Constant temperature measurement-type micro humidity sensor and producing method thereof

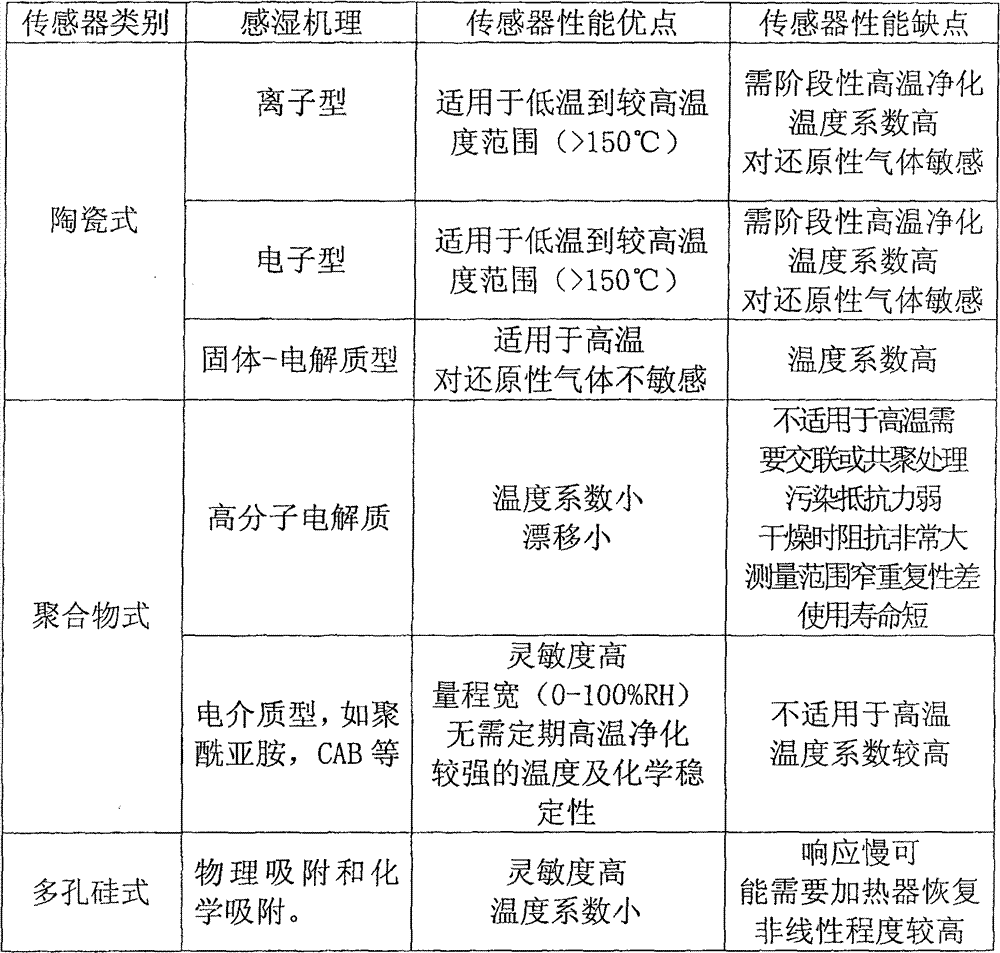

A humidity sensor and measuring technology, applied in the direction of material impedance, etc., can solve the problems of poor low temperature performance, large temperature coefficient, and performance easily affected by ambient temperature, and achieve the effect of low power consumption, good low temperature performance and small temperature coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

