Powder injection molding technology for producing micro-size hinged parts

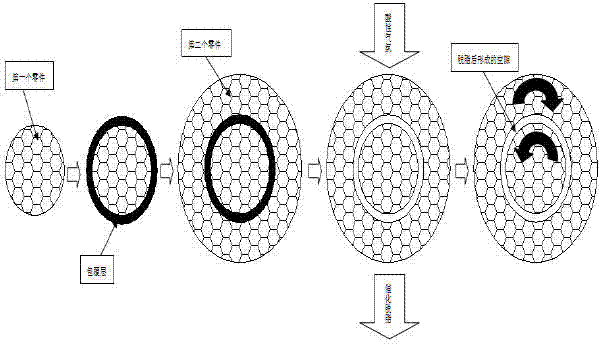

A technology of powder injection molding and injection molding, which is applied in the field of powder injection molding technology, can solve problems such as the inability to guarantee the overall strength of the mechanism, increase the connection volume, and difficulty in assembling parts, and achieve large production batches, lower overall costs, and simple production processes. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Example 1: 316L stainless steel powder is used to feed and inject two metal parts connected by a hinge.

[0018] (1) The powder feed adopts stainless steel 316L with an average particle diameter of 22um from BASF, with a melting temperature of 190°C, a mold temperature of 140°C, a holding pressure of 300bar, an injection speed of 250mm / s, and a cooling time of 10s. Injection molding is performed by the injection process. The injection molding machine can use the Microsystem 50 micro-injection molding machine of Battenfeld Company to obtain the injection base of the first part. After the injection base is taken out from the mold, the gating system is cut off with a knife.

[0019] (2) Overmolding is used for secondary molding, and polyoxymethylene (POM) is injected with a melting temperature of 190°C, a mold temperature of 100°C, a holding pressure of 300bar, an injection speed of 250mm / s, and a cooling time of 10s. To the cavity containing the injection base of the fir...

Embodiment 2

[0023] Example 2: Two ceramic parts connected by a hinge are formed by feeding injection with zirconia ceramic powder.

[0024] (1) The powder adopts zirconia powder particles with an average particle diameter of 7um, and the binder adopts an oil-based binder. First, add the binder into the internal mixer to heat and melt, then add zirconia powder particles, the loading amount is 55%, mix for 150 minutes, and the mixing temperature is 160°C. Use an extruder to extrude sheets three times and extrude strips three times. The extrusion temperatures are 120°C, 135°C, and 130°C respectively, and the rotation speed is 800r / min to obtain strip-shaped feed.

[0025] (2) Injection molding is then performed at an injection process with a melting temperature of 160°C, a mold temperature of 60°C, a holding pressure of 200bar, an injection speed of 250mm / s, and a cooling time of 10s. The injection molding machine can use the Microsystem 50 micro-injection molding machine of Battenfeld Comp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com