Method for producing magnetostrictive material

一种磁致伸缩材料、制造方法的技术,应用在用于磁致伸缩器件的材料选择、磁性材料、无机材料磁性等方向,能够解决磁致伸缩特性退化、脱模性存在问题、阻碍磁致伸缩延伸等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

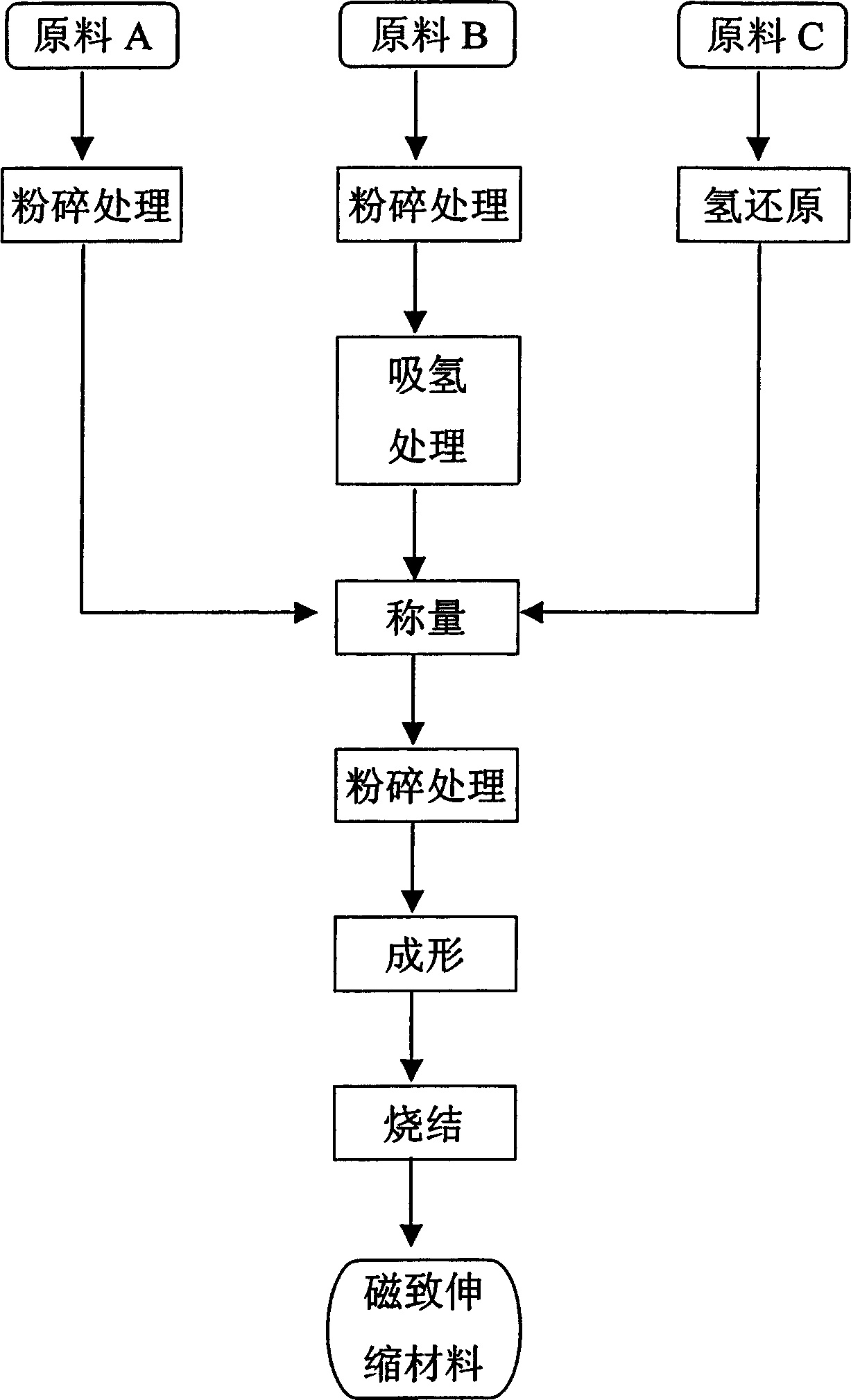

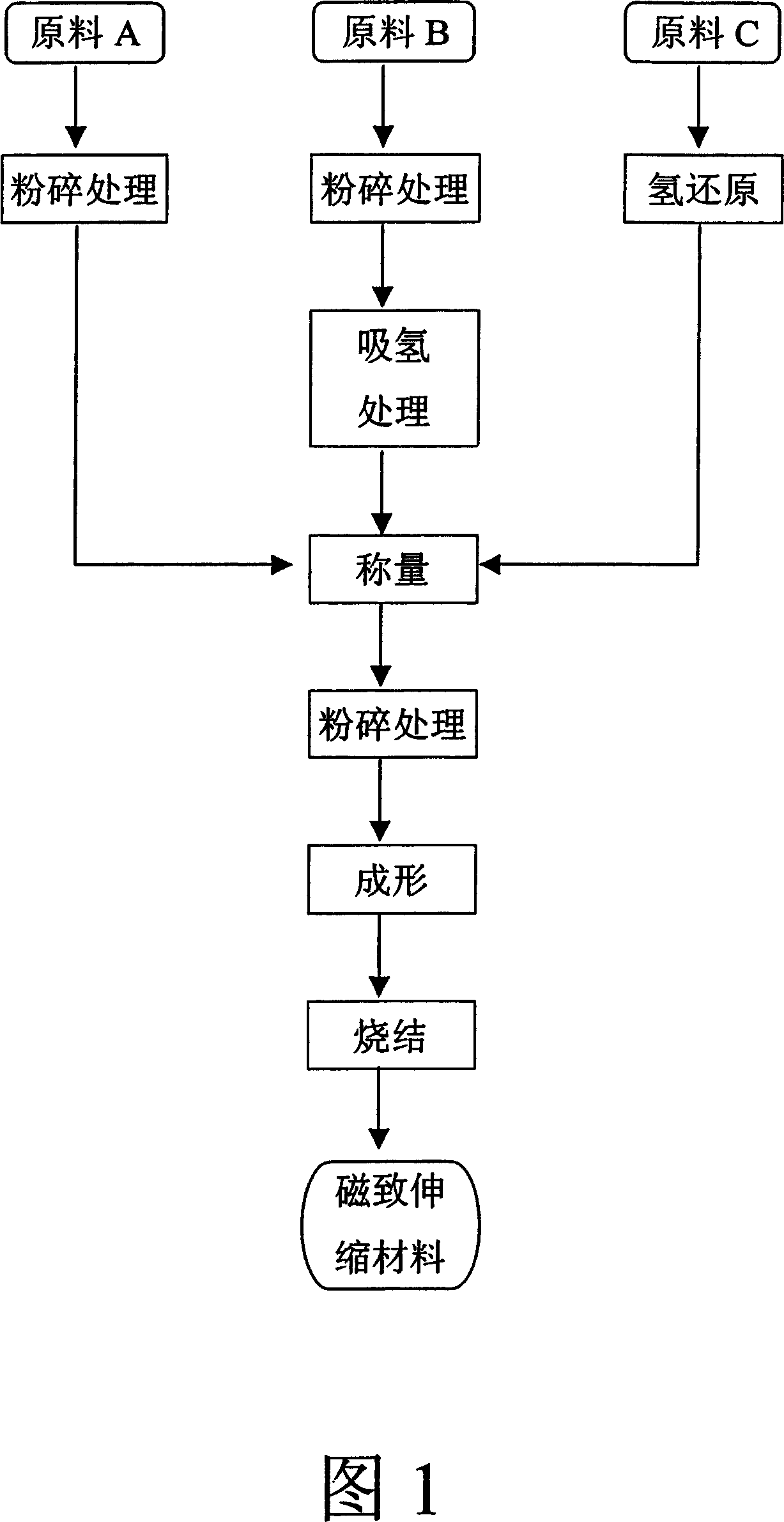

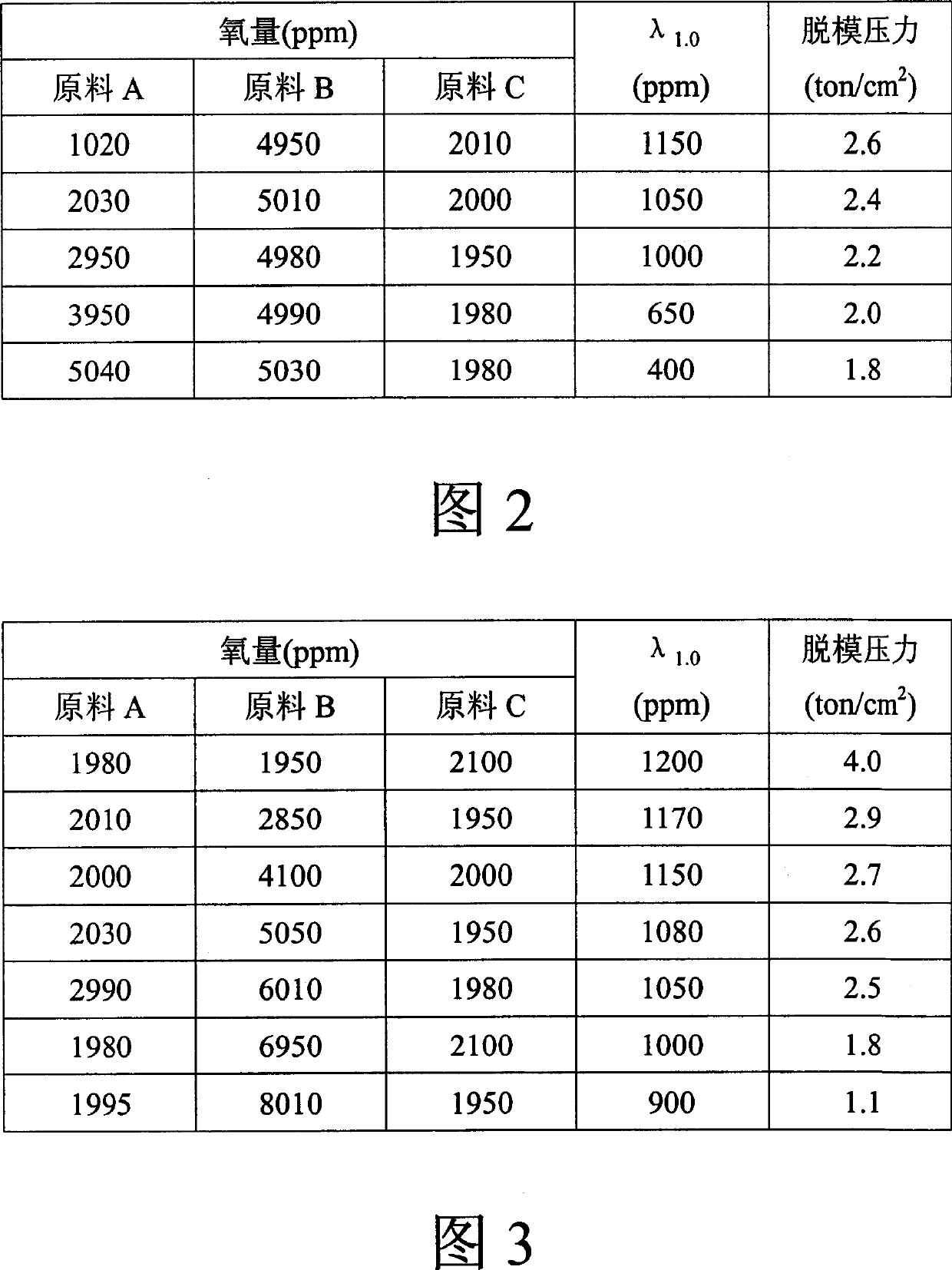

[0044] As raw material A, weigh Tb, Dy, Fe to make Tb 0.4 Dy 0.6 Fe 1.95 The composition of the alloy is smelted in an Ar atmosphere to make the raw material alloy. The alloy was annealed at 1170°C for 20 hours to make the concentration distribution of each metal element uniform and to eliminate the precipitated heterogeneous phase. Next, as shown in FIG. 1 , the annealed raw material alloy is pulverized (coarsely pulverized) by a Brownian mill. Coarse particles of 2 mm or larger are removed by sieving after coarse crushing, and the average particle size of the powder after removal of coarse particles is 500 μm. The average particle diameter is a value measured by a fine particle classifier (manufactured by Fishia Corporation). In addition, raw material A with various amounts of oxygen was obtained by changing the processing conditions of the powder.

[0045] Here, the amount of oxygen is a value measured by an oxygen amount measuring device (product of HORIBA: ZWGA-650A)...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com