Method for preparing zinc oxide nano-rod by using zinc quantum dot

A zinc oxide nanorod, zinc quantum technology, applied in the direction of zinc oxide/zinc hydroxide, etc., can solve the problems of order destruction and complex template method, and achieve high preparation efficiency, high application value and low energy consumption. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

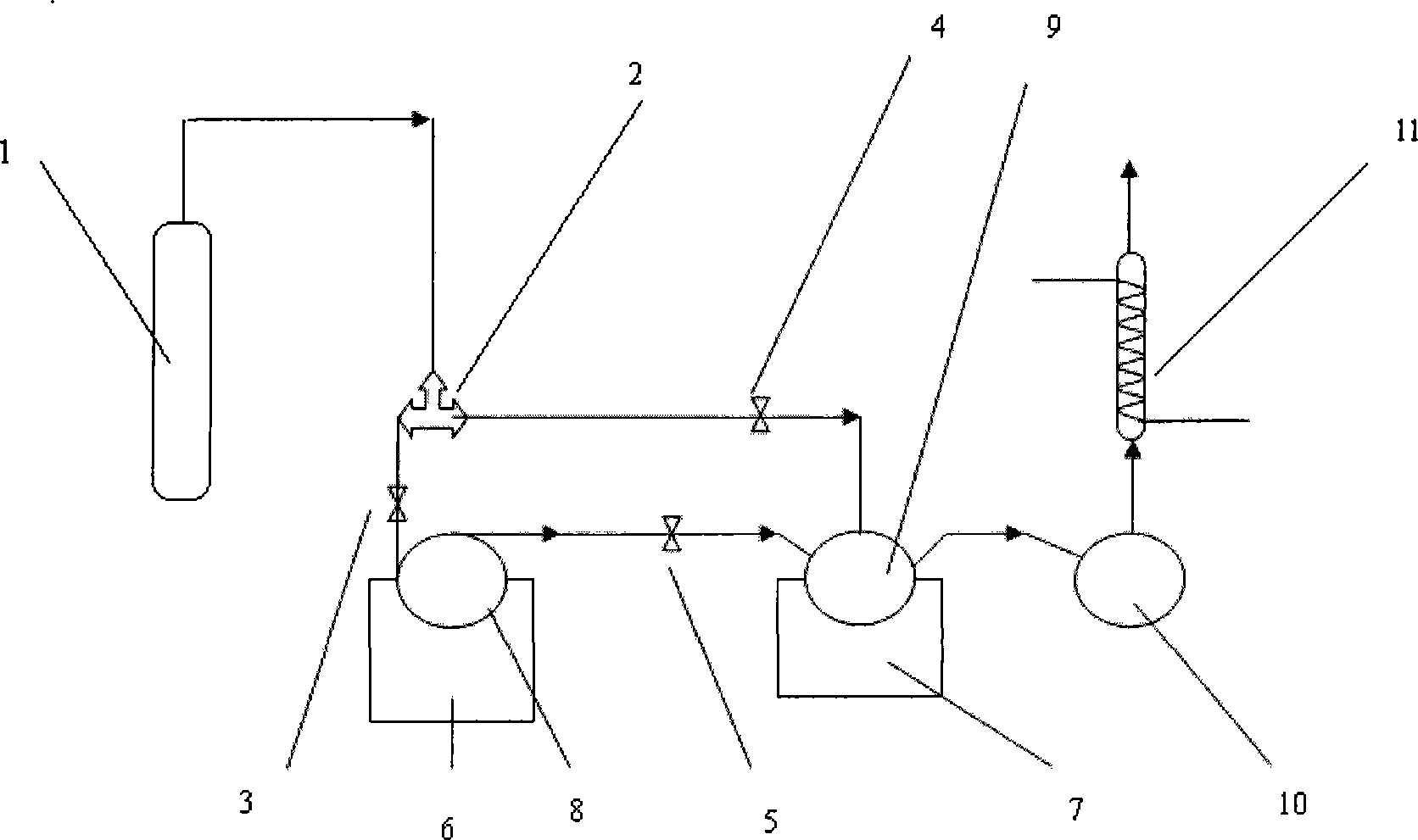

[0022] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

[0023] A three-necked flask is selected as the reactor; first, zinc quantum dots are prepared in a dry method at room temperature by using a rolling vibration mill.

[0024] In the first step, add pure water to the three-necked flask A8, add zinc quantum dots with a scale of 3-5 nanometers, a purity of more than 95%, and a mass of 10 g into the three-necked flask B9, and open the valves A3, B4, and C5 , the argon gas is passed into the three-necked flask A8 and the three-necked flask B9 with a purity of more than 99.9% from the argon gas bottle 1 at a flow rate of 1 L / min, so that the argon is fully purged and completely replaced by the three-necked flask A8 and the three-necked flask B9 In the air, this step was repeated at least 3 times. The second step is to close valve A3 and valve C5, power on the ordinary electric heating jacket 6 and the intel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com