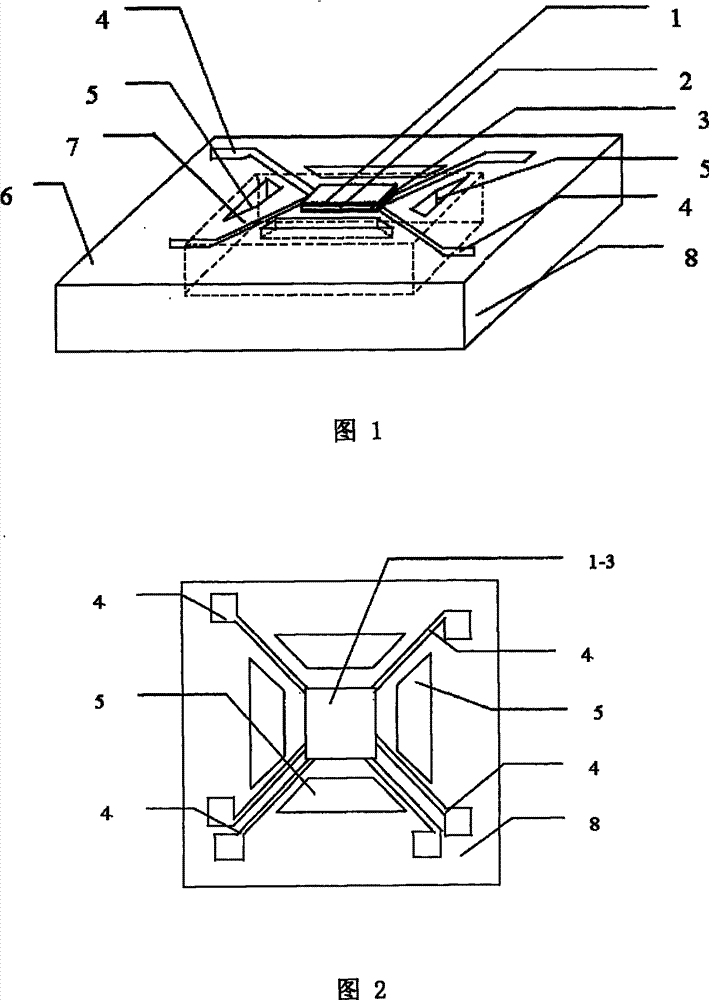

[0065] A manufacturing process and manufacturing steps of an example of this constant temperature measurement type miniature humidity sensor are as follows:

[0066] Step 1: Deposit 2000 μm on both [100] planes of a 500 μm thick, n-type silicon wafer thick silicon nitride film.

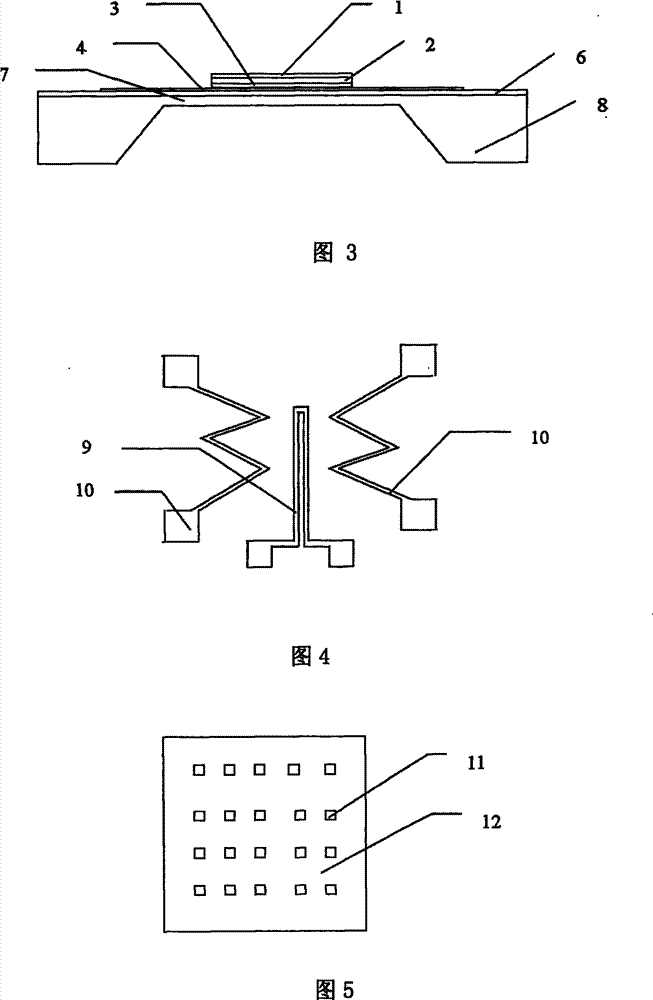

[0067] Step 2: On the silicon nitride on one side of the chip, use photolithography and wet etching techniques in MEMS technology to fabricate the hole or gap structure 5 with a depth of 60 μm required to support the diaphragm 7 .

[0068] Step 3: Evaporate a layer of 3000 on the silicon nitride on the other side thick aluminum film.

[0069] Step 4: Making an aluminum mask for deep etching by using photolithography and etching techniques in micro-electro-mechanical systems (MEMS) technology.

[0070] Step 5: On the silicon nitride film on the other side, use photolithography and sputtering technology in the microelectromechanical system (MEMS) system to make a 2000 Thick platinum bottom electr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com