Weldless special pipe hoop for well pipe and manufacturing method thereof

A technology with no welds and special-shaped pipes, applied in metal rolling, drinking water installations, water supply installations, etc., can solve problems such as complex operations, quality defects, and rough products, and achieve high mechanization, large production batches, and high product quality. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

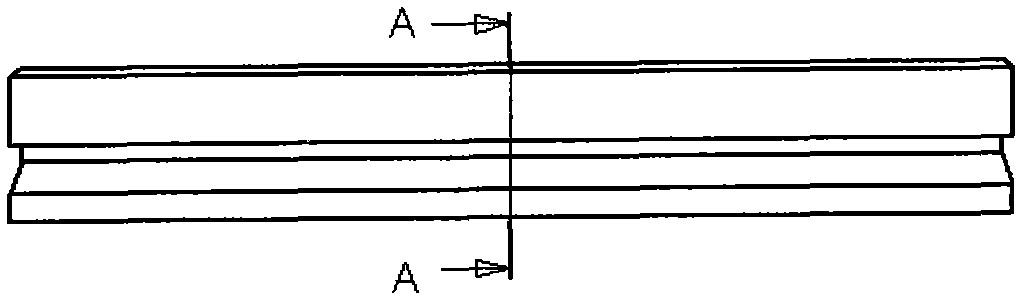

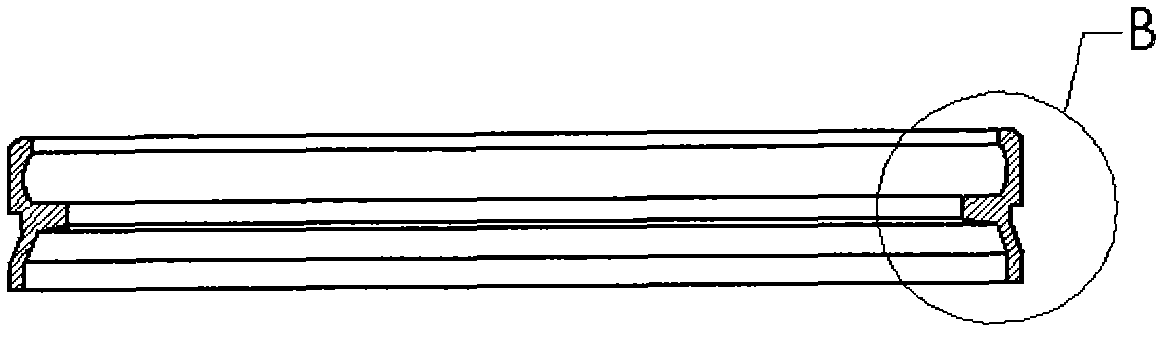

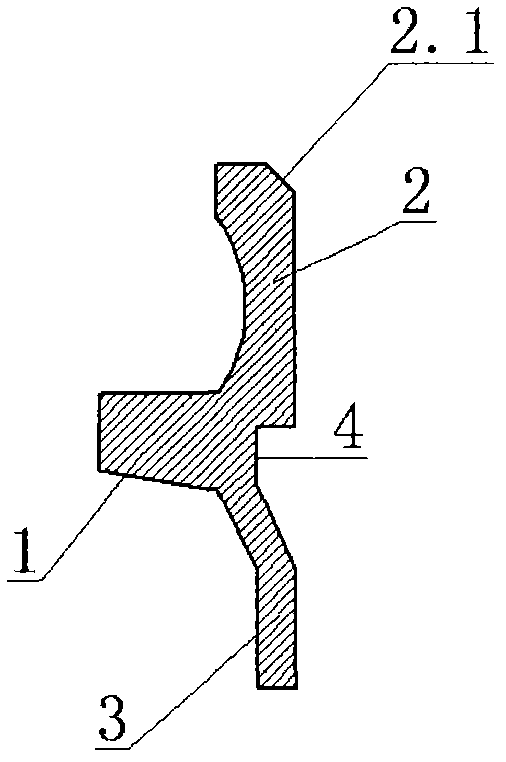

[0012] refer to Figure 1-Figure 3 The invention relates to a non-welded special-shaped pipe hoop for well pipes, which is an annular steel hoop. There is a boss 1 inside the steel hoop; with the boss 1 as the boundary, one side of the steel hoop is a connecting end 2, which is used to connect another well pipe; the outer side of the top of the connecting end 2 has a groove 2.1; the steel hoop The other side of the steel hoop is connected to the well pipe end 3; on the outside of the steel hoop, there is a groove 4 opposite to the boss 1, and the groove 4 is combined with the mold when the well pipe is used to play a tension effect.

[0013] The invention manufactures non-welded special-shaped pipe hoops for well pipes, and is formed by rolling at one time. In order to realize the technical solution of the above-mentioned non-welded pipe collar, the method is to put the heated pipe collar blank on the mandrel, and use the motor to drive the main mold to rotate. While rotating...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com