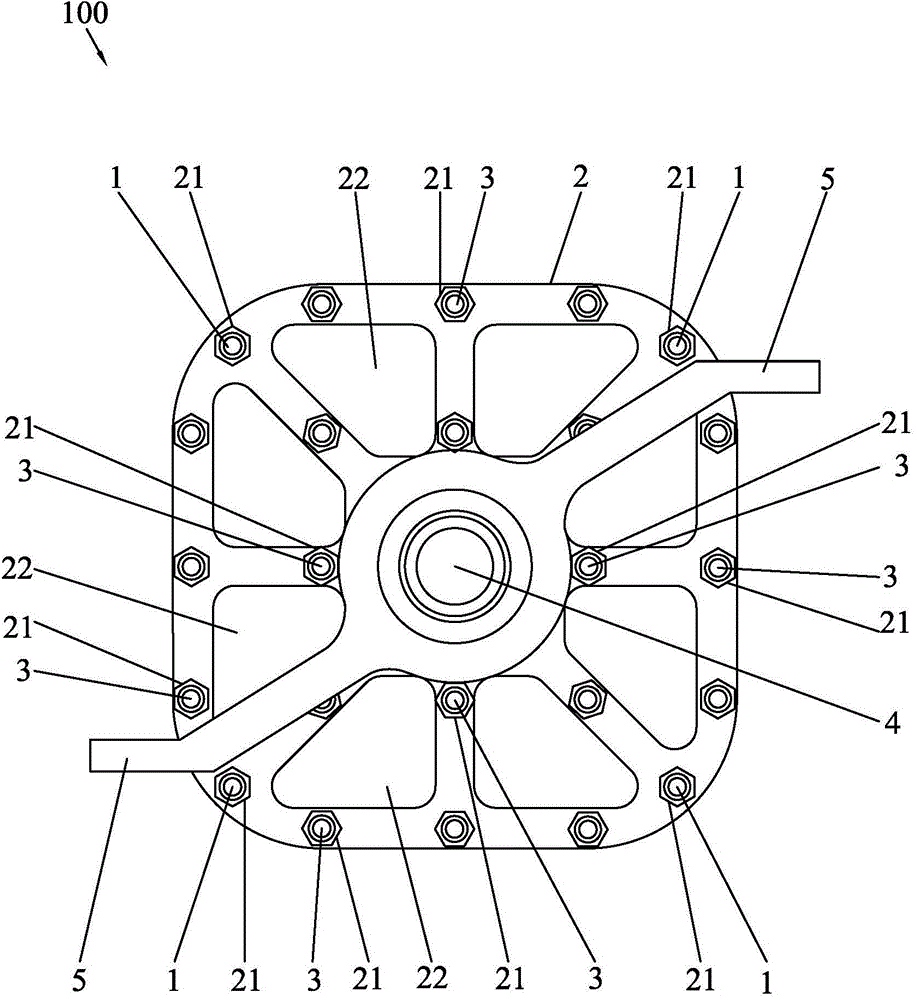

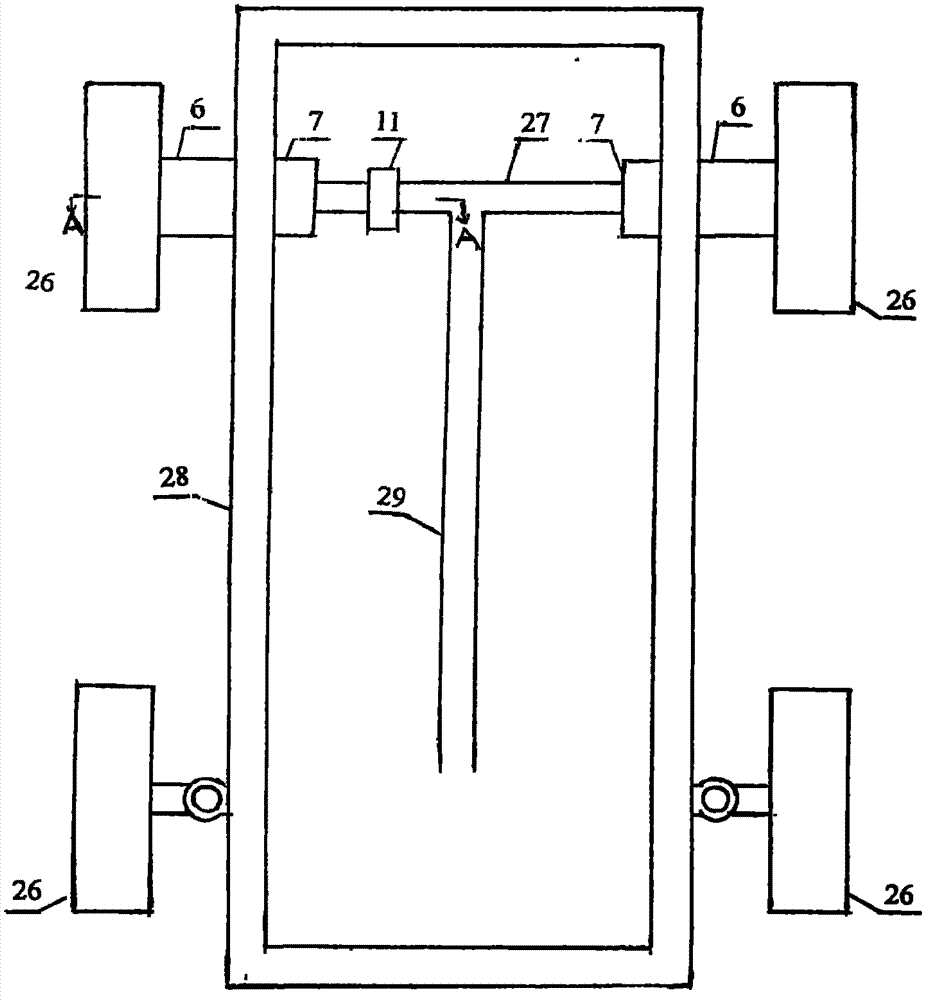

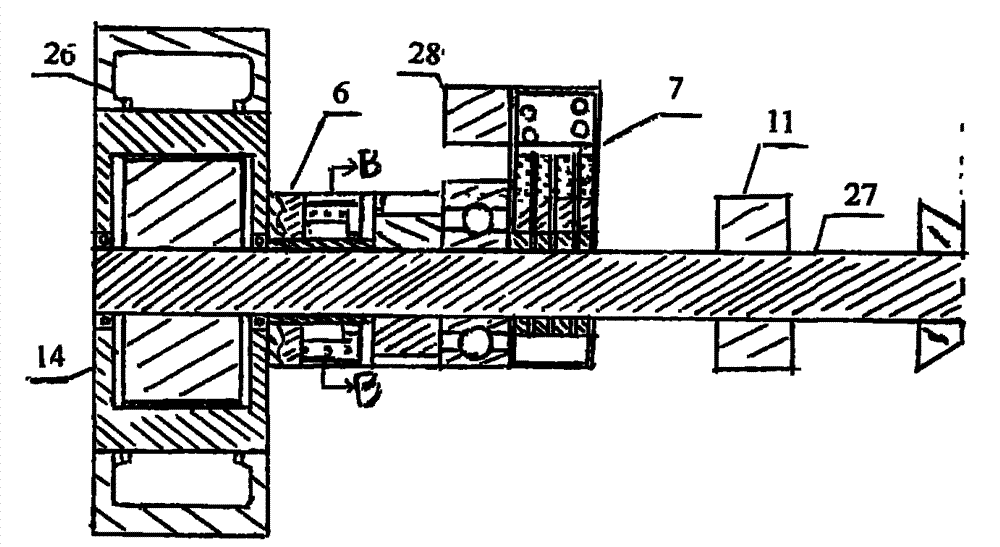

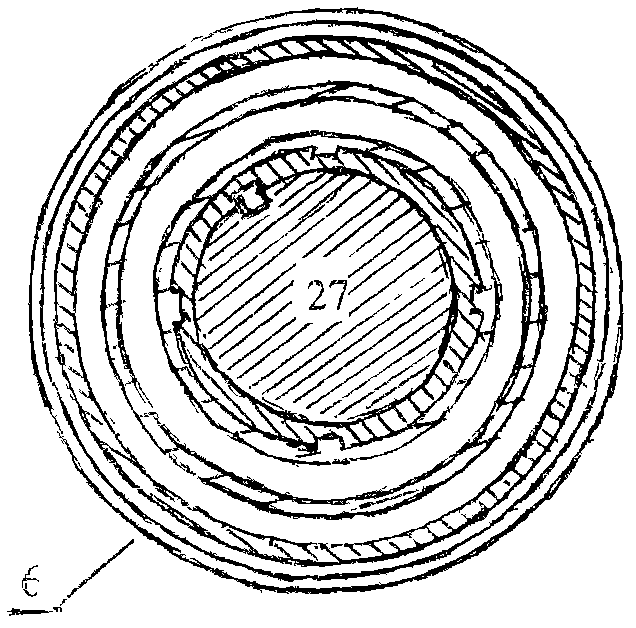

Improved structure of hose lamp

InactiveCN1880834AUniform continuous light effectLarge production batchPoint-like light sourceElectric circuit arrangementsEngineeringLED lamp

The invention relates to a tube lamp improvement, which comprises a core line, several LED inside the core line, one light emitter above the LED with the same length of core line, one coat covering the core line with the same length as core line and extruded shaped with the light emitter, one light-tight cover longitudinally arranged on the coat to shield the side light of LED tube, a connector connecting the tube lamp and the power wire, and a tail piston for covering the tail of tube lamp. The invention can be batch produced, with low cost and continuous uniform light.

Owner:GUANGDONG TONGFANG ILLUMINATIONS CO LTD

Freeze dried combination of Lansoprazole available for linjection and preparation method

InactiveCN1279909CImprove product qualityDoes not reduce efficacyPowder deliveryOrganic active ingredientsLansoprazoleFreeze-drying

The invention provides a lansoprazole freeze-dried composition available for injection and a preparation method thereof, which comprises lansoprazole as the main agent and adds auxiliary materials, and the components in parts by weight are: 30-60 parts of lansoprazole , 2-20 parts of auxiliary solvent, 5-50 parts of basic amino acid stabilizer, and 0.3-8.5 parts of water in auxiliary materials. It can prolong the time of lansoprazole precipitation and crystallization, and no crystallization occurs in the whole production process, so as to improve product quality, not reduce drug efficacy during use, reduce production cost, increase production batch, etc.

Owner:龙蓓

Method of utilizing stirred bioreactor to produce infectious Bursal disease virus

InactiveCN105368794AExpand the scope of operationWell mixedMicroorganism based processesViruses/bacteriophagesCell seedingViral culture

The invention provides a method of utilizing a stirred bioreactor to produce an infectious Bursal disease virus. Bioreactor microcarrier cell culture technology is used to replace conventional roller bottle culture, so that the problems of low production efficiency, unstable product quality and low virus titer can be solved. On this basis, biological characteristics of the infectious Bursal disease virus and DF1 cells are combined, and proper conditions are matched from the perspectives of microcarrier adding amount, cell inoculation density, virus inoculation amount, cell density during virus inoculation, virus collection time and reactor operation parameters, so that virus culture efficiency is improved remarkably, and unit culture titer is improved by 10-100 times. In addition, compared with roller bottle culture, the method utilizing the bioreactor has the advantages that culture scale is large, and parameter control is comprehensive, so that systematic risk of being polluted is lowered, quality stability is improved, and the method has a wide application prospect.

