A method for extracting refined polyprenol from ginkgo biloba dregs

A technology of polyprenol and ginkgo biloba, applied in chemical instruments and methods, preparation of oxygen-containing compounds, preparation of hydroxyl compounds, etc., can solve the problems of low purity and low utilization value of polyprenol, and achieve increased purity and production The effect of large batch and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

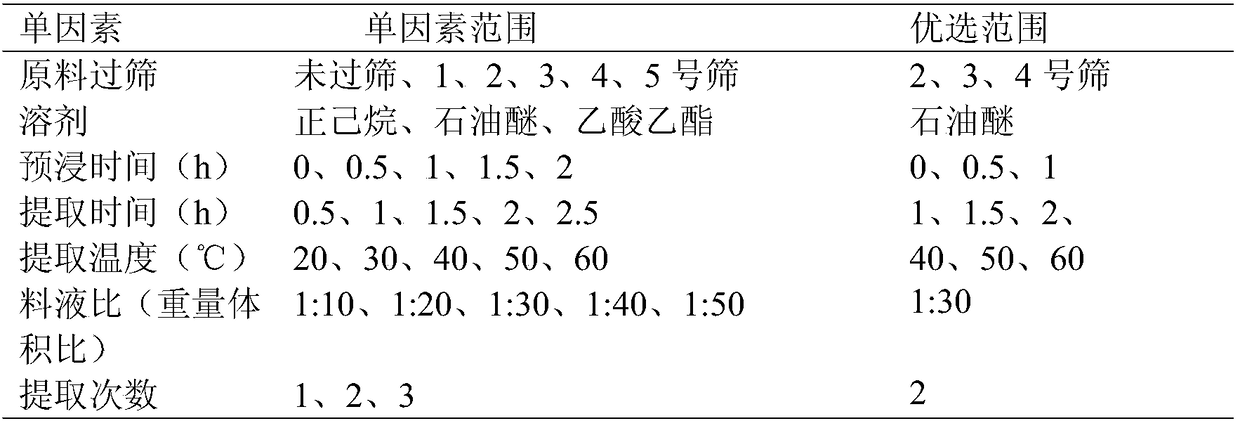

[0030] Embodiment 1 The optimization of polyprenyl alcohol extraction single factor

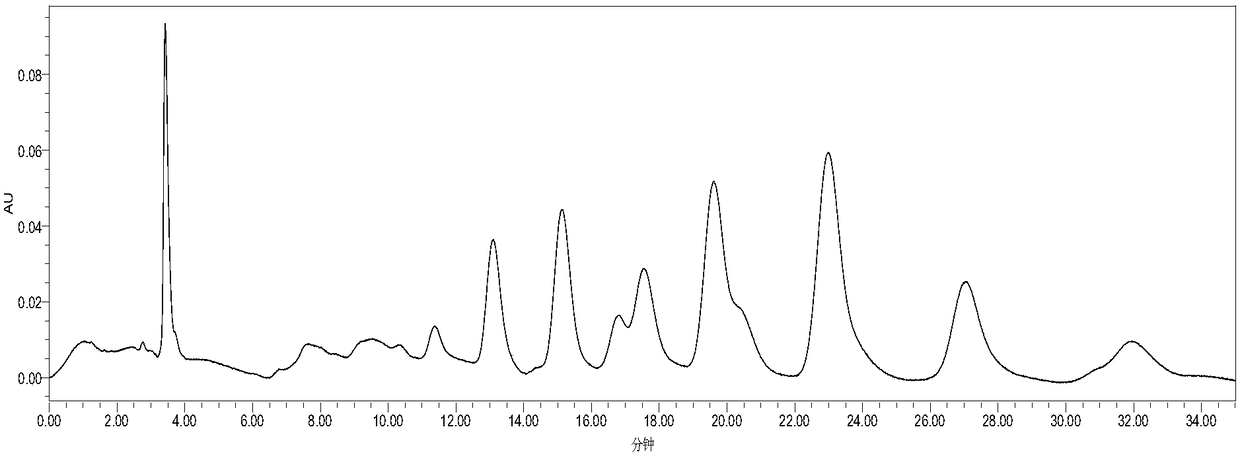

[0031] In the production process of ginkgolide injection, the ginkgo leaves were decocted in water for 3 times, and the dregs of ginkgo leaves produced after 2 hours each time were divided into six parts, one part was not crushed, and the rest were crushed into Nos. Sieve (pharmacopoeia standard), add ginkgo biloba dregs raw material weight-to-volume ratio (1:10, 1:20, 1:30, 1:40, 1:50) (n-hexane, petroleum ether, ethyl acetate) , presoak (0, 0.5, 1, 1.5, 2h), extract (0.5, 1, 1.5, 2, 2.5h) under (20, 30, 40, 50, 60°C) conditions, extract (1, 2, 3 times. Suction filtration, draw 2mL extract, add 2mL 4% sodium hydroxide methanol aqueous solution, ultrasonic 1h, the solution is concentrated to dryness by rotation, add 2mL n-hexane, enter high-performance liquid chromatography, measure the content of polyprenol, and select out relatively best factor level. The results are shown in Table 1:

...

