Preparation method of standard sample for spectral analysis of 400 series stainless steel, and standard sample

A standard sample and spectral analysis technology, which is used in the preparation of standard samples and standard samples for spectral analysis of 400 series stainless steel, and can solve the problems of high sample control manufacturing cost, high steel inclusion content, and low cleanliness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0094] The following describes a method for preparing a standard sample for spectral analysis of 400 series stainless steel SUS436L according to an embodiment of the present invention and a standard sample for spectral analysis of SUS436L prepared according to the preparation method.

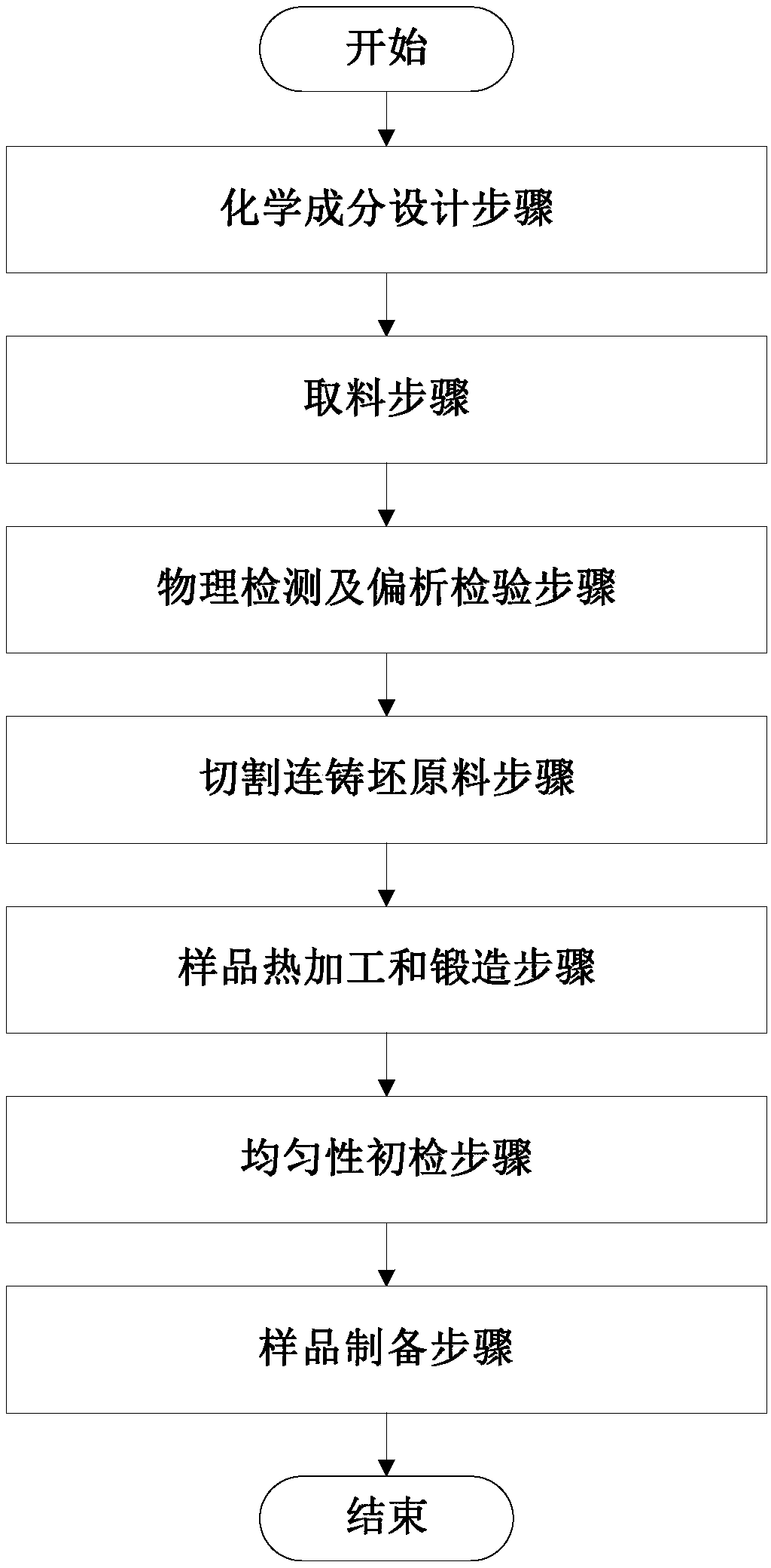

[0095] In one embodiment, the method for preparing a standard sample for spectral analysis of 400 series stainless steel SUS436L includes the following steps.

[0096] (1) Chemical composition design steps

[0097] When designing the content of the standard sample for SUS436L spectral analysis, refer to the composition range of 019Cr18MoTi (S11862) in GB / T 20878-2007 "Stainless Steel and Heat-resistant Steel Grades and Chemical Composition", design the chemical composition of the standard sample, see Table 1.

[0098] (2) Reclaiming step

[0099] Select the continuous casting slab raw material whose smelting composition meets the chemical composition design requirements, and take a cuboid contin...

Embodiment 2

[0177] The following describes a method for preparing a standard sample for spectral analysis of 400 series stainless steel SUS444 according to an embodiment of the present invention and a standard sample for spectral analysis of SUS444 prepared according to the preparation method.

[0178] In one embodiment, the method for preparing a standard sample for spectral analysis of 400 series stainless steel SUS444 includes the following steps.

[0179] 1. Chemical composition design steps

[0180] When designing the content of the standard sample for SUS444 spectral analysis, the chemical composition was designed with reference to the composition range of 019Cr19Mo2NbTi (S11972) in GB / T 20878-2007 "Stainless Steel and Heat-resistant Steel Grades and Chemical Composition", see Table 7.

[0181] (2) Reclaiming step

[0182] Select the continuous casting slab raw material whose smelting composition meets the chemical composition design requirements, and take a cuboid continuous casti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com