Owner:TIANJIN RINGPU BIO TECH

Improved raw cotton linters composition, method of making same and uses thereof

A composition of a loose mass of comminuted raw cotton linter fibers has a bulk density of at least 8 g / 100 ml and at least 50 % of the fibers in the mass passes through a US standard sieve size #10 (2 mm opening). This composition is made by obtaining a loose mass of first cut, second cut, third cut, or mill runs raw cotton linters or mixtures thereof and comminuting the loose mass of raw cotton linters to a size wherein at least 50 % pass through a US standard sieve size #10 (2 mm opening). This composition is used to make cellulose ether derivatives.

Owner:HERCULES INC

Method for preparing zinc oxide nano-rod by using zinc quantum dot

Disclosed is a preparing process for zinc oxide nano rods by zinc quantum dots, which utilizes zinc quantum dots to react with oxidation agent to prepare zinc oxide nano rods. The process comprises steps of putting zinc quantum dots which are 3-5 nm in size and over 95% in purity into a reacting device, completely substituting air in the reacting device with argon gas atmosphere, heating the reacting device to increase the temperature to 150 DEG C-300DEG C, keeping the temperature, thereby the argon gas carrying the oxidation agent can enter the reacting device and then achieving the contacting reaction with the zinc quantum dots, increasing flowing rate of the argon gas which carrying the oxidation agent, consciously providing oxidation agent to the reacting device until the reaction is finished, closing an oxidation agent inlet of the reacting device and leading pure argon gas into the reacting device, and then cooling the reacting device until the temperature reaches the indoor temperature, finally collecting the products in the reacting device, which is the zinc oxide nano. The preparing process has the advantages that the process needs no catalytic agent and does not pollute the products, the only secondary product in the preparing process is hydrogen gas which is non-pollution to environment, further the reaction temperature is low and the energy consumption is low and the obtained zinc oxide nano rods with specific growth direction are high in application value.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

Novel choke plug assembly for using pressurized water reactor to prepare radioactive source, and radioactive rod

InactiveCN104900288ADoes not affect safe operationEnsure safetyConversion in nuclear reactorPressurized water reactorEconomic benefits

The invention discloses a novel choke plug assembly for using a pressurized water reactor to prepare a radioactive source. The novel choke plug assembly comprises a connecting plate and stainless steel choke stoppers. The connecting plate is provided with mounting parts used for mounting the stainless steel choke stoppers. The 24 mounting parts are distributed in a scattered manner. The novel choke plug assembly further comprises N radioactive rods which are used to absorb neutrons and produce radioactive isotopes, wherein N is a natural number which is less than or equal to 24. The radioactive rods are correspondingly mounted on N mounting parts in a suspended manner, the stainless steel choke stoppers are correspondingly mounted on the remaining mounting parts in a suspended manner, and the radioactive rods and the stainless steel choke stoppers are parallel to each other. The novel choke plug assembly for using a pressurized water reactor to prepare a radioactive source not only can limit the reactor core coolant bypass flow, but also can produce radioactive isotopes, has remarkable economic benefit, and can greatly satisfy the needs of industrial, agricultural and medical use. The invention further discloses a radioactive rod.