Embodiment 2

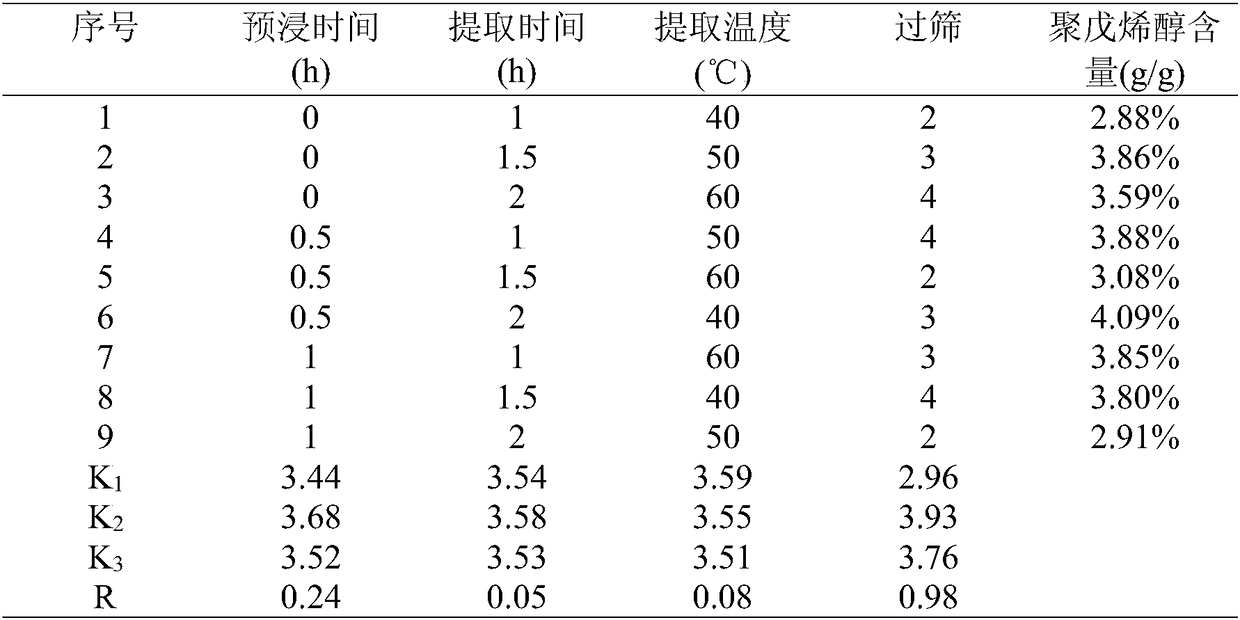

[0034] Example 2 Orthogonal optimization test of polyprenyl alcohol extraction

[0035] Taking the particle size, presoaking time, extraction time and extraction temperature of Ginkgo biloba raw material as the investigation factors, the optimal extraction scheme was determined through orthogonal experiments.

[0036] Table 2 Arrangement and results of polyprenyl alcohol extraction process test

[0037]

[0038] Table 3 polyprenol extraction analysis of variance results

[0039]

[0040]The results of range R showed that the degree of extraction process affecting polyprenol in Ginkgo biloba dregs was as follows: D (particle size) > A (presoaking time) > C (extraction temperature) > B (extraction time), A, The two factors D (P2 B 1 C 1 D. 2 , that is, the raw material of ginkgo biloba leaves is passed through a No. 3 sieve, the presoaking time is 0.5h, the extraction temperature is 40°C, and the extraction time is 1h.

Embodiment 3

[0041] Embodiment 3 The optimization of polyprenol hydrolysis single factor

[0042] Ginkgo biloba dregs produced during the production of ginkgolide injection were crushed through a No. 3 sieve, and petroleum ether with a ratio of raw material weight to solvent volume of 1:30 was added, presoaked for 0.5 h, extracted at 40°C for 1 h, and extracted twice . Suction filtration, draw 2mL extract, add 2mL (mass concentration 1%, 2%, 4%, 6%, 8%) sodium hydroxide (methanol, ethanol) water (alcohol water volume ratio is 1:4, 2 :3, 3:2, 4:1, 0:1) solution, ultrasonic (10, 20, 30, 40, 50, 60min), ultrasonic frequency (60, 70, 80, 90, 100KHz), solution rotary concentration To dryness, add 2mL of n-hexane, enter the high-performance liquid chromatography, and optimize the optimal factor level. The results are shown in Table 4:

[0043] Table 4 polyprenol hydrolysis single factor preferred experimental results

[0044]

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com