Owner:CHINA NUCLEAR POWER TECH RES INST CO LTD +2

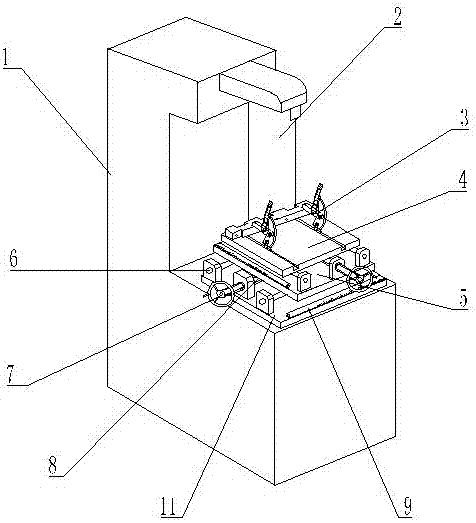

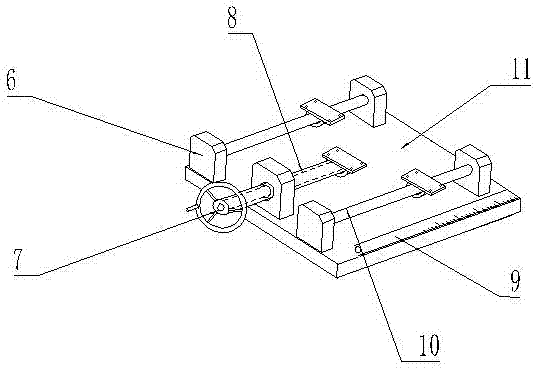

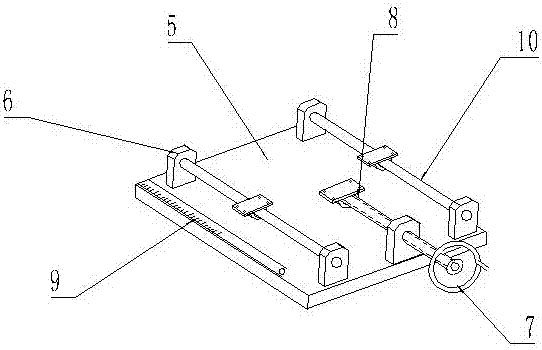

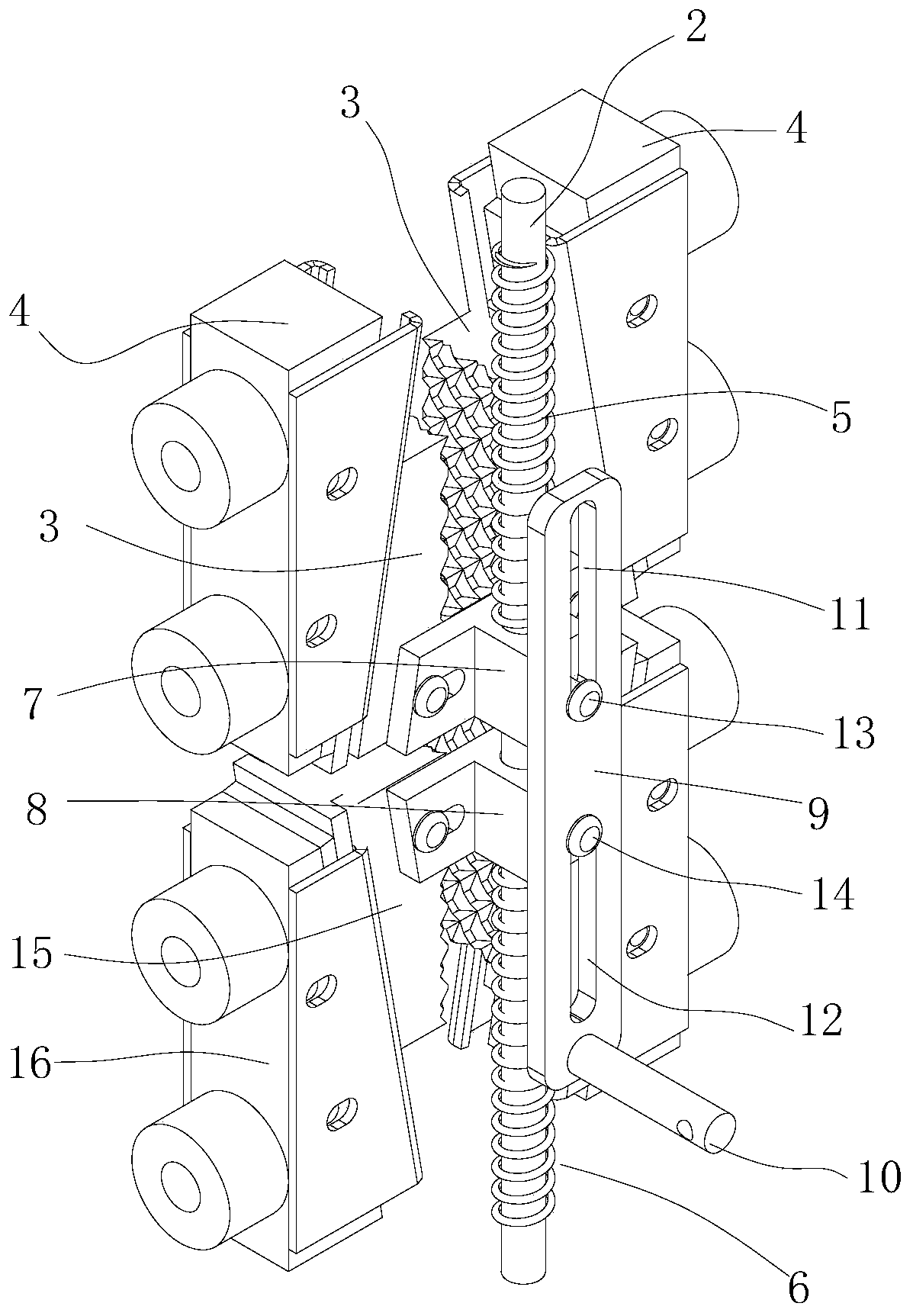

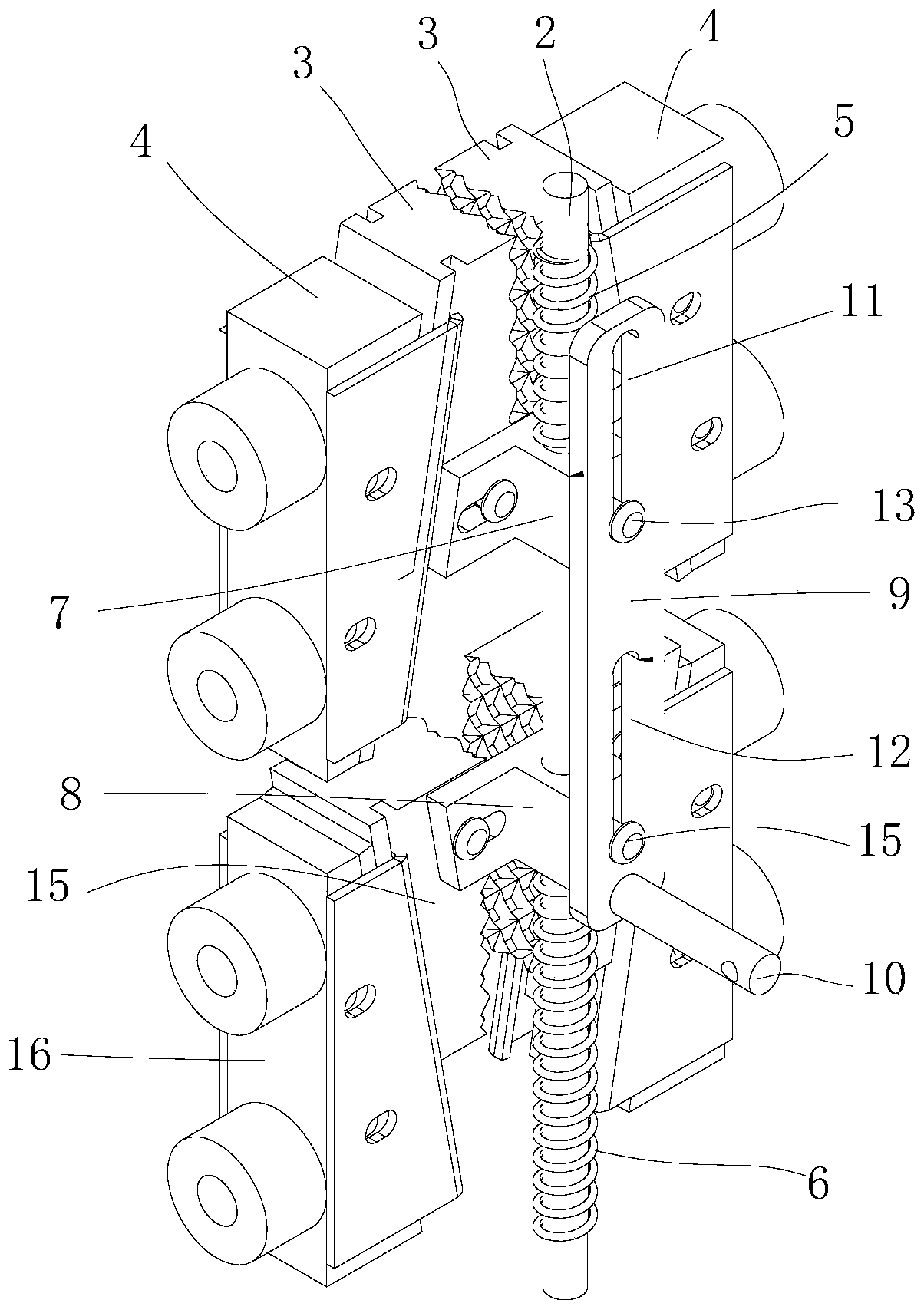

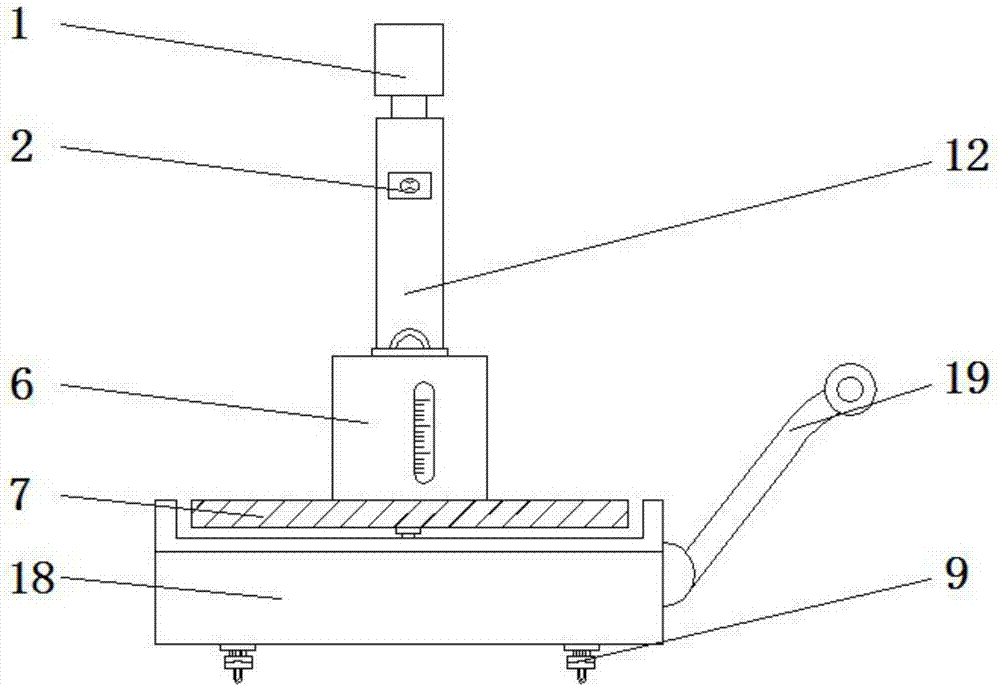

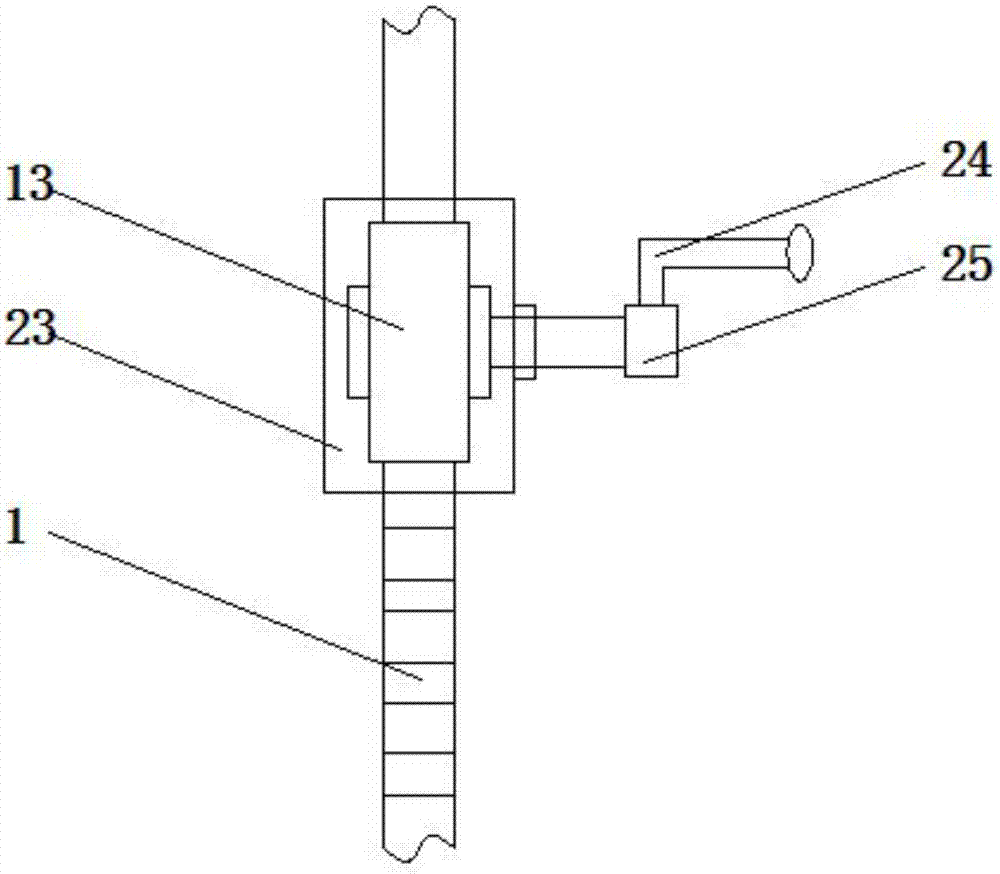

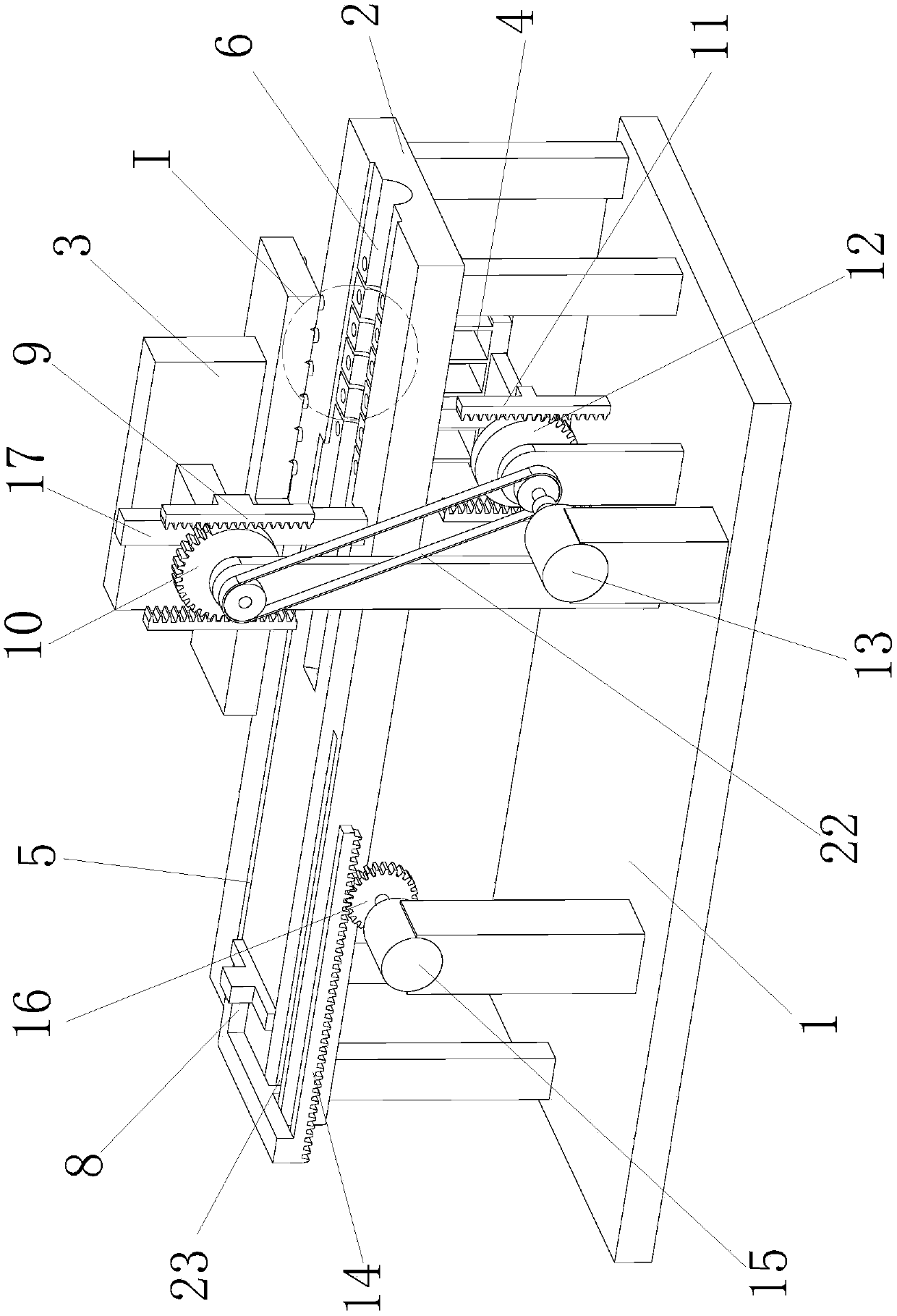

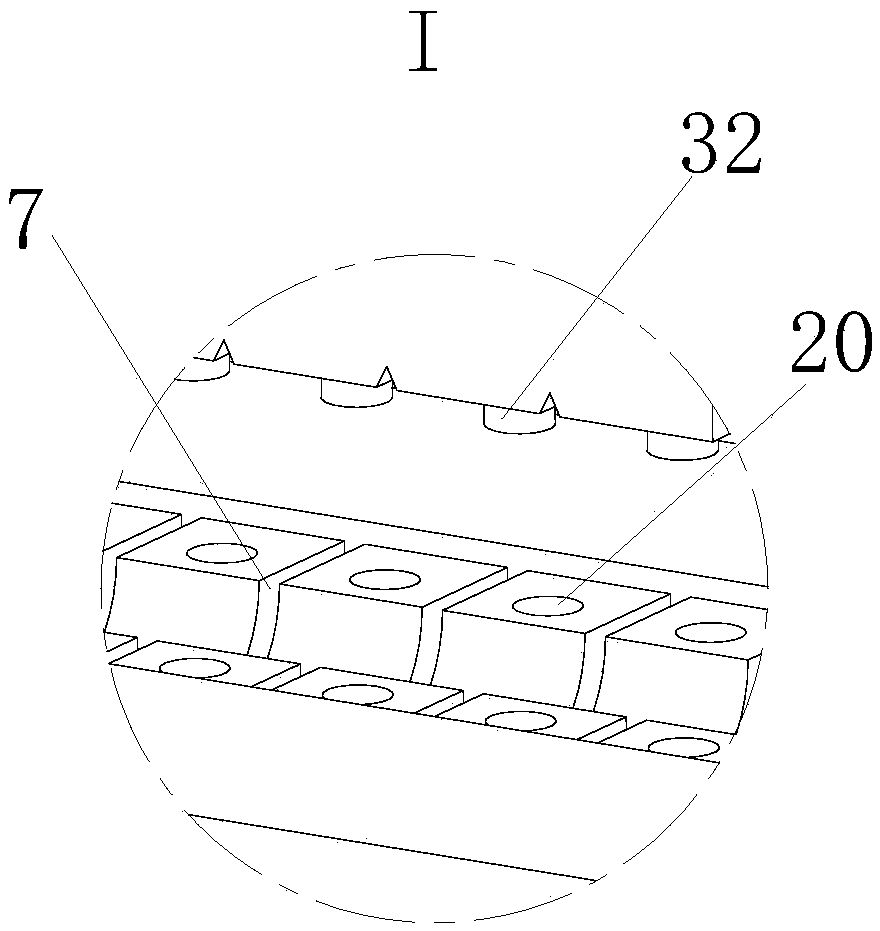

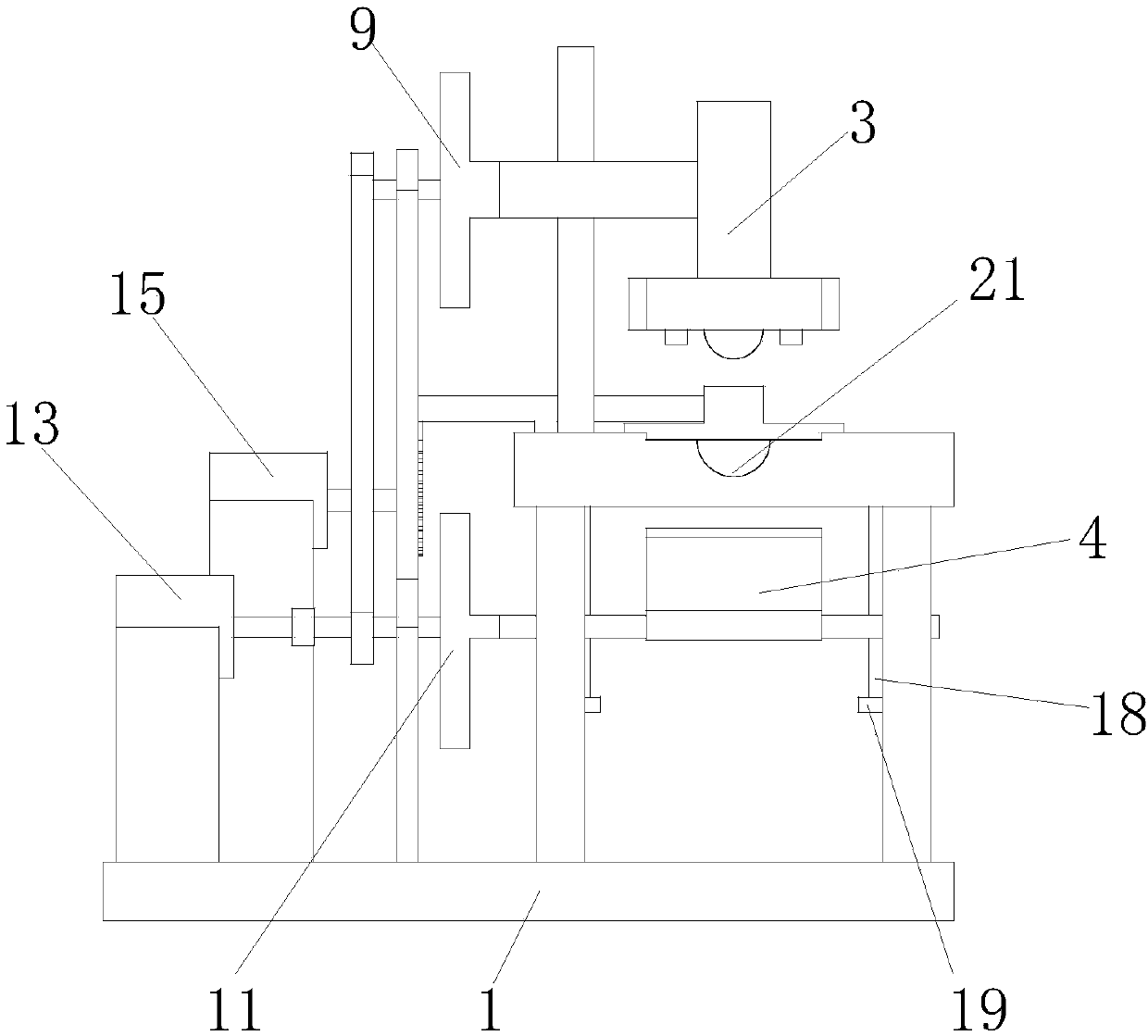

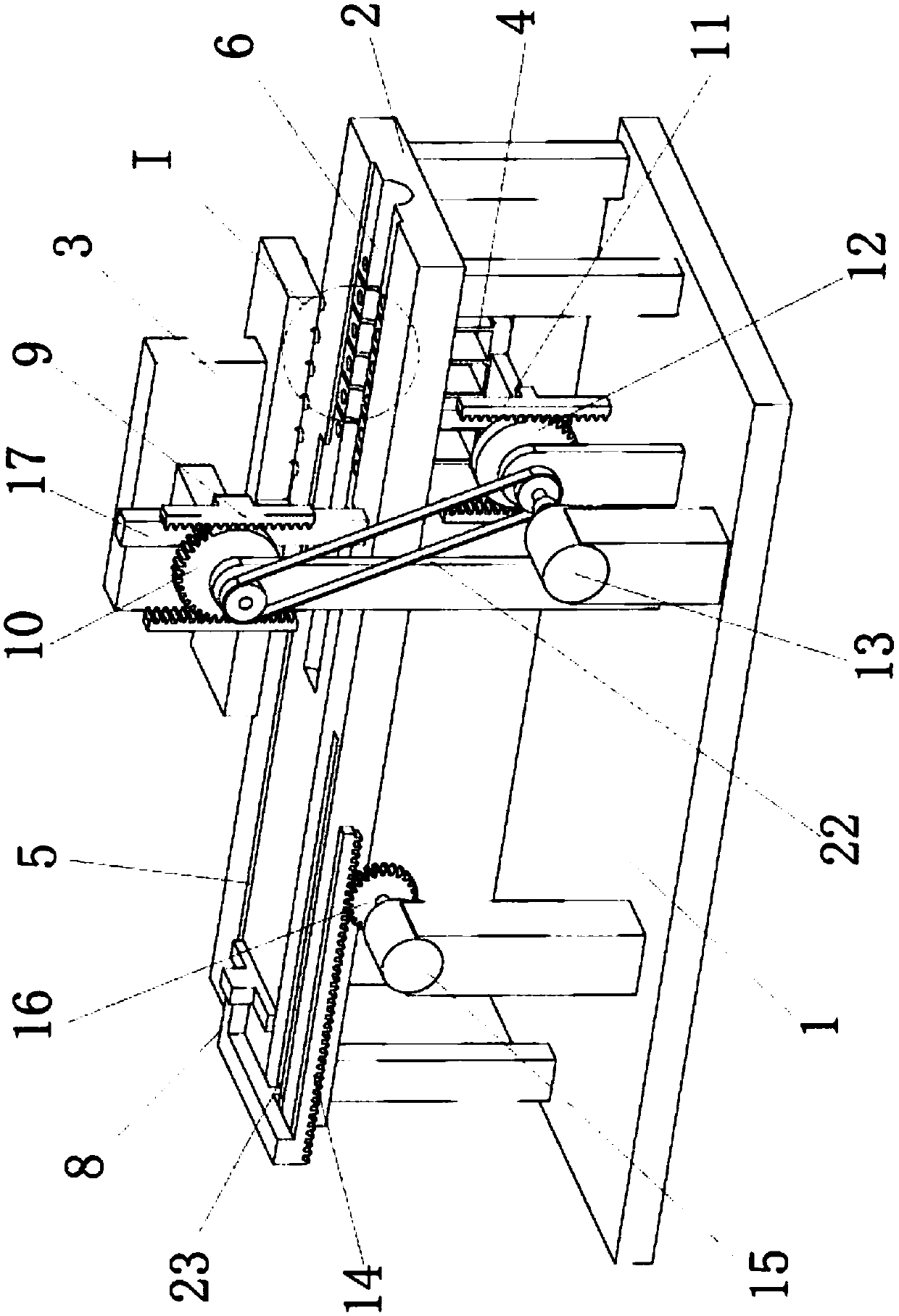

Machining equipment for wood insulation clamping element for transformer lead, and machining method for wood insulation clamping element

InactiveCN107160491ALarge production batchHigh degree of automationPower driven reciprocating sawsSawing componentsEngineeringTransformer

The invention relates to machining equipment for a wood insulation clamping element for a transformer lead, and a machining method for the wood insulation clamping element. The machining equipment for the wood insulation clamping element comprises a scroll saw machine, wherein the scroll saw machine is provided with a working platform and a scroll saw blade, and a machining fixture for the insulation element for the transformer lead is installed on the working platform; and the machining fixture comprises rapid pressing plates, an upper carriage, a lower carriage and a bottom plate. The machining method comprises the following machining steps: placing the wood clamping element on the upper carriage below the rapid pressing plates, rotating adjustment screw rods on the bottom plate and the lower carriage separately, and enabling the lower carriage and the upper carriage to move on a slide rod to move the machining position of the clamped wood clamping element to a position close to the scroll saw blade; starting the scroll saw machine, enabling the scroll saw blade to work, and reversely rotating the adjustment screw rods to retreat the machined wood clamping element after cutting is completed; re-rotating the adjustment screw rods to move another machining position of the wood clamping element to a position close to the scroll saw blade; and unscrewing the rapid pressing plates, and taking out the machined wood clamping element. The machining equipment for the wood insulation clamping element is simple in structure, high in automation degree, large in production lot size, and high in efficiency.

Owner:广西仙河电气有限公司

Submicron yttrium oxide having high specific surface area and preparation method thereof

ActiveCN110655099AChange the amount addedDifferent areaRare earth metal compoundsOXALIC ACID DIHYDRATEActive agent

The invention belongs to the technical field of preparation of rare earth compounds, and in particular, relates to submicron yttrium oxide having high specific surface area and a preparation method thereof. Yttrium oxide with different specific surface areas and particle sizes can be prepared by changing the addition amounts of an organic dispersing agent and an anionic surfactant, oxalic acid isused as a precipitator, and the method has the advantages of large production batch, simple process and accordance with environmental protection requirements. The submicron yttrium oxide having high specific surface area and produced by the method avoids tedious post-treatment avoided, can be prepared by direct sieving, has the advantages of high purity, small ignition vector, low impurity contentand the like, and can meet the requirements of customers on product performance to a greater extent.

Owner:CHANGZHOU GEOQUIN NANO NEW MATERIALS

Control method for wheel hub motor type hybrid electric vehicle

ActiveCN102627068BReduce volumeMature technologyHybrid vehiclesGas pressure propulsion mountingWireless internet accessAutomatic transmission

The invention discloses a wheel hub motor type hybrid electric vehicle. Both sides of a vehicle rear axle are respectively provided with a carbon brush group. A clutch is arranged between a shell and a rear axle of the wheel hub motor. An axle braking device is mounted on the rear axle. A magnetic induction wheel speed sensor is installed beside each wheel. A gear control device is arranged on an automatic transmission vehicle. Signals of the magnetic induction wheel speed sensors, a steering sensor, a front camera, a front radar, a rear camera, a rear radar, a satellite navigator, a throttle detection device, a brake pedal detection device and the like are input into a wireless internet access computer; and output control lines of the wireless internet access computer are respectively connected to a main controller and a special controller. Output lines of the special controller are respectively connected to a motor controller, an energy recovery converter, an electronically controlled clutch or a hydraulic clutch, the gear control device, the axle braking device, an electric oil pump and the like. An output line of the motor controller is connected to the wheel hub motor, and an output line of the energy recovery converter is connected to an energy recovery relay battery and a storage battery.

Owner:张英华

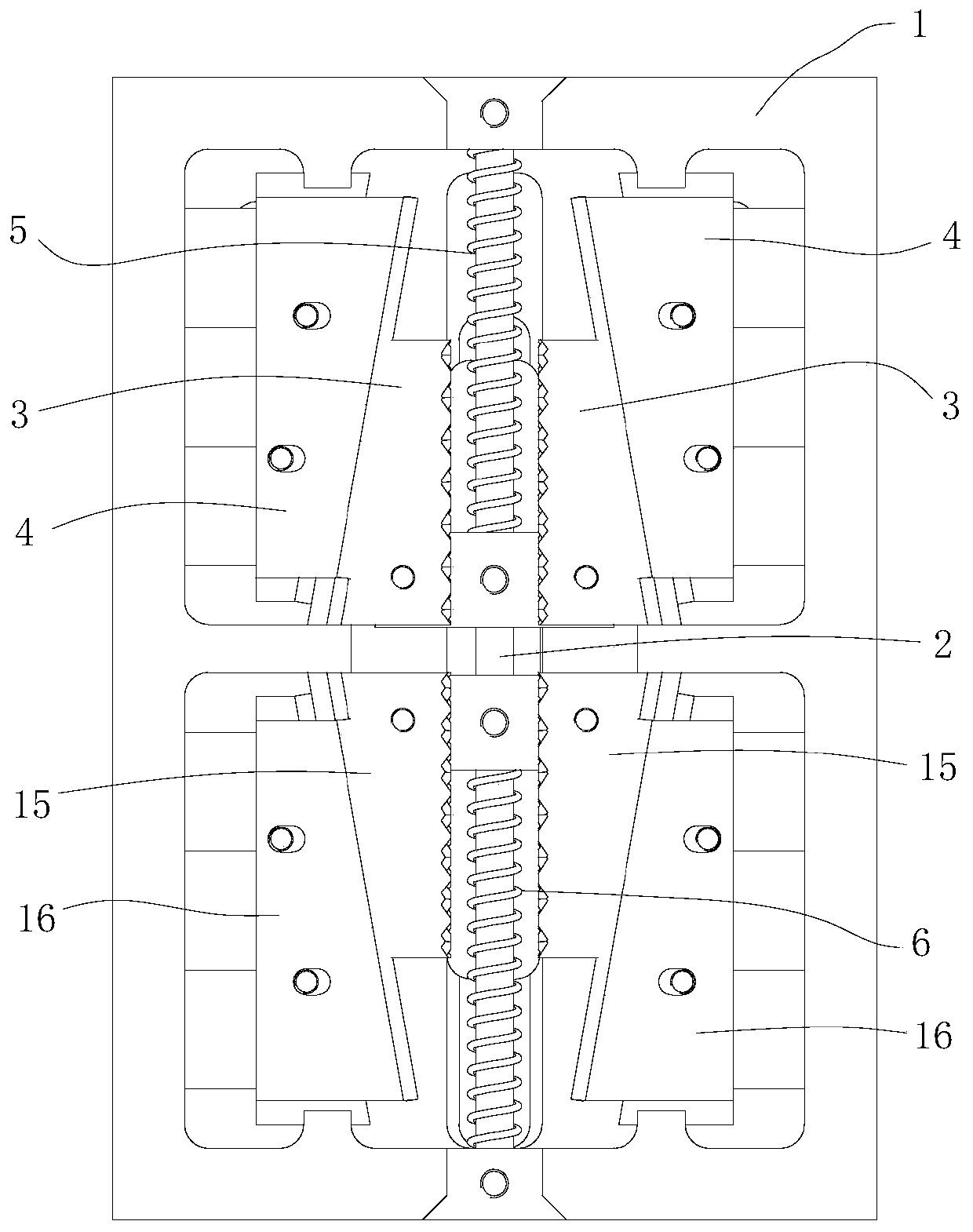

Elevator two-way safety clamp

PendingCN110027961ADoes not affect normal workRealize brake protectionElevatorsEngineeringBody frame

The invention relates to the technical field of elevator safety devices, in particular to an elevator two-way safety clamp. The elevator two-way safety clamp comprises a clamp body frame, an upper braking device and a lower braking device, an interlock lifting and pressing rod is arranged in the middle of the clamp body frame from top to bottom in a penetrating mode, and the upper braking device and the lower braking device are placed on the upper part and the lower part of the clamp body frame correspondingly; and the elevator two-way safety clamp further comprises a braking sliding sheet, the bottom end of the braking sliding sheet is connected with a braking rod, and the braking rod is connected with an elevator torsion rod; the braking sliding sheet is provided with an upper sliding groove and a lower sliding groove, an upper sliding column is arranged on one side of an upper sliding block in an extending mode, the upper sliding column is slidably arranged in the upper sliding groove, a lower sliding column is arranged on one side of a lower sliding block in an extending mode, and the lower sliding column is slidably arranged in the lower sliding groove. According to the elevator two-way safety clamp, the structure is simple and novel, the two-way safety clamp is operated through a single torsion rod, the normal work of existing two-way safety clamps is not affected, stop protection is achieved when a lift car moves at excessive speed, mass production is achieved, the structure is compact, the occupied space is small, and the cost is low.

Owner:ZHONGSHAN POLYTECHNIC

Method for preparing compound Ganmaoling granules

InactiveCN109288929ASimple processLarge production batchGranular deliveryRespiratory disorderEthanol contentHoneysuckle

The invention discloses a method for preparing compound Ganmaoling granules, which is characterized by comprising the following steps: a, pretreating, to be specific, cutting herba viticis, thin evodia twig and leaf, and scaly holly root into sections with length of about 2-15 cm, cutting baphicacanthus root into sections with length of about 3-30 cm, and bagging wild honeysuckle flower and wild chrysanthemum flower; b, extracting, to be specific, adding all the medicinal materials into a boiling and extracting tank in sequence, firstly, adding the scaly holly root and the herba viticis into the tank, then wild honeysuckle flower and wild chrysanthemum flower, and finally, adding the thin evodia twig and leaf and the baphicacanthus root into the tank; c, refining, to be specific, cooling the fluid extract to a temperature of 30-50 DEG C, adding ethanol to enable the ethanol content to reach 60-65 %, stirring evenly, allowing standing for 12-24 hours, filtering, and concentrating the filtrate into a thick extract with a relative density of 1.17-1.26 at a temperature of 70-80 DEG C; d, preparing, to be specific, adopting wet granulation, one-step granulation, high-speed extrusion granulation, spheronization granulation or spray granulation.

Owner:华润三九(郴州)制药有限公司

Constant temperature measurement-type micro humidity sensor and producing method thereof

InactiveCN101532975BSmall temperature coefficientLarge production batchMaterial impedanceCapacitanceAstronautics

The invention discloses a constant temperature measurement-type micro humidity sensor and a producing method thereof, relating to the sensor technology; the sensor consists of a humidity sensitive film capacitor and a pedestal, wherein at least one electrode in the lower electrode of the humidity sensitive film capacitor acts as a capacitance or impedance measuring electrode and a constant temperature-control heating electrode and works with a temperature sensor in the lower electrode under the control of an external circuit of the sensor to cause the micro humidity sensor to measure humidityat certain constant temperature. A thin supporting film for supporting the humidity sensitive film capacitor in the sensor has through holes or clearance structures, thereby reducing heat loss and causing the sensor to realize constant temperature measurement under relatively low power consumption. The micro humidity sensor is not affected by the environmental temperature, has small temperature coefficient and good low-temperature performance, realizes the humidity measurement at negative temperatures and has a volume smaller than 2mm*2mm*2mm. The invention is applied to daily life, industrial production, weather forecast, environment monitoring, aeronautics, astronautics and other fields.

Owner:INST OF ELECTRONICS CHINESE ACAD OF SCI

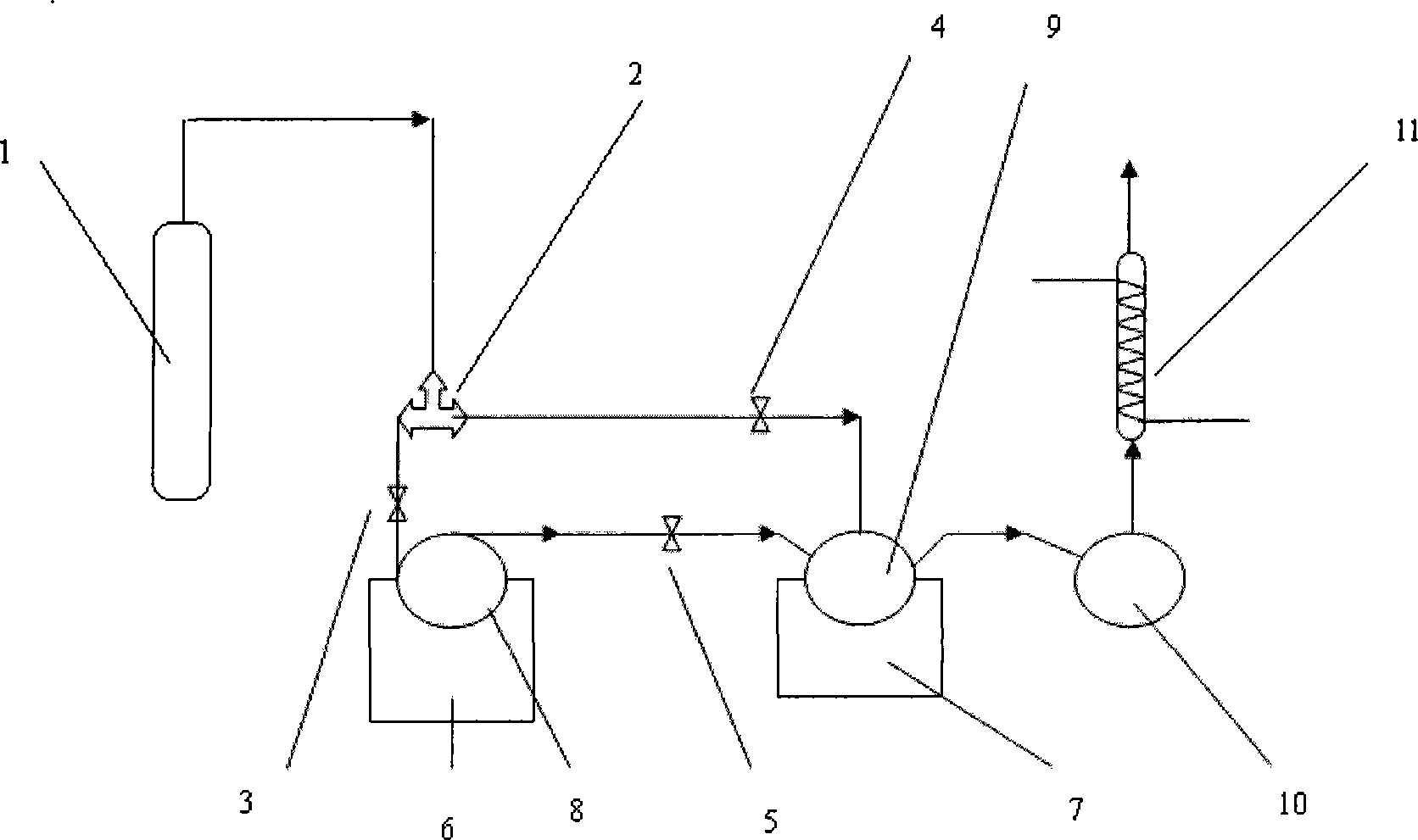

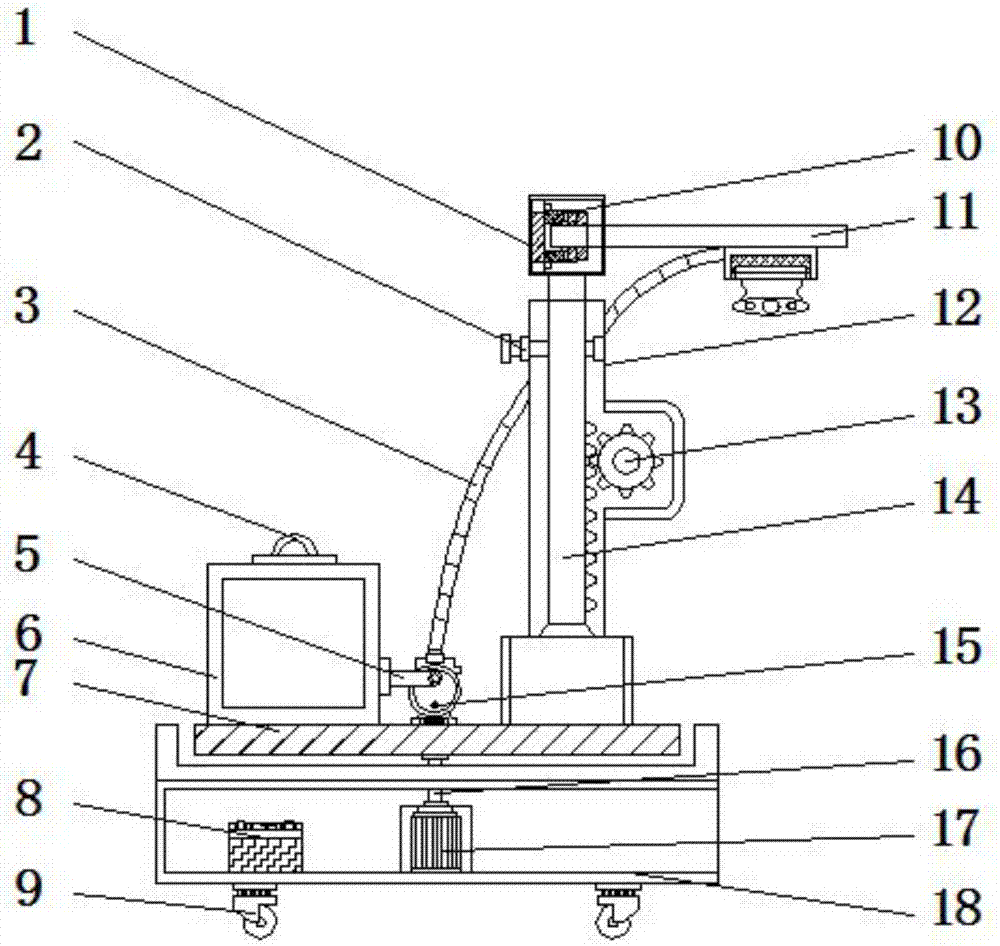

Powder spraying agricultural mechanical equipment for silkworm breeding

InactiveCN107350108ALarge production batchImprove dusting efficiencyLiquid spraying apparatusAnimal husbandryPistonAgricultural engineering

The invention relates to a powder-sprinkling agricultural mechanical equipment for silkworm breeding, which includes a bolt, a turntable, a chain rod and a machine body. A rotating motor is installed at the middle of the inner bottom of the body, and the rotating motor is electrically connected to a storage battery through a wire. One side of the top of the turntable is equipped with a medicine powder storage box, and the other side of the top of the turntable is equipped with a support rod, and a chain rod is installed vertically inside the support rod, and the chain rod is connected with a gear. The present invention is provided with a hydraulic oil cylinder, a piston and a turntable, the hydraulic oil cylinder extends the piston, and the turntable rotates to adjust the angle. With mutual cooperation, the silkworm medicine can be sprinkled on any part of the silkworm tool to sterilize all silkworm bodies, prevent and cure diseases At the same time, the device is equipped with a nozzle and an exhaust fan, and the exhaust fan runs to spray the powder through the nozzle in time, which solves the problem of time-consuming and laborious application of the drug by the user, thereby improving the powder spreading efficiency of the device.

Owner:李小燕

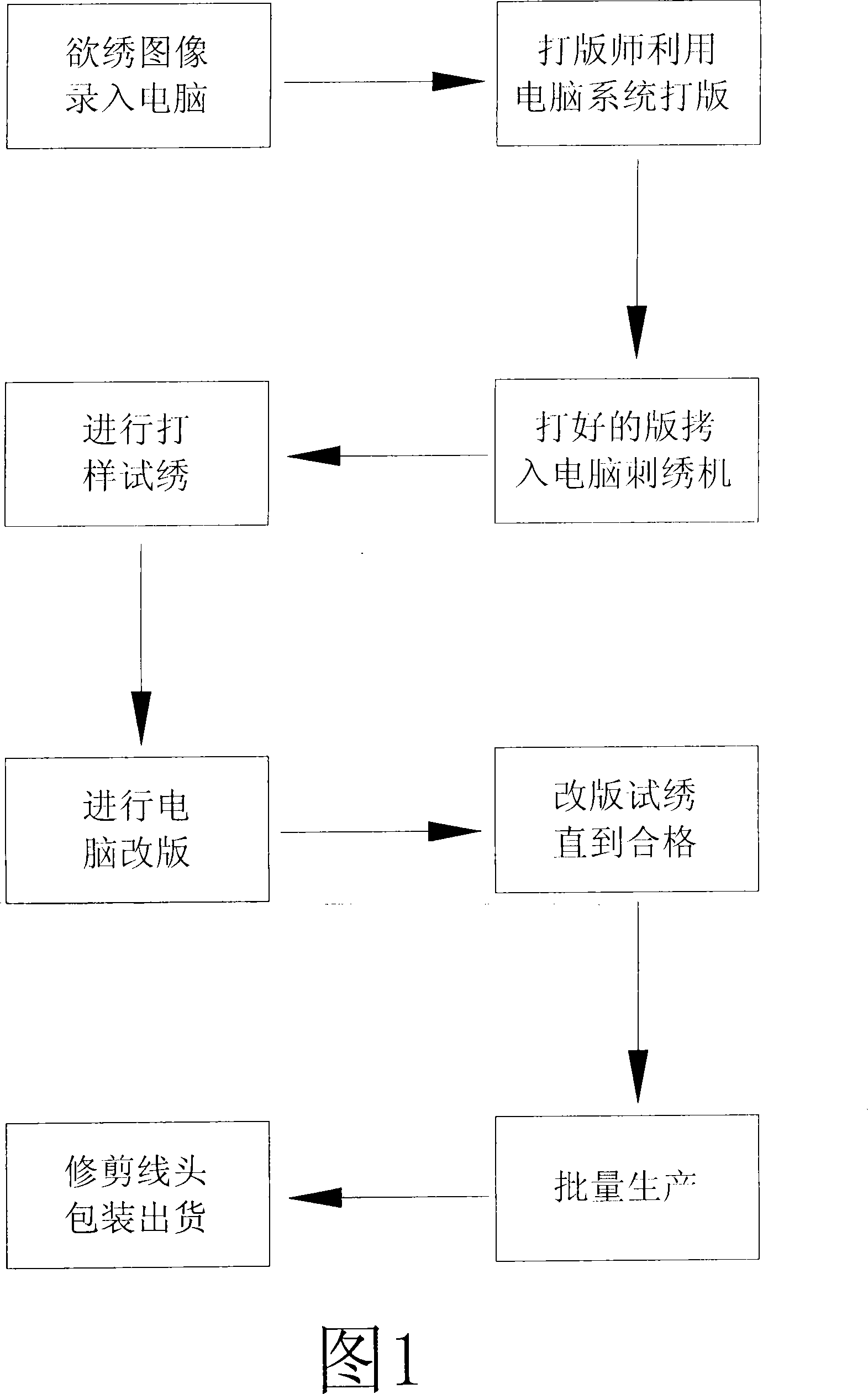

Computer machine embroidery technique

InactiveCN101240487AThe picture feels softPicture smoothingAutomatic machinesAuxillary devicesComputer engineering

The invention discloses a computer machine embroidery technique comprising following steps: inputting the pattern to be embroidered into the computer; making a plate for the input pattern by a plate maker using the computer; inputting the made machine embroidery plate into the computer embroidery machine to perform proofing; correcting the machine embroidery plate by using the computer, performing proofing again until the plate is determined; inputting the determined plate into the computer embroidery machine to perform lot production. Sub-threads are used when proofing and lot production are performed, and the rotating speed of the computer embroidery machine matches with the diameter of the sub-threads. The invented technique greatly reduces needle numbers of the embroidery, amount of the used thread, and production cost. At the same time, the embroidered product by using the invented technique has advantages of soft image feeling, natural transition between different color threads, a cubic effect, strong layered feeling, is not easy to expose the bottom layer and can compare beauty with handwork embroidery.

Owner:范金萍

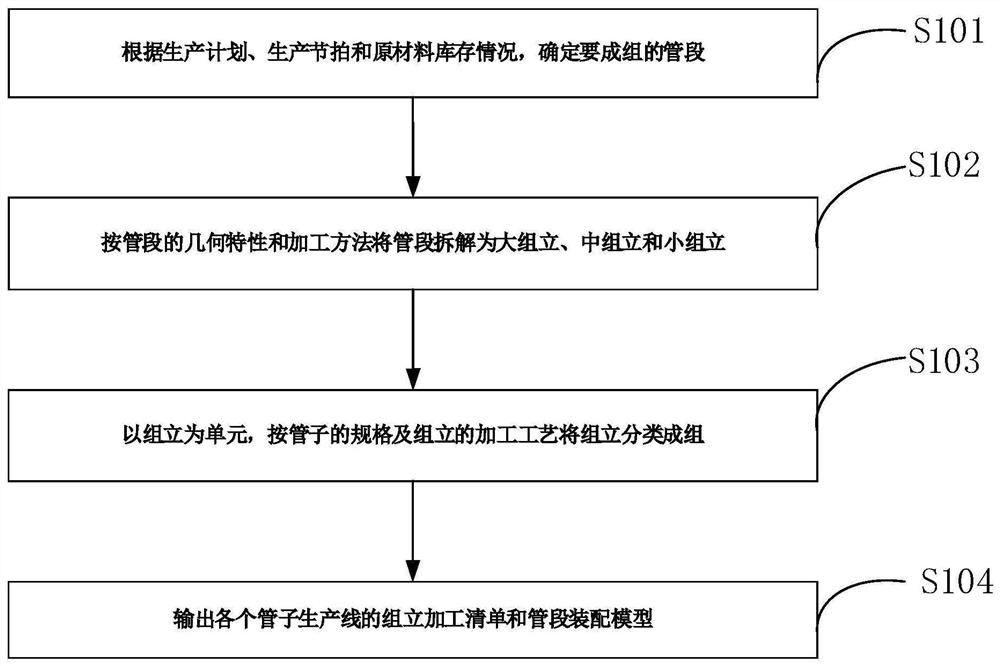

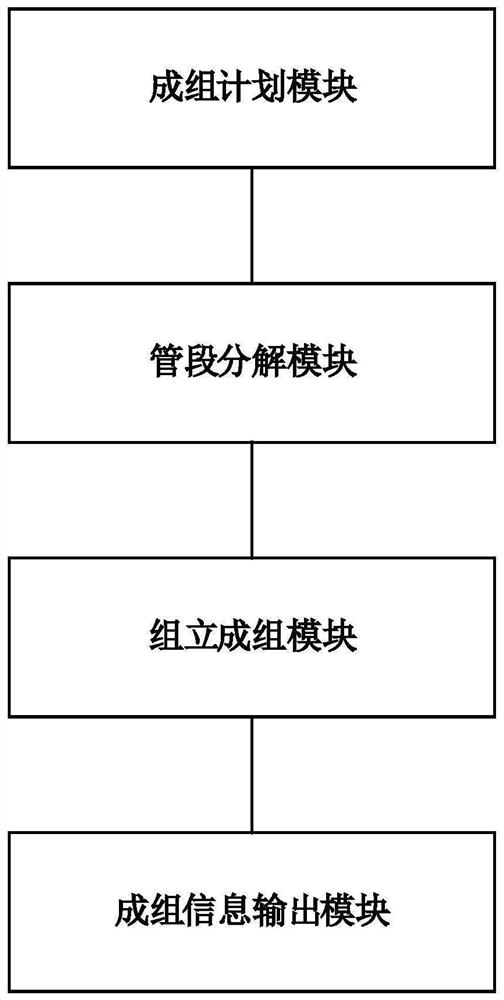

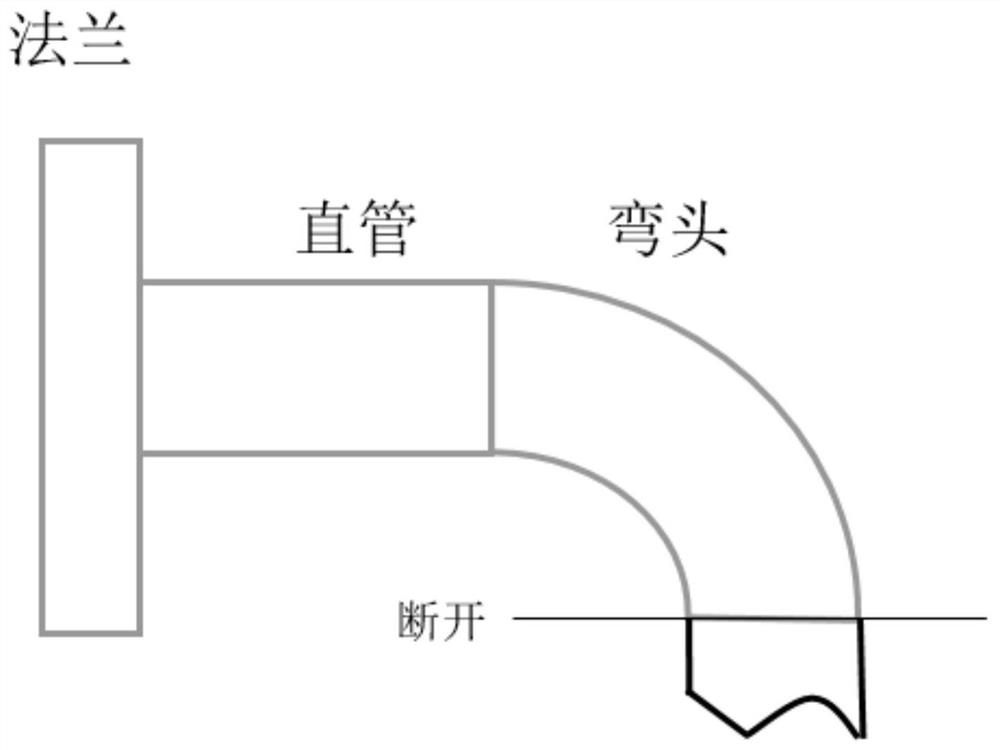

Automatic grouping method and system for ship pipe fitting family manufacturing

ActiveCN112446094AImprove production efficiencyImprove group rateGeometric CADCAD network environmentPipe fittingManufactured material

The invention provides an automatic grouping method and system for ship pipe fitting family manufacturing, and the method comprises the steps: determining to-be-grouped pipe sections according to a production plan, a production takt and a raw material inventory condition; the pipe section is disassembled into a large assembly, a middle assembly and a small assembly according to the geometrical characteristics and the machining method of the pipe section; taking the assemblage as a unit, and classifying the assemblage into groups according to the specification of the pipe and the machining process of the assemblage; and outputting an assembly processing list and a pipe section assembly three-dimensional model of each pipe production line. The method has the beneficial effects that the pipesection machining grouping technology is optimized, the pipe grouping rate is increased, the production batch is enlarged, the pipe section manufacturing production efficiency is improved, the timeliness and integrity of tray distribution are ensured according to the production plan of trays and the raw material inventory situation, and the problems that an existing pipe fitting family grouping technology is low in grouping rate, low in automatic welding application rate and high in production cost, and the integrity and timeliness of the pipe section tray are not high are solved.

Owner:JIANGNAN SHIPYARD GRP CO LTD

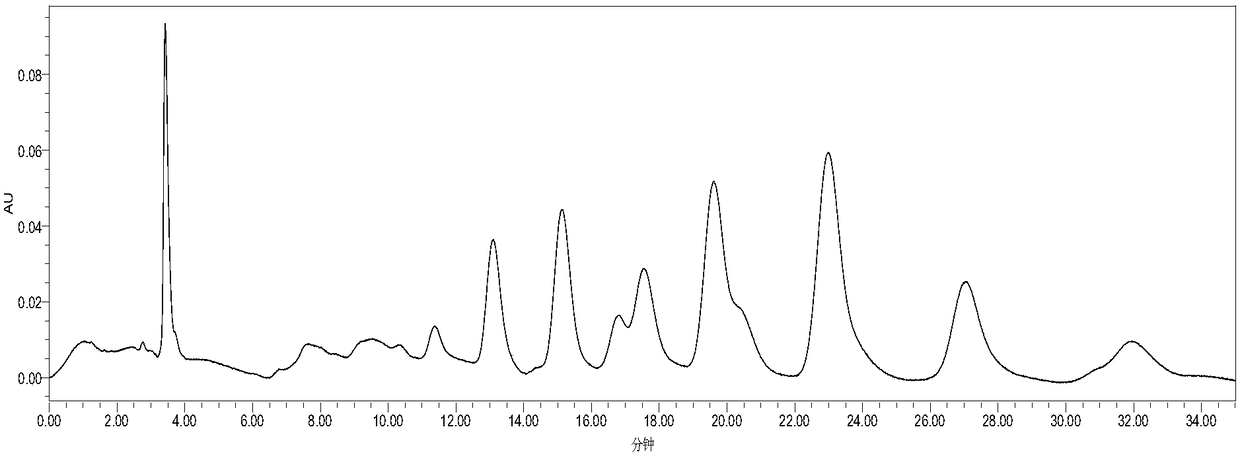

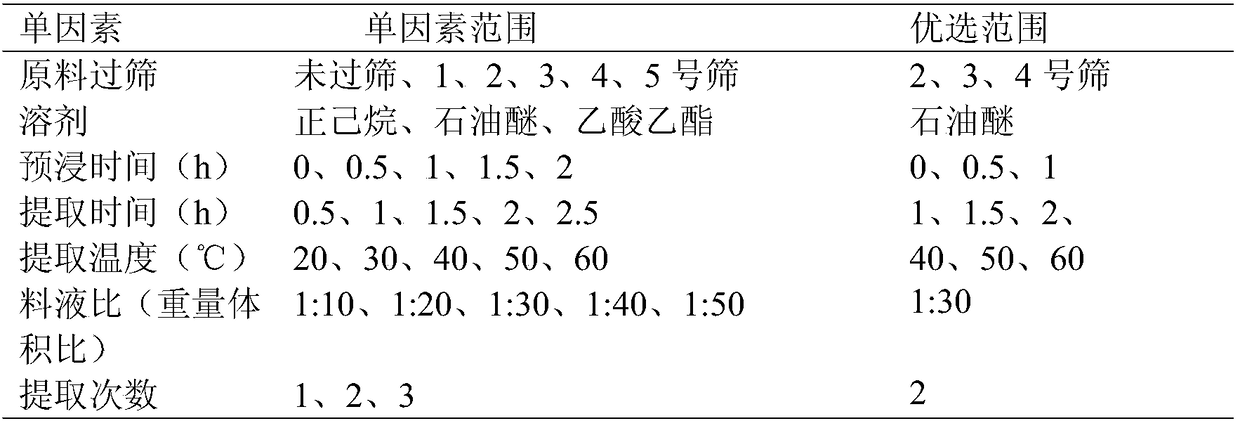

A method for extracting refined polyprenol from ginkgo biloba dregs

ActiveCN105884572BHigh purityLarge production batchOxygen-containing compound preparationOrganic compound preparationGinkgo bilobaSilica gel

The invention discloses a method of extracting refined polyprenol from ginkgo leaf residue. Through a lot of experiments, optimal ethyl ether extraction process, sodium hydroxide hydrolysis process, acetone impurity-removing process and silica gel column chromatography and C18 column chromatography impurity-removing process are screened out. Waste ginkgo leaf residue is used as a raw material, so that waste is recycled; the whole method is reasonable in design and high in operability; purity of polyprenol prepared by the method can reach higher than 95%, the method is supportive of industrial production and has important application value, and the defect that polyprenol prepared by the prior art is low in purity and application value can be overcome.

Owner:NANJING UNIVERSITY OF TRADITIONAL CHINESE MEDICINE

Connecting structure for unmanned aerial vehicle body and wing

InactiveCN100497088CSimple preparation processReasonable power transmissionToy aircraftsFuselagesStress concentrationUncrewed vehicle

The present invention discloses a connection structure of an airframe-airfoil of an unmanned aerial vehicle, which is realized by the connection of a pair of front and back joints of the airfoil and a pair of front and back joints at the oil box soleplate of the airframe that is the front joint of the airfoil is connected with the front joint of the airframe by bolts, and the back joint of the airfoil is connected with the back joint of the airframe by bolts. The airfoil and the airframe are linked just by four pairs of joints and four connection pieces, and the force transmission of the connection pieces is reasonable, which reduces the connection of joint parts and the concentration of stress; a majority of load is discharged during flying, which improves the anti-fatigue performance. The present invention has the characteristics of small size, good flexibility and large production batch. The structure can improve the rigidity of the joints to ensure the firm connection of the airframe and the airfoil and the high efficiency of the structure, and the structure belongs to the external connection, which has strong changeability and meets the requirement of combat readiness.

Owner:BEIHANG UNIV

Improved raw cotton linters composition, method of making same and uses thereof

A composition of a loose mass of comminuted raw cotton linter fibers has a bulk density of at least 8 g / 100 ml and at least 50 % of the fibers in the mass passes through a US standard sieve size #10 (2 mm opening). This composition is made by obtaining a loose mass of first cut, second cut, third cut, or mill runs raw cotton linters or mixtures thereof and comminuting the loose mass of raw cottonlinters to a size wherein at least 50 % pass through a US standard sieve size #10 (2 mm opening). This composition is used to make cellulose ether derivatives.

Owner:HERCULES INC

Weldless special pipe hoop for well pipe and manufacturing method thereof

InactiveCN102021931AEasy to operateHigh degree of mechanizationMetal rolling arrangementsDrinking water installationEngineeringWelding joint

The invention relates to a weldless special pipe hoop for a well pipe and a manufacturing method thereof. The pipe hoop is an annular steel hoop; a boss is arranged on the inner side of the steel hoop; with the boss as the boundary, one side of the steel hoop is an end in connection with other well pipe, and the other side of the steel hoop is an end for connecting the steel hoop with the well pipe to form the well pipe; a bevel edge is formed on the outer side of the top of the connection end; and a groove is formed on the outer side of the steel hoop opposite to the boss. In the manufacturing method of the pipe hoop, the pipe hoop blank is rolled and formed at a time by a rolling method. Without the processes such as cutting, coil stewing, reshaping and welding, the pipe hoop manufacturing method is simple to operate, and has the advantages of one-time rolling and forming, high mechanical degree, large production lot size, good product quality and time and labor saving while ensuring no welding quality problem of the product as welding joint does not exist.

Owner:清苑县清泉水泥制品有限公司

A powder metallurgy preparation method of diamond composite heat dissipation material

ActiveCN112941430BImprove sinter strengthReduce the sintering shrinkage coefficientFiberCarbon fibers

The invention discloses a powder metallurgy preparation method of a diamond composite heat dissipation material, comprising the following steps: S1: selection of raw materials: nickel plating with a mass fraction of 6.5% to 13.6% (corresponding to a volume concentration of 60 to 120%) Diamond single crystal, superfine CuSn15 bronze powder prepared by water atomization method with a mass fraction of 1-5%, and composite nickel-plated / copper carbon fiber with a mass fraction of 0.3-1.0%, or composite nickel-plated / copper silicon carbide Whiskers, the balance is electrolytic copper powder, and the alcohol solution of polyvinylpyrrolidone (K90) is used as a granulating agent. S2: Cold-pressed billet: Cold-press the sheet-shaped billet in a steel mold after mixing and granulating the material. The flaky diamond / copper composite material obtained by the invention can be applied in the field of heat dissipation materials such as electronic packaging materials, and has good development prospects of simple method, large batch size and low cost.

Owner:JILIN UNIV

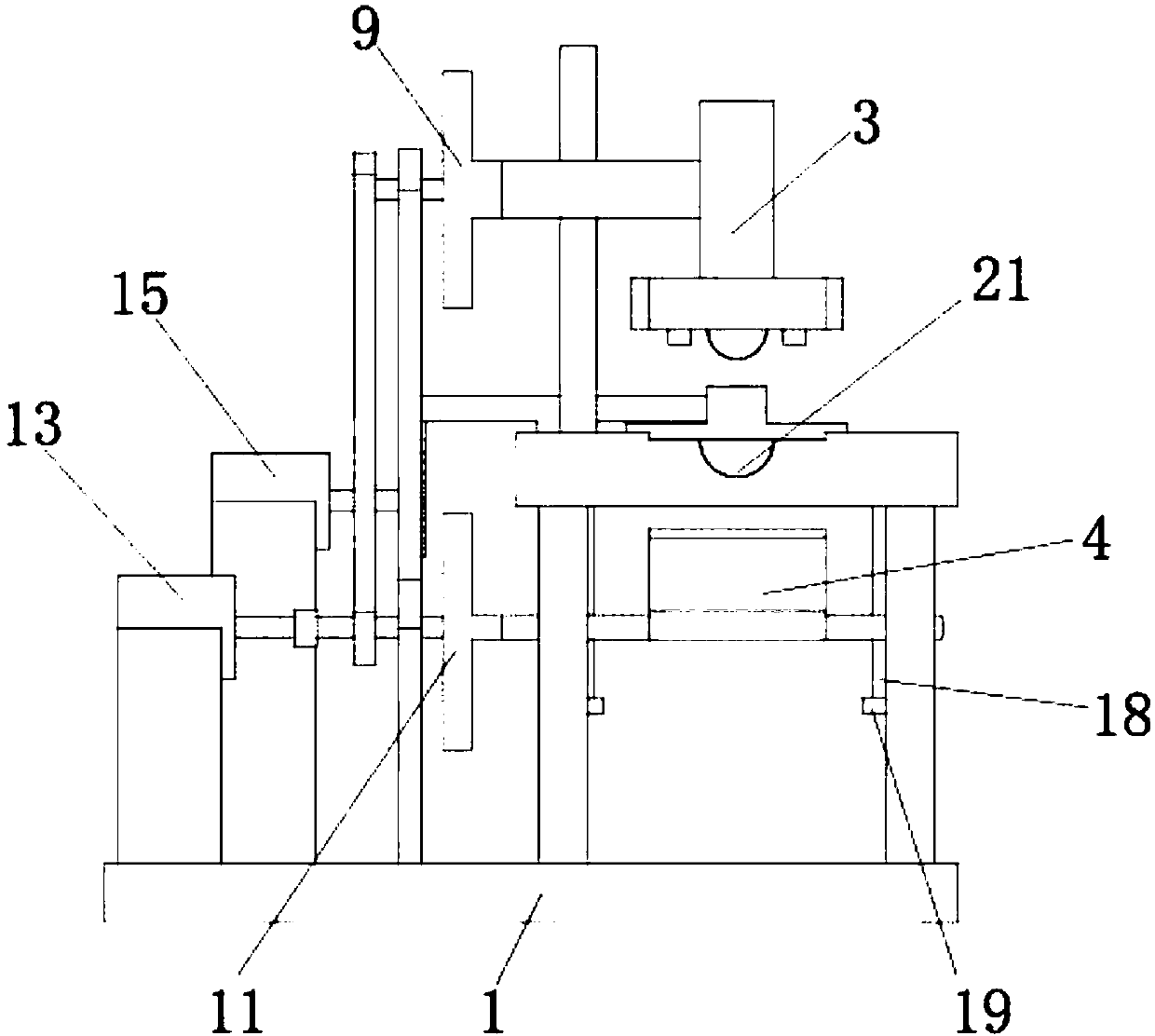

Auto parts processing device

ActiveCN107350811BEliminates the need for automated parts pickupReasonable structural designOther manufacturing equipments/toolsReciprocating motionBlock match

The invention relates to an automobile part machining device which comprises a bottom plate and a platform fixed to the bottom plate. A male die which vertically moves in a reciprocation mode is installed on the platform in a sliding mode. A tool which vertically moves in a reciprocation mode is installed below the platform in a sliding mode. The male die and the tool are jointly connected with a power device. The platform is provided with a feeding channel. The feeding channel is provided with a female die matched with the male die. The female die is provided with a knife edge matched with the tool. The left end of the platform is provided with a push block matched with the feeding channel. The push block is connected with a push device. One-time machining forming of bending, circular hole forming and cutting of plates can be achieved, automatic feeding and workpiece push-out functions can be achieved, continuous machining can be carried out, the production batch is large, and the whole device is small in size, simple and easy to operate.

Owner:芜湖德丰汽车零部件有限公司

Machining device for automobile parts

InactiveCN109909748AEliminates the need for automated parts pickupReasonable structural designOther manufacturing equipments/toolsReciprocating motionEngineering

The invention relates to a machining device for automobile parts. The machining device comprises a bottom plate, and a platform fixedly arranged on the bottom plate. A convex die with a vertical reciprocating motion is slidably arranged at the upper portion of the platform. A cutter with a vertical reciprocating motion is slidably arranged at the lower portion of the platform. The convex die and the cutter are jointly connected with a power device. The platform is provided with a feeding channel, a concave die matching with the convex die is arranged on the feeding channel, and a knife edge matching with the cutter is arranged on the concave die. A push block matching with the feeding channel is arranged on the left end of the platform, and the push block is connected with a push device. By means of the machining device for the automobile parts, one-time machining and molding of sheet metal bending, round hole making and cutting can be achieved; automatic feeding and workpiece pushingfunction can be achieved; and continuous machining can be carried out, and the production batch is large. The whole device has small volume, and is simple and easy to operate.

Owner:重庆柏孝机械配件有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com